LPG Truck Equipment Catalogue | Kosan Crisplant

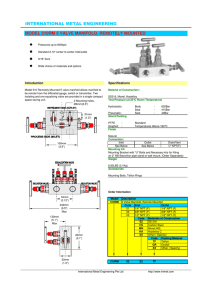

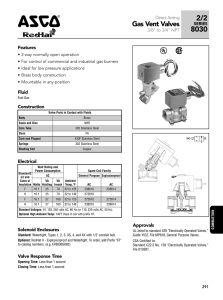

advertisement