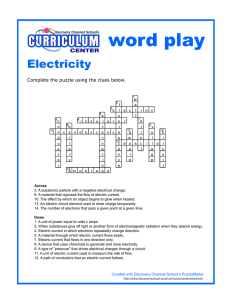

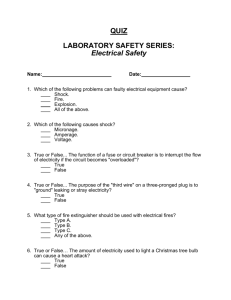

Experience Sharing – Electrical Safety

advertisement

Experience Sharing – Electrical Safety Architectural Services Department p 3 October 2012 3/10/2012 1 Topics covered: • • • • • • • • • • IIntroduction t d ti Electricity Principles Electrical Hazards Electrical Safety Devices Legislative requirements DEVB Policy on Electrical Safety ArchSD Site Safety Requirements on Electrical Safety Good Site Practice on Electrical Safety Common Personal Protective Equipment Lessons learnt 3/10/2012 2 Introduction: On 3 October 2011, an experience sharing session has been held with ArchSD contractors and site supervisory staff to promote and enhance awareness on electrical safety. safety The same powerpoint presentation materials used in the experience sharing session is posted in the ArchSD internet for reference. 3/10/2012 3 ELECTRICITY PRINCIPLES 3/10/2012 4 OHM’S LAW V=IxR V R I 3/10/2012 Based on the above formula,, during an electric shock of the human body, the current (I) is inversely proportional to the resistance (R), i.e. a reduction in resistance in the human body will lead to higher electrical currents p passingg through the body, the more serious will be the injury. 5 ELECTRICAL HAZARDS 3/10/2012 6 Electric Shock The electric shock is caused by a current passing through the body. The lethality of an electric shock is dependent on: ¾ Current (the higher the current, the more likely it is lethal); ¾ Duration (the longer the duration, the more likely it is lethal); ¾ Voltage (the higher the g , the more likelyy it is voltage, lethal); ¾ Pathway (if current flows muscle it is through the heart muscle, more likely to be lethal) 3/10/2012 Diagram showing how electric shock occurs: The severity of electric shock depends on the current flowing through the body (I) in Ampere, which is a function of the electromotive force (E) in volts, and the contact resistance (R) in ohms. F Formula: l I=E÷R I E R 7 Electric Shock ¾Dry skin (resistance around 10,000Ω) Current = 220V ÷ 10,000Ω = 0.022A ¾Wet skin (resistance around 500Ω) Current = 220V ÷ 500 Ω = 0.44A The effect of current passing through the human body is shown below: Current (amperes) Physiological effect 0.001A Threshold of feelingg an electric shock,, p pain 0.005A Maximum current which would be harmless. Sustained muscular contraction. 0 01 0 02A 0.01‐0.02A V Ventricular i l fibrillation. fib ill i 0.05A Can be fatal. 0 1‐0 3A 0.1‐0.3A Sustained ventricular contraction followed by normal heart rhythm. 6A These are the operation levels for a defibrillator. Temporary respiratory i t paralysis l i and d possibly ibl b burns. 3/10/2012 8 Effect of Electric Shock Heartbeat Failure (M i cause off death): (Main d h) ¾ When current passes through the heart, it will disrupt the rhythmic pumping action ti off th the heart h t and d eventually t ll ceases heart beat. ¾ The heart does not resume without external assistance. assistance Unless quickly treated, death is rapid. B Breathing hi FFailure il ¾ Current passing through the respiratory centre in the brain may disturb the nerve centre t and d stop t respiration i ti 3/10/2012 9 EFFECT OF ELECTRIC SHOCK Suffocation: ¾ Current passing through the upper limbs and across the chest contracts and holds the muscles as long as the current flows, eventually causing death from suffocation Muscle Contraction: ¾ Continuous contraction of the forearm muscles when current is passing through, thus unable to get free from the electric source 3/10/2012 10 ELECTRICAL HAZARD z Electric burns During an electric shock, shock the current passing through the body may lead to burns on the skin, muscles or internal organs As electric shocks and burns are organs. closely related, preventative measures should be considered together. z Fires and explosions High g temperatures p caused byy currents under abnormal conditions, may result in accidental fires and explosions. The common causes leading to high temperatures include: ¾Overloading of electricity ¾Insulator breakdowns or short circuits ¾Improper contact of electrical circuit ¾Improper maintenance of electrical appliances or wiring ¾Poor ventilation, etc. 3/10/2012 11 CAUSES OF ELECTRIC SHOCK Direct Contact A direct contact refers to a person coming into contact with a Live conductor Indirect Contact An indirect contact refers to a person coming into contact with a conductive part which is not normally alive, but has become alive accidentally (due to insulation failure or some other causes) 3/10/2012 12 ELECTRICAL SAFETY DEVICES 3/10/2012 13 Electrical Safety Devices Electrical circuit are mainly protected by the following safety devices: z FFuse ¾ It must be installed on “live” wires; ¾ It is a copper wiring with a set current f i value; fusion l ¾ If the current exceeds the set fusion value, the fuse will blow and cut‐off the electrical circuit circuit. z Circuit breakers (MCB) ¾ Tripping of circuit breakers are based on the thermal and electromagnetic principle. ¾ Under short circuit condition, the MCB will trip instantaneously by electromagnetic force. ¾ Under overload condition, the MCB will t i with trip ith time ti delay d l by b thermal th l principle. z3/10/2012 14 Fuse for 13A plug Miniature circuit breaker Electrical Safety Devices z EEarth th LLeakage k Ci Circuit it B Breaker k (ELCB) or Residual R id l currentt device (RCD) ¾ It monitors the operation of the “neutral” or “live” wires in the electrical circuit circuit. ¾ During current leakage, the current flows to electrical appliance via the “live” wire are not equal to the current returns through the “neutral” neutral wire; ¾ Such imbalance current flow detected by RCD or ELCB is then cut‐off the electrical source; ¾ Rating of the tripping current shall not exceed 30mA. During the leakage of electricity the return current (I out) is less than the entering current (I in). The residual id l currents t flows fl away after passing through the human body or the earth. So the difference of magnetic field produced and resulted in an automatic p power cutoff in tripping device. 3/10/2012 15 ELECTRICAL SAFETY DEVICES z Earthing Connection ¾ Earthing provides a low resistance way of discharging electricity to th ground the d in i case off currentt leakage; l k ¾ The current passes through the “earth” wire and is prevented from enteringg the human bodyy and causingg injury. j y 3/10/2012 16 ELECTRICAL SAFETY DEVICES z Double Insulation The basic requirement is that no single failure can result in dangerous voltage becoming exposed so that it might cause an electric shock and that this is achieved without relying on an earthed th d metal t l casing. i This Thi is i usually ll achieved at least in part by having two layers of insulating material surrounding live parts or by using reinforced insulation. Electrical appliances with double insulation bear the “回” 回 mark. z Extra‐low Voltage (ELV) Electrical tools using extra‐low voltage not exceeding 50 V a.c. may minimise injury in case of electric shock. ¾ Voltage (V) ≤ 50V A.C. 3/10/2012 17 Electric drill engraved with a “double insulated” symbol: “回” 回 by the manufacturer. manufacturer CABLE COLOUR CODE Since 99% of colour blind people l are suffering ff i from f red‐green colour blindness and combination of them (e.g. yellow), new cable colour identification was enforced for the electrical installation since 1 July 2009 to t ffacilitate ilit t cable(s) bl ( ) identification for the people p p who are colour blindness or colour deficient. Diagram 1: For single phase: Brown denotes phase (line) conductor, Blue denotes neutral conductor, Green-and-Yellow denotes earth conductor. For 3 phase: Brown denotes line 1 phase conductor, Black denotes line 2 phase conductor, Grey denotes line 3 phase conductor; Blue denotes neutral conductor; Green-and-Yellow denotes earth conductor. Diagram 2: A example An l off 13 Amp A power plug l connected to new colour code cables 3/10/2012 18 LEGISLATIVE REQUIREMENTS 3/10/2012 19 Legislative requirements: FACTORIES AND INDUSTRIAL UNDERTAKINGS ORDINANCE (CAP. 59), Enforced by Labour Department – Factories F t i and d Industrial I d t i l Undertakings U d t ki (El (Electricity) t i it ) Regulations, – Construction Site (Safety) Regulations Regulations, etc etc. ELECTRICITY ORDINANCE (CAP. (CAP 406) 406), Enforced by Electrical and Mechanical Services Department – Electricity (Wiring) Regulations, Regulations – Electricity Supply Lines (Protection) Regulation, etc. 3/10/2012 20 Legislative requirements: FACTORIES AND INDUSTRIAL UNDERTAKINGS (ELECTRICITY) REGULATIONS Cover page of the “Reference Manual for Inspection Reports on Construction Sites” published by Labour Department 3/10/2012 21 Legislative requirements: ELECTRICITY ORDINANCE (CAP. (CAP 406) Electricity (Wiring) Regulations 2009 Clause26K ‐ Temporary Supply Installation for Construction and Demolition Sites or Repair and Testing Purposes Extract phrase of EMSD’s Code of Practice on Electricity (Wiring) Regulations 2009: Clause 26K – Temporary Supply Installation for Construction and Demolition Sites or Repair and Testing Purpose – The parts “operating voltage” and “lighting accessible to public” 3/10/2012 22 Legislative requirements: ELECTRICITY ORDINANCE (CAP. (CAP 406) Electricity (Wiring) Regulations 2009 Clause26K ‐ Temporary Supply Installation for Construction and Demolition Sites or Repair and Testing Purposes (cont’) Extract phrase of EMSD’s Code of Practice on Electricity (Wiring) Regulations 2009: Clause 26K – Temporary Supply Installation for Construction and Demolition Sites or Repair and Testing Purpose – The parts “selection and erection of installation” and “protection of circuits” 3/10/2012 23 Legislative requirements: ELECTRICITY ORDINANCE (CAP. (CAP 406) Electricity (Wiring) Regulations 2009 Clause26K ‐ Temporary Supply Installation for Construction and Demolition Sites or Repair and Testing Purposes (cont’) Extract phrase of EMSD’s Code of Practice on Electricity (Wiring) Regulations 2009: Clause 26K – Temporary Supply Installation for Construction and Demolition Sites or Repair and Testing Purpose – The parts “protection against earth leakage” and “precaution against danger” 3/10/2012 24 Legislative requirements: ELECTRICITY ORDINANCE (CAP. (CAP 406) Electricity Supply Lines (Protection) Regulation Diagram 1, 2, 3 & 4: Same as the descriptions p on the top of the respective diagrams 3/10/2012 25 Legislative requirements: ELECTRICITY ORDINANCE (CAP. (CAP 406) Electricity Supply Lines (Protection) Regulation (cont’) Diagram 5, 6, 7 & 8: Same as the descriptions on the top of the respective ti diagrams di 3/10/2012 26 DEVB POLICY REQUIREMENTS ON ELECTRICAL SAFETY 3/10/2012 27 DEVB policy requirements: Chapter 3 – Contractual Provision of Construction Safety ( Construction Site Safety Manual) Rev. in Feb 2011 A. Weekly Safety Walk • • • 3/10/2012 Checkingg that the temporary p y lighting g g and electricallyy powered p hand‐held tools and equipment are all rated at 110V CTE (centre tapped to earth) in compliance with Particular Specification clause no. no 14(3) Checking scaffolding Checking site tidiness and cleanliness The Contractor shall prepare and agree with the Architect's Representative a comprehensive check‐list for use during safety walk and site inspections. It shall contain a table listing out the deficiencies identified during the walk /inspection with the proposed rectification measures, the names of the persons responsible for taking any necessary rectification measures and the corresponding completion dates. 28 DEVB policy requirements on Electrical Safety: Chapter 3 – Contractual Provision of Construction Safety ( Construction Site Safety Manual) Rev. in Feb 2011 A. Weekly Safety Walk (cont’) The Contractor shall take prompt action to rectify those deficiencies identified during the walk and shall report the status of actions taken at the forthcoming SSMC meeting. B P.S. B. P S on Site Safety ‐ Clause 15 Electrical Safety (1) Employ Registered Electrical Worker (REW) to handle the entire temporary electrical systems (TES) (2) Upon completion of TES, REW// REC to complete an individual Work Completion Certificate (WR1). Each of such Certificates shall include a circuit diagram. (3) TES, such as lighting fittings, distribution boards, socket outlets, plugs and cable couplers in outdoor or damp environment shall be of IP 54 or above. (4) The sheath of all electric portable cables shall be of heavy‐duty type. They shall be hung overhead as far as possible. PVC cables shall be enclosed in metallic conduits or trunkings and properly maintained. 3/10/2012 29 DEVB policy requirements: Chapter 3 – Contractual Provision of Construction Safety ( Construction Site Safety Manual) Rev. in Feb 2011 2) P.S. on Site Safety ‐ Clause 15 Electrical Safety (cont’) (5) Develop checklists and agreed by Architect Architect’ss Representative for routine inspections. Monthly comprehensive checking include checking the followings with the REW’s signature: ‐ – – – – – TES, temporary generators, functional test of earth leakage circuit breakers, breakers integrity of cables and connections, measurement of earthing resistance and those items listed in Checklists Nos. 3 and d 4 off the h COP where h appropriate i (6) Establish regular maintenance programme for permit‐to‐ work system and/or lock‐off system 3/10/2012 30 DEVB policy requirements: Chapter 3 – Contractual Provision of Construction Safety ( Construction Site Safety Manual) Rev. in Feb 2011 2) P.S. on Site Safety ‐ Clause 15 Electrical Safety (cont’) (7) Maintain updated circuit diagrams (affixed inside the cover of the temporary distribution boards), WR1 (complete with supporting documents) and records of inspection and checking of the TES by REW/REC in a dedicated file for inspection by site supervisory staff upon request. (8) Keep lock all temporary electrical distribution boards and accessible only by authorized persons. Legible warning notices (Danger‐ (Danger Electricity) in both Chinese and English, English names and telephone numbers of such authorized persons shall be p posted on the temporary p y distribution boards. 3/10/2012 31 DEVB policy requirements: Chapter 3 – Contractual Provision of Construction Safety ( Construction Site Safety Manual) Rev. in Feb 2011 2) P.S. on Site Safety ‐ Clause 15 Electrical Safety (cont’) (10) For occupied buildings, buildings except prior approval approval, no connection of fixed electric equipment directly to any existing permanent distribution boards, only through temporary distribution boards. (11) For arc welding machines and electrode holders: ‐ ‐ comply with BS 638 : Part 7, IEC 60974 – 1 (or BSEN60974 – 1) and BS EN 60974 – 11 or equivalent standards, ‐ fitted with no‐load voltage reducing device ‐ enclosed type with metal casing connected to earth, cable terminals l effectively ff l insulated l d 3/10/2012 32 DEVB policy requirements: Chapter 3 – Contractual Provision of Construction Safety ( Construction Site Safety Manual) Rev. in Feb 2011 2) P.S. on Site Safety ‐ Clause 15 Electrical Safety (cont’) (12) Hand Hand‐held held electrical tools and portable equipment (e.g. (e g submersible pumps) ‐ examined byy the REW ((visual inspection p for ggeneral condition,, functional checking for continuity, polarity and insulation aspects, ‐ registered and recorded for each after examination, ‐ identification labels (i.e. registration no., type, name of the owner and date of examination stamped with the Contractor's company chop) ‐ re‐examine every 3‐month or after repairs 3/10/2012 33 DEVB policy requirements: Chapter 3 – Contractual Provision of Construction Safety ( Construction Site Safety Manual) Rev. in Feb 2011 2) P.S. on Site Safety ‐ Clause 15 Electrical Safety (cont’) (13) Portable and hand hand‐held held tools and temporary site lighting shall be operated at a voltage of 110V or less supplied from a step‐ down transformer with its output winding centre‐tapped to earth and comply with BS 3535 : Part 2 : 1990 or equivalent. All cables shall be terminated within the transformer enclosure of Cl I and Class d IP55 and d the th outgoing t i circuit i it shall h ll be b provided id d with ith short circuit protection. In confined and damp environment, the voltage of temporary lighting and hand‐held hand held tools shall not exceed 25V. ((14)) For heavyy equipment q p such as hoists,, tower cranes,, etc.,, use voltage in excess of 110V equipped with an earth leakage circuit 3/10/2012 34 breaker. DEVB policy requirements: Chapter 3 – Contractual Provision of Construction Safety ( Construction Site Safety Manual) Rev. in Feb 2011 C. Safety Plan (14 elements) • Site Safety Cycle, e.g. Pre Pre‐work work activity, HIA, etc. • Safety Training, e.g. tool‐box talk on electrical safety ((talks on trainingg kits p published byy HKCA,, etc.)) • Safety Inspection ‐ TES • Process Control Programme – one of the high high‐risk risk activities : Electrical Equipment and Installations – 3/10/2012 include safety rules, regulations, safe working procedures, and in particular method statements and permit‐to‐work systems incorporating the findings of risk assessments conducted; y adopted p if workingg near or over water, or co‐worker system electrical work at or near exposed live conductors 35 DEVB policy requirements: Construction Site Safety Handbook (CSSH) D. Chapter 3 of CSSH • 3.9 3 9 Electric Arc Welding • 3.16 Electric Hand Tools E. Chapter 7 of CSSH y Protection • 7.2 Eye • 7.8 Safety Footwear • 7.10 7 10 Hand Protection 3/10/2012 36 ARCHSD SITE SAFETY REQUIREMENTS ON ELECTRICAL SAFETY 3/10/2012 37 ArchSD Site Safety requirements on Electrical Safety A. Follow DEVB policy B. Guidance Notes on Supervising High Risk Activities on Construction sites: ‐ – Item 16. Electrical works – Item 19 19. Excavation. Excavation Special care when near underground utility services – Item 20 20. Working near overhead electrical power line – Item 28. others risk (relating to electrical safety) high risk site activities for at least next two months • forecast of high‐risk and prepare risk assessment; • discuss in SSEMC meeting; • routine updating of risk assessment, wherever necessary. 38 3/10/2012 ArchSD Site Safety requirements on Electrical Safety C. Electrical Safetyy Audit Checklist 2012 1. Electrical installation a Were all electrical installations carried out and tested on completion by Registered a. Electrical Worker (REW)? b. Are there checklists developed by REW for carrying out periodic comprehensive checking on the temporary electrical system (TES)? c. Are electrical circuit diagrams and WR1/WR1a of the TES updated and kept by the Contractor? d. Are circuit breakers or suitable fuses installed? e. Are earth leakage circuit breakers installed? f. Is the poster of “First‐Aid for Electric Shocks” displayed? g Have there been any regular repairs and maintenance? g. h. Is the tower crane connected to a lightning protection system? i. Are the metal hoardings connected to earth by equipotential bonding conductors? j. Is the contact information of REW displayed at power distribution boards? S = Satisfactory; IR = Improvement is required; IIR = Immediate improvement is required; N/A = Not applicable 3/10/2012 39 ArchSD Site Safety requirements on Electrical Safety C. Electrical Safetyy Audit Checklist 2012 ((cont’)) h. Are there sufficient working space provided for on‐site maintenance of the temporary electrical power supply, e.g. switchboards, diesel generator set, step‐down transformers, etc.? 2. Electrical appliances and equipment a. Do the lighting fittings, distribution boards, sockets outlets, plugs and cable couplers meet g and contractual requirements? q the legislative b. Are there any cables lying on the ground? c. Is there any damage to cable sheathe? d Are d. A the h earth h wires i correctly l earthed? h d? e. Do emergency stop buttons properly function? (e.g. bench saw, steel bar cutting/bending machine, etc.) f.f Are the h temporary site i lighting li h i operated d at 110V or less? l ? g. Are the electrical workers provided with proper Personal Protective Equipment (PPE) and are the PPE correctly used when carrying out electrical work, e.g. wiring work, testing/ maintenance/ repairing works, etc.? h. Is there any excessive plugging of sockets which may lead to overloading of the circuit? 3/10/2012 40 ArchSD Site Safety requirements on Electrical Safety C. Electrical Safetyy Audit Checklist 2012 (cont’) ( ) 3. Portable electric tools a Is the register of portable electric tools properly maintained? a. b. Are the portable electric tools affixed with labels identifying their registration number, owner’s name and date of examination by competent electrician? c. Are the portable electrical tools connected to the earth or are they having double insulation for protection? portable electric tools use low voltage? g ((e.g. g 110V or less)) d. Do the p e. Do the plugs meet the legislative requirements? f. Is there any damage to cable sheathe? g. IIs the th site it environment i t for f electrical l t i l workk wett or having h i the th risk i k off getting tti electric l ti shock in the vicinity of the electrical equipment? 3/10/2012 41 ArchSD Site Safety requirements on Electrical Safety C. Electrical Safetyy Audit Checklist 2012 (cont’) ( ) 4. Special process (electric arc welding) a Is the working place close to where flammable substances are stored? a. b. Are the tools and work pieces correctly earthed? c. provided with suitable PPE and are the PPE correctlyy used? Are the welders p d. Is the ventilation in good condition? e. Are there water puddles in the working place or is the environment wet? f. Are the welding machines fitted with no‐load voltage reducing device for protection against electric shock at the output side? 3/10/2012 42 ArchSD Site Safety requirements on Electrical Safety C. Electrical Safetyy Audit Checklist 2012 (cont’) ( ) 5. General a Are waterproof cables and plugs used for outdoors and industrial purpose? a. b. Are the ladders made of non‐conductive materials? c. Is there permit‐to‐work system or co‐worker system put in place for works that cannot be done safely by a person working alone? (For example, example electrical work at or near exposed live conductors, etc.) d. Are doors to switch rooms or covers to fuse and miniature circuit breaker (MCB) boards locked shut and the keys held by a responsible person? e. Are there any signs of damage or overheating to the cables, plugs, sockets, etc.? f. Are emergency procedures planned for electric shock? g. Are the warning signs displayed before carrying out maintenance work on power supply? h. Are all places that are liable to fire hazards provided with fire‐fighting equipment, e.g. fire extinguishers? i. Are tool‐box talks or trainings on electrical safety provided for new workers? 3/10/2012 43 ArchSD Site Safety requirements on Electrical Safety C. Electrical Safetyy Audit Checklist 2012 (cont’) ( ) 6. Working under overhead cables or near underground cables a Has a “Safe system of work” established to prevent any damage to the overhead electricity a. lines or underground electricity cables prior to commencement of work on site? b. Was a competent person (e.g. registered in EMSD) employed to conduct underground y of work” to p protect underground g electricityy cables detection and ensure a “Safe system electricity cables prior to commencement of work on site? 7. Completion of installation, testing and commissioning for operation and maintenance a. Has the contractor completed the testing and commissioning works to the satisfaction of the consultant or ArchSD on the proper function of the low voltage cubicle switchboard installation? (by demonstrating a duly signed “testing and commissioning certificate on low voltage l cubicle bi l switchboard i hb d installation” i ll i ” after f a series i off tests including i l di insulation i l i test, dielectric test, polarity check for current transformer, secondary injection test, primary injection test, ductor test, temperature‐rise limit test, functional test of all devices, voltage test, phase sequence test, etc.) 3/10/2012 44 ArchSD Site Safety requirements on Electrical Safety C. Electrical Safetyy Audit Checklist 2012 (cont’) ( ) 7. Completion of installation, testing and commissioning for operation and maintenance (con’t) b. Has the contractor completed the testing and commissioning works to the satisfaction of the consultant or ArchSD on the proper function of the systems after installation? (by demonstrating a duly signed “testing and commissioning certificate on electrical installation installation” after a series of tests or measurements on continuity of circuits, continuity of protective conductors, polarity, insulation resistance, earth electrode resistance, earth fault loop impedance, function of all devices including overcurrent protective devices, additional checks for installations in hazardous environment, etc. ) c. Has the contractor verified through a series of tests and adjustments on the performance of the permanent installed equipment/systems (e.g. charger and battery set, lightning protection system, luminaries, power sockets, water pumps, electric motors, fans, heaters, electromagnetic equipment, equipment etc.) etc ) meeting with the specified design intent? d. Has the contractor captured, recorded and submitted the performance data (e.g. load distribution, total operating currents, power factor, etc.) of the whole installation for future operation and maintenance? 3/10/2012 45 ArchSD Site Safety requirements on Electrical Safety C. Electrical Safetyy Audit Checklist 2012 (cont’) ( ) 7. Completion of installation, testing and commissioning for operation and maintenance (con’t) e. Has the contractor checked on the integrity and connections of earthing of exposed conductive parts including the metallic conduits, trunkings and ducting for enclosure of cable(s)? f. Has the contractor checked on the integrity and connections of earthing of exposed conductive parts including the metallic enclosures of current distribution equipment, such as switchgear and controlgear assemblies? g Has the contractor checked on the integrity and connections of equipotential bonding and g. supplementary bonding connecting to the main earthing terminals for all extraneous conductive parts (e.g. main water pipes, gas installation pipes, other service pipes and ducting, exposed metallic ceiling grids/window/structural framework, etc.) by means of circuit protective conductors? 3/10/2012 46 ArchSD Site Safety requirements on Electrical Safety C. Electrical Safetyy Audit Checklist 2012 (cont’) ( ) 8. Documentary check for some electrical equipment/ systems which might have been energized near project final stage) a. Has the contractor demonstrated an example or a completed record of Permit‐to‐ work form for enhancement of safely isolation of circuit or proper earthing of electrical equipment concerned? b. Where the isolation of circuit is by means of circuit breaker or switch, the circuit breaker or switch should be locked off where practicable and a warning notice for repair affixed. The keys for locks used to lock off the circuit breaker or the switch should be kept under the control of the REW. Has the contractor demonstrated a record d off this thi lock‐off l k ff system t b means off a log by l book b k in i which hi h records d are properly kept? c. Has the contractor demonstrated an example or a record of a completed risk assessment form signed by the competent person (e.g. (e g REW) detailed with the associated specific safety precautions in line with Appendix 15 of the COP by EMSD prior to carrying out live work where it is considered unavoidable as stated in the conditions of the COP? d. Has the h contractor demonstrated an example l or a record off a completed l T&C records for those energized outgoing sub‐main and final circuits? 3/10/2012 47 ArchSD Site Safety requirements on Electrical Safety Electrical Installation work REW Power energization ?! 3/10/2012 T&C Inspection Handover of the Installation Safety measures: • Permit-to-work ? • Isolation of circuit with lock-off system and warning signs ? • Risk Assessment ? • T&C Record ? • Co-worker ? ……. 48 GOOD SITE PRACTICE ON ELECTRICAL SAFETY 3/10/2012 49 Good Practice on Site Safety – Electrical Safety 110V Temporary Power Supply 3/10/2012 Schematic wiring diagram 50 Good Practice on Site Safety – Electrical Safety 110V Temporary Power Supply with protective device 3/10/2012 110V Temporary Power Supply with warning signs 51 Good Practice on Site Safety – Electrical Safety Temporary Power Supply Board indicated with name of Competent Person (REW) 3/10/2012 In‐house safety rules – No unauthorized use of electricity 52 Good Practice on Site Safety – Electrical Safety Checklist for Temporary Power Supply signed by Competent Person (REW) 3/10/2012 Work Completion Certificate (Form WR1 ) 53 Good Practice on Site Safety – Electrical Safety Electric Cables Properly Hung Overhead 3/10/2012 54 Good Practice on Site Safety – Electrical Safety Temporary Power Supply for Fixed Installation 3/10/2012 Generator Set Sitted at Proper Position 55 Good Practice on Site Safety – Electrical Safety Effective Lightning Protection System 3/10/2012 56 Good Practice on Site Safety – Electrical Safety Metal ladder with rubber base 3/10/2012 Electrical Safety Promotion 57 Good Practice on Site Safety – Electrical Safety Portable Hand Tools Properly Registered and Recorded 1. 2. 3. 4. 3/10/2012 Identification label marked with registration number, b type of the tool, name of the owner and date of examination 58 Other Practices on Site Safety – Electrical Safety References from BS Site Supervisory Staff on Site Safety and OHS Wit posters on Electrical Safety for promotion in construction sites: (1) welding machine with no load protection device, (2) 110V transformer 3/10/2012 59 Important Points on Electrical Safety – Avoid live work. If this cannot be avoided, special safety provisions should be taken: ‐ • Prior risk assessment • Proper PPE • Screen to avoid danger from advertent contact with energized conductors • Warning signs and notices for repair, barriers and screens • Short duration and p precise of work • Isolation point should be clearly identified – Poor prevailing site conditions, such as wet weather, space constraints, surrounded by earthed structures – Clear instruction to workers on site – Co‐worker system as far as practicable 3/10/2012 60 COMMON PERSONAL PROTECTIVE EQUIPMENT ON ELECTRICAL SAFETY 3/10/2012 61 Common Personal Protective Equipment on Electrical Safety • • • • • Safety Helmet Safety Footwear Goggles Face Shield Leather Grooves 3/10/2012 62 Recommended Safety Measures TES examined, regular maintained and certified by REW Planned Site Supervision by REW and Safety Supervisor Hand-held equipment/tool equ p e / oo at a 110V by step-down transformer with its output winding centre-tapped pp to earth Effective earthing to the TES and hand tools/ equipment Co worker Co-worker system 3/10/2012 Risk Assessment Engagement of REW RECOMMENDED MEASURES FOR ELECTRICAL WORK Proper PPE Tool-box talks to the electricians,, e.g. working at height, working platform, use of the A-ladder, etc Identify and terminate all live parts from sources of electricity supply before work by REW Permit-to-work system, Lock the switch rooms/distribution boards by a designated key holder. Display warning signs to alert any stray persons 63 Recommended Safety Measures Welding machine fitted with a no-load voltage reducing device Risk Assessment Avoid excessive cables from welding machine hung on or twisted round the steel workpiece to be welded RECOMMENDED MEASURES FOR ELECTRIC ARC WELDING Effective earthing to the TES and hand t l / equipment tools/ i t Proper PPE 3/10/2012 Engagement of REW Welding machine complied with BS EN 60974-1 and BS EN 60974-11 Regular examined, regular maintained and certified by REW with record Tool-box talks to the h electricians, l i i e.g. working at height, working platform, use of the h A A-ladder, l dd etc 64 LESSONS LEARNT 3/10/2012 65 Lessons learnt – Electrical Safety Case 1 • The victim was assigned to carry out re‐wiring work for office lighting on a public holiday. • While he worked at a corner of the office floor being renovated he fallen down from a wooden A‐ladder on a level about 1.5 m high above the floor. • His forehead hit heavilyy on the floor and was later certified dead after arrival at hospital. • Apparently, the cause of death was due to falling from height. height However, However the autopsy report indicated that the primary cause was electrocution as burnt marks were observed on the upper limbs of the victim. victim 66 Lessons learnt – Electrical Safety Case 1 ‐ Precautionary Measures • Identifyy all p possible sources of electricityy supply pp y and terminate all live parts prior to commencing work. • Introduce permit‐to‐work permit to work system and display warning signs on switch rooms and distribution boards. • Provide adequate safety tool‐box tool box talks to electricians on working at height. • Provide suitable and safe working platform for working at height. • Avoid overtime work, unplanned work and working alone. 67 Lessons learnt – Electrical Safety Case 2 • • • • While a worker attempted to operate an electric l t i grinder i d for f the th metal t l cladding, l ddi he h was electrocuted. He was certified dead after delivered to h hospital. l Site investigation revealed that the earthing wire was not connected in the plug and the neutral wire within the grinder was touching its metal casing. So when the victim touched the metal casing of the grinder, a current flowed through his body and caused electrocution. Diagram showing how the victim was electrocuted: (1) a multi-plugs multi plugs was used on site without earth connection, (2) the neutral wire inside the electric grinder touched the grinder’s metal casing, (3) the neutral wire of the power cable was disconnected at its plug. 68 Lessons learnt – Electrical Safety Case 2 – Precautionary measures • Hand‐held tools on site should be operated at 110V or less. • Temporary electrical system and electric tools should be properly maintained by REW and with records properly kept. • A safety supervisor shall be assigned to conduct daily check on temporary electrical systems and electric tools. • Provide adequate tool‐box talks to site personnel or workers on electrical safety. • All electric tools should be protected by effective earthing and residual current protective device. 69 Lessons learnt – Electrical Safety Case 3: An example of Work Safety Alert issued by the Labour Department for contractors/employers where a list of 5 precautions are suggested to prevent electrical hazards during electrical repairing work. work 70 Lessons learnt – Electrical Safety Case 3 ‐ Precautionary Measures • Ensure all related live parts of the electrical system are rendered dead before works • Plan the work carefully with formulated safety measures and procedures • Lock out the isolated power sources with adequate notices and signs before works • Ensure workers received adequate q and p proper p trainingg and have adequate knowledge and experience • Exercise adequate management control and supervision to ensure safety measures to be strictly followed 71 Lessons learnt – Electrical Safety Case 4: Another example of Work Safety Alert issued by the Labour Department for contractors/employers where a list of 3 precautions are suggested to prevent electrical hazards d i electrical during l t i l repairing i i work: k (1) Identify electrically hazardous conditions n the sites; (2) Rectify electrically hazardous conditions n the sites; (3) Safeguard any person at work on the site against all electrically hazards conditions. 72 Lessons learnt – Electrical Safety Case 4 ‐ Precautionary Measures • Ensure all related live parts of the electrical system are rendered dead before works • Plan the work carefully with formulated safety measures and procedures • Lock out the isolated power sources with adequate notices and signs before works • Ensure workers received adequate q and p proper p trainingg and have adequate knowledge and experience • Exercise adequate management control and supervision to ensure safety measures to be strictly followed 73 Lessons learnt – Electrical Safety Case 5: A newspaper cutting from a local newspaper (date 30.9.2012) 30 9 2012) describing the happening of a fatal industrial accident possibly due to electrocution For Training Purpose 74 Lessons learnt – Electrical Safety Case 5 ‐Precautionary Measures • Ensure all related live parts of the electrical system are rendered dead before works • Plan the work carefully with formulated safety measures and procedures • Lock out the isolated power sources with adequate notices and signs before works • Ensure workers received adequate q and p proper p trainingg and have adequate knowledge and experience • Exercise adequate management control and supervision to ensure safety measures to be strictly followed 75 END 3/10/2012 76