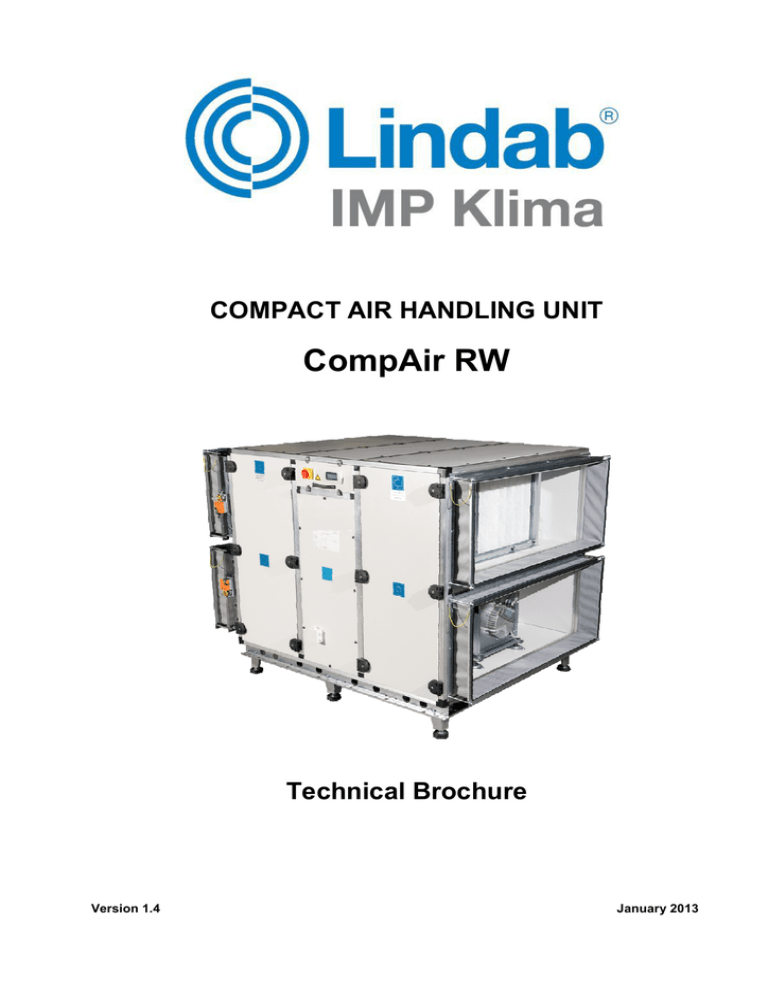

CompAir RW - Lindab IMP Klima

advertisement

COMPACT AIR HANDLING UNIT CompAir RW Technical Brochure Version 1.4 January 2013 INDEX: 1 GENERAL ..................................................................................................................... 4 2 COMPAIR RW 2000 ...................................................................................................... 8 2.1 Technical specification ............................................................................................................... 8 2.2 External static pressure/Air volume diagram .............................................................................. 8 2.3 Heat recovery diagram ............................................................................................................... 9 2.4 Sound data ................................................................................................................................. 9 2.5 Heat exchangers data .............................................................................................................. 10 2.6 Unit dimensions ........................................................................................................................ 10 2.7 Unit weights .............................................................................................................................. 11 3 COMPAIR RW 3000 .....................................................................................................12 3.1 Technical specification ............................................................................................................. 12 3.2 External static pressure/Air volume diagram ............................................................................ 12 3.3 Heat recovery diagram ............................................................................................................. 13 3.4 Sound data: .............................................................................................................................. 13 3.5 Heat exchangers data .............................................................................................................. 14 3.6 Unit dimensions ........................................................................................................................ 14 3.7 Unit weights .............................................................................................................................. 15 4 COMPAIR RW 4000 .....................................................................................................16 4.1 Technical specification ............................................................................................................. 16 4.2 External static pressure/Air volume diagram ............................................................................ 16 4.3 Heat recovery diagram ............................................................................................................. 17 4.4 Sound data ............................................................................................................................... 17 4.5 Heat exchangers data .............................................................................................................. 18 4.6 Unit dimension .......................................................................................................................... 18 4.7 Unit weights .............................................................................................................................. 19 5 COMPAIR RW 6000 .....................................................................................................20 5.1 Technical specification ............................................................................................................. 20 5.2 External static pressure/Air volume diagram ............................................................................ 20 5.3 Heat recovery diagram ............................................................................................................. 21 5.4 Sound data ............................................................................................................................... 21 5.5 Heat exchangers data .............................................................................................................. 22 5.6 Unit dimensions ........................................................................................................................ 23 5.7 Unit weights .............................................................................................................................. 23 6 COMPAIR RW 8000 .....................................................................................................24 6.1 Technical specification ............................................................................................................. 24 6.2 External static pressure/Air volume diagram ............................................................................ 24 6.3 Heat recovery diagram ............................................................................................................. 25 6.4 Sound data ............................................................................................................................... 25 6.5 Heat exchangers data .............................................................................................................. 26 6.6 Unit dimensions ........................................................................................................................ 27 Technical Brochure CompAir RW (ver. 1.4) 2 6.7 7 Unit weights .............................................................................................................................. 27 COMPAIR RW 10000 ...................................................................................................28 7.1 Technical specification ............................................................................................................. 28 7.2 External static pressure/Air volume diagram ............................................................................ 28 7.3 Heat recovery diagram ............................................................................................................. 29 7.4 Sound data ............................................................................................................................... 29 7.5 Heat exchangers data .............................................................................................................. 30 7.6 Unit dimensions ........................................................................................................................ 31 7.7 Unit weights .............................................................................................................................. 31 8 CONTROL SYSTEM ....................................................................................................32 8.1 Functional description............................................................................................................... 32 8.2 Functional diagram: .................................................................................................................. 32 8.3 Accessories 2 ........................................................................................................................... 33 Technical Brochure CompAir RW (ver. 1.4) 3 1 General CompAir RW basic technical data: - High efficiency air handling unit 6 types depends on airflow 2 direct driven fans with EC motor Supply filter class F7 Exhaust filter class G4 Inside & outside unit »plug play« unit with control system High efficiency counter flow heat exchanger > 80 % Housing Low power consumption and small possibility of condensation housing due to good thermal insulation and housing air-tightness. Sound insulation thickness of 50 mm is made of mineral wool with perpendicular oriented fibers to the surface of the wall. It is non-flammable and assures housing rigidity. Long life due to additional anticorrosion protection by powder painting or the use of stainless steel. Housing is certified by Eurovent. 2 types of housing 50 mm (EN 1886): - CompAir RW (housing TopAir): o T3: class of thermal transmittance o TB3: class of thermal bridges - CompAir Plus CF (housing TopAir Plus): o T2: class of thermal transmittance o TB2: class of thermal bridges Technical Brochure CompAir RW (ver. 1.4) 4 CompAir RW versions Inside version 1 supply intake 2 supply outlet Outside version 3 exhaust intake 4 exhaust outlet AHU CompAir RW Inside version Outside version Split inside version Split outside version I/O M/S R,L R,L R,L R,L I O I O M M S S R,L R,L R,L R,L R,L R,L R,L R,L R,L R,L R,L R,L R,L R,L R,L R,L R,L R,L R,L R,L I O I O I O I O I O I O I O I O I O I O function ACCESSORIES 1 inside version (empty section) outside version (empty section) inside version (heater) outside version (heater) inside version (cooler) outside version (cooler) inside version (heater cooler) outside version (heater + cooler) inside version (heater + cooler) outside version (heater+cooler) inside version (dx cooler) outside version (DX cooler) inside version (pre-heater) outside version (pre-heater) inside version (el. heater) outside version (el. heater) inside version (Water reversible coil) outside version (Water reversible coil) inside version (DX reversible coil) outside version (DX reversible coil) R … right L … left I … inside version KW … water cooler EW … water heater EWV … water preheater KD … dx cooler EE … electrical heater EEV … electrical preheater KW(EW) … reversible water coil D/K … reversible Dx coil Technical Brochure CompAir RW (ver. 1.4) O… outside version 5 M/S M/S M/S M/S M … monoblock E E EW EW KW KW EW+KW EW+KW EW+KD EW+KD KD KD EWV EWV EE EE KW(EW) KW(EW) D/K D/K S … splitted CompAir RW Sizes Mechanical Accessories - DA: Damper with actuator FC: Flexible canvas RC: Round connection PH: Protection hood BC: Bottom connection frame RF: Roof walley FT: Feet SY: Syphon SYH: Tracing syphon Electro control cabinets - ECC1: Controller PCO3 S, 4 temperature sensors - ECC2: Controller PCO3 L, 4 temperature sensors - ECC3: Controller PCO3 S, 4 temperature sensors, 2 differential pressure switches - ECC4: Controller PCO3 L, 4 temperature sensors, 2 differential pressure switches - ECC5 KW(EW): Controller PCO3 L, 4 temperature sensors, 2 differential pressure switches, additional module for reversible coils - ECC6 D/K: Controller PCO3 L, 4 temperature sensors, 2 differential pressure switches, additional module for reversible coils Technical Brochure CompAir RW (ver. 1.4) 6 Ordering key CompAir RW (Plus) 1000-R-I(1)-M-EW-DA1(1)3(1)-FC1234-RC1234-PH1(1)4(1)-FT-RF-SY-ECC1-PGD-PC1-QS1-PS1 Accessories 2 (regulation): PS1 PS2 PS3 x 2x Pressure sensor (room QBM66.201) 2x Pressure sensor (duct QBM66.202) 2x Pressure sensor (airflow QBM66.203) without pressure sensor QS1 Sensor CO2 - duct QS2 Sensor CO2 – room x Without CO2 sensor PC1 PC2 PC3 PC4 x PCO Web Card pCOWEB PCO Web Card pCOWEB with interface PCO Card LONFTT3 PCO Card MODBUS 3 Without card PGD Remote controller x Without remote controller ECC1 - 6 (See page 6) x Without ECC Accessories 3 (additional equipment): SY Roof walley SYH Heating syphon x Without syphon RF Roof walley x Without roof walley FT Feet x Without feet PH1(1)4(1) Protection hood on positions 1,4 PH1(2)4(2) Protection hood on back side of unit x Without protection hood RC1234 Round connections on positions 1,2,3,4 RC24 Round connections on positions 2,4 x Without round connection FC1234 Flexible canvas on positions 1,2,3,4 FC24 Flexible canvas on positions 2,4 x Without flexible canvas DA1(1)3(1) DA1(2)3(2) DA1(x)3(x) DA1(1) DA1(2) x Dampers on positions 1,3 with actuator on/off Dampers on positions 1,3 with spring actuator Without actuators on both dampers Damper on connections 1 with actuator on/off Damper on connections 1 with spring actuator Without dampers and actuators Accessories 1 (function): E EW KW EW+KW EW+KD KD EWV EE(6) EWV,EW EWV,EW,KW EEV,EW EEV,EW,KW KW(EW) D/K x Empty section Water heater Water cooler Water heater + water cooler Water heater + dx cooler Dx cooler Water preheater Electrical heater Water preheater + water heater Water preheater, water heater + cooler Electrical preheater + water heater Electrical preheater, water heater + cooler Water reversible coil Dx reversible coil Without function Unit type: M Monoblock S Splitted I(1) I(2) O(1) O(2) O(3) O(4) Inside unit with supply on under side Inside unit with supply on upper side Outside unit with supply on under side Outside unit with supply on upper side Outside unit with bottom connection Outside unit with bottom connection and frame R Right L Left Unit size: 1000 2000 3000 4000 6000 8000 10000 Housing type: Plus Plus housing (empty) Basic housing Heat recovery: CF Counter flow heat exchanger RW Rotary wheel exchanger Technical Brochure CompAir RW (ver. 1.4) 7 2 CompAir RW 2000 2.1 Technical specification Unit Type Airflow range Electrical supply Motor and fan type Frequency Input power (for one fan) Imax (for one fan) Housing Service door (on access side) Removable panel (on access side) Insulation Color Filter type Filter class Condense connection Duct dimension Round connection dimension Heat recovery Efficiency Operating temperature Optional 2.2 CompAir RW 2000 3 3 1100 m /h - 2700 m /h 3 x 380 V Plug fan backward curved blades with EC motor 50 Hz 1000 W 1,63 A Aluminium frame, painted inside and outside panels On filter and fan units On rotary wheel heat exchanger unit 50mm mineral wool RAL 7035 Panel filter Supply F7 Exhaust G4 DN40 935mm x 550mm Ø 450 mm Rotary wheel heat exchanger up to 85% -20°C to 40°C Water or electrical preheater, heater, water or DX cooler External static pressure/Air volume diagram Technical Brochure CompAir RW (ver. 1.4) 8 2.3 Heat recovery diagram Conditions: Supply air: T= -13°C, Relative humidity: 90% Exhaust air: T= 22°C, Relative humidity: 40% Supply air / Exhaust air =1 2.4 Sound data Airflow (m³/h) At 100 Pa external pressure At 200 Pa external pressure At 300 Pa external pressure Suction Pressure At distance Suction Pressure At distance Suction Pressure At distance side side 1m side side 1m side side 1m LwA(dB) LwA(dB) LpA(dB) LwA(dB) LwA(dB) LpA(dB) LwA(dB) LwA(dB) LpA(dB) 1100 52 72 50,1 58 78 54 62 80 55 1500 56 75 52 60 79 55 62 83 57 1900 60 79 54 61 81 57 63 86 59 2300 62 83 59 64 84 60 64 87 62 LwA (dB) … The sound power level on suction and pressure side of AHU LpA (dB) … The sound pressure level at distance of 1m from AHU Technical Brochure CompAir RW (ver. 1.4) 9 2.5 Heat exchangers data 3 Airflow (m /h) Capacity (kW) Air velocity (m/s) Air inlet temperature (°C) Air outlet temperature (°C) Air pressure drop (Pa) Medium Medium flow rate (l/s) Medium velocity (m/s) Medium inlet temperature (°C) Medium outlet temperature (°C) Medium pressure drop (kPa) Number of rows 3 Airflow (m /h) Capacity (kW) Air velocity (m/s) Air inlet temperature (°C) Air outlet temperature (°C) Air pressure drop (Pa) Medium Medium flow rate (l/s) Medium velocity (m/s) Medium inlet temperature (°C) Medium outlet temperature (°C) Medium pressure drop (kPa) Number of rows 3 Airflow (m /h) Capacity (kW) Rated voltage (A) Rated current (A) Air pressure drop (Pa) Protection class (IP) 2.6 Water heater 2300 26,32 1,65 -10 24 19 Water 0,32 0,83 80 60 7,86 2 Water preheater 2300 26,32 1,65 -10 24 19 Water 0,32 0,83 80 60 7,86 2 Water cooler 2300 15,85 1,65 28 16 47 Water 0,758 0,97 7 12 18,16 5 Dx - cooler 2300 12,9 1,65 28 16 34 4 Electrical heater (preheater) (6) Electrical heater (preheater) (12) Electrical heater (preheater) (15) 2300 6 3x400 8,7 2 43 2300 12 3x400 17,4 5 43 2300 15 3x400 21,7 6 43 Unit dimensions Monoblock inside unit: Technical Brochure CompAir RW (ver. 1.4) 10 Monoblock outside unit: Splitted inside unit: Splitted outside unit: Function L mm x (without coils) 1670 E, EW, KW, KD, EE 1980 EWV, EEV 1980 EW+KW, EW+KD 2100 EWV+EW, EWV+KW 2290 EWV+EW+KW or KD 2410 EEV+EW, EEV+KW 2290 EEV+EW+KW or KD 2410 2.7 Inside Outside Inside/Outside L1 L2 L3 L L1 L2 L3 B1 B H A C mm mm mm mm mm mm mm mm mm mm mm mm 590 490 590 1670 590 490 590 590 490 900 1980 590 490 900 900 490 590 1980 900 490 900 590 490 1020 2100 590 490 1020 1255 1055 1450 935 550 900 490 900 2290 900 490 900 900 490 1020 2410 900 490 1020 900 490 900 2290 900 490 900 900 490 1020 2410 900 490 1020 Unit weights Function x (without coils) E, EW, KW, KD, EE EWV, EEV EW+KW, EW+KD EWV+EW, EWV+KW EWV+EW+KW or KD EEV+EW, EEV+KW EEV+EW+KW or KD L kg 480 560 560 610 640 690 640 690 L1 kg 175 175 255 175 255 255 255 255 Technical Brochure CompAir RW (ver. 1.4) Inside L2 L3 kg kg 150 160 150 240 150 160 150 290 150 240 150 290 150 240 150 290 L1+L2+L3 kg 485 565 565 615 645 695 645 695 11 L kg 485 565 565 615 645 695 645 695 L1 kg 165 165 245 165 245 245 245 245 Outside L2 L3 kg kg 150 175 150 255 150 175 150 305 150 255 150 305 150 255 150 305 L1+L2+L3 kg 490 570 570 620 650 700 650 700 3 CompAir RW 3000 3.1 Technical specification Unit Type Airflow range Electrical supply Motor and fan type Frequency Input power (for one fan) Imax (for one fan) Housing Service door (on access side) Removable panel (on access side) Insulation Color Filter type Filter class Condense connection Duct dimension Round connection dimension Heat recovery Efficiency Operating temperature Optional 3.2 CompAir RW 3000 3000 3 3 2100 m /h - 3500 m /h 3 x 380 V Plug fan backward curved blades with EC motor 50 Hz 1000 W 1,7 A Aluminium frame, painted inside and outside panels On filter and fan units On rotary wheel heat exchanger unit 50mm mineral wool RAL 7035 Panel filter Supply F7 Exhaust G4 DN40 995mm x 550mm Ø 500 mm Rotary wheel heat exchanger up to 85% -20°C to 40°C Water or electrical preheater, heater, water or DX cooler External static pressure/Air volume diagram Technical Brochure CompAir RW (ver. 1.4) 12 3.3 Heat recovery diagram Conditions: Supply air: T= -13°C, Relative humidity: 90% Exhaust air: T= 22°C, Relative humidity: 40% Supply air / Exhaust air =1 3.4 Sound data: Airflow (m³/h) At 100 Pa external pressure At 200 Pa external pressure At 300 Pa external pressure Suction Pressure At distance Suction Pressure At distance Suction Pressure At distance side side 1m side side 1m side side 1m LwA(dB) LwA(dB) LpA(dB) LwA(dB) LwA(dB) LpA(dB) LwA(dB) LwA(dB) LpA(dB) 2000 58 81 56 62 84 57 64 85 58 2400 63 84 58 65 86 59 64 87 60 2800 66 87 61 65 88 61 68 89 62 3200 66 89 64 68 90 65 66 91 63 LwA (dB) … The sound power level on suction and pressure side of AHU LpA (dB) … The sound pressure level at distance of 1m from AHU Technical Brochure CompAir RW (ver. 1.4) 13 3.5 Heat exchangers data 3 Airflow (m /h) Capacity (kW) Air velocity (m/s) Air inlet temperature (°C) Air outlet temperature (°C) Air pressure drop (Pa) Medium Medium flow rate (l/s) Medium velocity (m/s) Medium inlet temperature (°C) Medium outlet temperature (°C) Medium pressure drop (kPa) Number of rows 3 Airflow (m /h) Capacity (kW) Air velocity (m/s) Air inlet temperature (°C) Air outlet temperature (°C) Air pressure drop (Pa) Medium Medium flow rate (l/s) Medium velocity (m/s) Medium inlet temperature (°C) Medium outlet temperature (°C) Medium pressure drop (kPa) Number of rows 3 Airflow (m /h) Capacity (kW) Rated voltage (A) Rated current (A) Air pressure drop (Pa) Protection class (IP) 3.6 Water heater 3200 36,62 2,02 -10 24 27 Water 0,45 0,77 80 60 5,6 2 Water preheater 3200 36,62 2,02 -10 24 27 Water 0,45 0,77 80 60 5,6 2 Water cooler 3200 23,05 2,15 28 16 54 Water 1,102 1,13 7 12 17,12 5 Dx - cooler 3200 17,94 2,16 28 16 62 5 Electrical heater (preheater) (9) Electrical heater (preheater) (18) Electrical heater (preheater) (24) 3200 9 3x400 13 7 43 3200 18 3x400 26,1 13 43 3200 24 3x400 34,8 18 43 Unit dimensions Monoblock inside unit: Technical Brochure CompAir RW (ver. 1.4) 14 Monoblock outside unit: Splitted inside unit: Splitted outside unit: Function L mm x (without coils) 1670 E, EW, KW, KD, EE 1980 EWV, EEV 1980 EW+KW, EW+KD 2100 EWV+EW, EWV+KW 2290 EWV+EW+KW or KD 2410 EEV+EW, EEV+KW 2290 EEV+EW+KW or KD 2410 3.7 Inside Outside Inside/Outside L1 L2 L3 L L1 L2 L3 B1 B H A C mm mm mm mm mm mm mm mm mm mm mm mm 590 490 590 1670 590 490 590 590 490 900 1980 590 490 900 900 490 590 1980 900 490 900 590 490 1020 2100 590 490 1020 1355 1155 1450 995 550 900 490 900 2290 900 490 900 900 490 1020 2410 900 490 1020 900 490 900 2290 900 490 900 900 490 1020 2410 900 490 1020 Unit weights Function x (without coils) E, EW, KW, KD, EE EWV, EEV EW+KW, EW+KD EWV+EW, EWV+KW EWV+EW+KW or KD EEV+EW, EEV+KW EEV+EW+KW or KD L kg 500 580 580 635 660 715 660 715 L1 kg 180 180 260 180 260 260 260 260 Technical Brochure CompAir RW (ver. 1.4) Inside L2 L3 kg kg 160 170 160 250 160 170 160 305 160 250 160 305 160 250 160 305 L1+L2+L3 kg 510 590 590 645 670 725 670 725 15 L kg 510 590 590 645 670 725 670 725 L1 kg 185 185 265 185 265 265 265 265 Outside L2 L3 kg kg 160 175 160 255 160 175 160 310 160 255 160 310 160 255 160 310 L1+L2+L3 kg 520 600 600 655 680 735 680 735 4 CompAir RW 4000 4.1 Technical specification Unit Type Airflow range Electrical supply Motor and fan type Frequency Input power (for one fan) Imax (for one fan) Housing Service door (on access side) Removable panel (on access side) Insulation Color Filter type Filter class Condense connection Duct dimension Round connection dimension Heat recovery Efficiency Operating temperature Optional 4.2 CompAir RW 4000 3 3 3100 m /h - 5100 m /h 3 x 380 V Plug fan backward curved blades with EC motor 50 Hz 1700 W 2,6 A Aluminium frame, painted inside and outside panels On filter and fan units On rotary wheel heat exchanger unit 50mm mineral wool RAL 7035 Panel filter Supply F7 Exhaust G4 DN40 1340mm x 550mm Ø 560 mm Rotary wheel heat exchanger up to 85% -20°C to 40°C Water or electrical preheater, heater, water or DX cooler External static pressure/Air volume diagram Technical Brochure CompAir RW (ver. 1.4) 16 4.3 Heat recovery diagram Conditions: Supply air: T= -13°C, Relative humidity: 90% Exhaust air: T= 22°C, Relative humidity: 40% Supply air / Exhaust air =1 4.4 Sound data Airflow (m³/h) At 200 Pa external pressure At 300 Pa external pressure At 400 Pa external pressure Suction Pressure At distance Suction Pressure At distance Suction Pressure At distance side side 1m side side 1m side side 1m LwA(dB) LwA(dB) LpA(dB) LwA(dB) LwA(dB) LpA(dB) LwA(dB) LwA(dB) LpA(dB) 3300 65 88 61 66 90 61 69 91 62 3800 67 91 64 67 90 60 76 93 65 4300 73 93 69 80 94 69 72 95 67 LwA (dB) … The sound power level on suction and pressure side of AHU LpA (dB) … The sound pressure level at distance of 1m from AHU Technical Brochure CompAir RW (ver. 1.4) 17 4.5 Heat exchangers data 3 Airflow (m /h) Capacity (kW) Air velocity (m/s) Air inlet temperature (°C) Air outlet temperature (°C) Air pressure drop (Pa) Medium Medium flow rate (l/s) Medium velocity (m/s) Medium inlet temperature (°C) Medium outlet temperature (°C) Medium pressure drop (kPa) Number of rows 3 Airflow (m /h) Capacity (kW) Air velocity (m/s) Air inlet temperature (°C) Air outlet temperature (°C) Air pressure drop (Pa) Medium Medium flow rate (l/s) Medium velocity (m/s) Medium inlet temperature (°C) Medium outlet temperature (°C) Medium pressure drop (kPa) Number of rows Water heater 4300 49,21 2,08 -10 24 28 Water 0,6 0,77 80 60 7,7 2 Water preheater 4300 49,21 2,08 -10 24 28 Water 0,6 0,77 80 60 7,7 2 Water cooler 4300 34,33 2,17 28 16 74 Water 1,64 1,2 7 12 23,61 5 Dx - cooler 4300 24,1 2,07 28 16 60 Electrical heater (preheater)(12) 3 Airflow (m /h) Capacity (kW) Rated voltage (A) Rated current (A) Air pressure drop (Pa) Protection class (IP) 4.6 Electrical Electrical Electrical heater heater heater (preheater)(15) (preheater)(24) (preheater)(36) 4300 12 3x400 17,4 3 43 4300 15 3x400 21,7 4 43 Unit dimension Monoblock inside unit: Technical Brochure CompAir RW (ver. 1.4) 5 18 4300 24 3x400 34,8 7 43 4300 36 3x400 52,2 10 43 Monoblock outside unit: Splitted inside unit: Splitted outside unit: Function L mm x (without coils) 1670 E, EW, KW, KD, EE 1980 EWV, EEV 1980 EW+KW, EW+KD 2100 EWV+EW, EWV+KW 2290 EWV+EW+KW or KD 2410 EEV+EW, EEV+KW 2290 EEV+EW+KW or KD 2410 4.7 Inside Outside Inside/Outside L1 L2 L3 L L1 L2 L3 B1 B H A C mm mm mm mm mm mm mm mm mm mm mm mm 590 490 590 1670 590 490 590 590 490 900 1980 590 490 900 900 490 590 1980 900 490 900 590 490 1020 2100 590 490 1020 1660 1460 1450 1340 550 900 490 900 2290 900 490 900 900 490 1020 2410 900 490 1020 900 490 900 2290 900 490 900 900 490 1020 2410 900 490 1020 Unit weights Function x (without coils) E, EW, KW, KD, EE EWV, EEV EW+KW, EW+KD EWV+EW, EWV+KW EWV+EW+KW or KD EEV+EW, EEV+KW EEV+EW+KW or KD L kg 590 675 675 735 760 820 760 820 L1 kg 225 225 310 225 310 310 310 310 Technical Brochure CompAir RW (ver. 1.4) Inside L2 L3 kg kg 180 195 180 280 180 195 180 340 180 280 180 340 180 280 180 340 L1+L2+L3 kg 600 685 685 745 770 830 770 830 19 L kg 605 690 690 750 775 835 775 835 L1 kg 210 210 295 210 295 295 295 295 Outside L2 L3 kg kg 190 215 190 300 190 215 190 360 190 300 190 360 190 300 190 360 L1+L2+L3 kg 615 700 700 760 785 845 785 845 5 CompAir RW 6000 5.1 Technical specification Unit Type Airflow range Electrical supply Motor and fan type Frequency Input power (for one fan) Imax (for one fan) Housing Service door (on access side) Removable panel (on access side) Insulation Color Filter type Filter class Condense connection Duct dimension Round connection dimension Heat recovery Efficiency Operating temperature Optional 5.2 CompAir RW 6000 3 3 4500 m /h - 7000 m /h 3 x 380 V Plug fan backward curved blades with EC motor 50 Hz 2950 W 4,6 A Aluminium frame, painted inside and outside panels On filter and fan units On rotary wheel heat exchanger unit 50mm mineral wool RAL 7035 Panel filter Supply F7 Exhaust G4 DN40 1660mm x 690mm Ø 630 mm Rotary wheel heat exchanger up to 85% -20°C to 40°C Water or electrical preheater, heater, water or DX cooler External static pressure/Air volume diagram Technical Brochure CompAir RW (ver. 1.4) 20 5.3 Heat recovery diagram Conditions: Supply air: T= -13°C, Relative humidity: 90% Exhaust air: T= 22°C, Relative humidity: 40% Supply air / Exhaust air =1 5.4 Sound data Airflow (m³/h) At 200 Pa external pressure At 300 Pa external pressure At 400 Pa external pressure Suction Pressure At distance Suction Pressure At distance Suction Pressure At distance side side 1m side side 1m side side 1m LwA(dB) LwA(dB) LpA(dB) LwA(dB) LwA(dB) LpA(dB) LwA(dB) LwA(dB) LpA(dB) 5000 79 85 61 79 86 62 79 87 63 6000 82 88 64 82 89 64 82 90 65 6400 83 90 65 83 90 65 84 91 66 LwA (dB) … The sound power level on suction and pressure side of AHU LpA (dB) … The sound pressure level at distance of 1m from AHU Technical Brochure CompAir RW (ver. 1.4) 21 5.5 Heat exchangers data 3 Airflow (m /h) Capacity (kW) Air velocity (m/s) Air inlet temperature (°C) Air outlet temperature (°C) Air pressure drop (Pa) Medium Medium flow rate (l/s) Medium velocity (m/s) Medium inlet temperature (°C) Medium outlet temperature (°C) Medium pressure drop (kPa) Number of rows 3 Airflow (m /h) Capacity (kW) Air velocity (m/s) Air inlet temperature (°C) Air outlet temperature (°C) Air pressure drop (Pa) Medium Medium flow rate (l/s) Medium velocity (m/s) Medium inlet temperature (°C) Medium outlet temperature (°C) Medium pressure drop (kPa) Number of rows Water heater 6400 73,24 2,06 -10 24 28 Water 0,9 0,92 80 60 7,85 2 Water preheater 6400 73,24 2,06 -10 24 28 Water 0,9 0,92 80 60 7,85 2 Water cooler 6400 49 2,06 28 16 67 Water 2,34 1,2 7 12 25 5 Dx - cooler 6400 35,88 2,06 28 16 59 5 Electrical heater (preheater)(18) 3 Airflow (m /h) Capacity (kW) Rated voltage (A) Rated current (A) Air pressure drop (Pa) Protection class (IP) Technical Brochure CompAir RW (ver. 1.4) Electrical Electrical Electrical heater heater heater (preheater)(24) (preheater)(36) (preheater)(48) 6400 18 3x400 26,1 4 43 6400 24 3x400 34,8 5 43 22 6400 36 3x400 52,2 8 43 6400 48 3x400 69,6 10 43 5.6 Unit dimensions Splitted inside unit: Splitted outside unit: Function x (without coils) E, EW, KW, KD, EE EWV, EEV EW+KW, EW+KD EWV+EW, EWV+KW EWV+EW+KW or KD EEV+EW, EEV+KW EEV+EW+KW or KD 5.7 L1 mm 680 680 990 680 990 990 990 990 Inside L2 L3 mm mm 490 680 490 990 490 680 490 1110 490 990 490 1110 490 990 490 1110 L1 mm 680 680 990 680 990 990 990 990 Outside L2 L3 mm mm 490 680 490 990 490 680 490 1110 490 990 490 1110 490 990 490 1110 B1 mm B mm 1980 1780 Inside/Outside H A mm mm 1730 Unit weights Function x (without coils) E, EW, KW, KD, EE EWV, EEV EW+KW, EW+KD EWV+EW, EWV+KW EWV+EW+KW or KD EEV+EW, EEV+KW EEV+EW+KW or KD L1 kg 300 300 410 300 410 410 410 410 L2 kg 290 290 290 290 290 290 290 290 Technical Brochure CompAir RW (ver. 1.4) Inside L3 L1+L2+L3 kg kg 260 850 370 960 260 960 460 1050 370 1070 460 1160 370 1070 460 1160 23 L1 kg 300 300 410 300 410 410 410 410 L2 kg 290 290 290 290 290 290 290 290 Outside L3 L1+L2+L3 kg kg 300 890 410 1000 300 1000 500 1090 410 1110 500 1200 410 1110 500 1200 1660 C mm 690 6 CompAir RW 8000 6.1 Technical specification Unit Type Airflow range Electrical supply Motor and fan type Frequency Input power (for one fan) Imax (for one fan) Housing Service door (on access side) Removable panel (on access side) Insulation Color Filter type Filter class Condense connection Duct dimension Round connection dimension Heat recovery Efficiency Operating temperature Optional 6.2 CompAir RW 8000 3 3 6500 m /h - 9100 m /h 3 x 380 V Plug fan backward curved blades with EC motor 50 Hz 2800 W 4,4 A Aluminium frame, painted inside and outside panels On filter and fan units On rotary wheel heat exchanger unit 50mm mineral wool RAL 7035 Panel filter Supply F7 Exhaust G4 DN40 1800mm x 855mm Ø 800 mm Rotary wheel heat exchanger up to 85% -20°C to 40°C Water or electrical preheater, heater, water or DX cooler External static pressure/Air volume diagram Technical Brochure CompAir RW (ver. 1.4) 24 6.3 Heat recovery diagram Conditions: Supply air: T= -13°C, Relative humidity: 90% Exhaust air: T= 22°C, Relative humidity: 40% Supply air / Exhaust air =1 6.4 Sound data Airflow (m³/h) At 200 Pa external pressure At 300 Pa external pressure At 400 Pa external pressure Suction Pressure At distance Suction Pressure At distance Suction Pressure At distance side side 1m side side 1m side side 1m LwA(dB) LwA(dB) LpA(dB) LwA(dB) LwA(dB) LpA(dB) LwA(dB) LwA(dB) LpA(dB) 7000 76 82 58 77 83 60 78 84 61 8000 79 84 60 79 85 61 80 86 63 8300 80 85 62 80 76 62 80 86 64 LwA (dB) … The sound power level on suction and pressure side of AHU LpA (dB) … The sound pressure level at distance of 1m from AHU Technical Brochure CompAir RW (ver. 1.4) 25 6.5 Heat exchangers data 3 Airflow (m /h) Capacity (kW) Air velocity (m/s) Air inlet temperature (°C) Air outlet temperature (°C) Air pressure drop (Pa) Medium Medium flow rate (l/s) Medium velocity (m/s) Medium inlet temperature (°C) Medium outlet temperature (°C) Medium pressure drop (kPa) Number of rows 3 Airflow (m /h) Capacity (kW) Air velocity (m/s) Air inlet temperature (°C) Air outlet temperature (°C) Air pressure drop (Pa) Medium Medium flow rate (l/s) Medium velocity (m/s) Medium inlet temperature (°C) Medium outlet temperature (°C) Medium pressure drop (kPa) Number of rows 3 Airflow (m /h) Capacity (kW) Rated voltage (A) Rated current (A) Air pressure drop (Pa) Protection class (IP) Technical Brochure CompAir RW (ver. 1.4) Water heater 8300 95 1,93 -10 24 25 Water 1,16 0,75 80 60 5,88 2 Water preheater 8300 95 1,93 -10 24 25 Water 1,16 0,75 80 60 5,88 2 Water cooler 8300 64 1,93 28 16 61 Water 3,01 1,31 7 12 24,02 5 Dx - cooler 8300 46,53 1,93 28 16 52 5 Electrical heater (preheater)(24) Electrical heater (preheater)(48) Electrical heater (preheater)(64) 8300 24 3x400 34,8 2 43 8300 48 3x400 69,6 3 43 8300 64 3x400 92,8 4 43 26 6.6 Unit dimensions Splitted inside unit: Splitted outside unit: Function x (without coils) E, EW, KW, KD, EE EWV, EEV EW+KW, EW+KD EWV+EW, EWV+KW EWV+EW+KW or KD EEV+EW, EEV+KW EEV+EW+KW or KD 6.7 L1 mm 740 740 1050 740 1050 1050 1050 1050 Inside L2 mm 490 490 490 490 490 490 490 490 L1 kg 370 370 490 370 490 490 490 490 L2 kg 330 330 330 330 330 330 330 330 L3 mm 740 1050 740 1170 1050 1170 1050 1170 Outside Inside/Outside L2 L3 B1 B H A C mm mm mm mm mm mm mm 490 740 490 1050 490 740 490 1170 2120 1920 2060 1800 855 490 1050 490 1170 490 1050 490 1170 L1 mm 740 740 1050 740 1050 1050 1050 1050 Unit weights Function x (without coils) E, EW, KW, KD, EE EWV, EEV EW+KW, EW+KD EWV+EW, EWV+KW EWV+EW+KW or KD EEV+EW, EEV+KW EEV+EW+KW or KD Technical Brochure CompAir RW (ver. 1.4) Inside L3 L1+L2+L3 kg kg 320 1020 440 1140 320 1140 560 1260 440 1260 560 1380 440 1260 560 1380 27 L1 kg 370 370 490 370 490 490 490 490 L2 kg 335 335 335 335 335 335 335 335 Outside L3 L1+L2+L3 kg kg 370 1075 490 1195 370 1195 610 1315 490 1315 610 1425 490 1315 610 1425 7 CompAir RW 10000 7.1 Technical specification Unit Type Airflow range Electrical supply Motor and fan type Frequency Input power (for one fan) Imax (for one fan) Housing Service door (on access side) Removable panel (on access side) Insulation Color Filter type Filter class Condense connection Duct dimension Round connection dimension Heat recovery Efficiency Operating temperature Optional 7.2 CompAir RW 10000 3 3 8000 m /h - 11500 m /h 3 x 380 V Plug fan backward curved blades with EC motor 50 Hz 5500 W 8,4 A Aluminium frame, painted inside and outside panels On filter and fan units On rotary wheel heat exchanger unit 50mm mineral wool RAL 7035 Panel filter Supply F7 Exhaust G4 DN40 2155mm x 855mm Ø 800 mm Rotary wheel heat exchanger up to 85% -20°C to 40°C Water or electrical preheater, heater, water or DX cooler External static pressure/Air volume diagram Technical Brochure CompAir RW (ver. 1.4) 28 7.3 Heat recovery diagram Conditions: Supply air: T= -13°C, Relative humidity: 90% Exhaust air: T= 22°C, Relative humidity: 40% Supply air / Exhaust air =1 7.4 Sound data Airflow (m³/h) At 200 Pa external pressure At 300 Pa external pressure At 400 Pa external pressure Suction Pressure At distance Suction Pressure At distance Suction Pressure At distance side side 1m side side 1m side side 1m LwA(dB) LwA(dB) LpA(dB) LwA(dB) LwA(dB) LpA(dB) LwA(dB) LwA(dB) LpA(dB) 9000 82 87 63 82 88 63 84 90 64 10000 84 90 65 84 90 65 85 91 65 10700 86 92 67 86 92 67 86 92 67 LwA (dB) … The sound power level on suction and pressure side of AHU LpA (dB) … The sound pressure level at distance of 1m from AHU Technical Brochure CompAir RW (ver. 1.4) 29 7.5 Heat exchangers data 3 Airflow (m /h) Capacity (kW) Air velocity (m/s) Air inlet temperature (°C) Air outlet temperature (°C) Air pressure drop (Pa) Medium Medium flow rate (l/s) Medium velocity (m/s) Medium inlet temperature (°C) Medium outlet temperature (°C) Medium pressure drop (kPa) Number of rows 3 Airflow (m /h) Capacity (kW) Air velocity (m/s) Air inlet temperature (°C) Air outlet temperature (°C) Air pressure drop (Pa) Medium Medium flow rate (l/s) Medium velocity (m/s) Medium inlet temperature (°C) Medium outlet temperature (°C) Medium pressure drop (kPa) Number of rows 3 Airflow (m /h) Capacity (kW) Rated voltage (A) Rated current (A) Air pressure drop (Pa) Protection class (IP) Technical Brochure CompAir RW (ver. 1.4) Water heater 10700 122,45 1,99 -10 24 26 Water 1,5 0,85 80 60 9,04 2 Water preheater 10700 122,45 1,99 -10 24 26 Water 1,5 0,85 80 60 9,04 2 Water cooler 10700 82,01 1,99 28 16 64 Water 3,92 1,18 7 12 16,15 5 Dx - cooler 10700 60 1,99 28 16 54 5 Electrical heater (preheater)(32) Electrical heater (preheater)(64) Electrical heater (preheater)(80) 10700 32 3x400 46,4 3 43 10700 64 3x400 92,8 4 43 10700 80 3x400 116 5 43 30 7.6 Unit dimensions Splitted inside unit: Splitted outside unit: Function x (without coils) E, EW, KW, KD, EE EWV, EEV EW+KW, EW+KD EWV+EW, EWV+KW EWV+EW+KW or KD EEV+EW, EEV+KW EEV+EW+KW or KD 7.7 L1 mm 740 740 1050 740 1050 1050 1050 1050 Inside L2 mm 490 490 490 490 490 490 490 490 L3 mm 740 1050 740 1170 1050 1170 1050 1170 Outside Inside/Outside L2 L3 B1 B H A C mm mm mm mm mm mm mm 490 740 490 1050 490 740 490 1170 2475 2275 2060 2155 855 490 1050 490 1170 490 1050 490 1170 L1 mm 740 740 1050 740 1050 1050 1050 1050 Unit weights Function x (without coils) E, EW, KW, KD, EE EWV, EEV EW+KW, EW+KD EWV+EW, EWV+KW EWV+EW+KW or KD EEV+EW, EEV+KW EEV+EW+KW or KD L1 kg 430 430 570 430 570 570 570 570 L2 kg 370 370 370 370 370 370 370 370 Technical Brochure CompAir RW (ver. 1.4) Inside L3 L1+L2+L3 kg kg 370 1170 510 1310 370 1310 655 1455 510 1450 655 1595 510 1450 655 1595 31 L1 kg 400 400 540 400 540 540 540 540 L2 kg 380 380 380 380 380 380 380 380 Outside L3 L1+L2+L3 kg kg 440 1220 580 1360 440 1360 725 1505 580 1500 725 1645 580 1500 725 1645 8 Control system 8.1 Functional description Basic electro control cabinet provides the following functions: - Step less or speed mode control heating and cooling Step less regulation of heat recovery Free cooling function (cooling with outside air during the transitional periods) Set different air flows through the monitor, external 0-10 V Time card Fire sequence, free programming Optionally possible: - 8.2 Manage unit via remote control with LCD panel Room temperature sensor CO2 or air quality sensor, which can be installed in a room or exhaust air Control device at a constant pressure across the pressure sensor Connectivity to central control systems with different protocols (Modbus, Lon Works, BACnet and TCP-IP) Remote monitoring via GSM or WEB Remote control via a color touch monitor PC software Functional diagram: Technical Brochure CompAir RW (ver. 1.4) 32 8.3 Accessories 2 PGD PCO Web Card pCOWEB Controller DDC PCO3 S PCO Card LONFTT3 Sensor CO2 - duct Sensor CO2 - room Controller DDC PCO3 L* PCO Card MODBUS 3 Sensor pressure room duct airflow Note: if you select more than 1 add. sensor, controller PCO3 L should be selected as well! Controller PCO3 S is included as standard. See also “Instructions for transport, installation, maintainance… for CompAir” ! Lindab IMP Klima d.o.o. Godovič 150, 5275 Godovič Slovenia T: +386 1 300 52 00 F: +386 1 436 76 19 E: imp-klima@lindab.com Technical Brochure CompAir RW (ver. 1.4) 33