DC Link and Dynamic Performance Features of PWM IGBT Current

advertisement

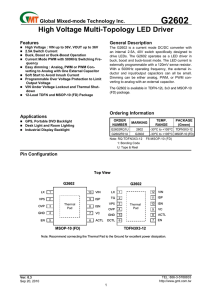

DC Link and Dynamic Performance Features of PWM IGBT Current Source Converter Induction Machine Drives with Respect to Industrial Requirements Friedrich W. Fuchs, Alfons Kloenne* Institute of Power Electronics and Electrical Drives; *now: Bosch GmbH Christian-Albrechts-University of Kiel Kiel, Germany fwf@tf.uni-kiel.de Abstract— When rating the IGBT PWM current source induction machine drive in relation to industrial requirements, there are some important performance features to be studied. These are especially the dynamic control performance and the size and influence of the inductance in the dc link. These subjects and their interference are evaluated here, giving a basis for rating. With a high pulse frequency of the converters, with respect to the current ripple, only a low inductivity in the dc link is necessary, leading to low weight and volume and improving the ideal basic dynamic performance, too. A high dynamic performance, comparable to PWM voltage source induction machine drives, is reached when, beneath a dc link inductance with suitable low inductivity, selected control methods as field oriented control and, as chosen here, optimal state control, are applied. The basic performance is analysed and the the results are partially verified by measurements at a 7.5 kW test drive. Keywords: variable speed drives; current source converter; current source inverter; induction machine; industrial requirements; dc link inductance; dynamic performance I. INTRODUCTION Nowadays converter fed electrical ac drives are used in industry in numerous applications and in high numbers. Basic type used in the power range from less than 1 kW to up to 2000 kW and more is the induction motor fed via PWM voltage source converter (PWM VSC IM) [1]. This drive fulfills today nearly all requirements given from industrial applications and so sets up the standard for drives. Nevertheless, research on this type of drive still continues. Besides this type of drive with voltage source converter there is the in some way dual type with induction machine fed via PWM current source converter (PWM CSC IM). This PWM CSC IM drive, however, today is used mainly only for special applications, preferably in the high power range [2] or for retrofitting existing fixed speed machines. There are possible new applications being investigated in the medium power range as there are high speed drives and feeding of superconducting magnetic energy storage systems, where only the rectifier is needed. The CSC is in competition with the widely spread PWM VSC IM drive and as a matter of fact has gained only a small application range. Nevertheless, regarding and investigating the performance of the PWM CSC IM drive, especially with IGBT, and in the medium power range, some remarkable features can be found. These show, that this drive is well applicable, moreover there are only limited technical disadvantages but also advantages compared to the PWM IGBT VSC IM drive. Some of these performance features are presented here. Industrial applications set up the economical and technical requirements for electrical drives. Though depending on the individual application, in general the performance requirements for drives can be defined for a certain group of applications, as for example for general industrial application. There, some most important technical performance requirements can be found. The basic requirement is to enable the motion function of the drive required from the process driven, in order to enable a required dynamic and stationary control of the torque or of the speed of the machine. Another requirement is a high efficiency, which means low losses in the drive, as this leads to low operation costs. Moreover, the drive has to withstand the environmental conditions. The electromagnetic interference of the drive has to be in the standardised limits to correspond to the laws and make an operation of other electronic systems possible. To avoid destruction, a suitable protection system has to be installed. An economical reliability and lifetime of the drive are required, in order to minimise the costs, too. Often a limited weight as well as a limited volume of the drive are further important requirements. In this article, for rating the PWM IGBT CSC IM drive two important performance features, with respect to industrial requirements, are selected, both influencing each other. These are the dynamic control performance and the properties and influence of the dc link inductance. These subjects will be evaluated, giving a basic aspect for rating. Nevertheless, analyses in this field are well known, for example from [3, 4]. Here, a special field of analysis is chosen, the focus is put on the interference of dc link inductivity, current ripple and control dynamics and on an advanced control sys- Ld uG1 ~ LL ASM ~ ~ CL CM Figure 1: PWM current source converter induction machine drive system, power section [5] tem. The results of the analysis are partially verified by measurements at a 7.5 kW test drive. The content of this investigation is structured in that way, that in section II the PWM CSC IM drive system is introduced. Section III covers the design of the dc link with respect to current ripple and to basic control dynamics, limited by the power circuit. In section IV the control structure is presented and the dynamic control performance is analysed. Section V contains the conclusion. II. III. DESIGN OF THE DC LINK A. Limiting the Current Ripple For steady state behaviour, the mean value of the mains and machine side dc link voltages have to be equal when neglecting losses. The inductance in the dc link has to smooth the dc link current to the determined ripple value to render regular drive operation. The difference of the alternating part of the line side ud,L,ac and machine side ud,M,ac dc link voltage affects the current pulsations. The inductivity Ld has to be designed according to the maximum voltage versus time integral [6] divided by the tolerable dc current ripple ∆id: 1 Ld min = ∫ u d , L , ac − u d , M , ac dt max . ∆i d PWM CSC IM DRIVE SYTEM The PWM CSC IM drive system, see fig. 1, consists of a mains side rectifier and a machine side inverter, both equipped with IGBTs and series diodes [5]. The diodes prevent back voltage on the IGBTs. Because of the use of IGBTs a high PWM switching frequency of for example 3 kHz or more, comparable to that of voltage source PWM converters, can be applied. Interphase capacitors have to be inserted at the line and machine side to enable a switched rectifier respectively inverter input current. Rectifier and inverter are connected via a direct current link by means of th dc link reactor. In recent years, several investigations on this PWM IGBT CSC IM drives have been carried out and published in the literature [3, 4, 5]. ( ) (1) The maximum of the integral is reached, when both components, on line and on machine side, have their maximum. For a PWM converter there is a maximum with half of the triangle voltage amplitude for half of the pulse period (at a modulation of 0,5). This leads to an inducitivity [3] of: L d min = 2 ⋅ UL 6 . ⋅ 4 f p ⋅ ∆I d max 8 7 6 5 4 L+dmin 3 2 + dmax −I = 0.3; 0.2; 0.1; 0.05 1 0 0 10 10 fp 1 10 2 + Figure 2: Necessary inductivity in the dc link of a PWM CSC versus pulse frequency (normalised) (2) The factor 2 represents that both, line and machine side, voltages have their influence. The necessary inductivity becomes lower with higher pulse frequency according to the smaller voltage pulses switched to the inductance. Figure 2 shows the dependency of the inductivity from the pulse frequency and the allowed current ripple. Here and in the following diagrams for normalised quantities are given to be independent on the power of the system. The quantities are related to their nominal values, normalised quantities marked by a “+”. The normalisation factors are given in the appendix. Fig. 2 shows the advantage of IGBT PWM CSCs with high pulse frequencies. For high power GTO PWM CSCs with low pulse frequency of for example 500 Hz (fp+= 10) a high inductivity is necessary. An IGBT PWM CSC with standard 3000 Hz (fp+= 60) pulse frequency makes an inductivity possible, that is six times lower, for 10.000 Hz (fp+= 200) it can be 20 times lower. From the diagram can be concluded, that a high pulse frequency has to be recommended. Corresponding to the following equations from [7]: W Ld = 1 ⋅ Ld ⋅ I d2 2 3/4 V Ld ~ m Ld ~ W Ld (3) UL 6 . ⋅ 48 f L ⋅ ∆I d max 30 tresp,id Ud,M+ = 0.9 20 [ms] 10 0 0 Ud,M+ = 0.1 0.2 (5) The prefactor in this equation is 12 times lower than that of the IGBT PWM CSC in eq. (2), for 20 % current ripple the necessary inductivity is 1.6. So, both types need the same dc link inductivity for a pulse frequency of 600 Hz (12⋅50 Hz). For higher pulse frequencies the inductivity for IGBT PWM CSC is lower than that of the line commutated CSC. 0.4 i+d,step 0.6 0.8 1 0 1.5 1 0.5 2 Ld + Figure 3: Step response performance of the dc link current with ideal rectifier voltage control without dynamic inverter influence (normalised quantities) control performance is given by a linear current rise, depending on the dc link inductivity Ld. The response time tresp on a reference current step id,step thus can be calculated to: (4) a low magnetic energy WLd, proportional to the inductivity Ld, leads to a lower weight mLd and lower volume VLd. This is especially advantageous for IGBT PWM CSCs compared to line commutated CSCs. So, small inductances can be made possible for PWM CSC with high pulse frequency by means of proper design in the dc link. The advantage of the IGBT PWM CSC against the former line commutated CSC can also be defined. Their dc voltage consists of time sections of the sinusoidal line or machine voltage. The maximum voltage at the inductance arises for a control angle of 90° with a voltage area of half of the triangle voltage amplitude decreasing during the half of one sixth of the mains period down to zero [6]. This leads to a dc link inductivity for line commutated inverters of: L d min = 2 ⋅ 40 t resp = Ld ⋅ i d ,step u d ,L − u d ,M . (6) It leads to a dc link current control performance as shown in figure 3. The step response time increases with higher dc link inductivity and higher machine side dc link voltage. Table I gives some response times for this system. The real control times of the whole system will be longer because of the delay of the real control on the line side and machine side. TABLE I Step response times for ideal control ud,M 0,1 ud,M,mean 0,3 ud,M,mean 0,9 ud,M,mean tid, resp tid, resp i+ d,step = 1 i+ d,step = 0.33 Ld+=1 Ld+=1 1.9 ms 0.6 ms 2.5 ms 0.8 ms 17.4 ms 5.8 ms tid, resp i+ d,step = 1 Ld+=0.2 0.4 ms 0.5 ms 3.6 ms Thus, as a basic action, for the PWM CSC IM drive a dc link inductivity with a low value has to be chosen, not only for low weight and cost, but also to allow fast current control. Nevertheless, a minimum value has to be kept to limit the dc link current ripple. IV. DYNAMIC CONTROL PERFORMANCE B. DC Link Basic Control Dynamics Assuming an ideal fast control of the line side dc link voltage ud,L at the rectifier, taking into account the influence of the machine side dc link voltage ud,M, the A. PWM IGBT CSI IM Drive Control Research results have been published on control of CSC IM drives as there are applications of standard control methods as field oriented control [8, 9] and, iLq,ref pre-control id,ref id ~iSq,ref tref nref n n control ΨR,ref iLd,ref ~ id control mInv, Field oriented control iSb mRec, ,ref Optimal state feedback control mRec,☺,ref ,ref ~ mInv,☺,ref iSa M 3~ Figure 4: Control structure of the PWM CSC IM drive moreover, of applying modern control methods to CSC IM drives, for example state feedback control on the machine side and on the mains side [10, 11]. The dynamic performance can be optimised in this way. The rectifier and inverter PWM control, vector control or similar procedures, have been investigated in many works. The resonant network on mains and machine side has to be included in the control design. The system design, here the inductance in the dc link, has a great influence on the dynamic performance. Some research work has also deepenend this field, some results are given in [12]. So, reports on the dynamic performance of the system components can be found, but there are not many results on the complete PWM CSC IM drive system. Some examples can be found, stating minimum 100 % torque step response times of about 10 ms [13] or presenting a step response up to 50 % of the nominal torque generating current of 2 ms [10], but only in simulation. In the CSC IM drive, see figure 1, the line side rectifier has to control the dc link current via the mains side dc link voltage. Disturbance value is the machine side dc link voltage, produced by the induction machine via the inverter. The control performance is basically influenced by the dc link inductivity. The machine side inverter has to control the current in the motor to adjust the motor torque to the reference value. This is mainly a phase control, as the current amplitude in the machine is given according to the amplitude of the dc link current controlled by the rectifier. Comparing a PWM IGBT CSC IM drive, where the rectified mains voltage being switched to the dc link inductance controls the dc link current and the current in the machine, with the PWM VSC IM drive, where the constant dc link voltage is being switched by the inverter directly to the machine, a worse dynamic behaviour of the CSC IM drive could be assumed. B. Control Structure and Methods For the real system, a control structure for the total drive as shown in figure 4 [5] has been chosen. Superimposed is a speed control, which gives the torque reference value tref. This torque is the input signal for the field oriented control of the induction machine. The reference active current isq,ref from this control is the reference value for the dc link current and the input signal of the dc link current controller, where an additional feedforward precontrol is added. The dc link current is controlled via the line side current controller. The machine side inverter and the machine have to be controlled for fast torque generation. Here, the standard field oriented control for CSI fed induction machines is selected, for which very short step response times are reported. The influence of the inverter output capacitors has been neglected in the control structure without relevant reduction of the dynamics [5]. The dc link current control is a standard PI control with precontrol. The line side current control is of high importance, because it has to work via the dc link on the machine and affects the system dynamic in a basic way. State feedback control has a superior performance for this multivariable system. Here, an optimal state feedback control is chosen, which operates according to the optimum criterium [14]: t 1 e J = ∫ xT ( t ) Q x( t ) + uT ( t ) R u( t ) dt . (7) 2 t 0 The precondition for the general control concept is, that the dc link current, for minimal losses in the drive, has to be kept to a minimum. This means a high modulation factor, preferably 1, at the machine side converter. To achieve constant flux in the machine the dc link current has to be controlled instantaneously as Figure 5: Torque step response (measurement) Without sufficient dc link current (left) and with sufficient dc link current (right); iSq; iSd; id , each 10 A/div (400 V/7,5 kW drive; machine voltage US=0,33 USN; Ld= 10 mH; reference torque step: T = 0 to TN (I+d=0 to 1); machine speed N=0,33 NN = 500 min-1) torque varies. A high pulse frequency of the converter is chosen and a low inductivity in the dc link is used, as evaluated. A suitable control parameter tuning is applied. C. Dynamic Performance of the Drive All these design and control methods, including the optimal state feedback control and optimised control parametrisation, have been applied to the drive leading to the control structure of figure 4. The control has been implemented in a DSP-system for a 7.5 kW drive. With these measures, the dynamic drive performance as shown in figure 5 has been achieved. On the left, the drive operates with minimum dc link current when the reference step starts, on the right the drive has a sufficient dc link current for the reference torque. A fast control with sufficient decoupling, avoiding greater influence from q- to d-axis, can be seen. The response time for a step from 0 % to 100 % of the nominal torque generating current occurs within ca. 4 ms. This torque step response time is very near to that of VSC IM drives (about 2 ms [15]). The system data are according to table I, right column, third line. So, that table gives an ideal response time of 0.5 ms. The response time from the test is about eight times higher according to non ideal control. The dc link current is well smoothed, the ripple is about 15 %. Further reducing the inductivity in the dc link could lead to even lower torque step response times, however with a higher current ripple. IV. CONCLUSION Performance features of PWM CSC IM drives have been investigated in relation to industrial requirements. The minimum limit for designing the inductivity in the dc link has been stated. The inductivity can be low for high pulse frequencies and thus its weight and volume is substantially lower compared to that of former mains commutated converters. The advantageous influence of a low inductivity on the basic dynamic performance of the drive has been evaluated. To optimise the dynamic performance of the drive, suitable control methods have been selected. They have been implemented and parameterisation has been optimised as well as a proper design of the dc link has been done. Torque response times have been reached which are very close to those of the voltage source induction machine drive used for industrial applications. So, concerning losses, volume and weight in the dc link as well as dynamic characteristics the PWM CSC IM drive investigated has a performance according to standard industrial requirements. V. APPENDIX A. Normalszation factors The normalised values are marked by a (+). TABLE II Normalisation factors Time (sometimes not normalised) Frequeny t+ = t /TLN Line voltage UL+= UL/ULN DC voltage ud+ = ud/(( 3 6 /π) ULN Line current IL+= IL / ILN DC current Id+ = Id/(π ILN/ 6 ) f+ = f /fLN Machine voltage UM+= UM/ULN Machine current IM+= IM / ILN [4] de la Parra, I.; Gonzales, S.; Tamarit, G.: Modulation and Control of Current Source Converters for High Dynamic Performance of Induction Motors; Euopean Conference on Power Electronics and Applications, 1997, vol. 3, pp. 756-761. [5] Kloenne, A.: Control and Modulation Strategies for Current Source Converters with Induction Motors; in German; Phdthesis, University of Kiel, Germany, 2002. B. Data of the test drive TABLE III Data of the test drive [6] Fuchs, F. W.; Mueller-Hellmann, A.: Control Methods for Reducing the Inductance in the DC Link of Current Source Inverters; IEEE Transactions on Industry Applications, Vol. IA19, No. 5, 1983, pp. 699-707. Line voltage (delta) 400 V [7] Heumann, C.: Current Source Converter with Pulse Width Modulation; in German; etz 1993, 2, pp.170-176. Line frequency 50 Hz Apparent power 7.5 kW [8] Busse, A.; Holtz, J.: Multiloop Control of a Unity Power Factor Fast Switching AC to DC Converter; IEEE Power Electronics Specialists Conference, 1982. Filter capacitance CF 16 µF Filter inductance LS 1 mH DC Link inductance Ld 10 mH Pulse frequency fp 3.125 kHz REFERENCES [1] Stemmler, H.: High Power Industrial Drives; in: Power Electronics Technology and Applications II; Editor, Lee, F.; IEEE, New York, 1998. [2] Zargari, N.; Xiao, Y.; Wu, B.: PEM CSI-Based Vector Controlled Medium Voltage AC Drive with Sinusoidal Input and Output Waveforms; Proceedings of the IEEE-IAS, 1997, vol. 1, pp. 768-774. [3] Kaltenbach, K.: Current Source PWM Inverter as Power Controller for Induction Machines; in German; PhD-thesis, Berlin, 1992. [9] Salo, M.; Tuusa, H.: A Vector Controlled Current- Source PWM Rectifier with a Novel Damping Method; IEEE Transactions on Power Electronics, Vol. 15, No. 3, 2000, pp. 464-470. [10] Hintze, D.; Schröder, D.: Four Quadrant AC-Motor Drive with a GTO Current Source Inverter with Low Harmonics and On Line Optimized Pulse Patterns; IPEC, Tokio 1990, p. 405-412. [11] Espinoza, J.; Joós, G.: State Variable Decoupling and Power Flow Control in PWM Current-Source Rectifiers; IEEE Transactions on Industrial Electronics, Vol. 45, No. 1, 1998, pp. 7887. [12] Hombu, M.; Ueda, S.; Ueda, A.: A Current Source GTO Inverter with Sinusoidal Inputs and Outputs; IEEE Transactions on Industry Applications, Vol. IA-23, 1987, no. 2, p.247-255. [13] Amler, G.: A PWM Current Source Inverter for high Quality Drives; EPE-Journal, Vol.1, 1991, no. 1, p.21-32. [14] Kloenne, A.; Fuchs, F. W.: Optimal State Feedback Control of a Vector Controlled Current Source Rectifier; Proceedings of the EPE conference, Graz, 2001. [15] Aaltonen, M.; Tiitinen, P.; Laly, J.; Heikkilä, S.: Direct Torque Control of AC Drives; ABB Technique 1995, p. 19 – 24.