Electrical Safety

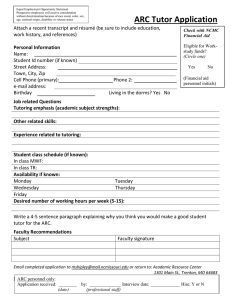

advertisement

Revision: 2 AECI – Health, Safety & Environmental Procedures Issued Apr ‐ 2013 Review Date: 9/4/2014 Electrical Safety DOC # SP 1301 1. Purpose This procedure provides guidance for all personnel that work with or around electrical equipment. It is also the intent of this procedure to comply with 29 CFR 1910.269, 29 CFR 1910 Subpart S and NFPA 70E. 2. Scope This procedure applies to all AECI employees, contractors and visitors who are required to perform work involving the use electrical equipment on or at AECI work sites. 3. Administrative Duties/Responsibilities The Plant Manager is responsible for monitoring, supporting, and promoting the safety and health programs for their employees. The plant Safety and Environmental Coordinator will support the Plant Manager by developing and coordinating safety and health programs that include, but are not limited to: written procedures and practices, job safety analysis, risk hazard analysis, training, and drills and exercises necessary to fully implement this procedure and monitor its effectiveness. Department Heads, Superintendents, and other supervisors are responsible for participating in company training, drills and exercises, as well as promoting and enforcing adherence to the provisions of all safety and health programs. In addition to the “general duty” to identify hazards and to work safely, all employees are required to follow the provisions of this procedure as well as those of all plant safety and health programs as a condition of employment. The EHS Department is responsible for reviewing and revising all safety and health programs at least annually. 4. Procedure 4.1 Definitions The Electrical Authority Having Jurisdiction (EAHJ) at AECI's Coal Plants is the Electrical and Instrumentation Superintendent; unless that position is vacant then the Plant Manager shall designate a qualified person to fill the EAHJ until the Electrical and Instrumentation Superintendent position is filled. Page 1 of 21 Revision: 2 AECI – Health, Safety & Environmental Procedures Issued Apr ‐ 2013 Review Date: 9/4/2014 Electrical Safety DOC # SP 1301 A Qualified Person / Worker is one who possesses the skills and knowledge related to the design and operating principles, of electrical equipment and their installation and has received training on the hazards involved and demonstrates the ability to recognize the various levels of exposure to electrical energy. Such a person is familiar with the proper use of precautionary techniques, personal protective equipment, insulating and shielding materials, insulated tools and test equipment. A person may be considered qualified with respect to certain equipment but still be unqualified for others. An Unqualified Person/Worker is any person who does not meet the definition of a Qualified Person/Worker. An Arc Flash Hazard is a dangerous condition associated with the possible release of energy caused by an electric arc. The Arc Flash Protection Boundary is the approach limit at a distance from a prospective arc source within which a person could receive a second degree burn if an electrical arc flash were to occur. An Electrical Hazard is any dangerous condition such that contact or equipment failure can result in electric shock, arc flash burn, thermal burn, or blast. An Electrical Hazard / Risk Category is the level of risk associated with a specific task. The categories are identified as 0, 1, 2, 3 or 4 (0 being the lowest risk category and 4 being the highest) based on the amount of fault current available, the time it takes to clear the arc and the distance from the source. The risk category determines the level of PPE required for the task. Diagnostics and Testing includes work performed on or near electrically live parts related to tasks such as electrical testing, troubleshooting, or voltage and current measurement. It may require the use of portable test instruments, but no other tools can be used on energized parts. Note: Repairing, replacing, or removing energized exposed components is considered energized work, but diagnostics and testing is not. Energized Work is defined as work performed on equipment or systems electrically connected to an energy source. 4.2 General Requirements 4.2A Temporary circuits A temporary electrical wiring is defined as “Approved wiring for power and lighting during a construction, remodeling, maintenance, repair or demolition, and decorative lighting, carnival power and lighting, and similar purposes”.…. Page 2 of 21 Revision: 2 AECI – Health, Safety & Environmental Procedures Issued Apr ‐ 2013 Review Date: 9/4/2014 Electrical Safety DOC # SP 1301 Temporary electrical circuits shall be periodically inspected (quarterly) and properly maintained. Once their intended purpose is complete, they shall be taken down. Temporary electrical cords shall be covered or elevated. They must be kept clear of walkways where they may be exposed to damage or create tripping hazards. Temporary lights will be equipped with bulb guards. Broken or burned out bulbs shall be replaced. 4.2B Extension Cords Extension cords used with portable electric tools and appliances must be heavy duty (no less than 12 gauge conductors) of the three wire grounding type and shall conform to OSHA standards. NO FLAT ELECTRICAL CORDS ARE ALLOWED. Extension cords are to be used per manufacturer recommendations. The maximum length for a twelve gauge extension cord with a 15 amp load is 100 feet, however AECI will permit the use of “engineered special used cords” that are marked and designated for a specific purpose. All extension cords shall be inspected as part of the Assured Grounding Program. Extension cords with a missing ground prong on its plug shall be taken out of service by cutting off the male plug. They may be repaired by a qualified person, but must be tested before placing in service. Extension cords that show damage such as, discoloration of the outer shell; cracked, swollen, pinched, or crushed insulation; loose, bent, or missing blades; etc., shall be taken out of service by having the male plug cut off and tagged or discarded. Extension cords shall not be run across walkways or aisles, concealed behind walls, ceilings or floors, or run through holes in walls, or anywhere they can become damaged or present a tripping hazard. Extension cords may be run through doorways, windows or other pinch points provided they are protected from damage and are used only to provide temporary power. Extension cords cannot be suspended or elevated with conductive material, such as being held up with metal wire. 4.2C Ground Fault Circuit Interrupters (GFCI) GFCIs shall be tested prior to use by depressing the “Test” button. If the device trips, it may be reset and used. If it does not trip when tested, it shall be tagged and taken out of service and checked by a qualified person. GFCIs shall be inspected as part of the Assured Grounding Program. GFCIs shall be used for all temporary 120V power for electrically powered hand tools (non‐battery) used by personnel during construction, remodeling, maintenance, repair or demolition of buildings, structures or during similar activities or locations. This Page 3 of 21 Revision: 2 AECI – Health, Safety & Environmental Procedures Issued Apr ‐ 2013 Review Date: 9/4/2014 Electrical Safety DOC # SP 1301 includes lighting for visual inspection or when work is being performed in damp and/or wet locations, such as outdoors, in basements, in metal tanks, etc... GFCIs are not required to be used with temporary lights unless the cord or lighting fixtures contain a receptacle for equipment to plug into. GFCIs may be of the receptacle, circuit breaker or in‐line type. 4.3 Assured Grounding Program All cord sets, plug and receptacle cord sets GFCI pigtails and any equipment connected by cord and plug used at AECI facilities that are not part of the permanent wiring of buildings or structures shall be tested, identified, and color‐coded using the following standards: 4.3A Removing Damaged or Defective Equipment from Service All equipment found damaged or defective or which fails any of the prescribed inspections or tests may not be used until repaired or replaced. All defective equipment shall be tagged with a notice tag stating “Do Not Use”; the tag shall also contain the name of person tagging the equipment and the date the equipment was removed from service. 4.3B Daily Visual Inspections The following shall be visually inspected before use for external damage (such as deformed or missing pins or damaged insulation) and for indication of possible internal damage: Cord sets; GFCI pigtails; Plug (attachment cap) and receptacle end of cord sets; Any equipment connected by cord and plug. 4.3C Test Frequency All required tests (visual inspection and continuity) shall be performed with the following frequency: Before first use (out of the box); Before equipment is returned to service following any repairs; Before equipment is used after any incident that can be reasonably suspected to have caused damage; At intervals not to exceed 3 months, except for cord sets and receptacles that are in fixed locations (offices) and not exposed to damage shall be tested at intervals not to exceed 6 months; and Page 4 of 21 Revision: 2 AECI – Health, Safety & Environmental Procedures Issued Apr ‐ 2013 Review Date: 9/4/2014 Electrical Safety DOC # SP 1301 GFCI protection devices, such as permanently wired GFCI and GFCI pigtails, shall be tested monthly to ensure they trip properly under a load. The testing of permanently wired GFCI shall be documented in the CMMS. All other GFCIs tested shall be documented by using the color code in Table 2. GFCI Breakers shall be tested annually to ensure they will trip under a load. Load test trips on breakers shall be documented in the CMMS. 4.3D Grounding Conductor Testing A qualified person shall use either a continuity tester or an ohmmeter. Each receptacle and plug of the following shall be tested for correct attachment of the equipment grounding conductor and the equipment grounding conductor shall be connected to its proper terminal: All cord sets: Receptacles that are not a part of the permanent wiring of the building or structure: and All plug‐connected equipment required to be grounded. (Note: This does not apply to double insulated hand or portable powered tools.) 4.3E Cord Set and GFCI Color Code Documentation All tested cord sets and cord and plug‐connected equipment shall be marked, at one or both ends, with colored tape to denote the quarter that the tests were performed or they may have a tag attached at either end with the written expiration date of the inspection. The previous quarter’s marking shall be removed (cutting of tape is prohibited) before adding the current quarter’s marking. Use the color code table below. If tags are used in lieu of tape, the expiration date of the inspection may not be crossed out and a new date written on the tag. Table 1: Color Codes for Cord Set Test Requirements Months Color Code Jan., Feb. & March White April, May & June Green July, Aug. & Sept. Red Oct., Nov. & Dec. Orange Page 5 of 21 Revision: 2 AECI – Health, Safety & Environmental Procedures Issued Apr ‐ 2013 Review Date: 9/4/2014 Electrical Safety DOC # SP 1301 All tested in‐line GFCIs (pigtails) shall be marked, at one or both ends, with colored tape to denote the quarter and month that the tests were performed or they may have a tag attached at either end with the written expiration date of the inspection. The previous quarter’s marking shall be removed (cutting of tape is prohibited) before adding the current quarter’s marking. Use the color code table below. If tags are used in lieu of tape, the expiration date of the inspection may not be crossed out and a new date written on the tag. Table 2: Color Code Table for GFCI Documentation Months January February March April May June July August September October November December 4.4 ARC Flash Analysis 1st Color White White White Green Green Green Red Red Red Orange Orange Orange 2nd Color Yellow Blue Brown Yellow Blue Brown Yellow Blue Brown Yellow Blue Brown An Arc Flash Hazard Analysis shall be performed prior to entering the arc flash protection boundary to work on energized equipment. All energized equipment that may produce an arc flash shall be labeled with appropriate warning labels (See Appendix B) and a label detailing the arc flash Information, such as: Flash Protection Boundary; PPE Category; Shock Hazard when cover is open; Limited, Restricted and Prohibited Approach boundary; and Available incident energy at corresponding working distance Arc Flash Hazard Analysis shall be reviewed every 5 years and/or when major changes have been made to the system that might affect the PPE Category rating of energized equipment. Page 6 of 21 Revision: 2 AECI – Health, Safety & Environmental Procedures Issued Apr ‐ 2013 Review Date: 9/4/2014 Electrical Safety DOC # SP 1301 An arc flash label shall be affixed to the incoming feed side of a breaker, breaker panel, or row of breakers. At least one label will be placed in a prominent position (preferably eye height), if the incoming voltage is the same for all breakers in panel or row of breakers. Arc flash labeling shall be visually inspected at least annually to verify: It is legible and in good condition (not torn or peeling off); It is in place. 4.5 Working On or Near Live Parts All energized electrical work with an ARC Flash Hazard Category of 3 or greater requires a Permit for Energized Electrical Task (PEET) to be filled out and approved by the EAHJ before the work can begin. A copy of the PEET form is provided in the Appendix. Work related to diagnostics and testing does not require the use of a PEET provided the appropriate safe work practices and PPE are used. The PEET shall be filled out by the person requesting that the energized work be completed. All PEETs shall be submitted to the Electrical/Instrumentation Superintendent or his/her designee for approval. The permit must be posted in the area where the energized work is taking place for the duration of the work. The following work practices shall be put in place to prevent electrical shock or other injuries resulting from either direct or indirect electrical contact: Job Briefing reviewing the specific JSA for the task to be performed; The use of the insulated tools; The use of the proper personal protective equipment (PPE) according to the PPE Category; The use of barricades to prevent unauthorized personnel from entering the arc flash protection boundary; Adequate lighting; Unqualified persons may only cross the Limited Approach Boundary when they are under the direct supervision of a qualified person. Crossing the boundary includes having any portion of the body break the plane of the boundary; Qualified persons may not cross or take any conductive object closer than the Restricted Approach Boundary unless one of the following conditions apply: a) The qualified person is insulated or guarded from the live parts and no un‐insulated part of the qualified person’s body crosses the Prohibited Approach Boundary; or b) The live parts are insulated from the qualified person and from any other conductive object at a different potential. Crossing the Prohibited Approach Boundary is considered the same as making contact with energized parts. Qualified persons may only cross this boundary when all of the following precautions have been taken: Page 7 of 21 Revision: 2 AECI – Health, Safety & Environmental Procedures Issued Apr ‐ 2013 Review Date: 9/4/2014 Electrical Safety DOC # SP 1301 a) The qualified person has specific training to work on energized parts; and b) The qualified person uses PPE appropriate for working on energized parts, which are rated for the voltage and energy level involved. When working on de‐energized parts, but still inside the flash protection boundary for nearby live exposed parts the following precautions shall be taken: If parts cannot be de‐energized, barriers such as insulated blankets must be used to protect against accidental contact or PPE must be worn; Employees shall not reach blindly into areas that might contain exposed live parts; Employees shall not enter spaces containing live parts unless illumination is provided that allows the work to be performed safely; Conductive articles of jewelry and clothing (such as watchbands, bracelets, rings, key chains, necklaces, metalized aprons, etc.) shall not be worn where they present an electrical contact hazard with exposed live parts; 4.6 Approach Boundaries to Exposed Live Parts for Shock Protection Arc Flash Boundary Limited Approach Boundary Restricted Approach Boundary Prohibited Approach Boundary Prohibited Space ● Restricted Space ● Limited Space ● Page 8 of 21 Revision: 2 AECI – Health, Safety & Environmental Procedures Issued Apr ‐ 2013 Review Date: 9/4/2014 Electrical Safety DOC # SP 1301 4.6A Alternating‐Current Systems Nominal System Voltage Range, Phase to Phase < 50 V 50 V – 300 V 301 V – 750 V 751 V – 15 kV 15.1 kV – 36 kV 36.1 kV – 46 kV 46.1 kV – 72.5 kV 72.6 kV – 121 kV 138 kV – 145 kV 161 kV – 169 kV 230 kV – 242 kV 345 kV – 362 kV 500 kV – 550 kV 765 kV – 800 kV Limited Approach Boundary Exposed Movable Exposed Fixed Circuit Conductor Part Not Specified Not Specified 3.0 m (10 ft. 0 in) 1.0 m (3 ft. 6 in) 3.0 m (10 ft. 0 in) 1.0 m (3 ft. 6 in) 3.0 m (10 ft. 0 in) 1.5 m (5 ft. 0 in) 3.0 m (10 ft. 0 in) 1.8 m (6 ft. 0 in) 3.0 m (10 ft. 0 in) 2.5 m (8 ft. 0 in) 3.0 m (10 ft. 0 in) 2.5 m (8 ft. 0 in) 3.3 m (10 ft. 8 in) 2.5 m (8 ft. 0 in) 3.4 m (11 ft. 0 in) 3.0 m (10 ft. 0 in) 3.6 m (11 ft. 8 in) 3.6 m (11 ft. 8 in) 4.0 m (13 ft. 0 in) 4.0 m (13 ft. 0 in) 4.7 m (15 ft. 4 in) 4.7 m (15 ft. 4 in) 5.8 m (19 ft. 0 in) 5.8 m (19 ft. 0 in) 7.2 m (23 ft. 9 in) 7.2 m (23 ft. 9 in) Restricted Approach Boundary; Includes Prohibited Inadvertent Movement adder Approach Boundary Not Specified Not Specified Avoid Contact Avoid Contact 0.3 m (1 ft. 0 in) 25 mm (0 ft. 1 in) 0.7 m (2 ft. 2 in) 0.2 m (0 ft. 7 in) 0.8 m (2 ft. 7 in) 0.3 m (0 ft. 10in) 0.8 m (2 ft. 9 in) 0.4 m (1 ft. 5 in) 1.0 m (3 ft. 3 in) 0.7 m ( 2ft 2 in) 1.0 m (3 ft. 4 in) 0.8 m (2 ft. 9 in) 1.2 m (3 ft. 10 in) 1.0 m (3 ft. 4 in) 1.3 m (4 ft. 3 in) 1.1 m (3 ft. 9 in) 1.7 m (5 ft. 8 in) 1.6 m (5 ft. 2 in) 2.8 m (9 ft. 2 in) 2.6 m (8 ft. 8 in) 3.6 m (11 ft. 10 in) 3.5 m (11 ft. 4 in) 4.9 m (15 ft. 11 in) 4.7 m (15 ft. 5 in) 4.6B Direct‐Current Voltage Systems Nominal Potential Difference < 100 V 100 V – 300 V 301 V – 1kV 1.1 kV – 5 kV 5 kV – 15 kV 15.1 kV – 45 kV 45.1 kV – 75 kV 75.1 kV – 150 kV 150.1 kV – 250 kV 250.1 kV – 500 kV 500.1 kV – 800 kV Limited Approach Boundary Exposed Movable Exposed Fixed Circuit Conductor Part Not Specified Not Specified 3.0 m (10 ft. 0 in) 1.0 m (3 ft. 6 in) 3.0 m (10 ft. 0 in) 1.0 m (3 ft. 6 in) 3.0 m (10 ft. 0 in) 1.5 m (5 ft. 0 in) 3.0 m (10 ft. 0 in) 1.5 m (5 ft. 0 in) 3.0 m (10 ft. 0 in) 2.5 m (8 ft. 0 in) 3.0 m (10 ft. 0 in) 2.5 m (8 ft. 0 in) 3.3 m (10 ft. 8 in) 2.5 m (8 ft. 0 in) 3.6 m (11 ft. 8 in) 3.6 m (11 ft. 6 in) 6.0 m (20 ft. 0 in) 6.0 m (20 ft. 0 in) 8.0 m (26 ft. 0 in) 8.0 m (26 ft. 0 in) Restricted Approach Boundary; Includes Prohibited Inadvertent Movement adder Approach Boundary Not Specified Not Specified Avoid Contact Avoid Contact 0.3 m (1 ft. 0 in) 25 mm (0 ft. 1 in) 0.5 m (1 ft. 5 in) 0.1 m (0 ft. 4 in) 0.7 m (2 ft. 2 in) 0.2 m (0 ft. 7 in) 0.8 m (2 ft. 9 in) 0.4 m (1 ft. 5 in) 1.0 m (3 ft. 2 in) 0.7 m ( 2ft 2 in) 1.2 m (4 ft. 0 in) 1.0 m (3 ft. 2 in) 1.6 m (5 ft. 3 in) 1.5 m (5 ft. 0 in) 3.5 m (11ft 6 in) 3.3 m (10 ft. 10 in) 3.5 m (16 ft. 5 in) 5.0 m (16 ft. 5 in) Page 9 of 21 Revision: 2 AECI – Health, Safety & Environmental Procedures Issued Apr ‐ 2013 Review Date: 9/4/2014 Electrical Safety DOC # SP 1301 4.7 Inspection Schedule for Rubber Insulating Equipment Type of Equipment Rubber insulating line hose Rubber insulating covers Rubber insulating blankets Rubber insulating sleeves Rubber insulating gloves When to Test Upon indication that insulating value is suspect Upon indication that insulating value is suspect Before first issue and every 12 months thereafter * Before first issue and every 12 months thereafter * Before first issue and every 6 months thereafter * (*) – If the insulating equipment has been electrically tested but not issued for service, it may not be placed into service unless said testing has taken placed within the previous 12 months. 4.8 Working in the Vicinity of Overhead lines 4.8A Unqualified Person When an unqualified person is working in an elevated position near overhead lines, or on the ground in the vicinity of overhead lines, the person may not bring any conductive object closer to unguarded, energized overhead lines than the following distances: For voltages to ground 50 kV or below ‐ 10 ft. For voltages to ground over 50 kV – 10 ft. plus 4 in. for every 10 kV over 50 kV 4.8B Qualified Person When a qualified person is working in the vicinity of overhead lines, whether in an elevated position or on the ground, the qualified person may not approach or take any conductive object without an approved insulating handle closer than 10 ft. on lines above 69 kV (phase to phase) 4.9 Grounding When ground cables are applied for energy control as part of the LOTO program each cable shall be identified as a separate tagging device on the LOTO clearance listing. 4.10 Switching Operations When switching operations are performed ARC Flash PPE requirements and boundaries shall be observed. When performing switching operations on unmarked distribution panels, category “0” PPE shall be worn. Page 10 of 21 Revision: 2 AECI – Health, Safety & Environmental Procedures Issued Apr ‐ 2013 Review Date: 9/4/2014 Electrical Safety DOC # SP 1301 5.0 Arc Flash Clothing, PPE and Other Protective Equipment Employees working in areas where electrical hazards are present shall be provided with, and shall use, protective equipment that is designed and constructed for the specific part of the body to be protected and for the work to be performed. When an employee is working within or is present within the Flash Protection Boundary when work is being performed he/she shall wear protective clothing and PPE based upon the ARC Flash Analysis Hazard/Risk Category. (Appendix A) 5.1 Protective Clothing and PPE Requirements “Arc‐ rated clothing (outer layer) with a minimum of 8 cal/cm2 is required as the regular daily work attire for Instrument Techs and Electricians. Any deviation from this practice requires approval from the Electrical and Instrumentation Superintendent. Flash suits design shall permit easy and rapid removal by the wearer. The entire flash suit, including the hood’s face shield, shall have an arc rating that is suitable for the arc flash exposure. Face Shields shall have an arc rating suitable for the arc flash exposure. Face shields without an arc rating shall not be used. Eye protection (safety glasses or goggles) and hearing protection shall always be worn under face shields or hoods. Heavy‐duty leather gloves or arc‐rated gloves shall be worn where required for arch flash protection. Heavy‐duty leather gloves shall have a minimum thickness of 0.03 in. (0.7mm). Where insulating rubber gloves are used for shock protection, leather protectors shall be worn over the rubber gloves. Heavy‐duty leather work shoes provide some arc flash protection to the feet and shall be used in all exposures greater than 4 cal/cm2. Clothing made from flammable synthetic materials that melt at temperatures below 315 ̊C (600 ̊F), such as acetate, nylon, polyester, polypropylene, and spandex, either alone or in blends, shall not be used. Non‐melting, flammable (non‐arc‐rated) materials (such as cotton, polyester‐cotton blends, nylon, nylon‐cotton blends, silk, rayon and wool fabrics) can be used as under layers to arc‐rated clothing, but they cannot be counted toward arc‐flash protection. Page 11 of 21 Revision: 2 AECI – Health, Safety & Environmental Procedures Issued Apr ‐ 2013 Review Date: 9/4/2014 Electrical Safety DOC # SP 1301 5.2 Care and Maintenance of Arc‐Rated Clothing and Arc‐rated Flash Suits Arc‐rated apparel shall be inspected before each use. The EAHJ or his/her designee shall inspect all arc flash suits and protective PPE semi‐annual to ensure that it is maintained properly. Work clothing or arc flash suits that are contaminated or damaged (ripped, torn, frayed or have excessive wear) to the extent that their protective qualities are impaired, shall not be used. Protective items that become contaminated with grease, oil, or flammable liquids or combustible materials shall not be used. Arc flash suits shall be maintained in a clean and sanitary condition, laundered at least 1x per year or as necessary to maintain them in a clean and sanitary condition. Damaged suits shall be taken out of service, repaired by the manufacturer or a laundry facility that is capable of repairing per industry standards: ASTM F 1506 or replaced. Suits shall be laundered per the manufacturer’s recommendations on the label of the garments. Arc Flash suit and protective face shields shall be replace when they become damaged, have lost their protective qualities, or have been in service for 8 years. When new suits and gear are purchased, their serial numbers shall be recorded and they will be tracked from cradle to grave by: service dates, laundering dates and repair dates. The EAHJ or his/her designee shall set up a tracking program for those departments that have ARC Flash Equipment. Arc‐rated apparel shall be stored in a manner that prevents physical damage; damage from moisture, dust, or other deteriorating agents (chemical fumes); or contamination from flammable or combustible materials. Protective leather gloves shall be replaced when they show excessive wear (holes or cuts that reduce their minimum thickness requirements). 5.3 Other Protective Equipment Insulated tools shall be rated for the voltage on which they are used. Insulating tools used on or around energized parts shall meet the requirements of IEC 60 900 and be stamped VDE certified or meet the requirements of ASTM F 1505 ‐ 10 and be stamped accordingly. Insulated tools and equipment shall be inspected prior to each use. The inspection shall look for damage to the insulation or damage that may limit the tool from performing its intended function or could increase the potential for an incident (example, screw driver with a damaged tip). Insulated tools whose outer protective coating has been damaged so that the undercoat color is visible shall be taken out of service and replaced. Page 12 of 21 Revision: 2 AECI – Health, Safety & Environmental Procedures Issued Apr ‐ 2013 Review Date: 9/4/2014 Electrical Safety DOC # SP 1301 Rubber insulating equipment (gloves, blankets, sleeves, etc.) shall be visually inspected before each day’s use. In addition to a visual inspection rubber gloves shall be given an air test inspection, compressed air is not to be used to inflate gloves for testing. All rubber insulating equipment shall be sent off to a third party for testing according to the schedule in section 4.7. Hot sticks shall be inspected before each use for damage and/ or defects, any hot stick found damaged or defective shall be removed from service and sent off for repair and electrical testing per ASTM F 711 before being placed back in service or replacement if repair not feasible. Hot sticks shall be electrically tested every two years per ASTM F 711 by a third party provider. 6. Enforcement Enforcement of this procedure, as with other procedures, will be in accordance with the provisions of AECI Policy No. 514 – Employee Conduct and Discipline. 7. Training Requirements 7.1 Training All personnel who work on or around electrical equipment or who can be reasonably expected to be exposed to an ARC Flash Hazard shall be trained on electrical safety related practices and this procedure. Personnel whose job requires them to rack out or in breakers and switch gear which requires some form of ARC Flash PPE to be worn, shall be trained in the selection of the proper gear, how to visually inspect and perform an air test for rubber gloves, inspect ARC flash suits for damage and how to properly maintain ARC Flash suits. This training may be conducted in house by a qualified employee. In addition, Qualified Personnel (employees) shall be trained in the proper use of personal protective equipment including arc flash suits; insulating and shielding materials; and insulated tools and test equipment. Personnel permitted to work within the limited approach boundary of exposed energized electrical conductors and circuit parts operating at 50 volts or more shall, at a minimum, be additionally trained in the following: 1. Skill and techniques necessary to distinguish exposed energized electrical conductors and circuit parts from other parts of electrical equipment. Page 13 of 21 Revision: 2 AECI – Health, Safety & Environmental Procedures Issued Apr ‐ 2013 Review Date: 9/4/2014 Electrical Safety DOC # SP 1301 2. Skills and techniques necessary to determine the nominal voltage of exposed energized electrical conductors and circuit parts. 3. Approach distances specified in section 4.6A & 4.6B of this procedure and the corresponding voltages to which the qualified person will be exposed. 4. Decision‐making process necessary to determine the degree and extent of the hazard and the personal protective equipment and job planning necessary to perform the task safely. Personnel will be trained in the proper selection of voltage detectors, their proper use and limitations. Personnel who are exposed to shock hazards and those employees who are responsible for taking action in case of an emergency shall be trained in methods of release for victims who come in contact with exposed energized electrical conductors or circuit parts. They shall also be trained annually on cardiopulmonary resuscitation (CPR) and the use of automatic external defibrillator (AED), and trained biennial in First Aid methods. Training can consist of classroom and/or on‐the‐job or a combination of both. The degree of training is determined by the amount of risk associated to an employee. 7.2 Retraining Employees shall be retrained on tasks that are performed less often than once per year before they are permitted to perform the task. Personnel shall receive additional training or retraining under any of the following conditions: 1. When the supervision or annual inspections indicate that personnel are not complying with the safety‐related work practices. 2. If new technology, new types of equipment, or changes in procedures necessitate the use of safety‐related work practices that are different from those that a person would normally use. 3. If personnel must employ safety‐related work practices that are not normally used during his or her regular job duties. Qualified Personnel shall receive retraining every 3 years at a minimum on this procedure and NFPA 70E updates or whenever this procedure is updated. Page 14 of 21 Revision: 2 AECI – Health, Safety & Environmental Procedures Issued Apr ‐ 2013 Review Date: 9/4/2014 Electrical Safety DOC # SP 1301 8. Recordkeeping Safety training records shall be updated in Training Tracking by the Environmental and Safety Administrator. Signature sheets, tests and any other applicable documents shall be scanned and uploaded to the EH&S SharePoint site by the Environmental and Safety Administrator. Page 15 of 21 Revision: 2 AECI – Health, Safety & Environmental Procedures Issued Apr ‐ 2013 Review Date: 9/4/2014 Electrical Safety DOC # SP 1301 Employee Acknowledgement I have read and been informed about the content, requirements, and expectations of Safety Procedure 1301 Electrical Safety. I have received a copy of the procedure and agree to abide by the procedural guidelines. I understand that if I have questions, at any time, regarding Safety Procedure 1301, I will consult with my immediate supervisor or Safety and Environmental Coordinator or Specialist. Please read Safety Procedure 1301 Electrical Safety carefully to ensure that you understand the procedure before signing this document. Printed Name Signature Employee Number Date Page 16 of 21 Revision: 2 AECI – Health, Safety & Environmental Procedures Issued Apr ‐ 2013 Review Date: 9/4/2014 Electrical Safety DOC # SP 1301 Permit for Energized Electrical Task (PEET) Part I: To Be Completed by the Requester: Job/Work Order Number_________________ (1) Description of circuit/equipment/job location: _________________________________________________ __________________________________________________________________________________________ (2) Description of work to be done: _____________________________________________________________ __________________________________________________________________________________________ __________________________________________________________________________________________ (3) Justification of why the circuit/equipment cannot be de‐energized or the work deferred until the next scheduled outage:___________________________________________________________________________ __________________________________________________________________________________________ __________________________________________________________________________________________ Part II: To Be Completed by the Electrically Qualified Persons Doing the Work: (1) Detailed job description has been developed for performing the above detailed work? (2) Description of safe work practices have been identified on a Job Safety Analysis Form? (3) An Arc Flash Analysis has been performed on equipment to be worked on? (4) Means used to restrict the access of unqualified persons from the work area have been identified? (5) A documented job briefing has been performed concerning the above work? (6) Does the work involve anyone besides an Electrically Qualified Person(s)? (7) Do you agree the above‐described work can be done safely? If no return to requester ____________________________________________ _______________________ Electrically Qualified Person(s) Date Yes/No Y/N Y/N Y/N Y/N Y/N Y/N Y/N Part III: Approval to Perform The Work While Electrically Energized: ____________________________________________ Electrical Authority Having Jurisdiction _______________________ Date Page 17 of 21 Revision: 2 AECI – Health, Safety & Environmental Procedures Issued Apr ‐ 2013 Review Date: 9/4/2014 Electrical Safety DOC # SP 1301 Appendix A PPE Category 0 Protective Clothing and PPE Protective Clothing, Non-melting or Untreated Natural Fiber (i.e., untreated cotton, wool, rayon, or silk, or blends of these materials) with a Fabric Weight of at Least 4.5 oz. /yd2 Shirt (long sleeve) Pants (long) Protective Equipment Safety glasses or safety goggles (SR) Hearing protection (ear canal inserts) Heavy duty leather gloves (AN) (See Note 1.) Electrical Shock Hazard PPE (Use when working on or near exposed live parts) Voltage Rated Gloves Leather Covers Voltage Rated Tools PPE Category 1 Protective Clothing and PPE Arc‐Rated Clothing, Minimum Arc Rating of 4 cal/cm2 (See Note 3.) Arc‐rated long‐sleeve shirt and pants or arc‐rated overall Arc‐rated face shield (see Note 2) or arc flash suit hood Arc‐rated jacket, parka, rainwear, or hard hat liner (AN) Category Protective Clothing and PPE Protective Equipment Hard hat Safety glasses or safety goggles (SR) Hearing protection (ear canal inserts) Heavy duty leather gloves (See Note 1.) Leather work shoes (AR) Electrical Shock Hazard PPE (Use when working on or near exposed live parts) Voltage Rated Gloves Leather Covers Voltage Rated Tools Page 18 of 21 Revision: 2 AECI – Health, Safety & Environmental Procedures Issued Apr ‐ 2013 Review Date: 9/4/2014 Electrical Safety DOC # SP 1301 PPE Category 2 Protective Clothing and PPE Arc‐Rated Clothing, Minimum Arc Rating of 8 cal/cm2 (See Note 3.) Arc‐rated long‐sleeve shirt and pants or arc‐rated overall Arc‐rated flash suit hood or arc‐rated face shield (See Note 2) and arc‐rated balaclava Arc‐rated jacket, parka, rainwear, or hard hat liner (AN) Protective Equipment Hard hat Safety glasses or safety goggles (SR) Hearing protection (ear canal inserts) Heavy duty leather gloves (See Note 1.) Leather work shoes Electrical Shock Hazard PPE (Use when working on or near exposed live parts) Voltage Rated Gloves Leather Covers Voltage Rated Tools PPE Category 3 Protective Clothing and PPE Arc‐Rated Clothing Selected so That the System Arc Rating Meets the Required Minimum Arc Rating of 25 cal/cm2 (See Note 3.) Arc‐rated long‐sleeve shirt (AR) Arc‐rated pants (AR) Arc‐rated coverall (AR) Arc‐rated arc flash suit jacket (AR) Arc‐rated arc flash suit pants (AR) Arc‐rated arc flash suit hood Arc‐rated gloves (See Note 1.) Arc‐rated jacket, parka, rainwear, or hard hat liner (AN) Protective Equipment Hard hat Safety glasses or safety goggles (SR) Hearing protection (ear canal inserts) Leather work shoes Electrical Shock Hazard PPE (Use when working on or near exposed live parts) Voltage Rated Gloves Leather Covers Voltage Rated Tools Page 19 of 21 Revision: 2 AECI – Health, Safety & Environmental Procedures Issued Apr ‐ 2013 Review Date: 9/4/2014 Electrical Safety DOC # SP 1301 PPE Category 4 Protective Clothing and PPE Arc‐Rated Clothing Selected so That the System Arc Rating Meets the Required Minimum Arc Rating of 40 cal/cm2 (See Note 3.) Arc‐rated long‐sleeve shirt (AR) Arc‐rated pants (AR) Arc‐rated coverall (AR) Arc‐rated arc flash suit jacket (AR) Arc‐rated arc flash suit pants (AR) Arc‐rated arc flash suit hood Arc‐rated gloves (See Note 1.) Arc‐rated jacket, parka, rainwear, or hard hat liner (AN) Protective Equipment Hard hat Safety glasses or safety goggles (SR) Hearing protection (ear canal inserts) Leather work shoes Electrical Shock Hazard PPE (Use when working on or near exposed live parts) Voltage Rated Gloves Leather Covers Voltage Rated Tools AN: as needed (optional). AR: as required. SR: selection required. (1) If rubber insulating gloves with leather protectors are required by Table 130.7(C)(15)(a), additional l leather or arc‐rated gloves are not required. The combination of rubber insulating gloves with leather protectors satisfies the arc flash protection requirement. (2) Face shields are to have wrap‐around guarding to protect not only the face but also the forehead, ears, and neck, or, alternatively, an arc‐rated arc flash suit hood is required to be worn. (3) Arc rating is defined in Article 100 and can be either the arc thermal performance value (ATPV) or energy of break open threshold (EBT). ATPV is defined in ASTM F 1959, Standard Test Method for Determining the Arc Thermal Performance Value of Materials for Clothing, as the incident energy on a material, or a multilayer system of materials, that results in a 50 percent probability that sufficient heat transfer through the tested specimen is predicted to cause the onset of a second‐degree skin burn injury based on the Stoll curve, in cal/cm2. EBT is defined in ASTM F 1959 as the incident energy on a material or material system that results in a 50 percent probability of break open. Arc rating is reported as either ATPV or EBT, whichever is the lower value. Page 20 of 21 Revision: 2 AECI – Health, Safety & Environmental Procedures Issued Apr ‐ 2013 Review Date: 9/4/2014 Electrical Safety DOC # SP 1301 Appendix B Acceptable Arc Flash Labels Pre‐2012 Labeling Boundaries PPE Requirements Max Incident Energy Note: Shock Hazard Voltage Included on label Note: Shock Hazard Voltage label is required in addition to this label Post 2012 Labeling Page 21 of 21