DB Sylomer SR450 Englisch.indd

advertisement

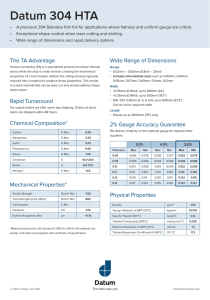

SR Sylomer 450 Material Data Sheet ® Material Colour mixed cellular polyurethane grey Standard Sylomer® range Static range of use Standard dimensions on stock Thickness: 12.5 mm with Sylomer® SR 450 – 12 25 mm with Sylomer® SR 450 – 25 Rolls: 1.5 m wide, 5.0 m long Stripes: max. 1.5 m wide, up to 5.0 m long SR 1200 SR 850 SR 450 0.45 N/mm2 SR 220 Other dimensions (also thickness) as well as stamped and molded parts on request. SR 110 Area of application Compression load SR 55 Delection SR 42 depending on form factor, values apply to form factor 3 Static range of use up to 0.45 N/mm2 approx. 10 % SR 28 up to 0.7 N/mm2 approx. 20 % SR 18 up to 5 N/mm2 approx. 70 % SR 11 (static loads) Operating load range (static plus dynamic loads) Load peaks (short term, infrequent loads) 10 Material properties Mechanical loss factor Rebound elasticity Compression set Static shear modulus Dynamic shear modulus Coeficient of friction (steel) Coeficient of friction (concrete) Abrasion Operating temperature = 0.11 Test methods Comment 0.01 DIN 53513* depending on frequency, load and amplitude DIN 53573 tolerance +/- 10 % <5% EN ISO 1856 50 %, 23 °C, 70 h, 30 min. after unloading 0.58 N/mm2 DIN ISO 1827* at speciic load of 0.45 N/mm2 1.0 N/mm2 DIN ISO 1827* at speciic load of 0.45 N/mm2, 10 Hz µS= 0.5 Getzner Werkstoffe dry µB= 0.7 Getzner Werkstoffe dry DIN 53516 load 10 N, bottom surface 400 mm3 -30 to 70 °C DIN IEC 93 Thermal conductivity 0.1 W/(mK) DIN 52612/1 B2 class E 0.001 Speciic load [N/mm2] short term higher temperatures possible > 1011 Ω·cm * Tests according to respective standards 0.1 60 % Speciic volume resistance Flammability 1 DIN 4102 EN ISO 11925-2 dry normal lammable EN 13501-1 All information and data is based on our current knowledge. The data can be applied for calculations and as guidelines, are subject to typical manufacturing tolerances and are not guaranteed. We reserve the right to amend the data. Further information can be found in VDI Guideline 2062 (Association of German Engineers). Further characteristic values on request. www.getzner.com 1 SR 450 ® Sylomer 0.9 Figure 1: Quasistatic load delection curve measured with a loading rate of 0.045 N/mm2/s 12.5 mm 0.8 25 mm 37.5 mm 0.7 50 mm 0.6 0.5 Static range of use 0.45 N/mm2 0.4 0.3 0.2 Dynamic range of use Speciic load [N/mm2] Load delection curve Testing between lat steel-plates; recording of the 3rd loading; testing at room temperature Form factor 3 0.1 0 0 1 2 3 4 5 6 7 8 9 10 Delection [mm] Modulus of elasticity Modulus of elasticity [N/mm2] Static range of use 12 Dynamic range of use Figure 2: Load dependency of the static and dynamic modulus of elasticity 2 0.45 N/mm Quasistatic modulus of elasticity as a tangent modulus taken from the load delection curve; dynamic modulus of elasticity due to sinusoidal excitation with a velocity level of 100 dBv re. 5 · 10-8 m/s (equal to an oscillating range of 0.22 mm at 10 Hz and 0.08 mm at 30 Hz, see also in the glossary) 8 30 Hz 10 Hz 4 Quasistatic Test according to DIN 53513 Form factor 3 0 0 0.1 0.2 www.getzner.com 2 0.3 0.4 0.5 0.6 0.7 0.8 0.9 Speciic load [N/mm2] 0.9 0.8 0.7 0.6 0.5 Static range of use 0.45 N/mm2 0.4 12.5 mm 37.5 mm 0.3 25 mm 50 mm 0.2 Dynamic range of use Speciic load [N/mm2] Natural frequency Figure 3: Natural frequency of a single-degree-of-freedom system (SDOF system) consisting of a ixed mass and an elastic bearing consisting of Sylomer® SR 450 based on a stiff subgrade Parameter: Thickness of elastomeric bearing Form factor 3 0.1 0 5 10 15 20 25 Natural frequency [Hz] Disturbing frequency [Hz] Vibration isolation eficiency 100 Figure 4: Reduction of the transmitted mechanical vibrations by implementation of an elastic bearing consisting of Sylomer® SR 450 90 -40 dB/99 % 80 -35 dB/98 % -30 dB/97 % -25 dB/94 % 70 60 -20 dB/90 % 50 Parameter: Factor of transmission in dB, isolation rate in % -15 dB/82 % -10 dB/69 % 40 -5 dB/44 % 30 0 dB/0 % 20 10 0 5 10 15 20 25 Natural frequency [Hz] www.getzner.com 3 Figure 5: Static load range Figure 6: Delection* Speciic load [N/mm2] Variation of delection [%] Inluence of the form factor In the igures below one can ind correction varying form factors. 0.55 0.5 0.45 0.4 70 % 60 % 50 % 40 % 30 % 20 % 0.35 10 % 0.3 0% 0.25 0.2 -10 % 0.1 0.5 1 3 Figure 7: Dynamic modulus of elasticity at 10 Hz* 10 % 0.1 0% -10 % -20 % -30 % 0.5 1 10 Form factor 3 10 Form factor 10 % 5% 0% -5 % -10 % -15 % -40 % -25 % 0.1 0.5 1 3 10 Form factor -30 % 0.1 0.5 1 * Reference value: speciic load 0.45 N/mm2, form factor 3 AUSTRIA — Bürs GERMANY — Berlin — Munich FRANCE — Lyon INDIA — Pune CHINA — Beijing USA — Charlotte JORDAN — Amman JAPAN — Tokyo www.getzner.com DB SR 450 en © Copyright by Getzner Werkstoffe GmbH l 09-2014 We reserve the right to amend the data. -20 % -50 % 4 3 Figure 8: Natural frequency* Variation of the natural frequency [%] Variation of the dynamic modulus of elasticity [%] -20 % 10 Form factor