TECHNICAL DATASHEET

PROTÉGÉ SENSOR SPECIFICATIONS

The Protégé, depending on the sensors it is equipped is a multi-gas personal monitor designed for

monitoring the atmosphere for potentially hazardous levels of Combustible Gases, Oxygen enrichment or

depletion, Carbon Monoxide and Hydrogen Sulphide.

Combustible Sensor

Sensor Limitations:

Certain chemicals can stop the combustible (catalytic bead) sensor from operating optimally (eg. H2S) or

permanently poison the sensors by forming a solid barrier over the surface of the sensor (eg. silicones).

This will lead to partial or complete loss of sensitivity.

Poisoning of the sensor will lead to permanent degradation of the sensor while exposure to chemicals

that slow or stop the response of the sensor can be overcome by exposure to clean air. For optimal

sensor performance it is best to avoid operating the Protégé in an environment that contains poisons or

inhibitors.

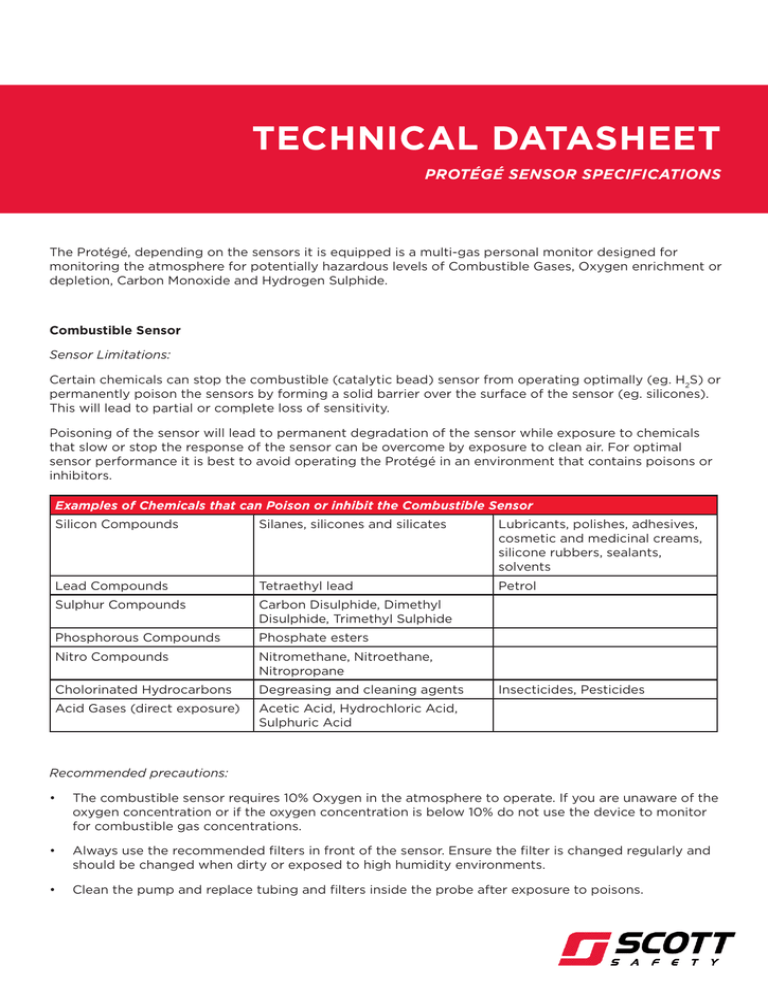

Examples of Chemicals that can Poison or inhibit the Combustible Sensor

Silicon Compounds

Silanes, silicones and silicates

Lubricants, polishes, adhesives,

cosmetic and medicinal creams,

silicone rubbers, sealants,

solvents

Lead Compounds

Tetraethyl lead

Petrol

Sulphur Compounds

Carbon Disulphide, Dimethyl

Disulphide, Trimethyl Sulphide

Phosphorous Compounds

Phosphate esters

Nitro Compounds

Nitromethane, Nitroethane,

Nitropropane

Cholorinated Hydrocarbons

Degreasing and cleaning agents

Acid Gases (direct exposure)

Acetic Acid, Hydrochloric Acid,

Sulphuric Acid

Insecticides, Pesticides

Recommended precautions:

•

The combustible sensor requires 10% Oxygen in the atmosphere to operate. If you are unaware of the

oxygen concentration or if the oxygen concentration is below 10% do not use the device to monitor

for combustible gas concentrations.

•

Always use the recommended filters in front of the sensor. Ensure the filter is changed regularly and

should be changed when dirty or exposed to high humidity environments.

•

Clean the pump and replace tubing and filters inside the probe after exposure to poisons.

PROTÉGÉ SENSOR SPECIFICATIONS

•

Reduce the exposure time of the sensor in poison environments and turn off the monitor when not in

use.

•

Decrease the flow rate of gases over the sensor during operation in poison environments, or use in

diffusion mode.

COMBUSTIBLE SENSOR SPECIFICATIONS

Range

0 to 80% LEL; 0 to 5.0% VV Gas

Response Time

T50=10 seconds; T90=30 seconds

Operating Temperature

-40 to +200°C

Humidity

0 to 90% RH, Non-Condensing

Storage Temperature

0 to 20°C

Poison Resistance

Resistant to H2S poisoning

H2S filter Lifetime

Typically 1,000ppm hr

Expected Life

2 years in air

Warranty

2 years

Oxygen Sensor

OXYGEN SENSOR SPECIFICATIONS

Range

0.0 to 25.0%

Response Time

T95=15 seconds

Operating Temperature

-20 to +50°C

Humidity

5 to 90% RH, Non-Condensing

Storage Temperature

0 to 20°C

Expected Life

2 years in air

Warranty

2 years

Pressure Effects:

The normal operating range for oxygen sensors is within 20% of ambient pressure. Pressure changes are

common when entering a tunnel, going underground or entering high-rise buildings. Ambient pressure

does not affect the sensor.

During sudden pressure changes the sensor needs time to stabilise. It is likely that the alarm will be

activated if the monitor is on. In such instances the Protégé should be allowed to equilibrate under the

new pressure BEFORE switching the monitor on. After stabilising the sensor will perform as normal.

Temperature Effects:

Oxygen sensors show almost no effect from gradual temperature changes. Sudden temerature changes

may cause the oxygen senosr to alarm but readings will equilibrate very quickly.

In the case of sensor drift caused from pressure or temperature changes perform a zero calibration.

PROTÉGÉ SENSOR SPECIFICATIONS

Carbon Monoxide Sensor

CARBON MONOXIDE SENSOR SPECIFICATIONS

Range

0 to 999pm

Resolution

1ppm

Response Time

T90 <25 seconds

Operating Temperature

-20 to +50°C

Humidity

15 to 90% RH, Non-Condensing

Storage Temperature

0 to 20°C

Expected Life

2 years in air

Warranty

2 years

The Carbon Monoxide sensor may exhibit a response to certain gases in the environment other than the

target gas. The sensor has been tested with a number of common gases and the results are shown in the

table. The table shows the typical response expected from a Carbon Monoxide sensor when exposed to a

given test gas.

CONCENTRATION AT TWA LEVELS

Sensor Cross Sensitivity

Filtered against H2S, 15ppm

<0.5ppm

Filtered against SO2, 5ppm

~0ppm

Nitric Oxide, 35ppm

<3ppm

Nitrogen Dioxide, 5ppm

-1ppm

Chlorine, 1ppm

~0ppm

Hydrogen, 100ppm

<40ppm

Ethylene, 100ppm

<50ppm

Ethanol, 200ppm

~0ppm

Hydrogen Sulphide Sensor

HYDROGEN SULPHIDE SENSOR SPECIFICATIONS

Range

0 to 500pm

Resolution

0.1ppm

Response Time

T90 <30 seconds

Operating Temperature

-20 to +50°C

Humidity

15 to 90% RH, Non-Condensing

Storage Temperature

0 to 20°C

Expected Life

2 years in air

Warranty

2 years

PROTÉGÉ SENSOR SPECIFICATIONS

The Hydrogen Sulphide sensor may exhibit a response to certain gases in the environment other than the

target gas. The sensor has been tested with a number of common gases and the results are shown in the

table. The table shows the typical response expected from a Hydrogen Sulphide sensor when exposed to

a given test gas.

CONCENTRATION AT TWA LEVELS

Sensor Cross Sensitivity

Carbon Monoxide at 300ppm

<2ppm

Sulfur Dioxide, 5ppm

~-1ppm

Nitric Oxide, 25ppm

<1ppm

Hydrogen, 10,00ppm

<10ppm

Nitrogen Dioxide, 5ppm

Australia: Scott Safety*

PO Box 876, Guildford, NSW 2161, Australia

Phone: 131 772 Fax: 1800 651 772

Email: scott.sales.anz@tycoint.com

* Scott Safety is a division of Rindin Enterprises Pty Limited ACN 089 330 914

New Zealand: Scott Safety

Private Bag 93011, New Lynn, Auckland, New Zealand

Phone: (64 9) 826 1716 Fax: (64 9) 826 2288

Email: scott.sales.anz@tycoint.com

~ppm

www.ScottSafety.com

© Scott Safety. All Rights Reserved