3126

149.0 bkW/200 bhp

FIRE PUMP ENGINE

3000 rpm

CATERPILLAR® ENGINE SPECIFICATIONS

In-Line 6 Cylinder, Four-Stroke-Cycle Diesel

Bore — mm (in). . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 110 (4.33)

Stroke — mm (in) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 127 (5.00)

Displacement — L (cu in) . . . . . . . . . . . . . . . . . . . . . . . . . 7.2 (442)

Aspiration . . . . . . . . . . . . . . . . . . . . . . . . Turbocharged-Aftercooled

Compression Ratio . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 16.0 to 1

Rotation (from flywheel end) . . . . . . . . . . . . . . . . Counterclockwise

Capacity for Liquids (engine only) — L (gal)

Cooling System . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13.2 (3.5)

Lube Oil System (refill) . . . . . . . . . . . . . . . . . . . . . . . . . . 25 (6.5)

Weight, Net Dry (approx) — kg (lb) . . . . . . . . . . . . . . . . 722 (1,592)

Image shown may not

reflect actual engine.

FEATURES

REGULATIONS

• Factory designed, assembled, tested,

and delivered in a package that meets NFPA 20

regulations. UL and FM certified.

SINGLE-SOURCE SUPPLIER

• Caterpillar:

– Casts engine blocks, heads, cylinder liners, and

flywheel housings

– Machines critical components

– Assembles complete engine

Ownership of these manufacturing processes

enables Caterpillar to produce high quality,

dependable product.

• Factory-designed systems built at Caterpillar ISO

certified facilities

TESTING

• Prototype testing on every model:

– proves computer design

– verifies system torsional stability

– functionality tests every model

• Every Caterpillar engine is dynamometer tested

under full load to ensure proper engine

performance.

UNMATCHED PRODUCT SUPPORT

OFFERED THROUGH WORLDWIDE

CATERPILLAR DEALER NETWORK

• More than 1,500 dealer outlets

• Caterpillar factory-trained dealer technicians

service every aspect of your industrial engine

• 99.7% of parts orders filled within 24 hours —

worldwide

• Caterpillar parts and labor warranty

• Preventive maintenance agreements available for

“repair before failure” options

• Scheduled Oil Sampling (S•O•SSM) program

matches your oil sample against Caterpillar set

standards to determine:

– internal engine component condition

– presence of unwanted fluids

– presence of combustion by-products

WEB SITE

• For all your industrial power requirements, visit

www.cat-industrial.com.

FULL RANGE OF ATTACHMENTS

• Wide range of bolt-on system expansion

attachments, factory designed and tested

5 July 2002

09:31 AM

3126

FIRE PUMP ENGINE

149.0 bkW/200 bhp

STANDARD ENGINE EQUIPMENT

Instrumentation

Instrument panel, LH; engine oil pressure gauge; fuel

pressure gauge; ammeter gauge; water temperature

gauge; tachometer/mag pickup; electric hour meter

Air Inlet System

Air cleaner, regular duty, dry, round type; turbocharger,

watercooled; jacket water aftercooled

Charging System

Charging alternator — 12 volt, 60 amp

Lube System

Crankcase breather; oil cooler; oil filter, RH; oil pan,

center sump; oil filler, RH; oil level gauge, RH;

lubricating oil

Control System

Governor control, vernier and positive lock; mechanical

governor

Mounting System

Front and rear supports

Cooling System

Thermostats and housing; jacket water pump, beltdriven, centrifugal; heat exchanger (installed);

expansion tank

Power Take-Offs

Flywheel stub shaft

Protection System

Stop-start system, automatic (compatible with NFPA 20

requirements, energizable from either of two battery

sources and capable of manual starter actuation)

Exhaust System

Exhaust manifold, watercooled; exhaust outlet, dry;

exhaust elbow 4-bolt flange

Flywheels and Flywheel Housings

Flywheel housing, SAE No. 3; flywheel, SAE No. 3;

SAE standard rotation

Starting System

12-volt electric starting motor, jacket water heater

(2250 watt, 120-240 volt)

Fuel System

Fuel filter, RH; fuel transfer pump (part of governor);

fuel priming pump; primary fuel filter/water separator SL

General

Paint, red; vibration damper; lifting eyes, belt guard

2

5 July 2002

09:31 AM

3126

FIRE PUMP ENGINE

149.0 bkW/200 bhp

PERFORMANCE DATA

Standby Fire Pump Rating — 149.0 bkW (200 bhp) @ 3000 rpm

DM7363-00

rpm

bkW

Percent

Load

g/bkW-hr

L/hr

rpm

bhp

Percent

Load

3000

149.0

100

251.5

44.7

3000

200

100

.413

11.8

3000

134.1

90

256.3

41.0

3000

180

90

.421

10.8

3000

119.2

80

262.8

37.3

3000

160

80

.432

9.9

3000

111.8

75

266.9

35.6

3000

150

75

.439

9.4

3000

104.3

70

271.8

33.8

3000

140

70

.447

8.9

3000

89.4

60

284.5

30.3

3000

120

60

.468

8.0

3000

74.5

50

303.0

26.9

3000

100

50

.498

7.1

3000

59.6

40

330.8

23.5

3000

80

40

.544

6.2

3000

44.7

30

377.1

20.1

3000

60

30

.620

5.3

3000

37.3

25

414.1

18.4

3000

50

25

.681

4.9

3000

29.8

20

469.6

16.7

3000

40

20

.772

4.4

3000

14.9

10

747.4

13.3

3000

20

10

1.229

3.5

3

lb/bhp-hr

5 July 2002

gal/hr

09:31 AM

3126

FIRE PUMP ENGINE

149.0 bkW/200 bhp

INDUSTRIAL RATINGS AND CONDITIONS

Standby Fire Pump ratings represent the output

which may be utilized to drive stationary fire pumps

where the pumping equipment has been sized

according to NFPA 20 guidelines and for expected

use of 30 to 100 hours per year where pump demand

is about 90 percent or less of the certified power.

Standby fire pumps are certified by UL and FM.

Engine performance obtained and corrected in

accordance with ISO 3046/1 standard atmospheric

conditions of 100 kPa (29.61 in. Hg), 30% relative

humidity and 25° C (77° F) at the stated

aftercooler temperature. Performance also in

accordance with SAE J1995, BS5514/1 and DIN

6271/1 standard reference conditions.

03

03

Performance and fuel consumption are based

on 35° API gravity fuel having an LHV of

42 780 kJ/kg (18,390 Btu/lb) when used at 29° C

(84.2° F) where the density is 838.9 g/L

(7.002 lb/U.S. gal).

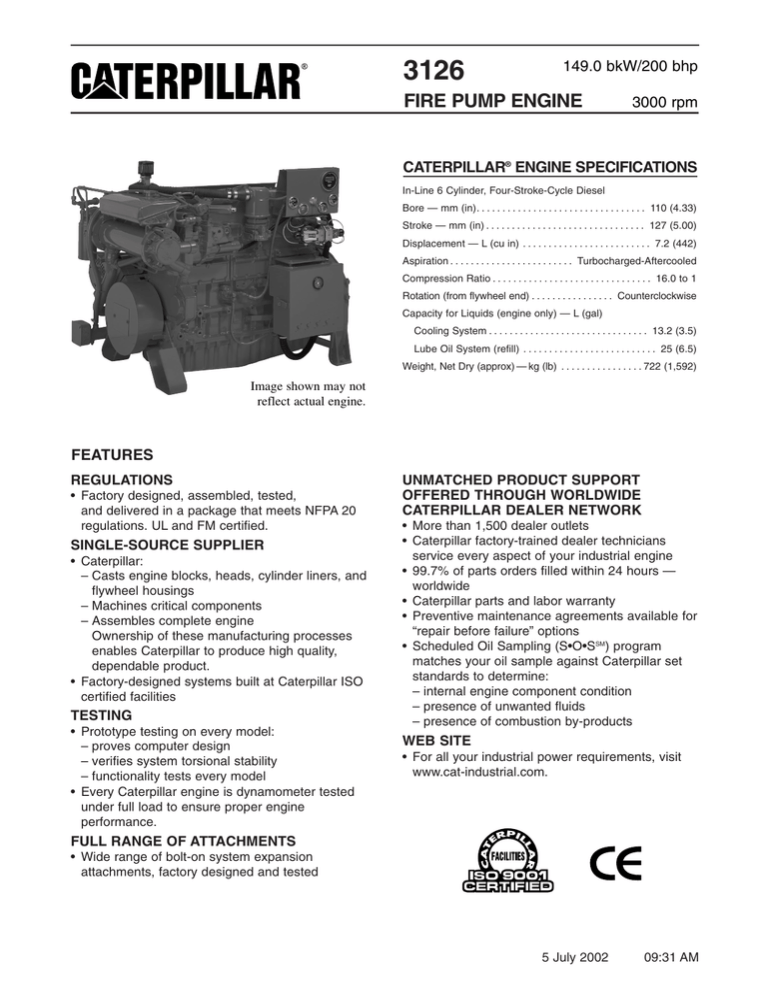

1308.7 mm (51.52 in.)

842.8 mm (33.18 in.)

978.8 mm (38.54 in.)

01

03

01

03

01

Engine Dimensions

(1) Length

1308.7 mm (51.52 in)

(2) Width

842.8 mm (33.18 in)

(3) Height

978.8 mm (38.54 in)

Note: Do not use for installation design. See

general dimension drawings for detail

(Drawing #205-8805).

PL Reference No.:

TMI Reference No.: DM7363-00

Materials and specifications are subject to change without notice.

The International System of Units (SI) is used in this publication.

LEHH2671-00 (7-02)

©2002 Caterpillar

All rights reserved.

5 July 2002

09:31 AM