Reference Guide

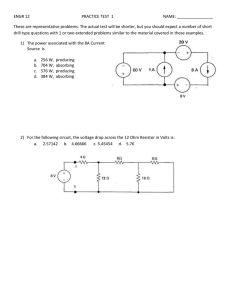

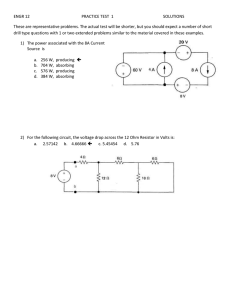

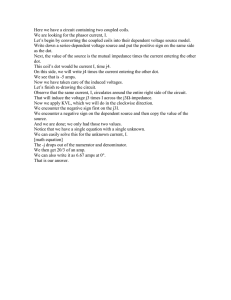

advertisement

TPC TRAINCO Real World Training...for Real World Needs Principles of LOTO ExecuƟon VeriĮcaƟon of an Electrically Safe Work CondiƟon (1) Determine all possible sources of electrical supply to the speciĮc equipment. Check applicable up-to-date drawings, diagrams, and idenƟĮcaƟon tags. (2) AŌer properly interrupƟng the load current, open the disconnecƟng device(s) for each source. (3) Wherever possible, visually verify that all blades of the disconnected devices are fully open or that draw-out type circuit breakers are withdrawn to the fully disconnected posiƟon. 1. Employee Involvement 2. Training 3. Retraining 4. Training DocumentaƟon 5. Plan 6. Control of Energy 7. IdenƟĮcaƟon 8. Voltage 9. CoordinaƟon Review Procedures for Hazardous Energy Control 1. Simple lockout/tagout procedure 2. Complex lockout/tagout procedure 3. CoordinaƟon of procedures (4) Apply lockout/tagout devices in accordance with a documented and established policy. (5) Use an adequately rated test instrument to test each phase conductor or circuit part to verify it is de-energized. Test each phase conductor or circuit part both phaseto-phase and phase-to-ground. Before and aŌer each test, determine that the test instrument is operaƟng saƟsfactorily, through veriĮcaƟon on a known voltage source. (6) Where the possibility of induced voltages or stored electrical energy exists, ground the phase conductors or circuit parts before touching them. Where it could be reasonably anƟcipated that the conductors or circuit parts being de-energized could contact other exposed energized conductors or circuit parts, apply ground connecƟng devices rated for the available fault duty. Electronic Sensing & Shunt Trip Test Resistor bypasses ≥6 mA of current for test CB Reset Note: Grounding conductor not required Receptacle & Plug 1. Lock applicaƟon 2. LOTO device 3. Lockout device 4. Tagout device 5. Electrical circuit Interlocks 6. Control devices Procedures – Equipment 1. Planning is required in procedures a. LocaƟng sources b. Exposed persons c. Person in charge d. Simple lockout/tagout e. Complex LOTO 2. Elements of Control must be IdenƟĮed a. De-energizing of equipment b. Release of stored energy c. DisconnecƟng means d. ResponsibiliƟes e. VeriĮcaƟon procedures f. TesƟng requirements g. Grounding h. ShiŌ change i. CoordinaƟon j. Accountability of personnel k. Lockout/Tagout applicaƟon l. Removal of Lockout/Tagout Devices (Ground-Fault Circuit Interrupter (GFCI). A device intended for the protecƟon of personnel that funcƟons to de energize a circuit or porƟon thereof within an established period of Ɵme when a current to ground exceeds the values established for a Class A device. [NEC® ArƟcle 100] InformaƟonal Note: Class A ground-fault circuit-interrupters trip when the current to ground is 6 mA or higher and do not trip when the current to ground is less than 4 mA. For further informaƟon see ANSI/UL 943 Standard for Ground-Fault. NFPA 70E® ArƟcle 110.4(C) Ground-Fault Circuit-Interrupter (GFCI) ProtecƟon. (2) Maintenance and ConstrucƟon. GFCI protecƟon shall be provided where an employee is operaƟng or using cord- and plug-connected tools related to maintenance and construcƟon acƟvity supplied by 125-volt, 15-, 20-, or 30-ampere circuits. Where employees operate or use equipment supplied by greater than 125-volt, 15-, 20-, or 30-ampere circuits, GFCI protecƟon or an assured equipment grounding conductor program shall be implemented. L2 Kirchoff’s law requires these values must be equal Equipment (1) General. Employees shall be provided with ground fault circuit-interrupter (GFCI) protecƟon where required by applicable state, federal, or local codes and standards. Listed cord sets or devices incorporaƟng listed GFCI protecƟon for personnel idenƟĮed for portable use shall be permiƩed. L1 Current Transformer Responsibility for LOTO 1. Employer establishes procedures and provides training on these procedures 2. Two forms of control permiƩed a. Simple LOTO b. Complex LOTO 3. Audit procedures (Annually) Coil inside portable tool Trips at ≥6 mA difference between L1 and L2 in less than 0.1 seconds (3) Outdoors. GFCI protecƟon shall be provided when an employee is outdoors and operaƟng or using cord- and plug-connected equipment supplied by 125-volt, 15-, 20-, or 30-ampere circuits. Where employees working outdoors operate or use equipment supplied by greater than 125-volt, 15-, 20-, or 30-ampere circuits, GFCI protecƟon or an assured equipment grounding conductor program shall be implemented. NFPA 70E® ArƟcle 110.4(D) Ground-Fault Circuit-Interrupter ProtecƟon Devices. GFCI protecƟon devices shall be tested in accordance with the manufacturer’s instrucƟons. For more informaƟon see OSHA Sub part S® or NFPA 70E® 1. Warning Item 1 complies with NEC® ArƟcle 110.16 and NFPA 70E® ArƟcle 130.7(E)(1) and warns people of the possible arc Ňash and shock hazard as well as the need to use proper PPE. 2. Arc Ňash protecƟon boundary This is the calculated distance from a possible arc source where the incident energy drops to 1.2 calories per square cenƟmeter and is widely recognized as the minimum energy required to produce the onset of a second-degree burn. People working within this boundary when an arc Ňash hazard exists must wear appropriate Ňame-resistant clothing and PPE. 3. Incident energy The incident energy is based on detailed calculaƟons at a speciĮc working distance from the perspecƟve arc source. The arc raƟng of the Ňame-resistant clothing and PPE must be equal to or greater than this value. 4. Table Method VS CalculaƟon Method System Voltage Range, Ø to Ø1 Limited Approach Boundary2 Exposed Movable Conductor3 Exposed Fixed Circuit Part Restricted Approach Boundary2 < 50 Volts not speciĮed not speciĮed 50 V - 150 V 10' - 0" 3' - 6" not speciĮed avoid contact > 151 V - 750 V 10' - 0" 3' - 6" 1' - 0" > 751 V - 15 kV 10' - 0" 5' - 0" 2' - 2" > 15.1 kV - 36 kV 10' - 0" 6' - 0" 2' - 7" > 36.1 kV - 46 kV 10' - 0" 8' - 0" 2' - 9" Available incident energy and the corresponding working distance, or the arc Ňash PPE category in Table 130.7(C)(15)(A)(b) or Table 130.7(C)(15)(B) for the equipment, but not both. 5. Shock hazard This is the voltage at which the equipment operates at. 6. Limited approach boundary DeĮnes the closest approach to an exposed electrical hazard, (conductor, component, etc.), for non-qualiĮed personnel, unless escorted by a qualiĮed worker. Determines the minimum safe distance for the placement of barricades for shock protecƟon if this distance is greater than the arc Ňash boundary. If the qualiĮed electrical workers are unable or unwilling to provide escort for unqualiĮed workers, the unqualiĮed worker may not enter the limited approach boundary. 7. Restricted approach boundary QualiĮed electrical workers only. All required PPE appropriate for the hazards shall be worn. The worker is now working near the exposed hazard. The worker must have an approved plan for the work they are to perform. They may cross the restricted boundary only to the extent that is necessary to perform their work. 8. Date of study/label NFPA 70E® ArƟcle 130.5 requires that the arc Ňash hazard analysis either be updated when major modiĮcaƟons or renovaƟons take place, or else it should be reviewed periodically at most every Įve years. 9. Where the panel is fed from Since much of the informaƟon from the arc Ňash study is equipment and locaƟonspeciĮc, an equipment idenƟĮcaƟon should be listed. 10. Study performed by This should be listed in case you have a quesƟon about the study. Nominal PotenƟal Diīerence Limited Approach Boundary Exposed Movable Conductor2 Exposed Fixed Circuit Part Restricted Approach Boundary2 < 100 Volts not speciĮed not speciĮed not speciĮed 100 V - 300 V 10' - 0" 3' - 6" avoid contact > 301 V - 1 kV 10' - 0" 3' - 6" 1' - 0" > 1.1 kV - 5 kV 10' - 0" 5' - 0" 1' - 5" > 5.1 kV - 15 kV 10' - 0" 5' - 0" 2' - 2" > 15.1 kV - 45 kV 10' - 0" 8' - 0" 2' - 9" > 45.1 kV - 75 kV 10' - 0" 8' - 0" 3' - 2" PPE Category 1 Arc Flash Hazard - A dangerous condiƟon associated with the possible release of energy caused by an electric arc. Personal ProtecƟon Equipment (PPE) Arc-Rated Clothing, Minimum Arc RaƟng of 4 cal/cm² (see Note 1) Arc-rated long-sleeve shirt and pants or arc-rated coverall Arc-rated face shield (see Note 2) or arc Ňash suit hood Arc-rated jacket, parka, rainwear, or hard hat liner (AN) ProtecƟve Equipment - Hard hat, Safety glasses or safety goggles (SR), Hearing protecƟon (ear canal inserts), Heavy duty leather gloves (see Note 3), Leather footwear (AN) 2 3 Arc-Rated Clothing, Minimum Arc RaƟng of 8 cal/cm² (see Note 1) Arc-rated long-sleeve shirt and pants or arc-rated coverall Arc-rated Ňash suit hood or arc-rated face shield (see Note 2) and arc-rated balaclava Arc-rated jacket, parka, rainwear, or hard hat liner (AN) Arc RaƟng - The value aƩributed to materials that describes their performance to exposure to an electrical arc discharge. The arc raƟng is expressed in cal/cm2 and is derived from the determined value of the arc thermal performance value (ATPV) or energy of break-open threshold (EBT) (should a material system exhibit a break-open response below the ATPV value). Arc raƟng is reported as either ATPV or EBT, whichever is the lower value. Balaclava (Sock Hood) - An arc-rated hood that protects the neck and head except for the facial area of the eyes and nose. ProtecƟve Equipment - Hard hat, Safety glasses or safety goggles (SR), Hearing protecƟon (ear canal inserts), Heavy duty leather gloves (see Note 3), Leather footwear Boundary, Limited Approach - An approach limit at a distance from an exposed energized electrical conductor or circuit part within which a shock hazard exists. Arc-Rated Clothing Selected so that the System Arc RaƟng Meets the Required Minimum Arc RaƟng of 25 cal/cm² (see Note 1) Arc-rated long-sleeve shirt (AR) Arc-rated pants (AR) Arc-rated coverall (AR) Arc-rated Ňash suit jacket (AR) Arc-rated Ňash suit pants (AR) Arc-rated Ňash suit hood Arc-rated gloves (see Note 1) Arc-rated jacket, parka, rainwear, or hard hat liner (AN) Boundary, Restricted Approach - An approach limit at a distance from an exposed energized electrical conductor or circuit part within which there is an increased likelihood of electric shock, due to electrical arc-over combined with inadvertent movement, for personnel working in close proximity to the energized electrical conductor or circuit part. ProtecƟve Equipment - Hard hat, Safety glasses or safety goggles (SR), Hearing protecƟon (ear canal inserts), Leather footwear (AN) 4 Arc Flash Suit - A complete arc-rated clothing and equipment system that covers the enƟre body, except for the hands and feet. Current-LimiƟng Over - Current ProtecƟve Device - A device that, when interrupƟng currents in its current-limiƟng range, reduces the current Ňowing in the faulted circuit to a magnitude substanƟally less than that obtainable in the same circuit if the device were replaced with a solid conductor having comparable impedance. De-energized - Free from any electrical connecƟon to a source of potenƟal diīerence and from electrical charge; not having a potenƟal diīerent from that of the earth. Arc-Rated Clothing Selected so that the System Arc RaƟng Meets the Required Minimum Arc RaƟng of 40 cal/cm² (see Note 1) Arc-rated long-sleeve shirt and pants or arc-rated coverall Arc-rated Ňash suit hood Arc-rated jacket, parka, rainwear, or hard hat liner (AN) Electrically Safe Work CondiƟon - A state in which an electrical conductor or circuit part has been disconnected from energized parts, locked/tagged in accordance with established standards, tested to ensure the absence of voltage, and grounded if determined necessary. ProtecƟve Equipment - Hard hat, Safety glasses or safety goggles (SR), Hearing protecƟon (ear canal inserts), Leather footwear (AN) Ground Fault - An unintenƟonal, electrically conducƟng connecƟon between an ungrounded conductor of an electrical circuit and the normally non–current-carrying conductors, metallic enclosures, metallic raceways, metallic equipment, or earth. Note: AN: as needed (opƟonal). AR: as required. SR: selecƟon required 1. Arc raƟng is deĮned in ArƟcle 100 2. Face shields are to have wrap-around guarding to protect not only the face but also the forehead, ears, and neck, or alternaƟvely, and are-rated arc Ňash suit hood is required to be worn. 3. If rubber insulaƟng gloves with leather protectors are used, addiƟonal leather or arcrated gloves are not required. The combinaƟon of rubber insulaƟng gloves with leather protectors saƟsĮes the arc Ňash protectors required. NFPA 70E® ANNEX H - SimpliĮed, Two-Category, Arc RaƟng Clothing System Incident Energy - The amount of thermal energy impressed on a surface, a certain distance from the source, generated during an electrical arc event. Incident energy is typically expressed in calories per square cenƟmeter (cal/cm2). Incident Energy Analysis - A component of an arc Ňash risk assessment used to predict the incident energy of an arc Ňash for a speciĮed set of condiƟons. InterrupƟng RaƟng - The highest current at rated voltage that a device is idenƟĮed to interrupt under standard test condiƟons. Clothing PPE Categories Arc Rated long sleeve shirt with Arc Rated pants or Arc Rated coveralls (min. ATPV of 8 cal/cm²) 1-2 Over-current - Any current in excess of the rated current of equipment or the ampacity of a conductor. It may result from overload, short circuit, or ground fault. Arc Flash Suit - A total clothing system consisƟng of Arc Rated shirt & pants and/or Arc Rated coveralls and/or Arc Flash coat and pants. Total arc raƟng of 40 cal/cm² 3-4 QualiĮed Person - One who has demonstrated skills and knowledge related to the construcƟon and operaƟon of electrical equipment and installaƟons and has received safety training to idenƟfy and avoid the hazards involved. ProtecƟve Rubber Glove and Sleeve InformaƟon Chart Rubber ClassiĮcaƟon Class 00 Class 0 Class 1 Class 2 Class 3 Class 4 Label Color Max Use Voltage (AC) Beige 500 Red 1,000 White 7,500 Yellow 17,000 Green 26,500 Orange 36,000 Type I (Non-ozone-resistant) Proof Test Voltage (DC) (AC) 750 2,500 1,500 5,000 11,250 10,000 25,500 20,000 39,750 30,000 54,000 40,000 Type II (Ozone-resistant) (DC) 10,000 20,000 40,000 50,000 60,000 70,000 Risk - A combinaƟon of the likelihood of occurrence of injury or damage to health and the severity of injury or damage to health that results from a hazard. Risk Assessment - An overall process that idenƟĮes hazards, esƟmates the potenƟal severity or damage to health, esƟmates the likelihood of occurrence of injury or damage to health, and determines if protecƟve measures are required. Shock Hazard - A dangerous condiƟon associated with the possible release of energy caused by contact or approach to energized electrical conductors or circuit parts. Leather protectors must meet ASTM speciĮcaƟon F696® and should always be worn over rubber insulaƟng gloves to prevent mechanical damage to the rubber gloves - except for those condiƟons detailed in ASTM F496®. Short-Circuit Current RaƟng - The prospecƟve symmetrical fault current at a nominal voltage to which an apparatus or system is able to be connected without sustaining damage exceeding deĮned acceptance criteria. Hard Hat ClassiĮcaƟon Voltage RaƟng Class E Class G Class C 20,000 V 2,200 V 0 Working On (energized electrical conductors or circuit parts) - IntenƟonally coming in contact with energized electrical conductors or circuit parts with the hands, feet, or other body parts, with tools, probes, or with test equipment, regardless of the personal protecƟve equipment a person is wearing. There are two categories of “working on”: DiagnosƟc (tesƟng) is taking readings or measurements of electrical equipment with approved test equipment that does not require making any physical change to the equipment; repair is any physical alteraƟon of electrical equipment. (such as making or Ɵghtening connecƟons, removing or replacing components, etc.) Basic DescripƟon Excellent protecƟon for electrical workers. Good impact protecƟon but limited voltage protecƟon Only protect workers from bumping against Įxed objects Type 1 hats are designed to protect from objects that might fall from above or into which you might collide. Type 2 hats protect from both verƟcal and horizontal threats. Task Reading a panel meter while operaƟng a meter switch Equipment CondiƟon* Arc Flash PPE Required Yes Any X The equipment is properly installed The equipment is not properly installed X X The equipment is properly maintained The equipment is not properly maintained Normal operaƟon of a circuit breaker (CB), switch, contactor, or starter X X All equipment doors are closed and secured All equipment doors are not closed and secured X X All equipment covers are in place and secured All equipment covers are not in place and secured X X There is no evidence of impending failure There is evidence of impending failure No X X Arc Flash PPE Required Task Equipment CondiƟon* Work on control circuits with exposed energized electrical conductors and circuit parts, 120 volts or below without any other exposed energized equipment over 120V including opening of hinged covers to gain access Any Work on control circuits with exposed energized electrical conductors and circuit parts greater than 120V Any X InserƟon or removal (racking) of CBs or starters from cubicles doors open or closed Any X InserƟon or removal of plug-in devices into or from busways Any X Work on exposed energized electrical conductors and circuit parts of equipment directly supplied by a panelboard or motor control center Any X InserƟon and removal of revenue meters (KW-hour, at primary voltage and current) Any X Opening Voltage Transformer or control power transformer compartments Any X Yes No X For AC systems: Work on energized electrical conductors and circuit parts, including voltage tesƟng Any X For DC systems: Work on energized electrical conductors and circuit parts of series-connected baƩery cells, including voltage tesƟng Any X Task 1 X Panelboards or other equipment rated 240V and below Parameters Maximum of 25KA short circuit current available; maximum of 0.03 sec (2 cycles) fault clearing Ɵme; work distance 455mm (18in) 485mm (19in) Panelboards or other equipment rated >240V and up to 600V Parameters Maximum of 25KA short circuit current available; maximum of 0.03 sec (2 cycles) fault clearing Ɵme; work distance 455mm (18in) 2 900mm (3Ō) 600V class motor control centers (MCC) Parameters Maximum of 65KA short circuit current available; maximum of 0.03 sec (2 cycles) fault clearing Ɵme; work distance 455mm (18in) 2 1.5m (5Ō) 600V class motor control centers (MCC) Parameters Maximum of 42KA short circuit current available; maximum of 0.33 sec (20 cycles) fault clearing Ɵme; work distance 455mm (18in) 4 4.3m (14Ō) 600V class switchgear (with power circuit breakers or fused switches) and 600V class switchboards Parameters Maximum of 35KA short circuit current available; maximum of 0.5 sec (30 cycles) fault clearing Ɵme; work distance 455mm (18in) 4 6m (20Ō) Other 600V class (277 through 600V, nominal) equipment Parameters Maximum of 65KA short circuit current available; maximum of 0.03 sec (2 cycles) fault clearing Ɵme; work distance 455mm (18in) 2 1.5m (5Ō) 4 X NEMA E2 (fused contactor) motor starters, 2.3KV trough 7.2KV Parameters Maximum of 35KA short circuit current available; maximum of 0.24 sec (15 cycles) fault clearing Ɵme; work distance 910mm (36in) 12m (40Ō) 4 X Metal-clad switchgear, 1KV trough 15KV Parameters Maximum of 35KA short-circuits current available; maximum of up to 0.24 sec (15 cycles) fault clearing Ɵme; working distance 910mm (36in) 12m (40Ō) X Arc-resistant switchgear Type 1 or 2 [for clearing Ɵmes of < 0.5 sec (30 cycles) with a perspecƟve fault current not to exceed the arc N/A resistant raƟng of the equipment], and metal-enclosed interrupter (doors closed) switchgear, fused or unfused of arc-resistant-type construcƟon, tested in accordance with IEEE C37.20.7, 1 kV through 15 kV Removal or installaƟon of CB or switches Any The equipment is properly installed The equipment is not properly installed X X The equipment is properly maintained Removal or installaƟon of covers for equipment such as wireways, juncƟon boxes and cable trays that does not expose bare energized electrical conductors and circuits parts The equipment is not properly maintained X X All equipment doors are closed and secured All equipment doors are not closed and secured X X All equipment covers are in place and secured All equipment covers are not in place and secured X X There is no evidence of impending failure There is evidence of impending failure Removal of bolted covers (to expose bare energized electrical conductors and circuit parts) For DC systems this includes bolted covers, such as baƩery terminal covers Any Opening hinged door(s) or cover(s) (to expose bare energized electrical conductors and circuit parts) Any Perform infrared thermography and other non-contact inspecƟons outside the restricted approach boundary. This acƟvity does not include opening of doors or covers X Parameters: Maximum of 35 kA short-circuit current available; maximum of up to 0.24 sec (15 cycles) fault clearing Ɵme; working distance 910 mm (36 in.) Any X Arc Flash PPE Arc Flash Category Boundary 4 (doors open) N/A (doors closed) 12m (40Ō) Fuse Size or Maximum Minimum Size Maximum Inverse Time Non-ConƟnuous of Wire ConƟnuous Load Breaker Load Wire sizes are based on 60 degree rated terminals See NEC® ArƟcles 110.14(C)(1)(a)&(b), 210.20(A) and Table 310.15(B)(16) Current SensaƟon 0.3 to 3 milliamps Tingling 3 to 10 milliamps Muscle contracƟon and pain 10 to 40 milliamps “Let-go” threshold 15 14 awg 12 amps 15 amps 30 to 75 milliamps Respiratory paralysis 20 12 awg 16 amps 20 amps 100 to 200 milliamps Ventricular ĮbrillaƟon 25 10 awg 20 amps 25 amps 200 to 500 milliamps Heart clamps Ɵght 30 10 awg 24 amps 30 amps 1.5 amps Tissue and organs start to burn 35 8 awg 28 amps 35 amps 40 8 awg 32 amps 40 amps 45 6 awg 36 amps 45 amps 50 6 awg 40 amps 50 amps 60 4 awg 48 amps 60 amps 70 4 awg 56 amps 70 amps 110° 6.0 Hours Cell breakdown begins 80 3 awg 64 amps 80 amps 158° 1.0 second Total cell destrucƟon Skin Temperature Time to Reach Temperature Damage Caused 90 2 awg 72 amps 90 amps 176° 0.1 second Second degree burn 100 1 awg 80 amps 100 amps 200° 0.1 second Third degree burn 110 1 awg 88 amps 110 amps 125 1/0 awg 100 amps 125 amps 150 3/0 awg 120 amps 150 amps 200 250 kcmil 160 amps 200 amps Wire size must be an ampacity equal to or greater than the ampacity of the breaker or fuse. Example: A #12 awg wire cannot be installed to a 30 amp Breaker* NEC® ArƟcle 430 & 440 are the excepƟon to this rule A conƟnuous load is any load that can run for 3 hours or more When energized work is permiƩed in accordance with 130.2(A), an energized electrical work permit shall be required under the following condiƟons: 1. When work is performed within the restricted approach boundary 2. When the employee interacts with the equipment when conductors or circuit parts are not exposed but an increased likelihood of injury from an exposure to an arc Ňash hazard exists Required by OSHA / 70E® • If the voltage is greater than 50 volts Category RaƟng CAT I Use Protected electronic equipment; high-voltage, low-energy sources derived from a high-winding resistance transformer. CAT II 1-phase receptacle connected loads; appliances, portable tools, outlets at more than 30 feet from CAT III source or more than 60 feet from CAT IV source. CAT III 3-phase distribuƟon, including single-phase commercial lighƟng; switchgear, polyphase motors, bus and feeders, lighƟng systems in larger buildings. CAT IV 3-phase at uƟlity connecƟon, any outdoor conductors; “Origin of installaƟon”, electricity meters, service drop from pole to building, overhead lines etc. • If equipment can not be placed in an electrically safe work condiƟon • Work is considered energized electrical work and can be performed by written permit only • Can only be Įlled out by qualiĮed persons • Example of Work Permit in Annex J of the NFPA 70E® ExcepƟons • TesƟng, troubleshooƟng, and voltage measuring • Thermography and visual inspecƟons if the restricted approach boundary is not crossed • Access to and egress from an area with energized electrical equipment if no electrical work is performed and the restricted approach boundary is not crossed • General housekeeping and miscellaneous non-electrical tasks if the restricted approach boundary is not crossed AlternaƟng Current (AC): Current that Ňows in one direcƟon, then reverses and Ňows in the opposite direcƟon. Ampere: Amps (I): The unit of measure of electrical current, the part of electricity that results in work or expended energy. Conductor: An electrical property that allows the Ňow of electricity. Any element with one free electron in the outermost orbit. Direct Current (DC): Current that Ňows in only one direcƟon. Frequency: The number of Ɵmes a sine wave repeats in one second. Also known as cycles or Hertz (Hz). Harmonics: AddiƟonal sine waves generated from the original sine wave. Third harmonics may cause overheaƟng problems in electrical circuits. InducƟon: The process in which an AC magneƟc Įeld causes a voltage and current to Ňow in another separate circuit within that magneƟc Įeld. Insulator: An electrical property that restricts the Ňow of electricity. Any element that has Įve or more electrons in the outermost orbit. MulƟmeter: An electrical instrument that can measure voltage, current, and resistance. Ohm: The unit of measure of resistance in an electrical circuit. Overload: CondiƟon in which the current raƟng of the load is exceeded. The load aƩempts to perform more work than that for which it is designed. Phase (Ø): The live, or hot conductor. Especially if there is more than one, such as 3 phase(Ø). Polarity: The relaƟonship of one coil or winding to another, clockwise and counter-clockwise. PotenƟal: The presence of voltage between two conductors. Resistance: The opposiƟon of current Ňow measured in ohms (ɏ). Resistor: A solid state device with a designated amount of resistance. Service: The entrance, or connecƟng point, for the power source of a building. Short Circuit: A circuit that has no load between the hot and neutral conductors. Transformer: An electrical device, with no moving parts, that can change the voltage level. Volt: The unit of measure of voltage (E). WaƩ: The unit of measure of power used in a circuit. I=E/R I=P/E E2/ R E / R I P=ExI 2 X P/E R EXI P I P X R E R P / R E/I 2 P/I E /P I X R P / I2 R=E/I E=P/I E=IxR T PC TRAINCO Real World Training...for Real World Needs