DC machines-Installation, use and maintenance

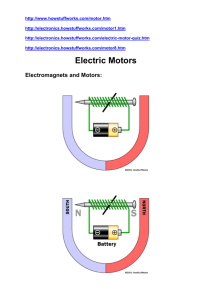

advertisement