conoflow - RM Controls

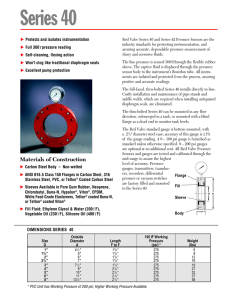

advertisement