Town of South Bruce Peninsula Quotation PW 15-16

advertisement

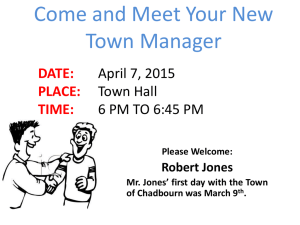

Town of South Bruce Peninsula Quotation PW 15-16 P age |1 Friday, August 14, 2015 DOCUMENT TSBP PW-15-16 Wiarton Wastewater Treatment Plant Upgrades ADDENDUM 3 Referring to the above Document PW-15-16, please note the following: The following are instructions to Vendors: 1.1. 1.2. Tender Closing Date (Extension) and Tender Validity 1.1.1. The tender closing date has been extended from August 21, 2015 to August 27, 2015 at 2:00pm at the exp office as stated on the tender package. 1.1.2. Tender shall be valid for a minimum period of 30 days. Contract Schedule A concern has been expressed by some bidders that contract end date is difficult to achieve. Please note the following in this context: 1.2.1. The federal and provincial funding applicable to this project requires substantial completion by March 31, 2016. Therefore, despite requests, we cannot move it. 1.2.2. The funding authorities also require a completion report by May 31, 2016, and it is anticipated that the contractor will assist the Town in achieving that. In other words, contractor can be on site longer than March 31, 2016 to complete sundry items as long as MBBR unit is substantially complete. 1.2.3. However, Town understands that the proposed dates are challenging but is committed to work flexibly with the contractor to achieve the required schedule including pre-billing to help achieve funding objectives. 1.2.4. To achieve schedule; it is foreseen that MBBR completion will be critical as it is the core process to the proposed improvements. It can be achieved by pouring the concrete for the MBBR building in early Fall and competing the MBBR installation indoors after that. 1.2.5. The MBBR vendors that the design team contacted during the design phase are aware of the project schedule and will work expeditiously to achieve it. The shop drawings should therefore be available on an accelerated schedule. 1.2.6. As the building has been designed to accommodate MBBR; pouring of the concrete can proceed at the same time as the shop drawings are being prepared by MBBR vendors. Most piping can be anticipated based on early discussions with vendors and remaining ones can be drilled in as required. Town of South Bruce Peninsula PO Box 310, 315 George Street Wiarton ON N0H 2T0 519-534-1400 ext 106 Town of South Bruce Peninsula Quotation PW 15-16 ADDENDUM 3 1.2.7. 1.2.8. 1.3. In order to expedite the start of work, the Town has following dates in mind: Potential contract award date: September 2, 2015. Potential pre-construction meeting: September 4, 2015. The potential construction start date would be September 14th, 2015 or earlier if feasible. Based on above guidance, please provide a construction schedule as part of the bid for evaluation by the Town. It will be critical item of evaluation. Revisions to the Contract and Form of Tender 1.3.1. List of Major Equipment Please supply in your tender a list of major equipment included in your bid. 1.3.2. List of Major Suppliers Please provide a list of major suppliers used in your bid. 1.3.3. Lump Sum Details Please provide details of how the lump sum price was arrived at. 1.3.4. References The “Reference” form on page 17 of the tender is replaced by the attached form (attached). 1.3.5. Supply, Install, Maintain and Subsequently Remove Field Office Under this item, the Contractor shall supply, erect and maintain a Field Office to be used by representatives of the Town and Consultant upon award of the contract and remove it after final completion of the contract works. Item to be priced per month for a period of 9 months. The Field Office shall have a minimum area of 20m2 and shall be furnished with a desk, a first aid kit, a drawing table and six chairs. The office shall be equipped with electric light and propane or electric heat thermostatically controlled (winter) or air conditioning (summer). A sanitary facility (portable toilet) or equivalent must be provided by the Contractor and erected and maintained within 10m of the field office. This facility shall be for the sole use of the Town and Consultant and its representatives and must have an exterior padlock with two keys available to the Town and Consultant staff. The office shall be erected and serviced as a first priority. The office, equipment and furniture shall be subject to acceptance by the Town and Consultant and shall not be removed from the site without the Town and Consultant’s permission. The Contractor shall bear the costs of heating, cooling, and lighting the field office and the installation and rental charges for the telephone. The Contractor will not be required to pay for long distance calls made by the Town and Consultant or its representative. The Contractor shall indemnify the Town and Consultant against loss and fire, theft and injury Page 2 of 10 Town of South Bruce Peninsula Quotation PW 15-16 ADDENDUM 3 to the building and its contents. The office shall be made vandal proof to the greatest extent possible. Failure of the Contractor to provide a field office when instructed will result in the Town and Consultant taking responsibility for this item. All costs incurred, including trailer rental, utility costs, sanitary facility, janitorial costs, insurance and 25 per cent overhead will be deducted from the Contractor’s Process Payment Certificate. The office shall have a power supply (110V@15A min) and an internet connection for the Town’s and Consultants use. 1.3.6. Performance Security A performance bond of 25% and maintenance bond of 25% of the tender amount is to be provided in a form acceptable to the municipality no later than 30 days after award. The bond shall be retained by the municipality until the satisfactory completion. The maintenance portion of the bond shall be held until the satisfactory period 2 year maintenance. 1.3.7. Changes related to Section 46 21 51.01 SCREEN 1.3.7.1. Article 2.2.7.6: Chain links and bushings shall be in 304 stainless steel 1.3.7.2. Article 2.3.2: The phrase “forming a frame width of 520mm.” is deleted. 1.3.7.3. Article 2.3.8 is revised as below: “In order to facilitate routine service, repair or replacement of damaged parts, the screen shall be equipped with a pivot system that allows the bottom part of the screen to be lifted to a level above the top of the screen channel. The pivot system shall not interfere with the operation and maintenance of the screen and the compactor hover. All designs shall ensure that day-to-day maintenance, replacement of chains and/or elements shall be done from the operating floor level. ” 1.3.7.4. Article 2.9.2 is revised as below: “The control system shall be automatically operated by a PLC. The required start/stop signals, timers and logic shall be included to control the equipment based on its sequence of operation.” 1.3.7.5. Article 2.9.4 is revised as below: “The control system shall be rated for the following classifications: .1 .2 Main control cabinet: NEMA-12, for installation in the electrical room (nonclassified) Local control station: NEMA-7 Epoxy painted aluminum enclosure, for installation in Class I, Division II, Group D” Page 3 of 10 Town of South Bruce Peninsula Quotation PW 15-16 ADDENDUM 3 1.3.7.6. Article 2.11.1.4 is revised as below: “Safety barrier for digital signal (float switch) and a backup high level signal from the ultrasonic level transmitter;” 1.3.7.7. Article 2.12.1 The following item is added to the scope of supply: “.4 One (1) float switch” 1.3.8. Changes related to Section 46 21 21 73 WASHER & COMPACTOR 1.3.8.1. Article 2.1.1 is revised as below: “All electrical equipment, fixtures and controls of shall meet the requirements of NEC Class I, Division 2, Group D.” 1.3.8.2. Article 2.11.1 is revised as below: “The screening bagging unit shall be made of stainless steel 304 with bag cassette in PVC.” 1.3.9. Changes related to Section 2.6 INSTRUMENTATION 1.3.9.1. Please add the following article: “2.6.4 Provide the control philosophy of the MBBR process. The MBBR process programming is the responsibility of Section 40 90 00.” 1.3.10. Add a fixed screen of 6 mm x 6 mm openings in the by-pass channel as shown in the attached drawings ADD3-MP-01 and ADD3-MP-02 1.3.11. Changes related to Section 46 53 33 MOVING BED BIOFILM REACTOR: Design load 1.3.11.1. The influent characteristics in Article 1.2.2 INFLUENT CHARACTERISTICS are revised as below: Parameter Average load Maximum load CBOD5 (total) 422 kg/d 629 kg/d CBOD5 (soluble) 211 kg/d 315 kg/d TSS 609 kg/d 910 kg/d TKN 102 kg/d 138 kg/d NH4-N 51 kg/d 69 kg/d Total phosphorous 9.8 kg/d 14 kg/d Page 4 of 10 Town of South Bruce Peninsula Quotation PW 15-16 ADDENDUM 3 1.4. Revision of drawings 1.4.1. 1.4.2. 1.4.3. Plan MP-01 and MP-02 Drawing MP-004: Is modified per Drawing ADD3-MP-01 (attached). Drawing MP-006: Should be read in conjunction with Drawing ADD3-MP-02 (attached), as drawing ADD3-MP-02 provides supplemental information. Plan S03 Drawing S-03: Section A of Drawing S-03 is modified per Drawing ADD3-01 (attached). Install polyurea coating on the interior of MBBR tank as shown in Drawing ADD301(attached). Drawing MP-001 1.4.3.1. Replace the table entitled “List of equipment” by the following table. List of Equipment Tag Description SC1 Mechanical screen, openings of 6 mm dia. WCU Screenings washing and compacting unit SC2 Fixed screen, SS 304, openings of 12mm x 12mm SC3 Fixed screen, SS 304, openings of 6mm x 6mm B1 Air blower, 35 m³/min, 55 kW, 600/60/3, with VFD B2 Air blower, 35 m³/min, 55 kW, 600/60/3, with VFD OTS Odor treatment scrubber, 1,000 cfm, 3.75 kW, 600/60/3 SMP Automatic sampler, 24 bottles, 120 v RCL-1 to RCL-13 Circulators, 2,25 kW, 600/60/3 Page 5 of 10 Town of South Bruce Peninsula Quotation PW 15-16 ADDENDUM 3 1.4.3.2. Replace the table entitled “Design Influent Concentrations and Loads” by the following table. Design Influent Concentrations and Loads Parameters Load 1.5. Average Average Maximum Concentration (kg/d) (kg/d) (mg/L) - CBOD5 422.4 628.9 96.0 - SS 609.0 909.7 138.4 - TKN 102.1 137.9 23.2 - NH3+NH4 as N 50.6 131.6 11.5 - P total 9.8 14.1 2.2 Revised Table of Contents A Revised table of contents is attached. The following are responses to questions from Vendors: 2.1. How will the Contractor be notified of any Addenda that are issued for this Tender? Or is it up to the Contractor to frequently check the Owners site? Town response: Addendums will be e-mailed to parties who have registered their intent to bid. The addendums will also be posted on the Town’s website. 2.2. Can I please get the list of bidders who have expressed interest in the project? Town response: The names of the companies who have contacted exp Services about this tender include: Allen-Hastings Limited Aqua Technical Sales Inc. Baseline Constructors Inc. BGL Contractors Group Core Tec. Contracting EC King Concrete Infilco Degremont Inc. Jeviso Construction Corporation K & L Construction Limited Kenaidan Contracting Ltd. M.J. Dixon Construction Limited Miller Group SPD Sales Limited Terrapin Water Veolia Water Technologies Canada Page 6 of 10 Town of South Bruce Peninsula Quotation PW 15-16 ADDENDUM 3 2.3. Wilhelm Concrete Wellington Construction Xterra Construction Inc. Will a list of potential General contractors and Mechanical contractors be listed for this project? Town response: See 2.2 above. 2.4. Section 031000 – Page 3, line item .15 – project calls out for formliner, however no specific formliner is specified (i.e. Zemdrain) and the locations specified are from a bridge tender. Please clarify where you would like formliner (i.e. for all surfaces in contact with liquid). Town response: Apply polyurea coating on the interior walls and bottom of all tanks as shown in drawing ADD3-01. 2.5. We cannot fit the proposed construction works into the schedule provided. Is there any chance this date could be changed, or is it tied to a funding requirement? Town response: The funding for this project is tied to federal and provincial funding and hence the project must be substantially completed and invoiced prior to March 31, 2016. 2.6. I just wanted to clarify bonding requirements for the above noted tender. I did not see anything in regards to bonds in the documents. Are final bonds required for this tender? Town response: Please see Item 1.2.2 2.7. Section 2.4.5, indicates that Lateral Piping Diffusers shall be in Schedule 5. Based on our experience on similar project with such reactor dimension, Lateral Piping diffusers shall be in Schedule 10. Can you confirm which schedule has to be used for Lateral Piping diffusers. Town response: Article 2.4.5: The first sentence is revised as below: “All Schedule 10, 304 Stainless Steel Lateral Piping Diffusers shall be welded to the main pipe and spaced equally to provide uniform air diffusion throughout the reactor cell's surface.” 2.8. Section 2.4.9 mentions that each lateral diffuser shall end with a 90 degrees drop-leg bend. In terms of process operation the 90 degrees bending does not any additional value. Can you confirm the aeration grids can be provided without the 90 degrees bending? Town response: Article 2.4.9 is deleted. 2.9. Section 46 53 33 1.2 2: Mentions the MBBR influent loads which equate to a certain concentration for influent parameters to the MBBR. However these are significantly higher than the design influent criteria provided on Drawing MP-001. Please confirm which loads and concentrations are to be used for the design i.e. the loads on Drawing MP-001 or Section 46 53 33 1.2 2? Particularly please confirm the influent concentrations for BOD, TKN and Ammonia-N to be used for the MBBR system design. Town response: See Item 1.3.11. Page 7 of 10 Town of South Bruce Peninsula Quotation PW 15-16 ADDENDUM 3 2.10. Section 46 53 33 1.2 2: Mentions the MBBR influent loads which equate to a certain concentration for influent parameters to the MBBR. Please confirm if the effluent guarantees are to be met for the average flow and loads or maximum flow and loads? Town response: The MBBR process shall be designed for treating the Maximum Daily Flow (5,700 m³/d) and Maximum load. 2.11. Section 46 53 33 1.2 2: Mentions the MBBR influent loads. It is our understanding that these are monthly 30 day averages. Please confirm. Town response: The average load corresponds to the annual average. The Maximum Load corresponds to the daily maximum. 2.12. Section 46 53 33 1.2 4: Mentions the treated effluent concentrations required. It is our understanding that these are requirements at the end of the aerated lagoons after the MBBRs. Please confirm. Town response: These requirements are for MBBR effluent before entering the lagoons 2.13. Section 46 53 33 2.7: Mentions the blower and VFD requirements for the MBBR system. It is our understanding that the MBBR system process air blowers and associated VFDs and instrumentation are to be provided by the Contractor and not the MBBR system supplier. Please confirm. Town response: The blowers, VFDs and instruments described in the Section 46 53 33 are to be provided by the MBBR system supplier. 2.14. Section 46 53 33 2.7: Mentions the Controls and VFD requirements. It is our understanding that these items i.e. the control panel, VFDs and associated hardware and software would be provided by the Contractor and not the MBBR system supplier. Please confirm. Town response: MBBR system supplier is to provide all equipment described in this section, as well as the control philosophy of the MBBR process. The control system programming is by others (see Section 40 90 00). 2.15. Section 46 53 33 2.7: Mentions the Controls and VFD requirements. It is our understanding that the MBBR system supplier shall only be responsible for providing the functional design specification for the controls and the remaining items would be provided by the Contractor. Please confirm. Town response: See response to Question 2.15. 2.16. Section 46 53 33 2.5: Mentions Aeration Control Valve which is a manual aeration valve that is located near the flange at the end of the vertical feed line connecting to the aeration grid in each reactor cell. It is our understanding that this valve is in the scope of supply of the Contractor and not the MBBR system supplier. Please confirm. Town response: This valve is in the scope of supply of the MBBR system supplier. Page 8 of 10 Town of South Bruce Peninsula Quotation PW 15-16 ADDENDUM 3 2.17. Section 46 53 33 2.5, Drawing MP-001 and IC-002: Mentions the Valves requirements. It is our understanding that all Automatic and Manual Valves mentioned are to be provided by the Contractor and not the MBBR system provider. Please confirm. Town response: The valves described in section 2.5 are manual valves, and are to be provided by the MBBR system supplier 2.18. Please confirm if the Dissolved Oxygen, Ammonia, pH, Temperature and level sensors in the MBBR reactors are to be provided by the MBBR system supplier or the Contractor. Town response: The MBBR supplier is to provide the instruments described in section 2.6 2.19. Drawing IC-003: It is our understanding that the drain screens are in the scope of supply of the Contractor and not the MBBR system supplier. Please confirm. Town response: The MBBR supplier is to provide the drain screens 2.20. Drawing IC-003: If the drain screens are in the scope of supply of the MBBR system supplier, please advise the dimensions of the drain. Town response: The drain screens are to be sized by the MBBR supplier. Each drain screen should be sized to allow the tank to be emptied in about 4 hours 2.21. The responses to the above questions would necessitate significant changes to the overall bid preparation, in order to provide the Wiarton WWTP a competitive and complete system proposal. Therefore, we request an extension of one week to the current submission date. Town response: See Section 1.1. Regards, Michael Humble CPA, CGA Treasurer / Manager of Financial Services Town of South Bruce Peninsula PO Box 310, 315 George Street Wiarton ON N0H 2T0 519-534-1400 ext 106 1-877-534-1400 ext 106 tsbpfinance@bmts.com www.southbrucepeninsula.com The Addendum number and date must be included in the Form of Tender in order for your bid to be given consideration. Page 9 of 10 Town of South Bruce Peninsula Quotation PW 15-16 ADDENDUM 3 Attachments Revised Table of Contents Updated References Page Drawing ADD3-01 Drawing ADD3-MP-01 Drawing ADD3-MP-02 Page 10 of 10 WIARTON – Table of Contents Page 1 Section No Title Division 00/01 00 01 07 00 01 10 00 11 21 00 21 13 01 11 00 01 29 00 01 31 19 01 32 16.07 01 33 00 01 35 29.06 01 35 35 01 35 43 01 41 00 01 45 00 01 51 00 01 61 00 01 71 00 01 73 00 01 74 11 01 77 00 01 78 00 01 79 00 01 91 13 01 91 31 01 91 33 01 91 41 02 00 00 Division 03 03 10 00 03 20 00 03 30 00 03 35 00 04 05 12 04 05 19 04 05 23 04 21 13 04 22 00 05 12 23 05 21 00 05 31 00 05 51 29 General Requirements Seals Page Table Of Contents Request For Proposal Instructions To Bidders Summary Of Work Payment Procedures Project Meetings Construction Progress Schedule − Bar (Gantt) Chart Submittal Procedures Health And Safety Requirements Dnd Fire Safety Requirements Environmental Procedures Regulatory Requirements Quality Control Temporary Utilities Common Product Requirements Examination And Preparation Execution Cleaning Closeout Procedures Closeout Submittals Demonstration And Training General Commissioning (Cx) Requirements Commissioning (Cx) Plan Commissioning Forms Commissioning Training Existing Conditions Concrete Concrete Forming And Accessories Concrete Reinforcing Cast−In−Place Concrete Concrete Finishing Masonry Mortar And Grout Masonry Anchorage And Reinforcing Masonry Accessories Brick Masonry Concrete Unit Masonry Structural Steel For Buildings Steel Joist Framing Steel Decking Metal Stairs And Ladders WIARTON – Table of Contents Page 2 07 13 53 07 21 29.03 07 24 10.03 07 55 56.14 08 11 00 08 71 00 09 91 23 Division 21/23 Elastomeric Sheet Waterproofing Sprayed Insulation − Polyurethane Foam Exterior Finish − Direct Applied Hot Fluid Applied Rubberized Asphalt Roofing Metal Doors And Frames Door Hardware Interior Painting Mechanical and Heating, Ventilating, and Air Conditioning (HVAC) 21 05 01 22 05 00 23 05 29 23 31 13.01 23 33 00 23 33 14 23 33 15 23 33 16 23 33 46 23 34 00 23 34 25 23 37 13 23 37 20 Division 26 26 05 00 26 05 14 26 05 20 26 05 21 26 05 22 26 05 27 26 05 28 26 05 29 26 05 31 26 05 32 26 05 33 26 05 34 26 05 39 26 09 23.02 26 12 16 26 24 01 26 27 16 26 27 26 26 28 13.01 26 28 20 Mechanical − General requirements Plumbing− General requirements Hangers And Supports For HVAC Piping And Equipment Metal Ducts − Low Pressure To 500 Pa Air Duct Accessories Dampers − Balancing Dampers − Operating Dampers − Fire And Smoke Flexible Ducts HVAC Fans Packaged Roof And Wall Exhausters Diffusers, Registers And Grilles Louvres, Intakes And Vents Electrical Electrical − General Requirements Power Cable And Overhead Conductors (1001 V) Wire And Box Connectors (0−1000 V) Wires And Cables (0−1000 V) Connectors And Terminations Grounding − Primary Grounding − Secondary Hangers And Supports For Electrical Systems Splitters, Junction, Pull Boxes And Cabinets Outlet Boxes, Conduit Boxes And Fittings Raceway And Boxes For Electrical Systems Conduits, Conduit Fastenings And Conduit Fittings Underfloor Raceways For Electrical Systems Lighting Control Devices − Photoelectric Dry Type, Medium Voltage Transformers Service Equipment Electrical Cabinets And Enclosures Wiring Devices Fuses − Low Voltage Ground Fault Circuit Interrupters − Class "A" WIARTON – Table of Contents Page 3 26 28 23 26 50 00 26 52 00 26 53 00 Division 31/32/33 31 05 16 31 00 00.01 31 23 33.01 32 70 00 32 91 19.13 32 92 19.16 33 31 13 33 71 73.02 Division 40/46 40 90 00 40 90 00.01 46 00 10 46 20 00 46 00 30 46 10 00 46 10 00.01 46 10 00.02 46 10 10 46 21 51.01 46 21 73 46 21 83 46 53 33 46 80 10 46 90 10 Disconnect Switches − Fused And Non−Fused Lighting Emergency Lighting Exit Signs Earthwork, Exterior Improvements and Utilities Aggregate Materials Earthwork − Short Form Excavating, Trenching And Backfilling Floating wetlands and circulators Topsoil Placement And Grading Hydraulic Seeding Public Sanitary Utility Sewerage Piping Underground Electrical Service Process Integration and Wastewater Equipment Instrumentation and Control for Process Systems Control system Start−up, Verification and Commissioning Process General requirements Identifications Seismic Restraints Process piping Pipe supports Pipe testing Valves Mechanical screen Screenings washing and Compacting Unit Septage receiving equipment Moving bed Biofilm Reactor Other equipment Field instruments Appendix A Geotechnical study report Town of South Bruce Peninsula Quotation PW 15-16 Page 17 of 18 References List below, three references of similar contracts (see note 1): Company Name / Contact Telephone # Contract Description 1. 2. 3. Note 1: In order to be qualified, the reference contracts must meet the following conditions: 1) The contract involves installation of a mechanical system of activated sludge process for treatment of municipal wastewater in Canada. 2) The reference project has been completed during the last 10 years. 3) The installed system is currently in operation.