Keysight B2980 Series Femto/Picoammeter Electrometer/High

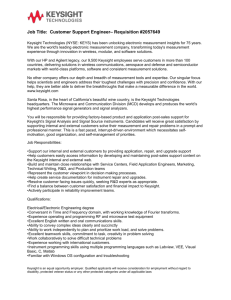

advertisement