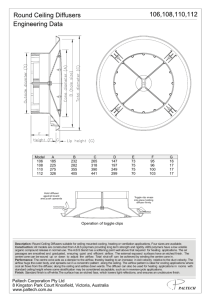

Commercial Specifications

advertisement