The PCB Design Magazine, August 2013

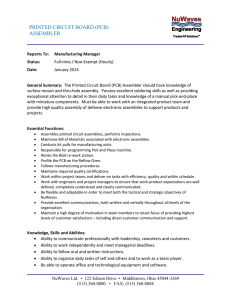

advertisement