The financial year 2012-2013 - Board of Radiation and Isotope

advertisement

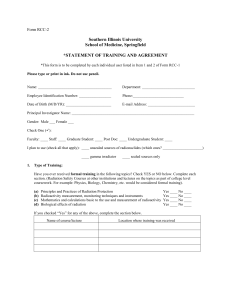

Annual Report 2012- 2013 Board of Radiation and Isotope Technology Executive Summary Radiation Technologies & Applications Board of Radiation & Isotope Technology (BRIT) supplies a vast array of high quality radioisotope products for medical and industrial use. Setting up of radiation processing plants in private sector is one of the important activities along with isotope application services. Iodine-131 capsule production Hot Cell Healthcare More than 60000 cold kits for formulation of 99mTc radiopharmaceuticals (code-TCK: 11 Products) were supplied to various Nuclear Medicine Centers. 200 Ci of 99Mo (TCM-2) for solvent extraction and around 200 Ci of Mo-99 as alumina column generator (New product-COLTECH) and Gel Generators were supplied to hospitals. 20000 Consignments of ready to use radiopharmaceuticals of 131I , 32P, 51Cr and 153Sm were supplied. 131I radiopharmaceuticals amounted to about 530 Ci in over 17000 consignments. The frequency of production and supply of injectable products 153SmEDTMP and 131I MIBG has increased. Two new products 99Mo-99mTc alumina column generator (Brand name “COLTECH”) and ready to use radiopharmaceutical Colloidal Samarium Phosphate 32P (SMPC) Code PHM-4 have been launched. The commissioning of the column generator production facility at BRIT and availability of generator “COLTECH” has made a great impact on the market. The prices of the similar capacity imported products have dropped considerably. With approval to full capacity BRIT will be able to cater to large number of nuclear medicine centres. 1 The introduction of colloidal Samarium [32P] Phosphate as a therapeutic radiopharmaceutical for radiation synovectomy has filled a major requirement in the treatment plan of hospitals across the country. The radiopharmaceutical brings relief to patients suffering from haemophilic arthropathy, rheumatoid arthritis,and osteoarthritis. BRIT has thus provided an indigenous alternative at economical prices to hospitals requiring this radiopharmaceutical. A new facility for production of high activity I-131 capsules has been set up at BRIT Complex. AERB has given approval for limited production runs. The new facility will enable BRIT to enhance the volume of I-131 capsules production and also manufacture capsules containing higher ( > 25 mCi) I-131 radioactivity for the treatment of thyroid cancer A total number of about 7000 radioimmunoassay (RIA) and immunoradiometric assay (IRMA) kits were produced and supplied. RIA Laboratory has achieved UKAS (United Kingdom Accreditation Services) accreditation and International Quality Standards ISO 9001:2008 and ISO 13485:2003 certification. IRMA procedure and prototype kit for human C-peptide was designed and is currently being evaluated for its performance. Regional Center Delhi supplied ~ 52,000 mCi of various ready-to-use 99mTc Radiopharmaceuticals in Delhi. Retail outlet for radiopharmaceuticals (ROR) Delhi supplied 1300 cold kits valued at Rs. 30 lakh. Regional centre, Bangalore supplied 72000 mCi of ready-to-use 99mTc formulations. Around 600 TCK cold kits were sold through retail outlet for radiopharmaceuticals. 1700 Blood bags were irradiated using BI 2000. Regional Centre of BRIT at Kolkata was engaged in 99mTc production through 100Mo (p,2n) reaction in the cyclotron. The purified 99mTc was suitable for preparation of 99mTcradiopharmaceuticals. This work was carried under the IAEA CRP. 99m Tc-HYNIC-HIS3-TATE was prepared using Fmoc solid-phase peptide synthesis for developing 99mTc-radiopharmaceuticals for imaging somatostatin receptor-positive tumors. This work was done in collaboration with IICB, Jadavpur, Kolkata. Retail outlet for cold kits for radiopharmaceuticals at RC, Kolkata was inaugurated in October 2012. The Regional Centre Dibrugarh located at Assam Medical College & Hospital rendered the RIA and IRMA diagnostic services for the benefit of patients of the entire northeastern region At Labelled Compounds laboratory tritium filled light sources of various types for defence applications were produced and met the desired requirements in military gadgets and instruments 40 nos of indigenously prepared 14C-urea breath cards were provided to RMC, Parel for quality evaluation. 2 Regional Centre Hyderabad developed a gel based PCR diagnostic kit for detection of M tuberculosis in collaboration with RMC, BARC, Mumbai. A total of 1508 consignments of 32P nucleotides, 32P orthophosphoric acid, 35S amino acids. radiopharmaceuticals cold kits (TCK products) were supplied and earned Rs. 208 Lakh. Radioanalytical laboratory carried out ~4000 tests on export commodities and 670 tests on domestic water samples (gross alpha, gross beta 226Ra & 228Ra). Around 5800 water samples were received from Punjab for the assay of uranium content. Setting up of new Radioanalytical Laboratory at Regional Centre, Bangalore and BRIT Project House, Deonar is in progress. Quality Control Monographs for 17 products for incorporation in Indian Pharmacopeia were prepared and submitted to RPC for approval. Batch records of TCK products were documented. Digitization of all the batch records is in progress. QA implementation in ready to use radiopharmaceuticals has been initiated with IOM-1. Five numbers of cobalt-60 teletherapy sources were supplied to different hospital with total activity 58 and 200 RMM. 172 kCi of high specific activity Cobalt-60 for the fabrication of Cobalt Teletherapy sources is imported from M/s Reviss, UK. 100 cm of ( Ir-192 + Pt Wire) with total activity of 644.67 mCi were supplied for various brachytherapy applications. Industrial Applications Irradiator sources of total of 1300 kCi activity were supplied to NIPRO, Satara, JPCL, Bhiwadi, UML Vadodara, and AVPP Ltd., Ambernath. ISOMED, Trombay was loaded with additional 78 kCi and RPP, Vashi received 200 kCi of cobalt-60 activity. Install and Operate Irradiator is to be loaded with 50 kCi of Cobalt-60 activity 900 Ir-192 Radiography Sources with a total activity of 40 kCi, 7 Co-60 Radiography Sources with a total activity of 400 Ci and 1 Tm-170 radiography source with 10 Ci activity were fabricated and supplied to various NDT users in the country. Radiation Sources of Co-60, Cs-137 and Tm-170 for Nucleonic Gauges and other various applications were made. 15 Numbers of GC-4000 pencils unloaded from GC-4000 unit supplied to Urugway have been brought to India , The sources were brought from USA in two numbers of Type A lead pots. Both the packages were sent back to USA after removal of sources. Five Blood Irradiators (BI 2000) were loaded with approx. 808 Ci of Another 27 sources are ready for loading in three BI 200 units. 60 Co-Cobalt activity. 3 First Radiometry of Install and irradiate operator was carried out and hot spots were detected. Next radiometry is planned after the repaired unit is received at HIRUP. 3 Ci Ir-192 HDR source was fabricated for the indigenous HDR unit for the first time The newly installed 3 port laser system is being used for the radiometry of the HDR transport flasks. A total Cobalt-60 activity of 861 kCi in 17 sub assemblies was processed at regional center, RAPPCOF, KOTA. 1170 kCi of activity was transported in 12 consignments. 15 numbers of W-91 sources were fabricated at RAPPCOF. Two teams of RAPPCOF has carried out source loadings at OGFL and JCPL, Bhiwadi successfully. 82488 no of boxes were processed at ISOMED earning a revenue of ~ Rs. 290 lakhs. The average plant utilization factor was around 96% and there was 100% load availability of healthcare products at ISOMED. The source strength has been augmented to 400 kCis RPP Vashi processed about 2733 MT of spices and other products were processed till December 2012. Revenue generation till December 2012 is about 195.67 lakhs. Source replenishment was carried out to enhance source strength from 400 kCi to 600 kCi. to cope up with the increased demand for radiation processing. Facility of e-payment has been provided to customers for payment of processing charges. MoU signed with M/s Divyakiran for Radiation Processing Plant at Anand, Gujarat Two Radiation Processing Plants namely, M/s Hindustan Agro Co-Operative Ltd., Rahuri, Maharashtra with source loading of 65 kCi and M/s Nipro India Corporation Pvt. Ltd, Pune with source loading of 275 kCi were commissioned. BRIT has been, for nearly a decade, working closely with customers to launch radiation processing plants all over the country. The tenth plant in private sector was 4 commissioned this year at Pune- Satara Road by NIPRO Corporation Pvt. Ltd. for sterilization of dialysis units manufactured by them. Using the 5 Mega curie Co-60 radiation processing facility NIPRO would be exporting the sterilized dialysis units worldwide. Mou was signed with M/s Isorad Tech Pvt Ltd, Chennai, M/s Divyakiran Agro Processing Pvt. Ltd, Anand, Gujarat and M/s Radura Irradiators, Nashik, Maharashtra for setting up of Radiation Processing plant. A crosslinked polymer blend material (LDPE and EVA) for moldable electrical insulation components meeting IEC standards were developed using 2 MeV electron beam ILU-6 EB accelerator. Gamma Chamber GC 1200 supplied and installed at National Botanical Research Institute, Lucknow. A Low dose Irradiator has been supplied and installed at INMAS, New Delhi. A GC 5000 unit is kept ready for export to Bangladesh Institute of Nuclear Agriculture is expected to be dispatched early in this year. A new source extraction tool has been developed for removing and transferring the decayed source from Gamma Chambers to type B(U) packages. . Three Blood Irradiator 2000 units (BI 2000) were supplied and installed at Rajeev Gandhi Cancer Institute, Delhi, Surat Raktadan Kendra, Surat and Apollo Hospital, Hyderabad. A new radiography camera model ROLI-2 was introduced in November 2012. BRIT supplied 58 radiography exposure devices, 371 ROLI cameras were serviced and 789 decayed sources were removed. 581 imported cameras were inspected Install and irradiate operator has been installed and functional test has been carried out successfully. It is now being planned for source loading and radiometry. ROLI 1 cameras were tested at the REPF workshop and the Radiological lab of BARC. Density measurements were carried out on cobalt-59 pellets and slugs and also chemical analysis and XRF analysis were carried out for the acceptance of the material for irradiation. Radiotracer technique was used for leak detection in series of heat exchangers at Chennai Petroleum Corporation Limited (CPCL), Chennai and Bharat Petroleum Corporation Limited (BPCL), Mumbai. On-line radioisotope techniques using 82Br as radiotracer, the leaky heat exchangers could be exactly identified saving them huge downtime losses. Gamma scanning of process columns were carried out in various refineries and chemical industries for troubleshooting. The gamma scanning of process columns was carried out by using sealed source 60Co. 5 The transportation of about 48524 consignments of radioisotope and allied products, majority of them by air was carried out in a safe manner. Eight fabrication work orders were executed for BC188 type source transportation cages (each carries nearly 100-125 KCi Cobalt) to supply the source to domestic and international Irradiators. BRIT website provided an updated information irway bill numbers for the despatched products and on receipt, inspection and ready for despatch status of radiography cameras on weekly basis. The work on ambitious Fission Molybdenum Project for setting up of a State-of-the Art GMP compliant facility capable of producing 300 Ci per week 99Mo is in progress. The construction of new building has commenced at the approved site near the ISOMED Complex at south site of BARC. The completion of this project will let BRIT take off to larger scales of production of 99Mo -99mTc column generator Kits in the Indian market. Kits with larger quantity available at the radiopharmacy level and uninterrupted distribution will enable BRIT to deepen the existing demand for kits as well as enlarge the customer base to include new Nuclear Medicine centers opening in the non-metro towns of India. With global shortage of 99mTc kits looming in the world market, BRIT will act as a major provider of the kit in times to come. Radioisotopes and allied products supplied by BRIT Sr.No Item 1 2 3 Consignments Activity Sale Value Actual between April-December, 2012 50000 1000 kilo curies Rs. 5000 lakhs Expected to be achieved April, 2012 – March, 2013 ~ 60000 ~ 1500 kilo curies ~ Rs. 7000 lakhs 6 Annual Report 2012- 2013 Board of Radiation and Isotope Technology Descriptive Part CH 4 Radiation Technologies & Applications Board of Radiation & Isotope Technology (BRIT) is a commercial unit of the Department of Atomic Energy which significantly contributes to the much varied needs of radioisotopes and radiation sources in the country. The applications of radiation and radioisotopes in science, medicine, agriculture, research and technology play a prominent part in the progress of mankind. BRIT has a mandate to fulfill this role by regular production and supply of a vast array of high quality radioisotope products and radiation sources. The major beneficiaries of the growth of BRIT as a national organization include healthcare, industry, research and agriculture. Sterilization of medical products, radioisotope labelled pharmaceuticals, 99mTc column generators, equipment and radiography sources for non-destructive radiographic devices are some of the major areas of BRIT’s operations. The application of isotopes for leak detection in various industrial processes is another significant contribution from BRIT. The medical cyclotron facility produces 18F labeled radiopharmaceuticals for many PET (Positron Emission Tomography) examinations. PET is considered as a major breakthrough in nuclear medicine after 99mTc radiopharmaceuticals. BRIT is engaged in setting up of a fission molybdenum production facility that would be operational in another two to three years time and provide a huge boost to its 99mTc Column Generator technology. BRIT is promoting setting up of radiation processing plants in the private sector for food and sterilization of Medical products. As a major element of the perspective plans of the department and as a program which has tremendous spin-off benefits to the society at large, the adoption of radiation processing as a sustainable business by private industry augurs well for the future. BRIT has been, for nearly a decade, working closely with customers to launch radiation processing plants all over the country. The tenth plant in private sector was commissioned this year at Pune- Satara Road by NIPRO Corporation Pvt. Ltd. for sterilization of dialysis units manufactured by them. Using the 5 Mega curie Co-60 facility NIPRO would be exporting the dialysis units worldwide . Development of many other new irradiators is also in progress. Radiation technology equipments such as blood irradiators, gamma chambers and low dose irradiators provide a valuable research tool for studying the effects of radiation in materials which find applications in medicine, agriculture and polymer industry. Applications of radioimmunoassays and immunoradiometric assays find diagnostic value in many disease conditions especially the thyroid related disorders. The availability of 14 C and tritium labeled compounds as tracers and the 32P and 35S labeled biomolecules have played a definitive role in molecular biology and agricultural research. Tritiated fluorescent sources find use in various defense applications. Several technetium ‘cold’ kits’ used in the preparation of 99mTc radiopharmaceuticals are also supplied by BRIT. 1 As a service provider, BRIT also operates plants for radiation sterilization of medical products (ISOMED) at Trombay; Radiation Processing Plant at BRIT Vashi Complex for radiation processing of spices and allied products, and runs Co-60 handling facility (RAPPCOF) at RAPS, Kota, JONAKI Laboratory at Hyderabad and has other Regional Centres located at Bangalore, Delhi, Kolkata and Dibrugarh. BRIT runs a Radioanalytical Laboratory at Vashi for detection of radioactivity in products for the benefit of various exporters and importers. Iodine-131 capsule production Hot Cell The various activities carried out by BRIT related to the production and supply of radioisotopes and allied products and radiation technology equipment for use in Healthcare, Industry, Agriculture and Research during the period of this report are as follows: 4.5 Healthcare 4.5.1. Radiopharmaceuticals More than 60,000 cold kits for formulation of 99mTc radiopharmaceuticals (11 products under the code of TCK) were supplied to various nuclear medicine centers. 200 Ci of 99 Mo (TCM-2) for solvent extraction and around 200 Ci of Mo-99 as alumina column generator (New product-COLTECH) and Gel Generators were supplied to hospitals for separation of 99mTc. In addition to this various accessories of 99mTc Generator systems and other products were supplied. Nearly 20,000 Consignments of ready to use radiopharmaceuticals of 131I , 32P, 51Cr and 153Sm were supplied to various Nuclear 2 Medicine Centers. Majority of these contained 131I radiopharmaceuticals, which amounted to about 530 Ci in over 17000 consignments. There has been a considerable reduction in the import of radioisotopes because of the local availability of the raw material radioisotopes from the reactor whose performance has been good. The production and supply of 32P as sodium orthophosphate was mainly due to nonavailability of quality 32P radioisotope. The frequency of production and supply of injectable products 153Sm-EDTMP and 131I MIBG has increased during the year 2012-13. Two new products 99Mo-99mTc alumina column generator (Brand name “COLTECH”) and ready to use radiopharmaceutical Colloidal Samarium [32P] Phosphate (SMPC) Code PHM-4 have been launched this year successfully. At present low specific activity Mo-99 is available from reactors at BARC. This Mo-99 is being supplied to nuclear medicine centers over the country and is being used with solvent extraction generators for elution of Tc-99m for labeling with cold kits for medical imaging. Solvent extraction is a lengthy and operator dependent procedure which is not preferred by the users. The commissioning of the column generator production facility at BRIT and availability of generator “COLTECH” has made a great impact on the market. The prices of the same capacity imported products have dropped considerably. At present the capacity of BRIT’s COLTECH generator production facility is limited due to initial approval of upto 20 Ci of 99Mo-99 from AERB. With approval to full capacity BRIT will be able to cater to large number of nuclear medicine centres. The introduction of colloidal Samarium [32P] Phosphate as a therapeutic radiopharmaceutical for radiation synovectomy has filled a major requirement in the treatment plan of hospitals across the country. The radiopharmaceutical brings relief to patients suffering from haemophilic arthropathy, rheumatoid arthritis,and osteoarthritis. Sterile pyrogen free, white colloidal solution is now being supplied as an injection for administration by intraarticular instillation. It has no systemic leakage from the joints and has no adverse effects. BRIT has thus provided an indigenous alternative at economical prices to hospitals requiring this radiopharmaceutical. 3 99m Tc - Coltech Generator A new facility for production of I-131 capsules consisting of shielded mini hot cell and fume hoods has been set up at BRIT Complex. It has better shielding features through remote operations in customized cell gadgets. The leak tight hotcells also ensure better performance compared to the existing facility. AERB has given approval for limited production runs. The new facility will enable BRIT to enhance the volume of I-131 capsules production and also manufacture capsules containing higher ( > 25 mCi) I-131 radioactivity for the treatment of thyroid cancer. Presently BRIT has been mainly supplying these radiopharmaceuticals in liquid doses. 4 Radiopharmaceutical Production Facility 4.5.2 Nuclear Medicine : Diagnostic & Treatment Service A total number of about 7000 radioimmunoassay (RIA) and immunoradiometric assay (IRMA) kits were produced and supplied to various hospitals, research centres and immunoassay laboratories in India. RIA Laboratory at BRIT Vashi Complex has achieved UKAS (United Kingdom Accreditation Services) accreditation and International Quality Standards ISO 9001:2008 and ISO 13485:2003 certification. Quality systems implemented by RIA laboratory were rigorously assessed by one of the leading ISO certification agency URS Certification Limited on recommendation of UKAS in December 2012. A contract research service pertaining to Chromium Release Assay was undertaken and successfully executed for Jai Research Foundation (JRF), Valvada, Gujarat. About 600 samples were analyzed for immunotoxicity studies using chromium release assay using in-house 51Cr. The work was jointly carried out at BRIT Vashi Complex and JRF, Valvada facilities. Development of IRMA procedure for human C-peptide was initiated last year is being continued. A prototype kit was designed and is currently being evaluated for its performance. Regional Center, Delhi was involved in the production and supply of around 52,000 mCi of various ready-to-use 99mTc Radiopharmaceuticals injections in compliance with GMP and RPC for diagnostic nuclear medicine studies in 21 hospitals in Delhi and NCR. The value of supplied 99mTc Radiopharmaceuticals is estimated to be Rs. 23.50 lakh. Retail outlet for radiopharmaceuticals (ROR) Delhi supplied 1300 cold kits for preparation of various 99mTc Radiopharmaceuticals valued at Rs. 32.5 lakh. Developmental work on 99mTc alendronate as an alternative bone imaging agent and reinduction of 99mTc- Ciprofloxacin is in progress. A renovated class 10000 laboratory for production of radiopharmaceuticals and labeled compounds is nearly complete. Regional centre, Bangalore supplied 72000 mCi of ready-to-use 99mTc formulations. Around 600 TCK cold kits were sold through retail outlet for radiopharmaceuticals. 1700 Blood bags were irradiated using BI 2000. 600 consignments were collected by the Bangalore centre on behalf of several nuclear medicine customers in the Bangalore region. Regional Centre of BRIT at Kolkata works in close collaboration with Radiopharmaceutical section, BARC, VECC, Kolkata and Indian Institute of Chemical Biology (IICB), Jadavpur. Natural Mo foil stacks (25-100 micron thick) were irradiated at 15-18 MeV proton for 5 min, 1 h, 3 h and 6 h to study 99mTc production through 100Mo (p,2n) reaction in the cyclotron. If enriched 100Mo target is irradiated at 15.6 MeV with 200 µA proton beam extracted 99mTc activity at the end of 6h bombardment would be ~7.5 Ci. Overall yield of 5 99m Tc was about 80%. After quality assessment the purified 99mTc was found to be suitable for preparation of 99mTc-radiopharmaceuticals. This work was carried under the IAEA CRP. 68 Ge-68Ga generator - 68Ge was produced by internal irradiation of natural zinc target using an α beam of variable energy cyclotron. 68Ge production yield was 0.86 μCi/ μAh. The suitability of 68Ga was assessed by labeling EDTMP with it. The radiochemical purity of the labeled 68Ga-EDTMP was about 95%. 99m Tc-HYNIC-HIS3-TATE – octreotide analogs of peptides find increased interest in nuclear oncology for targeted tumor diagnosis and therapy. New cyclic octapeptides conjugated with HYNIC were prepared using Fmoc solid-phase peptide synthesis. The purified analogs were labeled with 99mTc using Tricine and EDDA. Bio-distribution and image studies showed very high uptake in kidney. These can be useful for developing 99m Tc-radiopharmaceuticals for imaging somatostatin receptor-positive tumors. This work was done in collaboration with IICB, Jadavpur, Kolkata. Retail outlet for cold kits for radiopharmaceuticals at RC, Kolkata was inaugurated in October 2012. Nuclear medicine centers in and around the city are likely to benefit of directly obtaining the cold kits from ROR. The Regional Centre Dibrugarh located at Assam Medical College & Hospital rendered the RIA and IRMA diagnostic services for the benefit of patients of the entire northeastern region. More than 10,000 patients availed the services offered by this centre for analysis of hormones like T3, T4, TSH, LH, FSH, PRL, beta- HCG, Ferritin and insulin. 4.3.2 Nuclear & Biotechnological Tools 4.3.2.1 Labelled Compounds Labelled Compounds Programme of BRIT is involved in the synthesis and supply of a variety of 14C, 3H and 35S-labelled products, which are powerful and versatile tools and are used as radiotracers in diverse investigations in the fields of biology, agriculture, medicine and chemistry. The production and supply of tritium filled light sources of various types for defence applications met the desired requirements in military gadgets and instruments. Customsynthesis of a few compounds were carried out for some R&D organizations. Carbon-14 labelling of Tulsi and Brahmi plants were carried out using 14C- urea for a DST project sanctioned to Haffkine Institute of Research, Training & Testing, Mumbai 6 Labelling tulsi with 14C- urea for Haffkine Research Institute Details of the products dispatched during the year 2012 -13 is given below. Sl.No. 1. 2. 3. 4. 5. 6. 7. Product Category 14 C-products H-products 35 S-products Custom synthesis/TLS TFS &TTS (Tritium Sources) 14 C-urea capsules Taq DNA Polymerase 3 Total No. of Consignments* 11 19 60 nil 16 (4647 nos) 05 (480 nos) 01 (2 lakh units) * figure up to December 2012 Highlights 7 1. Custom synthesis of 14C-radiolabelled Ammonium thiocyanate (500 mCi). 2. Production and supply of large number of Tritium-filled self-luminous sources to various defence establishments. 3. 40 nos of indigenously prepared 14C-urea breath cards were provided to RMC, Parel for quality evaluation. 4.3.2.2 JONAKI Laboratory at CCMB Campus, Hyderabad Jonaki, Radioisotope Labelled Biomolecules Laboratory of BRIT at CCMB Campus is primarily involved in the production and supply of 32P labeled nucleotides and also a few molecular Biology kits and enzymes required for Molecular Biology, Biotechnology and Biomedical and drug discovery research of the country. It also markets a few products produced at BRIT Mumbai facility like 35S labeled amino acids products, and through its retail outlet supplies BRIT 99mTc cold kits (TCK) to the nuclear medicine centres of Andhra Pradesh. The laboratory has a well defined molecular diagnostic programme. A gel based PCR diagnostic kit for detection of M tuberculosis was developed in collaboration with RMC, BARC, Mumbai. The kit is now being supplied regularly. Real time PCR based M tuberculosis detection kit developed at Jonaki will shortly go for evaluation on clinical samples. This kit is based on a patented chemistry developed at Jonaki and is likely to be a good substitution for imported kits. Additional Real time PCR kits for determination of load of viruses like Hepatitis B and C, and a few cancer markers like EGFR, BCR-ABL are in the process of development. Further, a thorough validation of the Real time PCR chemistry developed here is also approaching completion. A total of 1508 consignments were supplied. These comprised mainly 32P nucleotides, 32 P orthophosphoric acid, 35S amino acids, LCK Kits, Taq Polymerase and PCR Product, radiopharmaceuticals cold kits (TCK products). The revenue earned was Rs. 208 Lacs. 4.3.2.3 Radio-Analytical Laboratory, Vashi Complex, Navi Mumbai Radioanalytical Laboratory at Vashi is engaged in the measurement and certification of residual radioactivity in commodities such as food samples, animal feed supplements, steel, water and soil samples and other miscellaneous items. Generally, food items are monitored for the presence of 137Cs & 134Cs. Water samples are routinely analysed for gross alpha/gross beta, uranium, 226Ra and 228Ra content, depending upon the requirement. BRIT also carried out 12 survey for certification of surface radiation dose of steel consignments. RAL has carried out more than 4000 tests on export commodities and 670 tests on domestic water samples (gross alpha, gross beta 226Ra & 228Ra) . During the year, 5772 water samples were received from Punjab State for the assay of uranium content. These figures are for the period upto December 2012. In addition to above, 198 samples imported from Japan, were also received for radioactivity assay and certification. Setting up of Radioanalytical laboratory at BRIT Regional Centre, Bangalore is completed and AERB accreditation procedure is in progress. 8 BRIT has also initiated work related to setting up of Radioanalytical laboratories at BRIT Project House, Deonar and also at BRIT Regional Centre, Hyderabad. Quality Control Program QCP is responsible for the analysis of various ready-to-use radiopharmaceuticals, Technetium cold kits, certifying the product for release of QC reports. Quality Control Monographs for 17 products for incorporation in Indian Pharmacopeia were prepared and submitted to RPC for approval. HPLC analysis of some of the radiopharmaceuticals were standardized. Bio-distribution studies for 153Sm-EDTMP injection has been discontinued as well as the use of column chromatography procedure as an alternate method for RCP has been implemented after getting the approval from RPC. Quality Assurance Batch records of TCK products were documented. Digitization of all the batch records is in progress. QA implementation in ready to use radiopharmaceuticals has been initiated with IOM-1. Calibration work was performed on radiation counters with C& I group. 4.5.3. Nuclear Medicine: Cancer Diagnostic & Treatment Services Co-60 Teletherapy Sources : Five numbers of teletherapy sources were supplied to different hospital with total activity 58 and 200 RMM. Another Nine sources are ready for supply. 11 numbers of decayed sources were unloaded from the teletherapy units and stored for fabrication of irradiator source. 172 kCi of high specific activity Cobalt-60 for the fabrication of Cobalt Teletherapy sources is imported from M/s Reviss. Coblat-60 flask for Cobalt teletherapy Source 9 Brachythearpy Applications : 100 cm of ( Ir-192 + Pt Wire) with total activity of 644.67 mCi were supplied for various brachytherapy applications. Industrial Applications 4.7.1. Radioisotope Sources. Industrial Irradiator Sources: 93 numbers of Irradiator sources were supplied to following Irradiator with total activity of 1100 kCi . Out of 93 sealed sources, 34 nos. of sealed sources was supplied first time to NIPRO, Satara in BC-188 type pencils. Source Loading at Radiation Processing Plant NIPRO Satara NIPRO, Satara Jhunsion Chemical Pvt. Ltd. Bhiwadi AV Processors Pvt. Ltd., Ambernath RVNRL, Kottayam ISOMED, Trombay RPP, Vashi - 274 kCi - 300 kCi - 150 kCi - 50 kCi - 178 kCi - 200 kCi 10 Cobalt-60 Rack Design of NIPRO Irradiator More irradiator sources are expected to be supplied in the last quarter of 2012-2013 : Universal Medicap Vadodara Agrosurg Irradiators (India) Pvt. Ltd. Vasai Install and Operate Irradiator NIPRO, Satara - 200 kCi in Jan 2013. - 200 kCi in Jan 2013 - 50 kCi in Jan 2013 - 900 kCI in April 2013 Radiography Sources : 900 Ir-192 Radiography Sources with a total activity of 38 kCi, 7 Co-60 Radiography Sources with a total activity of 400 Ci and 1 Tm-170 radiography source with 10 Ci activity were fabricated and supplied to various NDT users in the country. Another 500 Ir-192 radiography sources and 3 Cobalt-60 sources are likely to be supplied later in the year. One source of 30 Ci was loaded for export to Italy in TK 100 camera. Custom Made Sources: Following Custom Made Radiation Sources for Nucleonic Gauges and uses were made : Co-60 Cs-137 Tm-170 : 32 sources with activity of 2287 mCi : 3 sources with 214 mCi : 1 source of 10 Ci Gamma Chambers : One Gamma Chamber (GC 5000) unit was loaded with 10473 Ci of 60Co- Cobalt activity. Another Gamma Chamber (GC 1200) unit was loaded with 4950 Ci in the form of 22 pencils. Two more Gamma Chambers (GC 1200) are likely to be supplied in the financial year. The decayed sources were removed from 2 number of GC 900 and one Gammacell 200 units. 15 Numbers of GC-4000 pencils unloaded from GC- 11 4000 unit supplied to Uruguay have been brought to India , The sources were brought from USA in two numbers of Type A lead pots. Both the packages were sent back to USA after removal of sources. Blood Irradiators: Five Blood Irradiators (BI 2000) were loaded with approx. 808 Ci of 60 Co-Cobalt activity in each. A total number of 47 pencils were loaded in these units. Another 27 sources are ready for loading in three BI 200 units. A 3 Ci Ir-192 HDR source was fabricated for the indigenous HDR unit for the first time after the installation of the 3 port laser system in RLG Hotcells. This is being used for the radiometry of the HDR transport flasks. Two sources with 6-7 Ci will be fabricated for testing in HDR Unit developed by BRIT. Radiometry of HDR Flask At regional center, RAPPCOF, KOTA a total activity of 861 kCi in 17 sub assemblies was processed and 1170 kCi of activity was transported in 12 consignments. Another 6 consignments with 600 kCi are expected to be transported before 31st March 2013. Special permission for the transportation of the absorber rods were taken from AERB and 8 Numbers of Co-60 absorber rods were transported from KAIGA to RAPPCOF. 4 Numbers of absorber rods from RAPS-2, 8 Nos of absorber rods from RAPS-3 were unloaded during this financial year for the fabrication of the irradiator sources. 15 numbers of W-91 sources were fabricated at RAPPCOF. Two teams of RAPPCOF has carried out source loadings at OGFL and JCPL, Bhiwadi successfully. 4.7.2. Gamma Radiation Processing Services (GRPS) 12 4.7.2.1. Radiation Sterilization Plant for Medical Products (ISOMED) About 82000 boxes admeasuring approx 7000 Cubic Metre were processed in the facility fetching a revenue of 290 lakhs approx in the year 2012-13. The average plant utilization was 96% in the fiscal 2012-13 with 100% load availability in respect of terminal sterilization of healthcare products. The 24×7 facility operation ensured in full compliance to the requisite statutory requirements from the regulators / certification agencies. An average customer feed back rating of over 85% was maintained throughout the year during the course of gamma radiation processing services thus meeting the quality management system objectives framed for the year. The facility has received ISO 13485:2003 certification along with ISO 11137:2006 part 1 which is expected to fulfill one of the essential requirements in the changing business environment as far as radiation sterilization of medical products is concerned. Actions have also been initiated for the accreditation process in respect of OHSAS – 18000. To facilitate swift radiation processing of the customer’s consignments, Source Strength in the facility has been augmented by around 66% in November 2012. The current Source Strength in the facility is now around 400 kCis. 4.7.2.2 Radiation Processing Plant, Vashi (RPP, Vashi) Radiation Processing Plant, Vashi is providing gamma radiation processing services for Spices, Ayurvedic raw material, healthcare products and pet feed etc. to more than 200 customers from all over the country. Twenty new customers for Spice, Ayurvedic raw material and pet feed were registered with the facility during this period. During the current financial year, about 2800 MT of spices and other products were processed till December 2012 which is more than the quantity processed during the corresponding period last year (2700 MT) despite the decay in the source activity. Revenue generation till December 2012 is about 200 lakhs which is about 20% more than the revenue generated in corresponding period last year (160 lakhs). This year the plant is expected to process around 3500 MT spices and allied products yielding revenue of about 250 lakhs. Since its inception, this facility has processed about 23000 tonnes of products realizing revenue of about Rs. 1400 lakhs. Source replenishment was carried out to enhance source strength from 400 kCi to 600 kCi. to cope up with the increased demand for radiation processing. Re-certification Audit for ISO-9001:2008 (Quality Management Systems) was completed successfully and facility was certified for three more years. Surveillance Audit for ISO-22000:2005 (Food Safety Management Systems) was carried out by certifying agency and found in full compliance with standard’s requirements. Facility of e-payment has been provided to customers for payment of processing charges. 13 MoU signed with M/s Divyakiran for Radiation Processing Plant at Anand, Gujarat 4.7.2.3 New Radiation Processing Plants in Private Sector Two Radiation Processing Plants namely, M/s Hindustan Agro Co-Operative Ltd., Rahuri, Maharashtra with source loading of 65 kCi and M/s Nipro India Corporation Pvt. Ltd, Pune with source loading of 275 kCi were commissioned. 14 Radiation Processing Plant at Nipro India Corpn. Ltd., Pune is commissioned Mou was signed with M/s Isorad Tech Pvt Ltd, Chennai, M/s Divyakiran Agro Processing Pvt. Ltd, Anand, Gujarat and M/s Radura Irradiators, Nashik, Maharashtra for setting up of Radiation Processing plant. 15 MoU signed with M/s Isorad, Chennai 4.7.2.5 EB Processing A crosslinked polymer blend material for mouldable electrical insulation components meeting IEC standards were developed using 2 MeV electron beam ILU-6 EB accelerator. Optimum compositions of LDPE and EVA were blended without the use of conventional curing agents. The material finds various applications as HV electrical insulation components. The crosslinked material can be shaped into desired geometry using vacuum moulding technique at around 150o C. Electron Beam commercial processing services were continued at ILU-6 facility at Vashi. 4.7.3. Radiation Technology Equipment 4.7.3.1. Gamma Chambers During the current financial year various gamma chambers have been supplied and some others are to be supplied to the following Institutes/organizations. • • Gamma Chamber GC 1200 supplied and installed at National Botanical Research Institute, Lucknow. A Low dose Irradiator has been supplied and installed at INMAS, New Delhi. 16 • • • A Gamma Chamber 5000 unit is ready for export to Bangladesh Institute of Nuclear Agricultural, Mymensingh, Bangladesh. It will be delivered by road through M/s. Danver Hydromatics, Kolkata for US$ 159,000 FOB. Gamma Chamber (GC 5000) for RSD, BARC, Gamma Chamber GC 1200 for Dr. Ambedkar University, Lucknow are to be supplied later. Source replenishment for one Gamma Chamber 900 unit is in progress for supplu later. During the period 10 units of GC 900, GC 4000A and a Gamma Cell 1200 units were decommissioned and another 2 units from IIT, Chennai & IMRL Jammu will be decommissioned in 2012-13. A new source extraction tool has been developed for removing and transferring the decayed source from Gamma Chambers to type B(U) packages. The new tool has been used at Kandy, Sri Lanka for transferring the source from GC 900 to BLC 100. 4.7.3.2. Blood Irradiator 2000 Blood Irradiator 2000 units were supplied and installed at • • • Rajeev Gandhi Cancer Institute, Delhi, Surat Raktadan Kendra, Surat Apollo Hospital, Hyderabad Another 2 units are being supplied by the end of February to • • L&T Chennai- unit will be installed at JIPMER, Pondicherry & IMS & SUM Hospital, Bhubaneswar. 4.7.3.3. Radiography Camera ROLI-1 & III BRIT supplied 58 radiography exposure devices up December 2012. It is expected to sell another 30 cameras by March 2013. 500 ROLI cameras were serviced, nearly 1000 decayed sources were removed, 800 imported cameras were inspected for approval of source replenishment. A new radiography camera model ROLI-2 was introduced in November 2012. 4.7.3.4. Install & Operate Irradiator Install and irradiate operator has been installed and functional test has been carried out successfully. 4.7.3.5. QA of Sealed Sources, Radiometry Scanning and Irradiation Services ROLI 1 cameras were tested at the REPF workshop and the Radiological lab of BARC. Density measurements were carried out on cobalt-59 pellets and slugs and also 17 chemical analysis and XRF analysis were carried out for the acceptance of the material for irradiation. All the sealed sources were subjected to the various quality control checks before release. 4.7.3.6. Isotope Application Services Various radioisotopes, in sealed form and open sources were used for several troubleshooting applications in industries. Radiotracer technique was successfully used for leak detection in series of heat exchangers at Chennai Petroleum Corporation Limited (CPCL), Chennai and Bharat Petroleum Corporation Limited (BPCL), Mumbai. The refineries experienced problem of high sulphur content in rundown diesel which indicated a leak from feed (shell side) to reactor effluent side (tube side) in one or more than one heat exchangers (in series). Placement of detectors in heat exchangers for leak detection at CPCL, Chennai However locating a leaky heat exchanger using conventional technique was a difficult task since there are seven breech lock heat exchangers in series at CPCL and ten heat exchangers in series at BPCL. Conventionally leak could be identified only by hydrotesting of individual heat exchanger which would have extended downtime of the 18 refinery. However, on-line radioisotope techniques using heat exchangers could be exactly identified. 82 Br as radiotracer, the leaky Gamma scanning of process columns were carried out in various refineries and chemical industries for troubleshooting. The technique provided on-line and fast identification of problematic zones in the process columns. The gamma scanning was carried out by using sealed source 60Co. Interface detection for HF settler Tank settler at Reliance Industries Ltd. Interface detection of hydrofluoric acid (density 0.98 g/cc) and hydrocarbons (density 0.84 g/cc) was successfully carried out in a closed hydrofluoric settler tank for Reliance Industries Limited, Patlaganga. 19 Tangential pipe profiling in progress at HPCL, Mahul, Mumbai 4.14. Supporting Services 4.14.1. Customer Support Customer Support Programme provides various kind of support for the regular and uninterrupted supply of radioisotopes & allied products and radiation technology equipment to about 2000 user institutions in the healthcare, industrial, research and agricultural sector. BRIT continued to serve its customers through various modes of interactions with them to support co-ordination with the officials of BRIT and regulatory authorities in the matters related to procurement and use of radioisotope products, services and equipment. The retail outlet for supply of cold kits to nuclear medicine user institutions in and around Mumbai. The transportation of about 50000 consignments of radioisotope and allied products, majority of them by air was carried out in a safe manner. Major transportation activities carried out during the year includes movement of kilocurie amounts of radioactive sources from RAPPCOF, Kota to Mumbai, and transportation iof industrial irradiator sources from Mumbai to Satara, Bhiwadi, Ambernath, Kottayam and teletherapy sources from Mumbai to various cancer hospitals in the country and Gamma Chamber and Blood Irradiator units to various research centres and hospitals. 20 BRIT website provided information on the products, services and various other activities of BRIT. The airway bill numbers for the despatched products are displayed on website on a continuous basis. Frequent updates on receipt, inspection and ready for despatch status of radiography cameras helps NDT customers considerably. Organizational structure, telephone and email directory, annual report and milestones of BRIT are some other web pages that are modified periodically. Changes were implemented to adopt to new VPN services of NIC for BRIT. Hundred new email accounts in the domain britatom.gov.in have been obtained to strengthen a committed support to our customers. Radioisotopes and allied products supplied by BRIT Sr.No Item 1 2 3 Consignments Activity Sale Value Actual between April-December, 2012 50000 1000 kilo curies Rs. 5000 lakhs Expected to be achieved April, 2012 – March, 2013 ≈ 60000 ≈ 1500 kilo curies Rs. 7000 lakhs 4.14.2. Engineering Services Engineering services provided the vital infrastructure and utility services to BRIT and BARC facilities at Vashi Complex, Project House at Deonar and ISOMED at Trombay. A centralized Radiation Equipment Production Facility (REPF) workshop of Engineering Services equipped with vital infrastructure (including 2 nos. of 10 Ton capacity EOT cranes, 7 ton Capacity Forklift ) provided the technical support and services to various sections of BRIT such as Radiography Cameras, Laboratory Irradiators, TCGPF, LCO, and Radiation Processing Plants at Vashi and ISOMED at Trombay to meet their required flow processes of production and supply schedules as planned. Preliminary set up work of Calibration laboratory for Radiation measuring instruments including modification, design and development of exposure device has been brought to next level of work along with by workshop. During this year constant technical support has been provided by the workshop to Isotope Application Services (IAS) in gamma scanning work executed at HPCLMumbai, RIL- Gujarat and PRIVI Organics at Mahad. Regular technical support and services has been provided to execute the commissioning work of Mobile Hot Cell under progress. In the current year the workshop has planned to execute the eight fabrication work order from Sealed Source group. BC188 type source transportation cages (each carries nearly 100-125 KCi Cobalt) to supply the source to domestic and international Irradiators. Status of the Plan Projects X Plan Projects 21 BRIT has taken up several projects for execution under the plan project scheme. All these projects have been aimed to enhance its capacity for the development of new products, improvement in quality and also development of infrastructural facilities. Under the X Plan, in the three major projects, progress has been made as given below: Project: Integrated Facility for Radiation Technology (IFRT) Objective of the project is to set up a Hot Cell at BRIT Vashi Complex for handling, storage and fabrication of sealed sources up 300 kCi of Co-60. The financial outlay of the project is Rs. 1805 lakh. This project is in advanced stage of execution as civil construction for administrative building, water pool, Radiometry room and Hot Cell has been completed. Installation of crane and ventilation system is in progress. Project is expected to be completed by end of 2013 Project: DAE Medical Cyclotron Project: Pharmaceuticals Facility A medical cyclotron facility is being installed at VECC, DAE, and Kolkata for the production of PET and SPECT radioisotopes to be used for diagnostic and therapeutic purposes. Progress: Major equipment including hot cells has been procured. Isotope for establishing procedure for production is being procured. Casting of 10m deep basement which is the most complicated civil work of this project is about 90% complete. Works in the cyclotron vault area, 2nd floor of the remaining portion of the building and other service buildings are going on. Civil work is expected to be completed by June 2013. XI Plan Projects The XI plan projects are aimed towards development of new products, improvement in quality of existing products and improvement in manufacturing processes. An important project for setting up production facility for the medical grade fission molybdenum was approved last year. Brief description of the XI plan projects is given below: 1. Project : Integrator Irradiator Development Project Estimated Cost: Rs.300 lakhs Objectives To upgrade safety and security features in the RPP, Vashi and ISOMED facilities and to set up an Irradiator Training Facility for training of personnel for operation of irradiator. Progress: The project has been completed and following work has been carried out: • Access control system installed at Vashi. 22 • • • • • • System for vehicle tracking system has been installed Early fire warning system for ISOMED is procured Aerosol generator has been designed and fabricated Pamcrash software for safety evaluation of cask has been procured. Single bag blood irradiator has been fabricated and supplied Scale down model of Medical sterilizer has been fabricated and supplied 2. Project: Production Facility for 99Mo/ 99mTc Column Generators of High Specific Activity Mo-99. Estimated Cost: Rs. 750 lakhs Objectives Setting up of a new automated facility for production of using high specific activity Mo-99. 99 Mo – 99m Tc Column Generators The installation of the facility is complete. Cold runs have been completed This project has been completed as per schedule. AERB approval has been obtained. New product Coltech has been successfully launched in the market as planned. 3. Project: Construction of State-of–the-Art Immunoassay Facility Estimated Cost: Rs. 205 lakhs. Objectives • Development of building up of infrastructure for coated tube technology and state of the art Laboratory with GMP/GLP compliance with a special focus on contract manufacturing. • Development and building up of infrastructure for immunoassay based on nonisotopic labels. • Development of diagnostic kits for infectious diseases. Progress: Procurement of following equipments needed for development of isotopic/non-isotopic assays has been completed. Spectrophotometer Dehumidifier Multi-well RIA counter Laboratory has been refurbished partly BT reader RO water system T3 antibody 23 Last set of equipment is awaited for supply and it is expected that project will be completed by March 2013. 4. Project: Construction of State-of-the-Art GLP and GMP Estimated Cost: Rs. 340 lakhs. Objectives. Upgradation of the laboratory for GLP and GMP compliance by following: a. Removal of the existing corroded 20 years old fume hoods, cut and disposal through WMD. b. Installation of new fume hoods c. Wear resistant laboratory flooring of Laboratory. d. Furnish the lab and facelift office for aesthetic look. e. Introduce the state of the art synthesis facility, enhance the analytical evaluation, quality control of the labeled compounds. Introduction of microwave synthesis and introduction of instrumental analysis. f. Augmentation of oligo-nucleotides synthesis facility. g. Setting up of state of the art lab for C-14 urea capsule production and h. Setting up of low background counting lab food analysis. Progress: Following work has been carried out • • • • • Decontamination of working tables and fume hoods in two laboratories is completed Procurement of stainless steel fumehoods (12 Nos), new working tables, flooring, paneling etc. HPLC instrument is procured UV spectrophotometer and Portable liquid scintillation is procured. 12 nos of Fume hoods fabricated and supplied Installation of Fume hoods is in progress and project is expected to be completed by end of 2013. 5. Project: Indigenous HDR Brachytherapy Equipment (IHDR) Estimated cost: Rs. 800 lakhs Objectives: a) Establishing the complete process and facilities for fabrication of Ir-192 HDR b) sources for regular production. c) Development of indigenous, remote operated high dose rate (HDR) brachytherapy equipment including necessary treatment. Progress: Second prototype of KARKNIDON, HDR treatment unit has been made. Unit has under gone more than 50,000 cycle of operations. Reliabilities and robustness of stepper drive, 24 Safety interlocks, linear accuracy, repeatability, hardware & software were tested and recorded. Weaker components and software corrections are incorporated to ensure conformance of code. The second machine has been upgraded systematically and is much superior in technology to the earlier version. Third party evaluation will be undertaken by involving RPAD/BARC, prior to clinical trials. Development of Treatment planning software for the KARKNIDON, also been initiated. One type of Steel applicator suitable for the treatment of cervical cancer, already been developed. Prototype of Karknidon – HDR Treatment unit for cancer 6. Project: Setting up of facility for Molybdenum production of medical grade Fission A new project “Setting up of Medical use Mo-99 production (LEU fission based) facility” under XI plan has been sanctioned for BRIT by Atomic Energy Commission. Project is scheduled to be completed by 2014. Estimated Cost Rs. 128 crore The project consists of setting up of a State-of-the Art GMP compliant facility capable of producing 300 Ci (6 day pre-calibrated) per week 99Mo utilizing LEU targets. The scope includes commissioning of modern hot cells equipped with manipulators, in cell equipments, radiation surveillance instrumentation and data logging system, special AC & ventilation system, waste management equipments, civil construction of building and 25 setting up of world class quality control labs, modern security system, construction of new building at approved site in ISOMED Complex, BRIT near South Gate BARC. The completion of this project will let BRIT take off to larger scales of production of 99Mo -99mTc column generator Kits in the Indian market. Kits with larger quantity available at the radiopharmacy level and uninterrupted distribution will enable BRIT to deepen the existing demand for kits as well as enlarge the customer base to include new Nuclear Medicine centers opening in the non-metro towns of India. With global shortage of 99mTc kits looming in the world market, BRIT will act as a major provider of the kit in times to come. Objectives • Mo-99 production (LEU fission based) facility • Supply Fully indigenous column generators to various diagnostic centres and hospitals in the country. Progress : After the site clearance from AERB and the designs for the building are submitted to AERB, The work on construction of building has been taken up by DCSEM in parallel. As recommended by BARC and safety authorities, the work of construction of new RCC boundary wall for the ISOMED complex, new Watch tower and installation of new safely features was included in the scope of civil work. The work on the construction of new RCC boundary wall is nearly complete. Now work on construction of watchtower is being taken up and new electric security fencing and provisions are being made for installation of other security equipment. Work on the construction of main laboratory building has also started and the foundation piling work of 169 piles of total of 184 piles is complete. Main Laboratory Building under construction 26 Work on procurement of the production plant, on turnkey basis, is in advanced tender processing stage through DPS. Boundary wall under construction 27