ODU-MAC - ODU USA

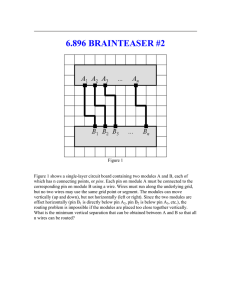

advertisement