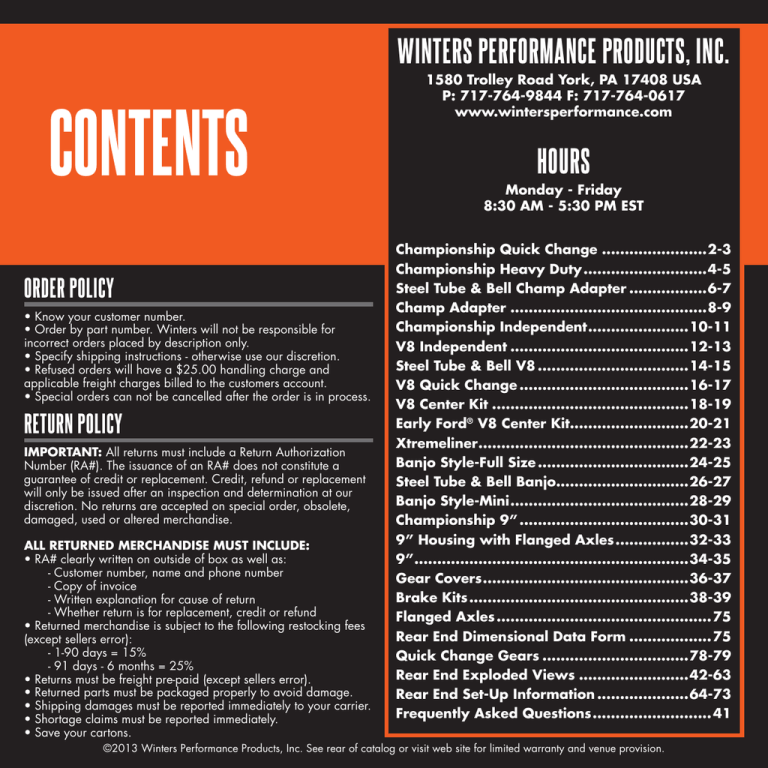

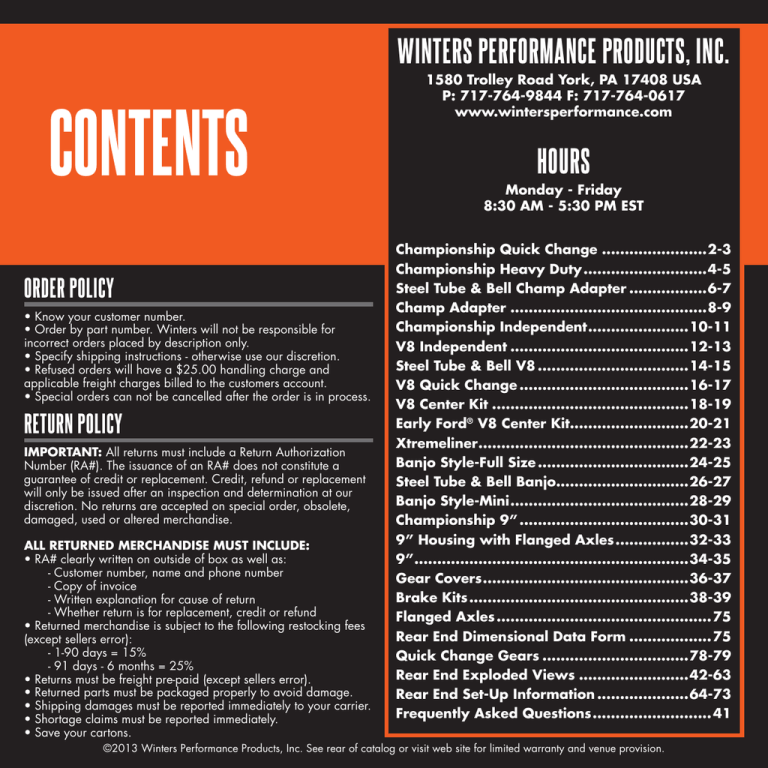

WINTERS PERFORMANCE PRODUCTS, INC.

CONTENTS

ORDER POLICY

• Know your customer number.

• Order by part number. Winters will not be responsible for

incorrect orders placed by description only.

• Specify shipping instructions - otherwise use our discretion.

• Refused orders will have a $25.00 handling charge and

applicable freight charges billed to the customers account.

• Special orders can not be cancelled after the order is in process.

RETURN POLICY

IMPORTANT: All returns must include a Return Authorization

Number (RA#). The issuance of an RA# does not constitute a

guarantee of credit or replacement. Credit, refund or replacement

will only be issued after an inspection and determination at our

discretion. No returns are accepted on special order, obsolete,

damaged, used or altered merchandise.

ALL RETURNED MERCHANDISE MUST INCLUDE:

• RA# clearly written on outside of box as well as:

- Customer number, name and phone number

- Copy of invoice

- Written explanation for cause of return

- Whether return is for replacement, credit or refund

• Returned merchandise is subject to the following restocking fees

(except sellers error):

- 1-90 days = 15%

- 91 days - 6 months = 25%

• Returns must be freight pre-paid (except sellers error).

• Returned parts must be packaged properly to avoid damage.

• Shipping damages must be reported immediately to your carrier.

• Shortage claims must be reported immediately.

• Save your cartons.

1580 Trolley Road York, PA 17408 USA

P: 717-764-9844 F: 717-764-0617

www.wintersperformance.com

HOURS

Monday - Friday

8:30 AM - 5:30 PM EST

Championship Quick Change........................2-3

Championship Heavy Duty............................4-5

Steel Tube & Bell Champ Adapter..................6-7

Champ Adapter............................................8-9

Championship Independent.......................10-11

V8 Independent........................................12-13

Steel Tube & Bell V8..................................14-15

V8 Quick Change......................................16-17

V8 Center Kit............................................18-19

Early Ford® V8 Center Kit..........................20-21

Xtremeliner...............................................22-23

Banjo Style-Full Size..................................24-25

Steel Tube & Bell Banjo..............................26-27

Banjo Style-Mini........................................28-29

Championship 9”......................................30-31

9” Housing with Flanged Axles.................32-33

9”.............................................................34-35

Gear Covers..............................................36-37

Brake Kits.................................................38-39

Flanged Axles................................................ 75

Rear End Dimensional Data Form................... 75

Quick Change Gears.................................78-79

Rear End Exploded Views.........................42-63

Rear End Set-Up Information.....................64-73

Frequently Asked Questions........................... 41

©2013 Winters Performance Products, Inc. See rear of catalog or visit web site for limited warranty and venue provision.

2

CHAMPIONSHIP

QUICK CHANGE

Traditional Hot Rodding With The

Very Latest Technology!

More than tradition, our Championship Quick

Change Rear features our Sprint Car Center

with a 10”, 4.12 Ring & Pinion, Heat Treated

Lower Shaft, Winters Track Differential (see

page 5), Axle Seals and your choice of a 10

Spline, Straight Cut Gear Set. Uses stock

appearing Flanged 31 Spline Axles (sold

separately) that will accommodate after-market

disc or stock brakes.

©2013 Winters Performance Products, Inc. See rear of catalog or visit web site for limited warranty and venue provision.

3

Hall of Fame!

Assembly P/N SR2520 shown with SR8186P 6 Rib Side Bells, Standard Gear

Cover, Option SR8277 Stainless Steel Hardware & Option SR8207 Polishing

ASSEMBLIES

SR2520 Big Bearing Flanged Axle

SR2525 Big Bearing Flanged Axle (Torino®)

Blacked Out Skull & Cross Bones Assembly

SR2520SC Big Bearing Flanged Axle

SR2525SC Big Bearing Flanged Axle (Torino®)

See Page 76 for Dimensional Data

See Pages 42-43 for Exploded View and Parts List

See Page 75 for Axle Ordering & Housing Info

Big Bearing Rears Accommodate Stock 3.150” O.D. Axle Bearings

POPULAR OPTIONS

SR2980

SR8207

SR8211CF

SR8247

SR8275-1

SR8277

Axle Set

Polishing

Billet Gear Cover

Helical Gear (Specify Ratio)

Yoke, 1350 Series

Stainless Steel Hardware

See Pages 36-37 For Optional Gear Covers

Assembly P/N SR2520 shown

with SR8186P 6 Rib Side Bells,

Option SR8211VM Gear Cover &

Option SR8207 Polishing

Assembly P/N SR2520SC shown

ALL THE OPTIONS YOU WANT

Assembly P/N SR2520 shown

with SR8136 4 Rib Side Bells,

Option SR8211 Billet Gear Cover

& Option SR8207 Polishing

Assembly P/N SR2520 shown

with SR8186P 6 Rib Side Bells

& Option SR8208 Thermal

Dispersant Coating

Assembly P/N SR2520 shown

Assembly P/N SR2520 shown

with SR8155PM 8 Rib Side Bells, with SR8186PM 6 Rib Side Bells,

Option SR8211VM Machined Gear Option SR8211VM Machined Gear

Cover & Option SR8207-DQC

Cover & Option SR8207-DQC

Detailed Polishing On Bells & Cover Detailed Polishing On Bells & Cover

©2013 Winters Performance Products, Inc. See rear of catalog or visit web site for limited warranty and venue provision.

Assembly P/N SR2520 shown with

SR8186P 6 Rib Side Bells, Option

SR8211CF Gear Cover & Option

SR8207 Polishing

4

CHAMPIONSHIP

HEAVY DUTY

“Worlds Finest Rear Ends!”

Maximum exposure might best describe our

Championship Heavy Duty Quick Change Rear.

This rear features our Heavy Duty Center with

a 10” 4.12 Ring & Pinion, Deep Dish Style Gear

Cover, Heat Treated Lower Shaft, Winters Track

Differential, Axle Seals and your choice of a 10

Spline, Straight Cut Gear Set. Uses stock

appearing Flanged 31 Spline Axles (sold

separately) that will accommodate after-market

disc or stock brakes.

©2013 Winters Performance Products, Inc. See rear of catalog or visit web site for limited warranty and venue provision.

5

Yes, Sign Me Up!

Assembly P/N SR2520HD shown with SR8155 8 Rib Side Bells, Standard Deep

Dish Gear Cover & Option SR8207-HD Polishing

ASSEMBLIES

SR2520HD Big Bearing Flanged Axle

SR2525HD Big Bearing Flanged Axle (Torino®)

Big Bearing Rears Accommodate Stock 3.150” O.D. Axle Bearings

POPULAR OPTIONS

SR2980

SR8207-HD

SR8247

SR8275-1

Axle Set

Polishing

Helical Gear (Specify Ratio)

Yoke, 1350 Series

See Pages 44-45 for Exploded View and Parts List

Use Winters Semi-Synthetic

Lube with Moly 80-90-140

P/N SR1730

WINTERS TRACK

P/N SR6513-31

Our 31 Spline Winters Track Differential is standard

equipment in all Championship Heavy Duty Assemblies. CNC machined to exacting tolerances. This

virtually unbreakable, parallel gear design automatically senses wheel spin and delivers positive traction.

Assembly P/N SR2520 shown with SR8155 8 Rib Side Bells (4 &

6 Rib also available) & Standard 1310 Series Yoke.

©2013 Winters Performance Products, Inc. See rear of catalog or visit web site for limited warranty and venue provision.

6

STEEL TUBE & BELL

CHAMP ADAPTER

Custom Shop!

Better than the originals, Winters Forged Steel

Tube & Bell Champ Adapter Rear End comes

complete. Built to your specs, it features our

Sprint Car Center with a 10”, 4.12 Ring &

Pinion, Heat Treated Lower Shaft, Winters Track

Differential, Axle Seals and your choice of a 10

Spline, Straight Cut Gear Set.

©2013 Winters Performance Products, Inc. See rear of catalog or visit web site for limited warranty and venue provision.

7

Car Art!

Assembly P/N SR2520STB shown with Option SR8207-CA Polishing

ASSEMBLIES

SR2520STB Big Bearing Flanged Axle

SR2525STB Big Bearing Flanged Axle (Torino®)

Big Bearing Rears Accommodate Stock 3.150” O.D. Axle Bearings

POPULAR OPTIONS

SR2980

SR8207-CA

SR8211CF

SR8247

SR8275-1

SR8277

Axle Set

Polishing

Billet Gear Cover

Helical Gear (Specify Ratio)

Yoke, 1350 Series

Stainless Steel Hardware

See Pages 36-37 For Optional Gear Covers

WINTERS TRACK

P/N SR2419

Our 31 Spline Winters Track Differential is

standard equipment in all Steel Tube & Bell

Champ Adapter Assemblies. If purchased separately, it must be used with P/N SR2493-01

Champ Adapter Bells.

A

Axle Flange to Axle Flange 56” Standard

B

Housing Flange to Housing Flange 51” Standard

See Pages 46-47 for Exploded View and Parts List

WINTERS STEEL TUBE & BELL

P/N SR4900

Steel Tube & Bell with Big

Bearing

P/N SR4905

P/N SR2493-01 Champ Adapter Bell. For use with Winters Steel Tube

& Bell. Must be used with Winters Track P/N SR2419.

Steel Tube & Bell with Big

Bearing (Torino®)

P/N SR12460

Steel Tube & Bell Tube Seal

©2013 Winters Performance Products, Inc. See rear of catalog or visit web site for limited warranty and venue provision.

8

CHAMP ADAPTER

Fabulous, High Performance

Rear Ends!

Ideal for big horsepower cars, this combination

adapts Original Early Ford® Style Steel Tubes

and Bells to our full size Championship Quick

Change Rear. This assembly includes a Winters

Track Differential designed specifically for this

application, Heat Treated Lower Shaft and a 10

Spline, Straight Cut Gear Set of your choice.

©2013 Winters Performance Products, Inc. See rear of catalog or visit web site for limited warranty and venue provision.

9

Put A Real Hot Rod Rear In Your

Hot Rod!

Assembly P/N SR3600 shown with Option SR8207

Polishing

ASSEMBLIES

SR3600 Sprint Center with Champ Adapter Bells

POPULAR OPTIONS

SR8207-CA

SR8211

SR8247

SR8275-1

Polishing

Billet Gear Cover

Helical Gear (Specify Ratio)

Yoke, 1350 Series

A

Axle Flange to Axle Flange

56” Standard

B

Housing Flange to Housing Flange

51” Standard

See Pages 46-47 for Exploded View and Parts List

See Pages 36-37 For Optional Gear Covers

WINTERS TRACK

P/N SR2419

Our 31 Spline Winters Track Differential is

standard equipment in all Champ Adapter

Assemblies. If purchased separately, it must be

used with P/N SR2493 Champ Adapter Bells.

P/N SR2493 Champ Adapter Bell.

For use with Early Ford® Style Steel

Tube & Bell. Must be used with

Winters Track P/N SR2419.

P/N SR3600 shown with Classic

Axle Tubes (not included), Standard

Gear Cover & Option SR8207

Polishing.

Use Winters Semi-Synthetic

Lube with Moly 80-90-140

P/N SR1730

©2013 Winters Performance Products, Inc. See rear of catalog or visit web site for limited warranty and venue provision.

10

CHAMPIONSHIP

INDEPENDENT

The Most Advanced Independent

Quick Change Available!

What happens when you cross an Independent

Rear with a Quick Change? The absolute

ultimate Independent Rear money can buy! This

assembly includes a 10”, 4.12 Ring & Pinion,

Heat Treated Lower Shaft, Winters Track

Differential, Caliper Mount Side Bells, Roller

Support Bearing Upgrade, Pinion Lock Nut

Assembly, 1350 Series Flange Yoke and your

choice of a 10 Spline, Straight Cut Gear Set.

©2013 Winters Performance Products, Inc. See rear of catalog or visit web site for limited warranty and venue provision.

11

Quality...Plain & Simple!

Assembly P/N SRP437 shown with Standard Gear Cover,

Kit P/N SR2838 Dual Inboard Brakes & Option SR8207

Polishing

ASSEMBLIES

See Pages 48-49 for Exploded View and Parts List

SRP437

10” Independent

SRP437NQ 10” Non-Quick Change

SRP337

10” Independent w/Aluminum Spool

POPULAR OPTIONS

SR8207

SR8211CF

SR8219

SR8247

SR8275-1

Polishing

Billet Gear Cover

CV Joint Flange, HD Porsche®

Helical Gear (Specify Ratio)

Yoke, 1350 Series

Aluminum Spool P/N SR3353

standard on Assembly

SRP337.

Assembly shown with Option

SR8219 CV Joint Flange.

Assembly P/N SRP437

Corvette Style shown with

Standard Gear Cover & Option

SR8207 Polishing.

WINTERS TRACK

P/N SR2418

Our 31 Spline Winters Track Differential is standard

equipment in all Championship Independent Assemblies. CNC machined to exacting tolerances. This

virtually unbreakable, parallel gear design automatically senses wheel spin and delivers positive traction.

Non-Quick Change Independent Assembly P/N SRP437NQ

Corvette Style shown.

©2013 Winters Performance Products, Inc. See rear of catalog or visit web site for limited warranty and venue provision.

12

V8

INDEPENDENT

Built From Scratch!

A V8 version of our Independent Quick Change.

This assembly includes a 8 3/8”, 3.78 Ring

& Pinion, Heat Treated Lower Shaft, Winters

Wedgelock Differential, Caliper Mount Side

Bells, Support Bearing Upgrade, Pinion Lock Nut

Assembly and your choice of a 6 Spline, Straight

Cut Gear Set.

©2013 Winters Performance Products, Inc. See rear of catalog or visit web site for limited warranty and venue provision.

13

ASSEMBLIES

SRP437-838

8 3/8” w/Wedgelock

SRP437-838-AS 8 3/8” w/Aluminum Spool

SRP437-838NQ 8 3/8” Non-Quick Change

POPULAR OPTIONS

SR8207

SR8211

SR8247

SR8275-1

SR9132

SR9133

SR9134

Polishing

Billet Gear Cover

Helical Gear (Specify Ratio)

Yoke, 1350 Series

Polished Gear Cover

Machined Gear Cover

Natural Cast Gear Cover

P/N SR12350P Polished

Gear Cover, Option

SR9132

P/N SR12350M

Machined Gear Cover,

Option SR9133

P/N SR12350 Natural

Cast Gear Cover, Option

SR9134

7” INDEPENDENT

ASSEMBLY P/N SRP437-7 w/Wedgelock

See Pages 36-37 For Optional Gear Covers

WEDGELOCK

P/N SR3252

The Wedgelock is an all gear drive differential and

is standard equipment in all V8 Independent Rears.

This unique race proven gear design automatically

senses wheel spin and delivers positive traction.

Machined to accept stock steel bells. Very Smooth!

Very Durable!

6 5/16”

9 3/32”

3 1/2”

2 1/2”

9 1/4”

©2013 Winters Performance Products, Inc. See rear of catalog or visit web site for limited warranty and venue provision.

14

STEEL TUBE & BELL

V8

The Difference Is In The Details!

Nostalgia has never been better! This amazing

assembly separates extraordinary from ordinary! Built to your specs, our Steel Tube & Bell

V8 Quick Change includes a 3.78 Ring & Pinion,

Wedgelock Differential (see page 17), Inner

Tube Seals and one set of Straight Cut , 6 Spline

Gears of your choice.

©2013 Winters Performance Products, Inc. See rear of catalog or visit web site for limited warranty and venue provision.

You Asked & We Delivered!

Assembly P/N SR2220STB shown with Option SR9132 Polished Gear Cover,

Option SR8277-STB Stainless Steel Hardware & Option SR8207 Polishing.

ASSEMBLIES

SR2220STB Big Bearing Flanged Axle

SR2550STB Big Bearing Flanged Axle (Torino®)

Big Bearing Rears Accommodate Stock 3.150” O.D. Axle Bearings

Please Note: When assembled, axle will be 1/2” longer on left side.

POPULAR OPTIONS

SR2980

SR8154-6

SR8154-10

SR8207-V

SR8211-V8B

SR8247-SRH6

SR8277-STB

SR9132

SR9133

SR9134

Axle Set

Closed Drive, 6 Spline

Closed Drive, 10 Spline

Polishing

Polished Billet Gear Cover

Helical Gear (Specify Ratio)

Stainless Steel Hardware

Polished Gear Cover

Machined Gear Cover

Natural Cast Gear Cover

A

Axle Flange to Axle Flange

56” Standard

B

Housing Flange to Housing Flange

51” Standard

See Pages 50-51 for Exploded View and Parts List

See Pages 36-37 For Optional Gear Covers

P/N SR12350P

Polished Gear

Cover, Option

SR9132

P/N SR12350M

Machined Gear

Cover, Option

SR9133

P/N SR12350

Natural Cast Gear

Cover, Option

SR9134

Assembly P/N SR2220STB shown with Standard Straight Finned

Gear Cover, Option SR8277-STB Stainless Steel Hardware &

Option SR8207-V Polishing.

©2013 Winters Performance Products, Inc. See rear of catalog or visit web site for limited warranty and venue provision.

15

16

V8

QUICK CHANGE

Get Use To The Stares!

Legendary styling and cutting edge technology

for you Roadster guys! Our V8 Quick Change

Rear features an 8 3/8” Ring & Pinion, Heat

Treated Lower Shaft, Wedgelock Differential, Axle Seals and one Straight Cut, 6 Spline

Gear Set of your choice. Uses stock appearing

Flanged 31 Spline Axles (sold separately) that

will accommodate after-marker disc or stock

brakes.

©2013 Winters Performance Products, Inc. See rear of catalog or visit web site for limited warranty and venue provision.

17

Outrageous!

Assembly P/N SR2220 shown with Standard Straight Finned Gear Cover, Option SR8277-V8

Stainless Steel Hardware & Option SR8207 Polishing.

ASSEMBLIES

SR2220 Big Bearing Flanged Axle

SR2550 Big Bearing Flanged Axle (Torino®)

Big Bearing Rears Accommodate Stock 3.150” O.D. Axle Bearings

Please Note: When assembled, axle will be 1/2” longer on left side.

POPULAR OPTIONS

SR2980

Axle Set

SR8207

Polishing

SR8211-V8B Billet Gear Cover

SR8247

Helical Gear (Specify Ratio)

SR8277-V8 Stainless Steel Hardware

SR9132

Polished Cast Gear Cover

SR9133

Machined Gear Cover

SR9134

Natural Cast Gear Cover

See Pages 36-37 For Optional Gear Covers

WEDGELOCK

See Pages 50-51 for Exploded View and Parts List

P/N SR12350P Polished

Gear Cover, Option

SR9132

P/N SR12350M

Machined Gear Cover,

Option SR9133

P/N SR12350 Natural

Cast Gear Cover, Option

SR9134

P/N SR1792-31 31 Spline

P/N SR1792-28 28 Spline

The Wedgelock is an all gear drive differential and is

standard equipment in all V8 Quick Change Rears. This

unique race proven gear design automatically senses

wheel spin and delivers positive traction. Machined to

accept stock steel bells. Very Smooth! Very Durable!

Assembly P/N SR2220 shown with Option SR8211-V8B Billet

Gear Cover & Option SR8207 Polishing.

©2013 Winters Performance Products, Inc. See rear of catalog or visit web site for limited warranty and venue provision.

18

V8

CENTER KIT

Old Time Rock & Roll!

A true American heritage, our V8 Quick Change

Center Section is machined to accept Original

Early Ford® Style Steel Tubes & Bells (not

included). The V8 Center Kit includes an

8 3/8”, 3.78 Ring & Pinion, Heat Treated

Lower Shaft, a Wedgelock Differential and one

6 Spline, Straight Cut Gear Set of your choice.

©2013 Winters Performance Products, Inc. See rear of catalog or visit web site for limited warranty and venue provision.

19

P/N SR12350P Polished

Gear Cover, Option

SR9132

P/N SR12350M

Machined Gear Cover,

Option SR9133

P/N SR12350 Natural

Cast Gear Cover, Option

SR9134

Bragging Rights!

ASSEMBLIES

SR3605-31 8 3/8” V8 Center Kit, 31 Spline

SR3605-28 8 3/8” V8 Center Kit, 28 Spline

Please Note: Assembly uses Late Model style 28 or 31 Spline Axles &

requires late style bearing ends machined and welded to Early Ford®

style tubes.

POPULAR OPTIONS

SR8154-6 Closed Drive, 6 Spline

SR8154-10 Closed Drive, 10 Spline

SR8207V

Polishing

SR8211V

Billet Gear Cover

SR8247

Helical Gear (Specify Ratio)

SR9132

Polished Cast Gear Cover

SR9133

Machined Gear Cover

SR9134

Natural Cast Gear Cover

See Pages 52-53 for Exploded View and Parts List

WEDGELOCK

P/N SR1792V-31 31 Spline

P/N SR1792V-28 28 Spline

The Wedgelock is an all gear drive differential and is standard equipment in all V8

Center kits. This unique race proven gear

design automatically senses wheel spin and

delivers positive traction. Machined to accept

stock steel bells. Very Smooth! Very Durable!

See Pages 36-37 For Optional Gear Covers

©2013 Winters Performance Products, Inc. See rear of catalog or visit web site for limited warranty and venue provision.

20

EARLY FORD ®

V8 CENTER KIT

Build Your Own Custom Rear End!

This assembly uses Original Early Ford® Steel

Tubes & Bells, axles and carrier assembly. This

kit comes complete with one Quick Change

Center Section, 4.11 Ring & Pinion, one axle

housing Gasket Set, one Carrier Bearing, one

Straight Cut, 6 Spline Gear Set of your choice,

all hardware and instructions.

©2013 Winters Performance Products, Inc. See rear of catalog or visit web site for limited warranty and venue provision.

21

Ready To Install!

ASSEMBLIES

SR3620

8 3/8” Early Ford® V8 Center Kit

Assembly shown with Option SR8154-6 Closed

Drive Line, 6 Spline

POPULAR OPTIONS

SR8154-6

SR8154-10

SR8207V

SR8211V

SR8247

SR9132

SR9133

SR9134

Closed Drive, 6 Spline

Closed Drive, 10 Spline

Polishing

Billet Gear Cover

Helical Gear (Specify Ratio)

Polished Cast Gear Cover

Machined Gear Cover

Natural Cast Gear Cover

Assembly P/N SR3620 shown with Standard

Straight Finned Gear Cover, Option SR8207-V

Polishing & Stock Steel Bells (not included)

See Pages 36-37 For Optional Gear Covers

Use Winters Semi-Synthetic

Lube with Moly 80-90-140

P/N SR1730

P/N SR12350P Polished

P/N SR12350M

P/N SR12350 Natural

Gear Cover, Option

Machined Gear Cover,

Cast Gear Cover, Option

SR9132

Option SR9133

SR9134

©2013 Winters Performance Products, Inc. See rear of catalog or visit web site for limited warranty and venue provision.

22

XTREMELINER

The Most Advanced QC Available!

We had the Bonneville Salt Flats in mind when

we created this center section and side bells for

our 10”, 3.08 and 2.00 Ratio Ring & Pinion

Quick Change. Whether you are going for a land

speed record or you just want a different ratio

for the street, you will benefit from a beefed-up

Center Section, Heat Treated Lower Shaft, 22

Spline Quick Change Gears, Heavy Duty Cover

and the largest size Pinion Gear ever in a Quick

Change.

©2013 Winters Performance Products, Inc. See rear of catalog or visit web site for limited warranty and venue provision.

23

300 MPH Club!

Choose from our standard 3.08 or optional 2.00 Ring & Pinion

Assembly P/N SR3920 shown with Standard Gear Cover & Option SR8207-308 Polishing

ASSEMBLIES

SR3920

SR3925

SR3910

SR3963

SR3975

3.08

3.08

3.08

3.08

3.08

Big Bearing Flanged Axle

Big Bearing Flanged Axle (Torino®)

Super Speedway Hubs

2 1/2” Grand National Hubs

2 1/2” Wide 5 Hubs

Big Bearing Rears Accommodate Stock 3.150” O.D. Axle Bearings

POPULAR OPTIONS

SR8207-308 Polishing

SR8121W

31 Spline Winters Track

SR8275-1

Yoke, 1350 Series

SR81200

2.00 Ratio Ring & Pinion

SR8121W-200 31 Spline Winters Track-2.00

Limited Applications

SR8115-31

31 Spline Aluminum Spool

SR8115-35

35 Spline Aluminum Spool

Dana Series

1280/1310 Yoke

See Pages 54-55 for Exploded View and Parts List

WINTERS TRACK

SR6513-31-200

2.00 Ratio Ring & Pinion can only be used with the

Winters Track Differential.

Assembly P/N SR3920 shown with Option SR8207308 Polishing & Option SR8275-1 1350 Series Yoke

Aluminum Spool

P/N SR4075A-31, 31 Spline

P/N SR4075A-35, 35 Spline

©2013 Winters Performance Products, Inc. See rear of catalog or visit web site for limited warranty and venue provision.

24

BANJO STYLE

FULL SIZE REAR

Crossing The Line!

Go wild or mild with nothing but the newest

parts and technology. This rear end assembly

features a 10”, 4.12 Ring & Pinion and our

Winters Track Differential. OEM style bearing

cups on the tube ends allow you to use flanged

axles, after-market disc or stock brakes and the

wheels you want.

©2013 Winters Performance Products, Inc. See rear of catalog or visit web site for limited warranty and venue provision.

25

When Only The Best Will Do!

ASSEMBLIES

SR4220 Big Bearing Flanged Axle

SR4225 Big Bearing Flanged Axle (Torino®)

Big Bearing Rears Accommodate Stock 3.150” O.D. Axle Bearings

POPULAR OPTIONS

SR2980

SR8207

Axle Set

Polishing

See Pages 56-57 for Exploded View and Parts List

WINTERS TRACK

P/N SR6513-31

Use Winters Semi-Synthetic

Lube with Moly 80-90-140

P/N SR1730

Our 31 Spline Winters Track Differential is standard

equipment in all Full Size Banjo Style Assemblies.

CNC machined to exacting tolerances. This virtually

unbreakable, parallel gear design automatically

senses wheel spin and delivers positive traction.

©2013 Winters Performance Products, Inc. See rear of catalog or visit web site for limited warranty and venue provision.

26

STEEL TUBE & BELL

BANJO

Sometimes We Find The Chance To

Improve What Henry Built!

Taking the Banjo to the next level! Stock

appearing cast aluminum Banjo Center with

Winters Steel Tubes and Bells. Built to your

specs, this rear comes complete with an

8 3/8”, 3.78 Ratio Ring & Pinion and a

Wedgelock Differential.

©2013 Winters Performance Products, Inc. See rear of catalog or visit web site for limited warranty and venue provision.

27

Puttin’ Power To The Pavement!

ASSEMBLIES

SR4220MSTB Big Bearing Flanged Axle

SR4225MSTB Big Bearing Flanged Axle (Torino®)

Big Bearing Rears Accommodate Stock 3.150” O.D. Axle Bearings

POPULAR OPTIONS

SR2980

SR8207-BAN

Axle Set

Polishing

WEDGELOCK

A

P/N SR1792-31 31 Spline

P/N SR1792-28 28 Spline

The Wedgelock is an all gear drive differential and

is standard equipment in all Steel Tube & Bell Banjo

Rears. This unique race proven gear design automatically senses wheel spin and delivers positive

traction. Machined to accept stock steel bells. Very

Smooth! Very Durable!

Axle Flange to Axle Flange

56” Standard

B

Housing Flange to Housing Flange

51” Standard

See Pages 58-59 for Exploded View and Parts List

Use Winters Semi-Synthetic

Lube with Moly 80-90-140

P/N SR1730

©2013 Winters Performance Products, Inc. See rear of catalog or visit web site for limited warranty and venue provision.

28

BANJO STYLE

MINI REAR

Taking The Banjo To A New Level!

The 12 Rib Side Bell Mini Version of our Banjo

Style Rear features an 8 3/8”, 3.78 Ring &

Pinion and our Wedgelock Differential. OEM

style bearing cups on the tube ends allow you

to use flanged axles, after-market disc or stock

brakes and the wheels you want.

©2013 Winters Performance Products, Inc. See rear of catalog or visit web site for limited warranty and venue provision.

29

Ooooh Baby!

ASSEMBLIES

SR4220M

SR4225M

Big Bearing Flanged Axle

Big Bearing Flanged Axle (Torino®)

Big Bearing Rears Accommodate Stock 3.150” O.D. Axle Bearings

POPULAR OPTIONS

SR2980

Axle Set

SR8207-MB Polishing

WEDGELOCK

P/N SR1792-31 31 Spline

P/N SR1792-28 28 Spline

See Pages 58-59 for Exploded View and Parts List

The Wedgelock is an all gear drive differential and

is standard equipment in all Mini Style Banjo Rears.

This unique race proven gear design automatically

senses wheel spin and delivers positive traction.

Machined to accept stock steel bells. Very Smooth!

Very Durable!

Use Winters Semi-Synthetic

Lube with Moly 80-90-140

P/N SR1730

©2013 Winters Performance Products, Inc. See rear of catalog or visit web site for limited warranty and venue provision.

30

CHAMPIONSHIP 9”

Break With Tradition!

Suddenly traditional rears know no boundaries. Breaking new ground, our Championship

9” Rear shouts Hot Rodding! Made from super

strong 206 alloy, this 9” offers a new level of

refinement that other rears will be measured

against for years. This rear comes assembled

with Ring & Pinion (specify ratio), Truetrac®

Posi-Trac Differential and aluminum “Daytona”

style Pinion Retainer. Accepts most stock or

after-market equivalent components.

©2013 Winters Performance Products, Inc. See rear of catalog or visit web site for limited warranty and venue provision.

31

Hot Rod History!

ASSEMBLIES

SR92520CR

SR92525CR

Housing Only

SR92540CR

SR92545CR

Big Bearing Flanged Axle

Big Bearing Flanged Axle (Torino®)

with Tubes Installed

Big Bearing Flanged Axle

Big Bearing Flanged Axle (Torino®)

Big Bearing Rears Accommodate Stock 3.150” O.D. Axle Bearings

POPULAR OPTIONS

SR2980

Axle Set

SR8207-3611 Polishing, Cover Only

SR8207-9CR Polishing, Complete

Cover positioned so that fins are horizontal.

TRUETRAC®

P/N SR2230-31

The gear drive, 31 spline Truetrac® uses a unique

gear design that automatically senses wheel spin

and delivers positive traction. 1.782” bearing

journals.

See Pages 60-61 for Exploded View and Parts List

PINION RETAINERS

P/N SR6897

Aluminum

“Daytona” Style

Cover positioned so that fins are vertical.

P/N SR6897-1

Aluminum

“Daytona” Style

Use Winters Semi-Synthetic

Lube with Moly 80-90-140

P/N SR1730

©2013 Winters Performance Products, Inc. See rear of catalog or visit web site for limited warranty and venue provision.

32

9” HOUSING

WITH FLANGED AXLES

American Rodder!

Built to your specs, this assembly includes our

Polished 9” Housing with Steel Tubes, Inner

Tube Seals and a complete set of 31 Spline

Flanged Axles. Pop in a stock Third Member.

Done!

©2013 Winters Performance Products, Inc. See rear of catalog or visit web site for limited warranty and venue provision.

33

Shopping For A New Rear?

Your Shopping Cart Is Now Full!

ASSEMBLIES

SR2540PA

SR2545PA

Big Bearing Flanged Axle

Big Bearing Flanged Axle (Torino®)

See Page 75 for Flanged Axle Info & Ordering Specs

Big Bearing Rears Accommodate Stock 3.150” O.D. Axle Bearings

3RD MEMBERS

3rd Member Assembly consists of housing, carrier bearing

retaining caps, adjusting nuts, pinion nose roller bearing,

locking tabs, level plug and hardware.

Use Winters Semi-Synthetic

Lube with Moly 80-90-140

P/N SR1730

P/N SR1842-03

Nodular Iron with 3 1/4” Bearing Bores.

P/N SR6791-03

Aluminum with 3 1/4” Bearing Bores.

Includes one pair of Adapter Races for

1.782” Differential Bearing Journals.

Hidden Oil Fill/Breather Plug behind the detailed fins.

©2013 Winters Performance Products, Inc. See rear of catalog or visit web site for limited warranty and venue provision.

34

9”

What Cars Dream About!

Clean, simple lines best describes Winters 9”

Rears. With two different impressive housing designs to choose from, this rear comes

assembled with Ring & Pinion (specify ratio),

Truetrac® Posi-Trac Differential, Aluminum 3rd

Member Housing and an Aluminum “Daytona”

Style Pinion Retainer. Uses stock appearing

Flanged 31 Spline Axles (sold separately) that

will accommodate after-market disc or stock

brakes.

©2013 Winters Performance Products, Inc. See rear of catalog or visit web site for limited warranty and venue provision.

35

The Cure For Average!

ASSEMBLIES

SR92520

SR92525

Housing Only

SR2540

SR2545

TRUETRAC®

Big Bearing Flanged Axle

Big Bearing Flanged Axle (Torino®)

with Tubes Installed

Big Bearing Flanged Axle

Big Bearing Flanged Axle (Torino®)

P/N SR2230-31

The gear drive, 31 spline Truetrac®

uses a unique gear design that

automatically senses wheel spin and

delivers positive traction. 1.782”

bearing journals.

Big Bearing Rears Accommodate Stock 3.150” O.D. Axle Bearings

See Page 33 for Available 3rd Members

POPULAR OPTIONS

SR2980

SR8207-9CR

SR8207-D

SR8208-9

SR8249

See Pages 62-63 for Exploded View and Parts List

Axle Set

Polishing, Complete

Detailed Polished Fins

Thermal Dispersant

Machined Housing

Use Winters Semi-Synthetic

Lube with Moly 80-90-140

P/N SR1730

INDIVIDUALIZE YOUR 9”

P/N SR5243 Standard Housing

without Tubes

P/N SR5243 shown with Option

SR8207-9WO Polishing

P/N SR5243 shown with Option

SR8249 Machined Housing &

Option SR8207-9WO Polishing

P/N SR5243 shown with Option

SR8294 Machined Housing &

Option SR8207-D Detailed Polished

Fins

P/N SR5243 shown with Option

SR8294 Machined Housing, Option

SR8207-D Detailed Polished Fins

& Option SR8208-9 Thermal

Dispersant

©2013 Winters Performance Products, Inc. See rear of catalog or visit web site for limited warranty and venue provision.

36

GEAR COVERS

Just Showin’ Off!

Want to be the center of attention? Then trick

out your Quick Change Rear with one of our

optional Billet Aluminum Gear Covers.

©2013 Winters Performance Products, Inc. See rear of catalog or visit web site for limited warranty and venue provision.

37

Option SR8211CF

Option SR4873

Option SR8211

Option SR8211VM

Option SR6630

Option SR6630-Specify Color

Fits Championship Quick Change,

Steel Tube & Bell Champ Adapter,

Champ Adapter & Champ

Independent

Fits Championship Quick Change,

Steel Tube & Bell Champ Adapter,

Champ Adapter & Champ

Independent

Fits Championship Quick Change,

Steel Tube & Bell Champ Adapter,

Champ Adapter, Champ Independent,

V8 Quick Change, Steel Tube & Bell

V8 Quick Change & V8 Center Kits

Fits Championship Quick Change,

Steel Tube & Bell Champ Adapter,

Champ Adapter & Champ

Independent

Fits Championship Quick Change,

Steel Tube & Bell Champ Adapter,

Champ Adapter & Champ

Independent

Fits Championship Quick Change,

Steel Tube & Bell Champ Adapter,

Champ Adapter & Champ

Independent

Also available with

red or blue bearing

caps.

Option SR8211V

Fits V8 Quick Change, Steel Tube &

Bell V8 Quick Change & V8 Center

Kits

Option SR8211-V8B

Fits V8 Quick Change, Steel Tube &

Bell V8 Quick Change & V8 Center

Kits

©2013 Winters Performance Products, Inc. See rear of catalog or visit web site for limited warranty and venue provision.

38

BRAKE KITS

©2013 Winters Performance Products, Inc. See rear of catalog or visit web site for limited warranty and venue provision.

39

STAINLESS STEEL REAR BRAKE KIT

KIT P/N SR4917SS

All mounting hardware and backing plates are made of stainless steel. The zinc plated rotors are drilled and slotted for that

great look and stopping power. Calipers come polished to

top off this kit. All hardware is included.

• 3.062” Pilot

• 2 1/2” Offset

• 12 1/8” Rotor Diameter

DUAL INBOARD BRAKE KIT

KIT P/N SR2838

Built specifically for an Independent Quick Change that

requires Inboard Brakes. Kit comes with Polished calipers and

all hardware needed to install.

REAR DRUM BRAKE KIT

KIT P/N SR4918

•

•

•

•

11” x 2 1/4” Shoe

5 x 5 1/2”, 5 x 4 1/2” & 5 x 4 3/4” Bolt Pattern

Fits Torino® Style Housing End with 2 3/8” Offset

2.875” Pilot

©2013 Winters Performance Products, Inc. See rear of catalog or visit web site for limited warranty and venue provision.

40

TECH INFO

SAVE THIS INFO FOR REFERENCE

This tech info is intended to be used as a guide in the maintenance and set-up of your Winters

Performance Rear End. Our instructions, along with your common sense, will give you the satisfaction and performance that you expect and deserve when you use Winters Performance.

MODEL #

TYPE

SERIAL #

PURCHASE DATE

©2013 Winters Performance Products, Inc. See rear of catalog or visit web site for limited warranty and venue provision.

FREQUENTLY ASKED QUESTIONS

41

vented cap

• What type of oil should I use in my Winters Rear End?

Use a good quality lube, such as Winters 80-90-140 semi-synthetic with moly.

• What oil level should I maintain in my Winters Rear End?

At two places. (1) The rear end cavity. (2) Quick change gear cavity. See Figure 1 at right. DO NOT OVER

FILL. To much lube causes excessive heat!

Championship 10”

Maintain oil level at 2” below axle center line. Make sure the car is level when checking oil.

V8 8 3/8”, Mini

Maintain oil level at 1 3/4” below axle center line. Make sure the car is level when checking oil.

breather/fill can

Can be drilled

& tapped

for fill can.

Pinion inspection plug (option)

can be used for filling. NOT OIL LEVEL

Filling Port

Oil Level Plug

CL

2"

RIGHT SIDE

Always maintain oil level at 2" below center line.

Make sure rear is level when checking oil.

LEFT SIDE

Q.C. gear cavity oil level plug

Figure 1

• How do I fill my Winters Rear End and quick change gear cavity with oil?

The level plug is in the right side bell (See Figure 1). Optional pinion inspection plug in the right bell may be used as a fill plug. DO NOT USE INSPECTION PLUG TO DETERMINE FLUID LEVEL.

• Ring Gear Bolt Torque Specifications

Threaded Ring Gear Bolts- 60 ft lbs using red thread lock.

• Thru Bolt & Side Bell Stud Torque Specifications

Full Size Rears (7/16” Thru Bolts)- 35 ft lbs

V8/Mini (3/8” Studs)- 30 ft lbs

• How do I install a side tube into a side bell?

DO NOT TORCH! Bell cracking may occur. Place the tube in a 5 gallon bucket filled with ice. Make sure the bell is clean and free of chemicals and flammable materials. Heat the side bell in an oven

to 270°-300°F. Vaseline the bell bore and drop the tube into the bell.

• Can I weld brackets to my steel side tubes?

Yes. Weld a series of 1/2” long “tracks” along the bracket starting at the ends, then alternate back and forth towards the center. Long continuous welds will heat and “draw” the tubing, causing

distortion.

• Can I use helical quick change gears in my Winters Rear End?

Helical cut gears, although not recommended in racing applications, do have their advantages in street applications. Quick change gear noise at highway speeds can be reduced with helical cut

gears versus conventional straight cut gears. Quick change gear end play (clearance) must be limited to .010 max.

• Can gears from different gear sets be mixed to form new ratios?

No. Gears are matched by pitch, diameter, tooth count and paired for proper backlash. Once two gears are paired, they must remain together.

• What is the correct way to install quick change gears?

The machined lip faces out.

• Can I remove my tubes and bells for painting?

Yes. Remove left side bell first by standing rear on right side tube, this will keep the differential from falling out. Before reassembling, now is a good time to pre-lube all seals and bearings.

Maintaining a dirt free environment will result in a clean rear.

• How do I remove my pinion in my Winters Rear End?

Make sure the center is clean and free of chemicals and flammable materials. Heat the center in an oven to 270°-300°F. EXERCISE CAUTION- MAGNESIUM CAN BE IGNITED! Torching your center

will damage the casting and ring & pinion life will be adversely affected.

• Can I determine ring & pinion ration without opening the rear?

Yes. Elevate the car (engine off). Remove quick change gears. Chalk mark the tire at the 12 o’clock position. Chalk mark the pinion at the 12 o’clock position. Rotate the tire by hand one complete

revolution. Count pinion rotation as tire is rotated. Just past four revolutions = 4.11/4.12, 3 7/8 revolutions = 3.78.

©2013 Winters Performance Products, Inc. See rear of catalog or visit web site for limited warranty and venue provision.

CHAMPIONSHIP QUICK CHANGE

42

SR2520 Big Bearing Flanged Axle

SR2525 Big Bearing Flanged Axle (Torino®)

See pages 64-66 for Set-Up Instructions

56

55

54

44

50

51

12

57

48

49

43

11

3

45

4

6

38

7

39

40

41

42

47

4 Rib

8

13

9

10

37

36

5

61 60

6 Rib

14

17

26

25

24

23

22

21

20

19

18

10

16

1

16

58

9

8

59

7

34

15

8 Rib

35

53

2

51

29

28

51

6

52

27

8 Rib Contoured

Use Winters Semi-Synthetic

Lube with Moly 80-90-140

P/N SR1730

33

©2013 Winters Performance Products, Inc. See rear of catalog or visit web site for limited warranty and venue provision.

CHAMPIONSHIP QUICK CHANGE

43

Must be specific when ordering replacement parts. P/N’s shown are unpolished. Polishing

available at extra charge.

#

P/N

DESCRIPTION

1

2*

2*

2*

3*

3*

3*

3*

3*

4

5

6*

6*

7

8

9*

10*

11

12

13

14

15

16

17

18

19

20

21

22

23

24

25

26

27

5840

6697-01

1663-01

5016-01

6697-02

1663-02

5016-02

5016-05

5016-02M

6513-31

5714

7403

7403T

7205

7310

7340

5295

7852

7815

7111B

7331

7339

7308

7307

5055

6485R

7445

6484

5020

6296A

2374

7110

8500

6729HD

Aluminum “Sprint” Center

Aluminum 4 Rib Right Side Bell

Aluminum HD 6 Rib Right Side Bell

Aluminum HD 8 Rib Right Side Bell

Aluminum 4 Rib Left Side Bell

Aluminum HD 6 Rib Left Side Bell

Aluminum HD 8 Rib Left Side Bell

Aluminum Lightweight 8 Rib Right Side Bell

Aluminum Lightweight 8 Rib Left Side Bell

Winters Track, 31 Spline

Ring & Pinion (4.12 Ratio Standard)

O’Ring, 8 Rib Bell

O’Ring, 4 & 6 Rib Bell

Seal, Side Bell

Bearing Cup, Side Bell

Bearing Cone, Differentials

Shim Kit, Differentials

Ring Gear Bolt, Threaded Ring Gear

3/8” Belleville Washer, Threaded Ring Gear

3/8” Recessed Socket Head Pipe Plug

Roller Bearing, Pinion Nose

Shielded Ball Bearing, Lower Shaft

Bearing Cone, Pinion Shaft

Double Bearing Cup, Pinion Shaft

Bearing Washer

Posi-Lock Nut, Pinion Shaft

O’Ring, Posi-Lock

Posi-Lock Retainer, Pinion Shaft

Retaining Ring, Pinion

Retaining Plate, Pinion

Lock Tab

3/8-16 x 1” HHCS, Retaining Plate

Quick Change Gear Set

Gasket, Gear Cover, HD

QTY REQ’D

1

1

1

1

1

1

1

1

1

1

1

2

2

2

2

2

1

12

12

2

1

1

2

1

1

1

1

1

1

1

3

6

1

1

#

P/N

DESCRIPTION

28*

29*

33

34

35

36

37

38

39

40

41

42

43

44

45

47*

47*

47*

48

49

50

51

52

53

54*

54*

55

56

57

58*

58*

59

60

61

6508

7332

7794

7398

7802

7610

5003

7390

7413

7652

7204T

7474

5018-01M

7114

7107

3533

5038AS

388

5037

7109Y

7176

7178

7177

7117

7155

6149

7167

7137

5010

7109

7109S

7114

7454

6857

Gear Cover

Ball Bearing, Gear Cover

3/8-16 Steel High Nut

5/16” Diameter Ball, Gear Cover

3/8-16 x 1 3/4” Stud, Gear Cover

Retaining Ring, Lower Shaft

Heat Treated Lower Shaft

Front Ball Bearing, Lower Shaft

O’Ring, Seal Plate

Retaining Ring, Seal Plate (.750” Seal)

Seal, Seal Plate (Thick Seal .750”)

O’Ring, Seal

Seal Plate, .750” Seal (.375” P/N 5018M)

3/8” SAE Flatwasher

3/8-16 x 1 1/4” HHCS, Seal Plate

Drive Yoke, 1310, Steel

Drive Yoke, 1310, Billet Aluminum

Drive Yoke, 1350, Steel

Retaining Washer, Drive Yoke

3/8-24 x 1” HHCS, Drive Yoke

7/16-20 x 5 1/2” Thrubolt

7/16” SAE Flatwasher, Thrubolt

7/16-20 Flanged Locknut, Thrubolt

7/16-14 x 1 1/4” HHCS

1/2-13 Adjusting Screw, 8 Rib Bell

1/2-13 Adjusting Screw, 4 & 6 Rib Bell

1/2” SAE Flatwasher, Adjusting Screw

1/2-13 Jam Nut, Adjusting Screw

Thrustblock

3/8-24 x 1” HHCS, 8 Rib Side Bell

3/8-24 x 3/4” HHCS, 4 & 6 Rib Side Bell

3/8” SAE Flatwasher

O’Ring, Plug

Inspection Plug

* Part Numbers in this list may vary depending on options ordered at time of purchase. Please check the assembly tag included with your rear.

©2013 Winters Performance Products, Inc. See rear of catalog or visit web site for limited warranty and venue provision.

QTY REQ’D

1

2

10

10

10

1

1

1

1

1

1

1

1

6

6

1

1

1

1

1

10

22

10

2

1

1

1

1

1

16

16

16

1

1

CHAMPIONSHIP HEAVY DUTY

44

SR2520HD Big Bearing Flanged Axle

SR2525HD Big Bearing Flanged Axle (Torino®)

See pages 64-66 for Set-Up Instructions

49

48

47

37

44

38

40

41

45

36

42

2

43

50

4

26

25

33

27

34

35

39

4 Rib

32

28

29

54

31

30

6 Rib

5

6

29

7

1

8

11

13

56

16

17

10

9

7

28

51

27

12

10

14

19

22

23

20

24

21

25

45

53

3

45

18

55

8 Rib

52

26

46

15

Use Winters Semi-Synthetic

Lube with Moly 80-90-140

P/N SR1730

©2013 Winters Performance Products, Inc. See rear of catalog or visit web site for limited warranty and venue provision.

8 Rib Contoured

CHAMPIONSHIP HEAVY DUTY

45

Must be specific when ordering replacement parts. P/N’s shown are unpolished. Polishing

available at extra charge.

#

P/N

DESCRIPTION

1

2*

2*

2*

3*

3*

3*

3*

3*

4

5

6

7

8

9

10

11

12

13

14

15

16

17

18

19

20

21

22

23

24

25*

25*

26

5012

6697-02

1663-02

5016-02

6697-01

1663-01

5016-01

5016-05

5016-02M

6513-31

5714

7331

7308

7307

5055

5032R

5056

7339

5020

6296A

5021

7110

2374

8500

8659

1764HD

5017HD

7111B

7108

7114HD

7403

7403T

7205

Aluminum “Sprint” Center

Aluminum 4 Rib Left Side Bell

Aluminum HD 6 Rib Left Side Bell

Aluminum HD 8 Rib Left Side Bell

Aluminum 4 Rib Right Side Bell

Aluminum HD 6 Rib Right Side Bell

Aluminum HD 8 Rib Right Side Bell

Aluminum Lightweight 8 Rib Right Side Bell

Aluminum Lightweight 8 Rib Left Side Bell

Winters Track, 31 Spline

Ring & Pinion (4.12 Ratio Standard)

Roller Bearing,Pinion Nose

Bearing Cone, Pinion Shaft

Double Bearing Cup, Pinion Shaft

Bearing Washer

Jam Nut, Pinion Shaft

Bearing Lockwasher

Shielded Ball Bearing, Lower Shaft

Retaining Ring, Pinion

Retaining Plate, Pinion

Quick Change Gear Spacer

3/8-16 x 1” HHCS, Retainer Plate

Lock Tab

Quick Change Gear Set

Ball Bearing, Gear Cover

Gasket, Gear Cover, HD

Aluminum Gear Cover, Less Bearings

3/8” SH Pipe Plug

3/8-16 x 4” HHCS, Gear Cover

3/8” HD Flatwasher

O’Ring, 8 Rib Side Bell

O’Ring, 4 & 6 Rib Side Bell

Seal, Side Bell

QTY REQ’D

1

1

1

1

1

1

1

1

1

1

1

1

2

1

1

2

1

1

1

1

1

6

3

1

2

1

1

4

6

6

2

2

2

#

P/N

DESCRIPTION

27

28*

29

30

31

32

33

34

35

36

37

38

39*

39*

39*

40

41

42

43

44

45

46

47

48

49

50

51

52

53

54

55

56

7310

7340

5295

7610

5003

7311

7413

7652

7204T

5018-01M

7114

7107

5038

5038AS

3588M

5037

7109Y

7852

7815

7176

7178

7177

7155

7167

7137

5010

7109

7114

7117

7111B

3258

8087

Bearing Cup, Side Bell

Bearing Cone, Differentials

Shim Kit, Differentials

Retaining Ring, Lower Shaft

Heat Treated Lower Shaft

Double Row Ball Bearing, Lower Shaft

O’Ring, Seal Plate

Retaining Ring, Seal Plate (.750” Seal)

Seal, Seal Plate (Thick Seal .750”)

Seal Plate, .750” Seal

3/8” SAE Flatwasher

3/8-16 x 1 1/4” HHCS, Seal Plate

Drive Yoke, 1310, Steel

Drive Yoke, 1310, Aluminum

Drive Yoke, 1350, Steel

Retaining Washer, Drive Yoke

3/8-24 x 1” HHCS, Drive Yoke

Ring Gear Bolt, Threaded Ring Gear

3/8” Belleville Washer

7/16-20 x 5 1/2” Thrubolt

7/16” SAE Flatwasher

7/16-20 Flanged Locknut

1/2-13 Adjusting Screw

1/2” SAE Flatwasher

1/2-13 Jam Nut, Adjusting Screw

Thrustblock, Adjusting Screw

3/8-24 x 1” HHCS, Side Bell

3/8” SAE Flatwasher

7/16-14 x 1 1/4” HHCS

3/8” SH Pipe Plug

Bearing Retainer, Gear Cover

1/4-20 x 1/2” BHCS

* Part Numbers in this list may vary depending on options ordered at time of purchase. Please check the assembly tag included with your rear.

©2013 Winters Performance Products, Inc. See rear of catalog or visit web site for limited warranty and venue provision.

QTY REQ’D

2

2

2

1

1

1

1

1

1

1

6

6

1

1

1

1

1

12

12

10

22

10

1

1

1

1

16

16

2

2

1

6

CHAMP ADAPTER

46

SR3600 “Sprint” Center with Champ Adapter Bells

*SR2520STB Big Bearing Flanged Axle

*SR2525STB Big Bearing Flanged Axle (Torino®)

* Steel Tube & Bell Assembly

See pages 64-66 for Set-Up Instructions

44

45

48

49

43

11

12

62

4

6

38

7

8

13

9

39

40

41

42

47

37

10

36

5

Use Winters Semi-Synthetic

Lube with Moly 80-90-140

P/N SR1730

61

60

14

10

17

26

28

27

25

24

23

22

21

20

19

18

16

9

8

1

7

16

34

15

35

6

62

29

65

Ste

33

Steel Tube & Bell Tube Seal

Assembly P/N SR12460

el T

64

ub

e&

63

Be

ll S

69

et-

Up

68

67

66

©2013 Winters Performance Products, Inc. See rear of catalog or visit web site for limited warranty and venue provision.

CHAMP ADAPTER

47

Must be specific when ordering replacement parts. P/N’s shown are unpolished. Polishing

available at extra charge.

#

P/N

DESCRIPTION

1

4

5

6

7

8

9

10

11

12

13

14

15

16

17

18

19

20

21

22

23

24

25

26

27

28

29

33

5840

2419

5714

7403T

7205

7357

7358

6115

7852

7815

7111B

7331

7339

7308

7307

5055

6485R

7445

6484

5020

6296A

2374

7110

8500

6729HD

6508

7332

7794

Aluminum “Sprint” Center Section

Winters Track, 31 Spline

Ring & Pinion, 4.12 Standard

O’Ring, 4 & 6 Rib Bell

Seal, Side Bell

Bearing Cup, Side Bell

Bearing Cone

Shim Kit

Ring Gear Bolt, Threaded Ring Gear

3/8” Belleville Washer, Threaded Ring Gear

3/8” Recessed Socket Head Pipe Plug

Roller Bearing, Pinion Nose

Shielded Ball Bearing, Lower Shaft

Bearing Cone, Pinion Shaft

Double Bearing Cup, Pinion Shaft

Bearing Washer

Posi-Lock Nut, Pinion Shaft

O’Ring, Posi-Lock

Posi-Lock Retainer, Pinion Shaft

Retaining Ring, Pinion

Retaining Plate, Pinion

Lock Tab

3/8-16 x 1” HHCS, Retaining Plate

Quick Change Gear Set

Gasket, Gear Cover, HD

Gear Cover

Ball Bearing, Gear Cover

3/8-16 Steel High Nut

QTY REQ’D

1

1

1

2

2

2

2

1

12

12

2

1

1

2

1

1

1

1

1

1

1

3

6

1

1

1

2

10

#

P/N

DESCRIPTION

34

35

36

37

38

39

40

41

42

43

44

45

47*

47*

47*

48

49

60

61

62*

62*

63†

64†

65†

66†

67†

68†

69†

7398

7802

7610

5003

7390

7413

7652

7204T

7474

5018-01M

7114

7107

3533

5038AS

3588

5037

7109Y

7454

6857

2493

2493-01

SR4900

8060

7451

SR4933

SR8376

SR8896

SR7468

5/16” Diameter Ball, Gear Cover

3/8-16 x 1 3/4” Stud, Gear Cover

Retaining Ring, Lower Shaft

Heat Treated Lower Shaft

Front Ball Bearing, Lower Shaft

O’Ring, Seal Plate

Retaining Ring, Seal Plate (.750” Seal)

Seal, Seal Plate (Thick Seal .750”)

O’Ring, Seal

Seal Plate, .750” Seal

3/8” SAE Flatwasher

3/8-16 x 1 1/4” HHCS, Seal Plate

Drive Yoke, 1310, Steel

Drive Yoke, 1310, Billet Aluminum

Drive Yoke, 1350, Steel

Retaining Washer, Drive Yoke

3/8-24 x 1” HHCS, Drive Yoke

O’Ring, Plug

Inspection Plug

Champ Adapter Bell, Early Ford® Steel Tube & Bell

Champ Adapter Bell, Winters Steel Tube & Bell

Steel Tube & Bell Assembly

12pt Side Bell Bolts

8 3/8” Side Bell O’Ring

Seal Adapter

Seal

Retaining Ring

O’Ring

* Part Numbers in this list may vary depending on options ordered at time of purchase. Please check the assembly tag included with your rear. † Steel Tube & Bell Assembly.

©2013 Winters Performance Products, Inc. See rear of catalog or visit web site for limited warranty and venue provision.

QTY REQ’D

10

10

1

1

1

1

1

1

1

1

6

6

1

1

1

1

1

1

1

2

2

2

20

2

2

2

2

6

CHAMPIONSHIP INDEPENDENT

48

SRP437 10” Independent

SRP437NQ 10” Non-Quick Change

SRP337 10” Independent w/Aluminum Spool

See page 67 for Set-Up Instructions

As

sem

bly

81

67

66

49

64

5

63

79

6

78

51

50

36

57

48

75

25

24

23

22

21

20

19

18

17

16

10

14

14

44

55

62

1

15

52

33

13

77

58

32

10

80

9

8

26

79

7

31

47

46

45

59

61

9

41

76

12

8

38

40

35

2 73

7

37

39

43

34

11

71

27

42

55

65

56

72

33

7

53

80

54

70

NS

RP

52

4

68

69

P/

Use Winters Semi-Synthetic

Lube with Moly 80-90-140

P/N SR1730

tio

Op

2

4

70

72

74

69

68

2

R8

nS

19

82

65

6

5

64

78

63

66

Must be specific when ordering replacement parts. P/N’s shown are unpolished. Polishing

available at extra charge.

©2013 Winters Performance Products, Inc. See rear of catalog or visit web site for limited warranty and venue provision.

67

CHAMPIONSHIP INDEPENDENT

#

P/N

DESCRIPTION

1

2

4

5

6

7

8

9

10

11

12

13

14

15

16

17

18

19

20

21

22

23

24

25

26

27

31

32

33

34

35

36

37

38

39

40

41

42

43

44**

5840

2928

7619

7236

7413

7403T

7357

7358

6115

5714

7331

7339

7308

7307

5055

6485R

7445

6484

5020

6296A

2374

7110

8500

6729HD

6508

7332

7794

7802

7398

7610

5003

7390

7413

7653

7204T

7474

5018-01M

7114

7107

6532

Aluminum “Sprint” Center Section

Side Bell

Retaining Ring

Seal, Side Bell

O’Ring, Side Bell Seal

O’Ring, Side Bell

Bearing Cup, Side Bell

Bearing Cone, Differential

Shim Kit

Ring & Pinion, 4.12 Standard

Roller Bearing, Pinion Nose

Shielded Ball Bearing, Lower Shaft

Bearing Cone, Pinion Shaft

Double Bearing Cup, Pinion Shaft

Bearing Washer, Pinion

Posi-Lock Nut

O’Ring, Posi-Lock Retainer

Posi-Lock Retainer

Retaining Ring

Retainer Plate

Lock Tab

3/8-16 x 1” HHCS

Quick Change Gear Set

Gasket, Gear Cover, HD

Gear Cover

Double Roller Ball Bearing w/Snap Ring

3/8-16 Steel High Nut

3/8-16 x 1 3/4” Stud, Gear Cover

5/16” Diameter Steel Ball, Gear Cover Stud

Retaining Ring, Lower Shaft

Heat Treated Lower Shaft

Ball Bearing, Lower Shaft

O’Ring, Seal Plate

Retaining Ring, Seal Plate

Seal, Seal Plate

O’Ring, Seal

Seal Plate, .750” Seal (.375” P/N 5018M)

3/8” SAE Flatwasher

3/8-16 x 1 1/4” HHCS

Spacer, Drive Yoke

QTY REQ’D

1

2

2

2

2

2

2

2

1

1

1

1

2

1

1

1

1

1

1

1

3

6

1

1

1

2

10

10

10

1

1

1

1

1

1

1

1

6

6

1

#

P/N

DESCRIPTION

45*

45*

46

47

48

49

50

51

52

53

54

55

56

57

58

59

61

62

63

63

64

65

66

67

68

69

70

71

72

73

74

75

76

77

78

79

80

81*

82*

3533

5038AS

5037

7109Y

7111A

7852

7815

8069

8005

2940

1459-01

6315-01

6329-02

6330-01

6329-01

6361

6330-02

2941

2943-31

2944CV

2945

7531

6320

7740

7137

7167

6149

7176

7177

5010

7177N

6857

7454

8058

7195

7117

7178

3353

2944CV

Drive Yoke, Steel

Drive Yoke, Aluminum

Retaining Washer, Drive Yoke

3/8-24 x 1” HHCS

Plug

Ring Gear Bolt, Threaded Ring Gear

3/8” Belleville Washer, Threaded Ring Gear

1/2-20 x 2” HHCS

1/2” Belleville Washer

Housing End, Ring Gear Side

Sleeve

Wear Plate

Pinion Gear, Left Hand

Side Gear, Left Hand

Pinion Gear, Right Hand

Central Housing

Side Gear, Right Hand

Housing Cover

Output Flange, Corvette Style

Output Flange, Porsche CV Joint

Seal Plate, Output Flange

Bearing (Remove Shields)

Yoke, For Use With 2943-31 Only

7/16-20 x 3/4” 12pt

1/2-13 Jam Nut, Adjusting Screw

1/2” Flatwasher

1/2-13 Adjusting Screw

7/16-20 x 5 1/2” HHCS

7/16” SAE Flatwasher

Thrust Block

7/16-20 Flanged Locknut

Small Inspection Plug

O’Ring, Inspection Plug

1/2-20 x 1 1/2” HHCS

Bolt

7/16-14 X 1 1/4” HHCS

7/16” SAE Flatwasher

Aluminum Spool

Output Flange, Porsche ® Style

49

QTY REQ’D

* Part Numbers in this list may vary depending on options ordered at time of purchase. Please check the assembly tag included with your rear. ** Used only with P/N 5038AS.

©2013 Winters Performance Products, Inc. See rear of catalog or visit web site for limited warranty and venue provision.

1

1

1

1

1

12

12

4

8

1

4

2

4

1

4

1

1

1

2

2

2

2

2

8

2

2

2

10

22

1

10

1

1

4

16

2

2

1

2

V8 QUICK CHANGE

50

SR2220 Big Bearing Flanged Axle

SR2550 Big Bearing Flanged Axle (Torino®)

*SR2220STB Big Bearing Flanged Axle

*SR2550STB Big Bearing Flanged Axle (Torino®)

* Steel Tube & Bell Assembly

See page 68 for Set-Up Instructions

8

7

11

6

17

5

10

18

2

9

54

55

53

4

59

1

16

Use Winters Semi-Synthetic

Lube with Moly 80-90-140

P/N SR1730

48

22

60

49

50

51

52

56

57

58

61

23

26

25

33

35

34

32

31

29

30

28

27

5

24

6

7

24

63

8

62

4

43

42

47

37

44

45

9

46

2

32

10

11

61

66

Ste

41

36

el T

Steel Tube & Bell Tube Seal

Assembly P/N SR12460

ub

60

65

e&

64

Be

ll S

et-

70

Up

69

68

67

©2013 Winters Performance Products, Inc. See rear of catalog or visit web site for limited warranty and venue provision.

V8 QUICK CHANGE

51

Must be specific when ordering replacement parts. P/N’s shown are unpolished. Polishing

available at extra charge.

#

P/N

DESCRIPTION

1

2

3

4

5

6

7

8

9*

10*

11*

16

17*

18*

22

23

24

25

26

27

28

29

30

31

32

33

34

35

36

37

41

2524HD-01

3180

3180

8411

5295

7340

7310

7205

7905

7916

7885

1792-31

7852

7815

6811

7392

7527

7525

7878

6824

6821

7455

6822

6751

1372

4500

6703

3056

7874

7532-01

7794

Aluminum Center Section

Aluminum Right Side Bell

Aluminum Left Side Bell

O’Ring, Side Bell

Shim Kit

Bearing Cone

Bearing Cup, Side Bell

Seal, Side Bell

3/8-16 x 2” Stud

3/8” Belleville Washer

3/8-16 Nylon Lock Nut

Wedgelock

3/8-24 Ring Gear Bolt

3/8” Belleville Washer

Ring & Pinion, 3.78 Standard

Ball Bearing, Pinion Nose

Bearing Cone, Pinion Shaft

Flanged Double Cup, Pinion Shaft

3/8-16 x 1” BHCS

Bearing Washer, Pinion

Pinion Nut

O’Ring, Pinion Nut

Pinion Nut Retainer

Bearing Retainer

Gear Spacer, For 1” Gears Only

Quick Change Gear Set, 1 3/8” Wide

Gasket, Gear Cover, HD

Gear Cover

#6 AN Port Plug

Bearing, Gear Cover

3/8-16 Steel High Nut

QTY REQ’D

1

1

1

2

1

2

2

2

20

20

20

1

10

10

1

1

2

1

5

1

1

1

1

1

2

1

1

1

3

2

10

#

P/N

DESCRIPTION

41†

42

43

44

45

46

47*

48

49

50

51

52

53

54

55

56*

56*

56*

57

58

59

60

61

62

63

64†

65†

66†

67†

68†

69†

70†

7735

7802

7398

7534

7655

7658

6881-03

6680

7390

7413

7204T

7474

5018M

7114

7110

5038

5038AS

3588M

5037

7109Y

7111B

6857

7454

7114

7109S

SR4900

7735

7451

SR4933

SR8376

SR8896

SR7486

Gear Cover Bolts

3/8-16 x 1 3/4” Stud

5/16” Diameter Steel Ball

Bearing, Lower Shaft (Rear)

Retaining Ring, Rear Bearing

Retaining Ring, Lower Shaft

Heat Treated Lower Shaft

Spacer

Bearing, Lower Shaft

O’Ring, Seal Plate

Seal, Seal Plate (Thick Seal .750”)

Internal O’Ring, Seal Plate

Seal Plate

3/8” Flatwasher

3/8-16 x 1” HHCS

Drive Yoke, 1310, Steel

Drive Yoke, 1310, Aluminum

Drive Yoke, 1350, Steel

Retaining Washer, Drive Yoke

3/8-24 x 1” HHCS

3/8” Socket Pipe Plug

Small Inspection Plug w/O’Ring

O’Ring, Small Inspection Plug

3/8” SAE Flatwasher

3/8-24 x 3/4” HHCS

Steel Tube & Bell Assembly

Side Bell Bolts

8 3/8” Side Bell O’Ring

Seal Adapter

Seal

Retaining Ring

O’Ring

QTY REQ’D

10

10

10

1

1

1

1

1

1

1

1

1

1

6

6

1

1

1

1

1

3

2

2

16

16

2

20

2

2

2

2

6

* Part Numbers in this list may vary depending on options ordered at time of purchase. Please check the assembly tag included with your rear. † Steel Tube & Bell Assembly.

©2013 Winters Performance Products, Inc. See rear of catalog or visit web site for limited warranty and venue provision.

V8 CENTER KIT

52

SR3605 8 3/8” V8 Center Kit

See pages 69-70 for Set-Up Instructions

6

5

17

18

54

55

53

4

59

1

16

7

22

48

60

49

50

51

52

25

33

35

34

32

28

29

30

31

27

57

58

61

23

26

56

5

24

6

24

43

4

42

47

37

44

46

45

32

41

36

Use Winters Semi-Synthetic

Lube with Moly 80-90-140

P/N SR1730

©2013 Winters Performance Products, Inc. See rear of catalog or visit web site for limited warranty and venue provision.

V8 CENTER KIT

53

Must be specific when ordering replacement parts. P/N’s shown are unpolished. Polishing

available at extra charge.

#

P/N

DESCRIPTION

1

4

5

6

7

16

17

18

22

23

24

25

26

27

28

29

30

31

32

33**

33**

34

35

36

2524HD-01

4606

3171

8606

3097

1792V

7852

7815

6811

7392

7527

7525

7878

6824

6821

7455

6822

6751

1372

4400

4500

6703HD

3056

7874

Center Section

Gasket, Side Bell

Shim Kit

Bearing Cone

Spacer

Wedgelock

3/8-24 Ring Gear Bolt

3/8” Belleville Washer

Ring & Pinion, 3.78 Standard

Ball Bearing, Pinion Nose

Bearing Cone, Pinion Shaft

Flanged Double Cup, Pinion Shaft

3/8-16 x 1” BHCS

Bearing Washer, Pinion

Pinion Nut

O’Ring, Pinion Nut

Pinion Nut Retainer

Bearing Retainer

Gear Spacer, For 1” Gears Only

Quick Change Gear Set, 1” Wide

Quick Change Gear Set, 1 3/8” Wide

Gasket, Gear Cover, HD

Gear Cover

#6 AN Port Plug

QTY REQ’D

1

2

1

2

1

1

10

10

1

1

2

1

5

1

1

1

1

1

2

1

1

1

1

3

#

P/N

DESCRIPTION

37

41

42

43

44

45

46

47

48

49

50

51

52

53

54

55

56*

56*

56*

57

58

59

60

61

7532

7794

7802

7398

7534

7655

7658

6881-03

6680

7390

7413

7204T

7474

6854

7114

7110

5038

5038AS

3588M

5037

7109Y

7111B

6857

7454

Bearing, Gear Cover

3/8-16 Steel High Nut

3/8-16 x 1 3/4” Stud

5/16” Diameter Steel Ball

Bearing, Lower Shaft (Rear)

Retaining Ring, Rear Bearing

Retaining Ring, Lower Shaft

Lower Shaft, Heat Treated

Spacer

Bearing, Lower Shaft

O’Ring, Seal Plate

Seal, Seal Plate (Thick Seal .750”)

Internal O’Ring, Seal Plate

Seal Plate

3/8” Flatwasher

3/8-16 x 1” HHCS

Drive Yoke, 1310, Steel

Drive Yoke, 1310, Aluminum

Drive Yoke, 1350, Steel

Retaining Washer

3/8-24 x 1” HHCS

3/8” Socket Pipe Plug

Small Inspection Plug

O’Ring, Small Inspection Plug

QTY REQ’D

2

10

10

10

1

1

1

1

1

1

1

1

1

1

6

6

1

1

1

1

1

3

1

1

* Part Numbers in this list may vary depending on options ordered at time of purchase. Please check the assembly tag included with your rear. ** Not Included with Assembly.

©2013 Winters Performance Products, Inc. See rear of catalog or visit web site for limited warranty and venue provision.

XTREMELINER

54

SR3920 Big Bearing Flanged Axle

SR3925 Big Bearing Flanged Axle (Torino®)

SR3910 Super Speedway Hubs

SR3963 2 1/2” Grand National Hubs

SR3975 2 1/2” Wide 5 Hubs

See pages 64-66 for Set-Up Instructions

49

48

37

47

46 44

45

38

40

41

36

42

2

35

50

33

4

26

25

34

39

32

54

27

28

53

29

31

30

5

15

6

9

8

29

7

1

7

10

14

11

17

12

Lower Shaft Must Be

Pre-Assembled Before

Installation.

51

28

27

52

26

55

25

13

57

3

18

45

56

19

44

46

Use Winters Semi-Synthetic

Lube with Moly 80-90-140

P/N SR1730

22

20

24

21

23

©2013 Winters Performance Products, Inc. See rear of catalog or visit web site for limited warranty and venue provision.

XTREMELINER

55

Must be specific when ordering replacement parts. P/N’s shown are unpolished. Polishing

available at extra charge.

#

P/N

DESCRIPTION

1

2

3

4*

4*

5*

5*

6

7

8

9

10

11

12

13

14

15

17

18

19

20

21*

22

23*

24

25

26

27

28*

5012-308

5016-02

5016-308

5034-11L

6513-31-022

25308

25200

8634

8633

3440

7713

7308

3179

7329

7869

3178

3194

3308

308__

8659

1764-308

5017HD

7111B

7108

7114

7403