2011 - Türk Loydu

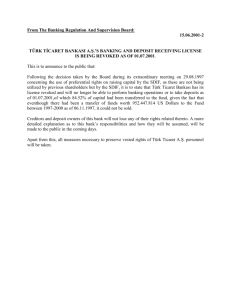

advertisement