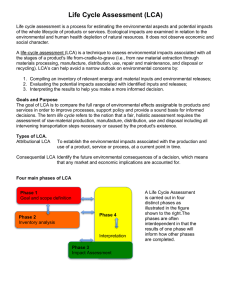

Guidance on Life-Cycle Thinking

advertisement