Data Sheet

advertisement

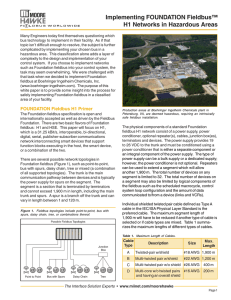

750-837 16-bit CPU 01 02 CANopen Fieldbus connection 231 Series (MCS) STOP A RUN B I/O D + USR Programming of the application is done in accordance with IEC 61131-3. The programmer can access all fieldbus and I/O data. Supply 24 V 0V Supply via power jumper contacts 24 V — — 0V Configuration and programming interface The CANopen PLC combines control functionality, I/O interface and fieldbus in one device. Status voltage supply -System -Power jumper contacts Data contacts + ON 1 2 3 4 5 6 7 8 DIP switch for node ID and baud rate C TX 24V 0V OVERFLOW RX 750-837 100 PLC - CANopen Programmable Fieldbus Controller, MCS W 3 Power jumper contacts Features and applications: • Use of decentralized control can better support a PLC or PC • Complex applications can be divided into individually testable units • Programmable fault response in the event of a fieldbus failure • Signal pre-processing reduces fieldbus transmissions • Peripheral equipment can be controlled directly, resulting in faster system response times • Stand-alone, compact controller Notice: EDS files required Description Item No. Pack. Unit System Data CANopen Controller MCS CANopen Controller MCS Program memory 256 Kbytes; Data memory 192 Kbytes CANopen Controller MCS Program memory 640 Kbytes; Data memory 832 Kbytes 750-837 750-837/020-000 1 1 No. of controllers connected to Master Transmission medium Max. length of bus line 750-837/021-000 1 Baud rate Buscoupler connection Accessories Item No. Pack. Unit Programming 1 IEC 61131-3 EDS files Download: www.wago.com WAGO-I/O-PRO V2.3, RS-232 kit 759-333 Miniature WSB Quick marking system plain 248-501 with marking see Section 11 110 Shielded Cu cable 3 x 0.25 mm² 30 m ... 1000 m (depends on baud rate/cable) 10 Kbaud ... 1 Mbaud 5-pole male connector, 231 Series (MCS), female connector 231-305/ 010-000 (included) WAGO-I/O-PRO 32, from firmware version SW 11, also programmable with WAGOI/O-PRO V2.3 IL, LD, FBD (CFC), ST, FC 5 Approvals Conformity marking Korea Certification Marine applications (versions upon request) r UL 508 r ANSI/ISA 12.12.01 TÜV 12.1297 X (Brazil) 4 TÜV 07 ATEX 554086 X IECEx TUN 09.0001 X WAGO Kontakttechnik GmbH & Co. KG Subject to design changes 1 ABS, BV, DNV, GL, KR, LR, NKK, PRS, RINA Class I, Div. 2, Grp. ABCD, T4 Ex nA IIC T4 Gc I M2 Ex d I Mb, II 3 G Ex nA IIC T4 Gc, II 3 D Ex tc IIIC T135°C Dc Ex d I Mb, Ex nA IIC T4 Gc, Ex tc IIIC T135°C Dc 26.01.2016 Postfach 2880 - D-32385 Minden Hansastr. 27 - D-32423 Minden Tel.: +49(0)571/887-0 E-Mail: info@wago.com Fax: +49(0)571/887-169 www.wago.com 3 101 FIELDBUS INTERFACE I/O modules 24 V 1 24 V 5 24 V /0 V 10 nF 5V ELECTRONICS 5V 0V 2 6 24 V 24 V ELECTRON ICS 3 FIELDBUS INTERFACE 7 1) 2) 0V 0V 10 nF 1) 1 M Ω • 4 8 2) 10 nF /500 V 750-837 3.2 Technical Data Number of I/O modules Max. input process image Max. output process image Max. input variables Max. output variables Configuration Program memory Data memory Non-volatile memory (retain) Cycle time No. of PDOs No. of SDOs Communication profile Device profile COB ID distribution Node ID distribution Other CANopen features Power supply Max. input current (24 V) Power supply efficiency Internal current consumption (5 V) Total current for I/O modules (5 V) Isolation Voltage via power jumper contacts Current via power jumper contacts (max.) General Specifications 64 512 bytes 512 bytes 512 bytes 512 bytes automatic 128 Kbytes 64 Kbytes 8 Kbytes < 3 ms for 1,000 statements / 256 dig. I/Os 32 Tx / 32 Rx 2 server SDOs / 16 client SDOs DS-301 V4.01 DS-401 V 2.0 Marginal check Edge-triggered PDOs Programmable error response DSP 405 using function blocks NMT master can be programmed SDO, standard DIP switches NMT slave Minimum boot-up Variable PDO mapping Emergency message Life guarding / heartbeat Configuration of virtual modules 24 V DC (-25 % ... +30 %) 500 mA 87 % 350 mA 1650 mA 500V system/supply 24 V DC (-25 % ... +30 %) 10 A DC Operating temperature Wire connection Cross sections Strip lengths Dimensions (mm) W x H x L Weight Storage temperature Relative air humidity (no condensation) Vibration resistance Shock resistance Degree of protection EMC immunity of interference EMC emission of interference 0 °C ... +55 °C CAGE CLAMP® 0.08 mm² ... 2.5 mm² / AWG 28 ... 14 8 ... 9 mm / 0.33 in 51 x 65 x 100 Height from upper-edge of DIN 35 rail 200 g -25 °C ... +85 °C 95 % acc. to IEC 60068-2-6 acc. to IEC 60068-2-27 IP20 acc. to EN 61000-6-2, marine applications acc. to EN 61000-6-4, marine applications