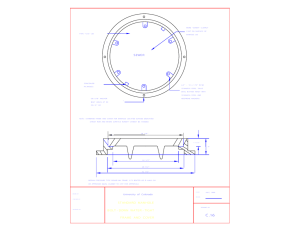

20” inspection manhole

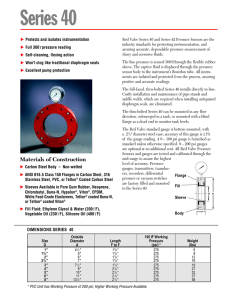

advertisement

20” INSPECTION MANHOLE Clamp Ring Style • EASILY INSTALLED • LOW MAINTENANCE • ECONOMICAL • LARGE OPENING Tiona Inspection Manholes provide quick, safe entrance and exit from your tanks. Heavy gauge metal and welded construction minimizes maintenance. Manholes are certified and marked in accordance with 49CFR178.345-5 with a test pressure of 36 psi [2.48 bar]. Cover Plate Clamping Ring Clamping Bolt and Washer Clamping Bolt Nut Wt. Assembly No. Steel Zinc Plt. Steel Zinc Plt. Steel Zinc Plt. Brass 21.7 lb. 8008BX* Stnls 304 Stnls 304 Stnls 304 Stnls 304 22.2 lb. Stnls 316 Stnls 304 Stnls 304 Stnls 304 22.2 lb. * Add letters to part number to designate seal material. See material table at right for designation. [10.1 kg] [10.1 kg] 8008CX* 8008DX* Letter Gasket Material B Buna-N Temp. Range -40°F to +220°F V Viton -20°F to +400°F EPDM (White) -40°F to +260°F W White Hypalon -40°F to +250°F T PTFE Envelope w/ White Hypalon Insert -40°F to +250°F P “X” in assembly number designates manhole collar sold separately. Collars are available in aluminum, steel and stainless steel. Please see parts page for part numbers. [9.8 kg] [-40°C to +104°C] [-29°C to +204°C] [-40°C to +127°C] [-40°C to +121°C] [-40°C to +121°C] During installation and welding to the tank, care should be exercised to insure collars remain flat and round. If necessary, a welding fixture should be used to prevent distortion. TM INDUSTRIES, INC. WARREN, PA. Tel. (814) 723-1250 ⋅ Fax (814) 723-7030 ⋅ E-Mail: betts@bettsind.com ⋅ Web Site: www.bettsind.com August 2008 Section 86 Page 1A Parts List 20” Inspection Manhole NO. REQ. 1 1 Cover Plate 2 1 Bolt – Clamp Ring (3/8 – 16 Thd.) * 3 1 Nut – Clamp Ring (3/8 – 16 Thd.) * 4 1 Washer – Clamp Ring * 5 1 Clamp Ring 6 7 DESCRIPTION Manhole Gasket (Channel Style) B V P W Manhole Gasket (Flat Style) T 1 1 B C D Manhole Collar (Sold Separately) MATERIAL Steel Zinc Plated 304 Stainless Steel 316 Stainless Steel Steel Zinc Plated 304 Stainless Steel Brass 304 Stainless Steel Steel Zinc Plated 304 Stainless Steel Steel Zinc Plated 304 Stainless Steel Nitrile (Buna-N) FKM (Viton) EPDM (White) White Hypalon PTFE Envelope w/ W. Hypalon Insert Steel ¼” Aluminum 304 Stainless Steel 316 Stainless Steel PART NO. 3034ZC 3034SL 3034SS 3029ZC 3029SL 3030BR 9Q5809 3031ZC 3031SL 3036ZC 3036SL 3560BN 3560VT 3560WE 3560WH 3033TF 3176MS 3176AE 3176SL 3176SS ∗ Use part # 4121ZC001 for kit with Nut (3), Bolt (2), and Washer (4). MAINTENANCE: Manhole assemblies should be inspected with sufficient frequency and due regard to the products carried to insure a liquid tight closure. Any worn, damaged or missing parts must be replaced. Gaskets should be replaced if their effectiveness is impaired in any way. Replacement gaskets must be compatible with products carried. WARNING: Use only genuine BETTS INDUSTRIES INC. replacement parts. Substitute parts can impair the proper function of this product. TM Tel. (814) 723-1250 ⋅ Fax (814) 723-7030 ⋅ E-Mail: betts@bettsind.com ⋅ Web Site: www.bettsind.com August 2008 Section 86 Page 1B R 20” ROUND MANHOLE with 10” FILL MODERN DESIGN CT-0040 COVERED BY PATENTS ISSUED AND PENDING LOW COST BETTS INDUSTRIES, INC. WARREN, PA. U.S.A. CLEAN LINES Note: Not legal for DOT specification tanks. Combining all the features of all full 20” manhole opening for inspection PLUS the 10” fill cap, Tiona Model No. 8020 is a real 2-in-1 value, offering both inspection and loading features in one husky unit. We pay more for top quality material but furnish it as standard equipment at competitive prices. Secondary Latch is standard on all assemblies. Clamping Ring, Cover Plate, Clamping Bolt Clamping Fill Cover, Vent Wt. (lb.) Fill Gasket Retainer, and Washer Bolt Nut Shim Washer Strongback, Latch Steel Steel Steel Zinc Plt. Brass Alum. 26.5 Steel Zinc Plt. Steel Zinc Plt. Steel Zinc Plt. Brass Alum. 26.5 Stnls 304* Steel Zinc Plt. Steel Zinc Plt. Brass Alum. 27.0 Stnls 304 Stnls 304 Stnls 304 Stnls 304 Alum. 27.0 Stnls 304 Stnls 304** Stnls 304 Stnls 304 Alum. 27.0 * Fill Gasket Retainer and Shims-Aluminum **Fill Cover Material-Stainless 316 Assembly No. FVA8020SXB FVA8020BXB FVA8020GXB FVA8020CXB FVA8020DXB NOTE: Inspection manhole assemblies, as listed above, have a 6238AL vent (prefix “FVA”) and Buna-N gaskets (suffix “B”). For variation or additional vents see catalog Section 95 for proper prefix or assembly number. For variation in gasketing change last letter of suffix as follows. Suffix “V” indicates Viton gasket Suffix “W” indicates White Hypalon gasket Suffix “T” indicates Teflon fill and collar gasket w/ White Hypalon backer Manhole collars are available in aluminum, steel, and stainless steel. Please see parts page for correct numbers. When welding collars to tank, exercise care to insure collar remains flat and round. TM INDUSTRIES, INC. WARREN, PA. Oct 1998 Section 86 Page 2A PARTS LIST 20” Manhole w/ 10” Fill No. Description Material Part No. No. Description Material Part No. Steel 3021MS Steel 3036MS 8 Clamping Ring Steel Zinc Plt. 3021ZC Steel Zinc Plt. 3036ZC 1 Fill Cover Stnls 304 3021SL Stnls 304 3036SL Stnls 316 3021SS B Buna-N 3560BN Bethane 3024BU V Viton 3560VT Manhole Gasket 9 Viton 3024VT W Wh. Hypalon 3560WH Channel Type 2 Fill Gasket Wh. Hypalon 3024WH Teflon Env. T 3033TF w/ Wh. Hypalon Non-Asbestos 3024NA Teflon 3024TF Steel 3176MS 1 Steel 3213MS /4 Aluminum 3176AE Manhole Collar 10 Channel Type Aluminum 3213AL Stnls 304 3176SL 3 Retainer Stnls 304 3213SL Stnls 316 3176SS Stnls 316 3213SS 11 Vent Assembly Alum./Stnls 6238AL Steel 3023MS 12 Gasket Buna-N 3716BN 4 Shim Washer Aluminum 3023AL Gasket Maximum Temperature Stnls 316 3023SS Bethane 250°F Steel Zinc Plt. 3029ZC 5 Bolt-Clamp Viton 400°F Stnls 304 3029SL White Hypalon 250°F Nut-Clamp Brass 3030BR 6 3 Teflon 400°F /8-16 Thd. Stnls 304 9Q5809 Teflon Envelope w/ White Hypalon Insert 250°F 7 Steel Zinc Plt. 3031ZC Non-Asbestos 350°F Washer-Clamp Stnls 304 3031SL MAINTENANCE: Manhole assemblies should be inspected with sufficient frequency and due regard to the products carried to insure a liquid tight closure. Any worn, damaged or missing parts must be replaced. Gaskets should be replaced if their effectiveness is impaired in any way. Replacement gaskets must be compatible with products carried. Adjustment due to gasket wear may be necessary to insure proper sealing of the 10” fill. A shim washer, item No. 4, is provided for this purpose. To increase the sealing force of the 10” fill, remove shim from location shown above and re-position it above fill cover No. 1. WARNING Use only genuine Betts Industries Inc. replacement parts. Use of substitute parts can impair the proper functioning of this product. TM INDUSTRIES, INC. WARREN, PA. Sept 1996 Section 86 Page 2B R 20” PAF450 MANHOLE BETTS INDUSTRIES, INC. WARREN, PA. U.S.A. NORMAL VENT WROUGHT STEEL COVER COVERED BY PATENTS ISSUED AND PENDING With Pressure Relief Valve SECONDARY SAFETY LATCH HEAVY DUTY CLAMP RING Not legal as replacement on MC306 cargo tanks after August 31, 1998 Pressure Relief Valve setting 3.0 psig. Rated Pressure Actuated Emergency Venting: 375,000 cu. ft. free air per hour @ 5.0 psig. PAF Manholes with Model PAF450 10” Pressure Relief Valve are certified for use on MC306 cargo tanks. Manholes are certified and marked in accordance with 49CFR178.345-5 with test pressure of 36 psig. Per 49CFR180.405(h)(3), PAF450 assemblies may not be installed on MC306 cargo tanks after August 31, 1998. However, relief valves installed on MC306 cargo tanks on or before August 31, 1998, may be repaired if required. PAF450 relief valves may be installed on non-specification tanks or in tanks built in countries other than the United States where regulations permit. Relief valve also serves as a 10” latch style fill which can be easily opened for filling the tank or for inspection. Standard features include heavy duty clamp ring, secondary safety latch and model 6238AL Normal Vent. *No provision has been made for venting of product due to overfilling. Manholes are also available with a self-latching feature which allows the Pressure Relief Valve cover to open only 91 degrees and drop closed and securely latch upon movement of the tank if the cover is inadvertently left open. For selflatching model substitute 9763 for 9720 in assembly number. Cover Plate PRV Cover Steel Zinc Plt. Stnls 304 Stnls 316 Alum. Clamping Ring, Clamping Spring Bolt & Washer, Spring Ring Nut Bolt & Nut Strongback, Latch Steel Zinc Plt. Brass Stnls 304** Van Stnls 304 Stnls 304 Stnls 304 Steel Stnls 304 Stnls 304 Stnls 304 **Nut Material – Steel Zinc Plated Normal Vent Wt. (lb.) Assembly No. Alum. 29.2 29.7 29.7 FVA9720BXB FVA9720CXB FVA9720DXB NOTE: Manhole assemblies, as listed above, have a 6238AL vent (prefix “FVA”) and Buna-N (suffix “B”). For variation or additional vents see catalog Section 95 for proper prefix or assembly number. For variation in gasketing change last letter of suffix as follows. Suffix “V” indicates Viton gasket Suffix “W” indicates White Hypalon gasket Suffix “T” indicates Tef-Sil pressure relief valve gasket and Teflon Envelope w/ White Hypalon insert collar gasket Manhole collars are available in aluminum, steel, and stainless steel. Please see parts page for correct numbers. When welding collars to tank, exercise care to insure collar remains flat and round. TM INDUSTRIES, INC. WARREN, PA. Sept 1998 Section 86 Page 7A PARTS LIST 20” PAF 450 MANHOLE Self-Latching Model Illustrated No. 1 1a Description Cover-Relief Valve Cover (O-Ring Grvd.) 2 GasketRelief Valve 2a 3 O-Ring Bolt 1 4 Hex Nut /2-13 Thd. 5 Spring 6 Bolt-Clamp 7 Nut-Clamp /8-16 Thd. 8 Washer-Clamp 9 Clamping Ring 3 Material Aluminum Aluminum Buna-N Viton Wh. Hypalon Tef-Sil Stnls 304 Steel Zinc Plt. Stnls 304 Van Steel Steel Zinc Plt. Stnls 304 Brass Stnls 304 Steel Zinc Plt. Stnls 304 Steel Steel Zinc Plt. Stnls 304 Part No. 8241AL 8246AL 3119BN 3119VT 3119WH 3902TS 3876SL 9Q5812 9Q5853 3859EY 3029ZC 3029SL 3030BR 9Q5809 3031ZC 3031SL 3036MS 3036ZC 3036SL No. 10 Description Manhole Gasket Channel Type B V W T 11 Manhole Collar Channel Type 12 13 14 15 Vent Assembly Gasket Plastic Cap Bellows Material Buna-N Viton Wh. Hypalon Teflon Env. w/ Wh. Hypalon Steel Aluminum Stnls 304 Stnls 316 Alum/Stnls Viton Polyethylene Buna-Urethane Gasket Maximum Temperature Buna-N (Nitrile) Viton White Hypalon Teflon-Silicone Teflon Envelope w/ White Hypalon Insert Part No. 3560BN 3560VT 3560WH 3033TF 3176MS 3176AE 3176SL 3176SS 6238AL 3716VT 9Z6150 4020BU 250°F 400°F 250°F 400°F 250°F MAINTENANCE: Manhole assemblies should be inspected with sufficient frequency and due regard to the products carried to insure a liquid tight closure. Any worn, damaged or missing parts must be replaced. Gaskets should be replaced if their effectiveness is impaired in any way. Replacement gaskets must be compatible with products carried. WARNING Use only genuine Betts Industries Inc. replacement parts. Use of substitute parts can impair the proper functioning of the Pressure Relief Valve and Manhole Assembly. TM INDUSTRIES, INC. WARREN, PA. Aug 1997 Section 86 Page 7B R 20” PAF450 MANHOLE With Pressure Relief Valve COVERED BY PATENTS ISSUED AND PENDING BETTS INDUSTRIES, INC. WARREN, PA. U.S.A. NORMAL VENT WROUGHT STEEL COVER SECONDARY SAFETY LATCH HEAVY DUTY CLAMP RING Not legal as replacement on MC306 cargo tanks after August 31, 1998 Pressure Relief Valve setting 3.0 psig. Rated Pressure Actuated Emergency Venting: 375,000 cu. ft. free air per hour @ 5.0 psig. PAF Manholes with Model PAF450 10” Pressure Relief Valve are certified for use on MC306 cargo tanks. Manholes are certified and marked in accordance with 49CFR178.345-5 with test pressure of 36 psig. Per 49CFR180.405(h)(3), PAF450 assemblies may not be installed on MC306 cargo tanks after August 31, 1998. However, relief valves installed on MC306 cargo tanks on or before August 31, 1998, may be repaired if required. PAF450 relief valves may be installed on non-specification tanks or in tanks built in countries other than the United States where regulations permit. Relief valve also serves as a 10” latch style fill which can be easily opened for filling the tank or for inspection. Standard features include heavy duty clamp ring, secondary safety latch and model 6238AL Normal Vent. *No provision has been made for venting of product due to overfilling. Manholes are also available with a self-latching feature which allows the Pressure Relief Valve cover to open only 91 degrees and drop closed and securely latch upon movement of the tank if the cover is inadvertently left open. For selflatching model substitute 9763 for 9720 in assembly number. 1 NOTE: 3 /2” vent and Liquid Level Switch not included in assembly. Clamping Ring, PRV Clamping Spring Cover Plate Bolt & Washer, Spring Cover Ring Nut Bolt & Nut Strongback, Latch Steel Zinc Plt. Steel Zinc Plt. Brass Stnls 304** Van. Alum. Stnls 304 Stnls 304 Stnls 304 Stnls 304 Steel Stnls 316 Stnls 304 Stnls 304 Stnls 304 **Nut Material – Steel Zinc Plated Normal Vent Wt. (lb.) Assembly No. Alum. 28.4 28.9 28.9 FVA9820BXB FVA9820CXB FVA9820DXB NOTE: Manhole assemblies, as listed above, have a 6238AL vent (prefix “FVA”) and Buna-N (suffix “B”). For variation or additional vents see catalog Section 95 for proper prefix or assembly number. For variation in gasketing change last letter of suffix as follows. Suffix “V” indicates Viton gasket Suffix “W” indicates White Hypalon gasket Suffix “T” indicates Tef-Sil pressure relief valve gasket and Teflon Envelope w/ White Hypalon insert collar gasket Manhole collars are available in aluminum, steel, and stainless steel. Please see parts page for correct numbers. When welding collars to tank, exercise care to insure collar remains flat and round. TM INDUSTRIES, INC. WARREN, PA. Sept 1998 Section 86 Page 8A PARTS LIST 20” PAF 450 MANHOLE Self-Latching Model Illustrated No. 1 1a Description Cover-Relief Valve Cover (O-Ring Grvd.) 2 GasketRelief Valve 2a 3 O-Ring Bolt 1 4 Hex Nut /2-13 Thd. 5 Spring 6 Bolt-Clamp 7 Nut-Clamp /8-16 Thd. 8 Washer-Clamp 9 Clamping Ring 3 Material Aluminum Aluminum Buna-N Viton Wh. Hypalon Tef-Sil Stnls 304 Steel Zinc Plt. Stnls 304 Van Steel Steel Zinc Plt. Stnls 304 Brass Stnls 304 Steel Zinc Plt. Stnls 304 Steel Steel Zinc Plt. Stnls 304 Part No. 8241AL 8246AL 3119BN 3119VT 3119WH 3902TS 3876SL 9Q5812 9Q5853 3859EY 3029ZC 3029SL 3030BR 9Q5809 3031ZC 3031SL 3036MS 3036ZC 3036SL No. 10 Description Manhole Gasket Channel Type B V W T 11 Manhole Collar Channel Type 12 13 14 15 Vent Assembly Gasket Plastic Cap Bellows Material Buna-N Viton Wh. Hypalon Teflon Env. w/ Wh. Hypalon Steel Aluminum Stnls 304 Stnls 316 Alum/Stnls Viton Polyethylene Buna-Urethane Gasket Maximum Temperature Buna-N (Nitrile) Viton White Hypalon Teflon-Silicone Teflon Envelope w/ White Hypalon Insert Part No. 3560BN 3560VT 3560WH 3033TF 3176MS 3176AE 3176SL 3176SS 6238AL 3716VT 9Z6150 4020BU 250°F 400°F 250°F 400°F 250°F MAINTENANCE: Manhole assemblies should be inspected with sufficient frequency and due regard to the products carried to insure a liquid tight closure. Any worn, damaged or missing parts must be replaced. Gaskets should be replaced if their effectiveness is impaired in any way. Replacement gaskets must be compatible with products carried. WARNING Use only genuine Betts Industries Inc. replacement parts. Use of substitute parts can impair the proper functioning of the Pressure Relief Valve and Manhole Assembly. TM INDUSTRIES, INC. WARREN, PA. Apr 2000 Section 86 Page 8B R 20” HOT PRODUCT MANHOLE With 10” Fill 25 PSIG YIELD PRESSURE MOUNT TO 20” PAF WELD COLLARS HEAVY DUTY CLAMP RING Hot Product Manholes are designed for use on tanks hauling elevated temperature materials and are rated with a 25 PSIG yield pressure to meet the requirements of 49CFR 173.247(g)(2), which states: “…Closures must be designed and constructed to withstand, without exceeding the yield strength of the packaging, twice the static loading produced by the lading in any packaging orientation and at all operating temperatures.” Hot Product Manholes are designed to retrofit existing PAF Manholes on elevated temperature tanks in order to bring them into compliance with the current closure requirements, as well as for new construction tanks. The design features a 10” fill to provide tank access for filling or inspection and a heavy duty clamp ring which can be removed to provide access into the tank. Steel assemblies are black epoxy coated for corrosion resistance. Cover & Fill Material Clamping Ring Steel E-Coated Steel Zinc Plt. NOTE: 20” Model not available in stainless steel. Clamping Bolt & Washer Steel Zinc Plt. Wt. 37.5 lb. Assembly No. 8269YXV NOTE: Manhole assemblies, as listed above, have Viton gaskets (suffix “V”). For other gaskets available, see parts page for correct suffix. During installation and welding the collars to the tank, care should be exercised to insure collars remain flat and round in order to assure proper performance. If necessary, a weld fixture should be used to prevent distortion. TM INDUSTRIES, INC. WARREN, PA. Jan 1995 Section 86 Page 11A PARTS LIST 20” HOT PRODUCTS MANHOLE No. 1 2 Description Cover B V W Gasket* E 3 4 5 6 7 8 9 10 11 Wing Nut Snap Ring Snap Ring Washer Swing Bolt Swing Bolt Pin Roll Pin-Swg Bolt Hinge Pin Roll Pin-Hinge Pin Cover Assembly Material Steel Buna-N Viton White Hypalon White Non-Asbestos with Teflon Suspensoid (Woven) Stnls 304 Stnls 304 Stnls 304 Stnls 304 Stnls 304 Stnls 304 Stnls 304 Stnls 304 Steel Part No. 6554EY 3567BN 3567VT 3567WH 3567NT 3576SL 9Q4933 3575SL 3765SL 3086SL 9Q8593 3618SL 9Q8601 6552EY No. Description 12 Bolt-Clamp 13 Washer-Clamp 14 Nut-Clamp 15 Clamping Ring 16 *Gasket Maximum Temperature Buna-N (Nitrile) 250°F Viton 400°F White Hypalon 250°F Pure Teflon 500°F 500°F White Non-Asbestos with Teflon Suspensoid GASKETS: Check the condition of all gaskets and replace if their effectiveness as a seal is impaired in any way. Replacement gaskets must be compatible with products carried. Manhole Gasket Channel Type B V W T Material Steel Zinc Plt. Stnls 304 Steel Zinc Plt. Stnls 304 Brass Stnls 304 Steel Steel Zinc Plt. Stnls 304 Buna-N Viton White Hypalon Teflon Envelope w/ White Hypalon Part No. 3029ZC 3029SL 3031ZC 3031SL 3030BR 9Q5809 3036MS 3036ZC 3036SL 3560BN 3560VT 3560WH 3033TF MAINTENANCE: Manhole assembly should be inspected with sufficient frequency and with due regard to the products carried to insure a liquid tight closure. Any worn, damaged, or missing parts must be replaced. WING NUTS AND SWING BOLTS: All swing bolt and wing nut assemblies must be secured to the cover and tightened to insure the pressure and product retention performance of the manhole assembly. WARNING Use only genuine Betts Industries Inc. replacement parts. Use of substitute parts can impair the proper functioning of this product. TM INDUSTRIES, INC. WARREN, PA. Jan 1995 Section 86 Page 11B R 20” PAF 406-98 MANHOLE With Integral Relief Valve/10” Fill MEETS DOT 178.345-5 TEST PRESSURE 36 PSIG CT-0040 COVERED BY PATENTS ISSUED AND PENDING LESS THAN 1 LITER LEAKAGE BETTS INDUSTRIES, INC. WARREN, PA. U.S.A. INTEGRAL RELIEF VALVE/10” FILL SET PRESSURE ADJUSTMENT INCREASED FLOW RATE SECONDARY SAFETY LATCH Pressure Relief Valve setting 3.63 psig Rated Pressure Actuated Emergency Venting: 494,084 cu. ft. free air per hour @ 6.25 psig Rated Liquid Flow Capacity 1335 gpm @ 5.0 psig PAF manholes with integral latch style surge suppression relief valves are designed for use on DOT406 and replacement on MC306 specification cargo tanks. Manholes are certified and marked in accordance with 49CFR178.345-5 with a test pressure of 36 psig. Manhole covers are 7 gage steel or stainless and are secured to the tank weld collar with a clamp ring and bolt which can be easily removed to provide access into the tank. The integral 10” relief valve provides emergency pressure relief and meets the 1 liter surge leakage limit imposed by 49CFR178.345-10(b)(3)(ii). The relief valve also serves as a 10” latch style fill which can be easily opened to provide access for filling the tank or for inspection. Relief valves contain an adjustment feature to allow for fine-tuning of set pressure in the field. Other standard features include a heavy duty clamp ring, secondary safety latch and model 6496ALB pressure-vacuum vent mounted in the 10” relief valve cover. Manholes are available with a self-latching feature that allows the 10” relief valve/fill cover to drop and securely latch upon movement of the tank if the cover is inadvertently left open. For self-latching model substitute L720 for L763 in assembly number. Cover Plate Relief Valve Steel Zinc Plt. Stnls 304 Stnls 316 Alum. Alum. Alum. Clamping Ring, Bolt, Washer, Strongback, & Latch Steel Zinc Plt. Stnls 304 Stnls 304 Clamping Ring Nut Brass Stnls 304 Stnls 304 Normal Vent Wt. (lb.) Assembly No. Alum. Alum. Alum. 30.5 31.0 31.0 PPVL720BXB PPVL720CXB PPVL720DXB Note: Manhole assemblies, as listed above, have Buna-N gaskets (suffix “B”). For variation in gasketing change last letter of assembly number as follows. Suffix “V” indicates Viton collar gasket & Viton 10” fill gasket Suffix “W” indicates White Hypalon collar gasket & White Hypalon 10” fill gasket Suffix “T” indicates Teflon envelope collar gasket & Tef-Sil 10” fill o-ring Manhole collars are available in aluminum, steel, and stainless steel. Please see parts page for correct numbers. When welding collars to tank, care should be exercised to insure collar remains flat and round. TM INDUSTRIES, INC. WARREN, PA. Sept 1999 Section 86 Page 18A PARTS LIST 20” PAF 406-98 MANHOLE Self-Latching Model Illustrated No. 1 1a Description Fill Cover Fill Cover (O-Ring Grvd.) 2 Gasket Integral Relief Valve 2a O-Ring 3 Bolt-Clamp Ring 4 Nut-Clamp Ring 5 Washer-Clamp Ring 6 Clamping Ring 7 Manhole Gasket Channel Type 8 Manhole Collar Channel Type Material Alum/E-Coated Alum/E-Coated Buna-N Viton Wh. Hypalon Tef-Sil Steel Zinc Plt. Stnls 304 Brass Stnls 304 Steel Zinc Plt. Stnls 304 Steel Steel Zinc Plt. Stnls 304 Buna-N Viton Wh. Hypalon Teflon Env. w/ Wh. Hypalon Steel Aluminum Stnls 304 Stnls 316 Part No. 8297ALEY 8297ALEY389 3119BN 3119VT 3119WH 3902TS 3029ZC 3029SL 3030BR 9Q5809 3031ZC 3031SL 3036MS 3036ZC 3036SL 3560BN 3560VT 3560WH 3033TF 3176MS 3176AE 3176SL 3176SS No. 9 10 11 12 13 14 15 17 18 19 20 21 22 23 24 25 26 Description Vent Assembly Gasket Cylinder Assembly Piston Stem Spring 1 /2” NPT Plug Zinc Plt. Stem O-Ring -112 Cylinder O-Ring –137 Piston O-Ring –137 O-Ring Retainer Retainer Ring Bellows 7 Lockwasher Ext. Tooth /16” 7 Nut Hex /16x20 Plastic Plug 3 /8-16 Hex Nut w/ Insert Material Aluminum Buna-N Aluminum Aluminum Stnls 304 Steel Steel Zinc Plt. Buna-N Buna-N Tef-Sil Alum/E-Coated Stnls 304 EPDM Stnls 304 Stnls 304 Polyethylene Steel Zinc Plt. Gasket Maximum Temperature Buna-N (Nitrile) Viton White Hypalon Teflon-Silicone Teflon Envelope w/ White Hypalon Insert Part No. 6496ALB 3716BN 6657AL 6654AL 6688SL 4122MS 9V4907 4118BN 4015BN 4015TS 4117ALEY 9Q4961 4020EPDM 9Q5961 9Q5960 9Z6163 9Q5896 250°F 400°F 250°F 400°F 250°F Replace oil cylinder using Automatic Transmission Fluid Dexron III/Mercon, SAE 5W-20 with viscosity of 177 SUS at 100°F and a pour point of no greater than –45°F. MAINTENANCE: Manhole assemblies should be inspected with sufficient frequency to insure 10” Integral Relief Valve functions properly. Any worn, damaged or missing parts must be replaced. Gaskets should be replaced if their effectiveness to insure a liquid tight seal is impaired in any way. Replacement gaskets must be compatible with products carried. WARNING Consult PAF406-98 maintenance manual prior to disassembly of this relief valve. Use only genuine Betts Industries Inc. replacement parts. Use of substitute parts can impair the proper functioning of this product. TM INDUSTRIES, INC. WARREN, PA. Sept 1999 Section 86 Page 18B R 20” PAF 406-98 OFFSET MANHOLE With Integral Relief Valve/10” Fill CT-0040 COVERED BY PATENTS ISSUED AND PENDING LESS THAN 1 LITER LEAKAGE BETTS INDUSTRIES, INC. WARREN, PA. U.S.A. MEETS DOT 178.345-5 TEST PRESSURE 36 PSIG INTEGRAL RELIEF VALVE/10” FILL SET PRESSURE ADJUSTMENT INCREASED FLOW RATE SECONDARY SAFETY LATCH Pressure Relief Valve setting 3.63 psig Rated Pressure Actuated Emergency Venting: 494,084 cu. ft. free air per hour @ 6.25 psig Rated Liquid Flow Capacity 1335 gpm @ 5.0 psig PAF manholes with integral latch style surge suppression relief valves are designed for use on DOT406 and replacement on MC306 specification cargo tanks. Manholes are certified and marked in accordance with 49CFR178.345-5 with a test pressure of 36 psig. Manhole covers are 7 gage steel or stainless and are secured to the tank weld collar with a clamp ring and bolt which can be easily removed to provide access into the tank. The integral 10” relief valve provides emergency pressure relief and meets the 1 liter surge leakage limit imposed by 49CFR178.345-10(b)(3)(ii). The relief valve also serves as a 10” latch style fill which can be easily opened to provide access for filling the tank or for inspection. Relief valves contain an adjustment feature to allow for fine-tuning of set pressure in the field. Other standard features include a heavy duty clamp ring, secondary safety latch and model 6496ALB pressure-vacuum vent mounted in the 10” relief valve cover. Manholes are available with a self-latching feature that allows the 10” relief valve/fill cover to drop and securely latch upon movement of the tank if the cover is inadvertently left open. For self-latching model substitute L863 for L820 in assembly number. 1 Note: 3 /2” Vent and Liquid Level Switch not included in assembly. Clamping Ring, Cover Relief Clamping Ring Bolt, Washer, Plate Valve Nut Strongback, & Latch Steel Zinc Plt. Alum. Steel Zinc Plt. Brass Stnls 304 Alum. Stnls 304 Stnls 304 Stnls 316 Alum. Stnls 304 Stnls 304 Normal Vent Alum. Alum. Alum. Wt. (lb.) Assembly No. 29.7 30.2 30.2 PPVL820BXB PPVL820CXB PPVL820DXB Note: Manhole assemblies, as listed above, have Buna-N gaskets (suffix “B”). For variation in gasketing change last letter of assembly number as follows. Suffix “V” indicates Viton collar gasket & Viton 10” fill gasket Suffix “W” indicates White Hypalon collar gasket & White Hypalon 10” fill gasket Suffix “T” indicates Teflon envelope collar gasket & Tef-Sil 10” fill o-ring Manhole collars are available in aluminum, steel, and stainless steel. Please see parts page for correct numbers. When welding collars to tank, care should be exercised to insure collar remains flat and round. TM INDUSTRIES, INC. WARREN, PA. Sept 1999 Section 86 Page 19A A B C D E F G H PARTS LIST 20” PAF 406-98 MANHOLE Self-Latching Model Illustrated No. 1 1a Description Fill Cover Fill Cover (O-Ring Grvd.) 2 Gasket Integral Relief Valve 2a O-Ring 3 Bolt-Clamp Ring 4 Nut-Clamp Ring 5 Washer-Clamp Ring 6 Clamping Ring 7 Manhole Gasket Channel Type 8 Manhole Collar Channel Type Material Alum/E-Coated Alum/E-Coated Buna-N Viton Wh. Hypalon Tef-Sil Steel Zinc Plt. Stnls 304 Brass Stnls 304 Steel Zinc Plt. Stnls 304 Steel Steel Zinc Plt. Stnls 304 Buna-N Viton Wh. Hypalon Teflon Env. w/ Wh. Hypalon Steel Aluminum Stnls 304 Stnls 316 Part No. 8297ALEY 8297ALEY389 3119BN 3119VT 3119WH 3902TS 3029ZC 3029SL 3030BR 9Q5809 3031ZC 3031SL 3036MS 3036ZC 3036SL 3560BN 3560VT 3560WH 3033TF 3176MS 3176AE 3176SL 3176SS No. 9 10 11 12 13 14 15 17 18 19 20 21 22 23 24 25 26 PLAN VIEW DIMENSIONS 1 4 /4” Dia. (107.95mm) 7 8 Holes-.390 Dia. (9.90mm) on 4 /8” (123.83mm) B.C. 3 2 /8” Dia. (60.325mm) Hole 1 /4” N.P.T. Coupling 7” Rad. (177.8mm) 3 6 /8” (161.93mm) 3 4 /4” (120.65mm) 1 3 /4” (82.55mm) Description Vent Assembly Gasket Cylinder Assembly Piston Stem Spring 1 /2” NPT Plug Zinc Plt. Stem O-Ring -112 Cylinder O-Ring –137 Piston O-Ring –137 O-Ring Retainer Retainer Ring Bellows 7 Lockwasher Ext. Tooth /16” 7 Nut Hex /16x20 Plastic Plug 3 /8-16 Hex Nut w/ Insert Material Aluminum Buna-N Aluminum Aluminum Stnls 304 Steel Steel Zinc Plt. Buna-N Buna-N Tef-Sil Alum/E-Coated Stnls 304 EPDM Stnls 304 Stnls 304 Polyethylene Steel Zinc Plt. Gasket Maximum Temperature Buna-N (Nitrile) Viton White Hypalon Teflon-Silicone Teflon Envelope w/ White Hypalon Insert Part No. 6496ALB 3716BN 6657AL 6654AL 6688SL 4122MS 9V4907 4118BN 4015BN 4015TS 4117ALEY 9Q4961 4020EPDM 9Q5961 9Q5960 9Z6163 9Q5896 250°F 400°F 250°F 400°F 250°F Replace oil cylinder using Automatic Transmission Fluid Dexron III/Mercon, SAE 5W-20 with viscosity of 177 SUS at 100°F and a pour point of no greater than –45°F. MAINTENANCE: Manhole assemblies should be inspected with sufficient frequency to insure 10” Integral Relief Valve functions properly. Any worn, damaged or missing parts must be replaced. Gaskets should be replaced if their effectiveness to insure a liquid tight seal is impaired in any way. Replacement gaskets must be compatible with products carried. WARNING Consult PAF406-98 maintenance manual prior to disassembly of this relief valve. Use only genuine Betts Industries Inc. replacement parts. Use of substitute parts can impair the proper functioning of this product. TM INDUSTRIES, INC. WARREN, PA. Sept 1999 Section 86 Page 19B R 20” PAF 306-98 MANHOLE INTEGRAL 10” FILL/PRESSURE RELIEF VALVE WITH MC306 SET PRESSURE • LESS THAN 1 LITER LEAKAGE • SECONDARY SAFETY LATCH MEETS DOT 178.345-5 TEST PRESSURE 36 PSIG • CT-0040 REPLACEMENT FOR PAF9000 MODELS COVERED BY PATENTS ISSUED AND PENDING • BETTS INDUSTRIES, INC. WARREN, PA. U.S.A. With Integral Relief Valve/10” Fill Pressure Relief Valve setting 3.0 psig Rated Pressure Actuated Emergency Venting: 250,000 cu. ft. free air per hour @ 5.0 psig Rated Liquid Flow Capacity 1012 gpm @ 5.0 psig PAF manholes with integral latch style surge suppression relief valves are designed for use as a replacement for PAF9000 model manhole assemblies on MC306 tanks. Manholes are certified and marked in accordance with 49CFR178.345-5 with a test pressure of 36 psig. Manhole covers are 7 gage steel or stainless and are secured to the tank weld collar with a clamp ring and bolt which can be easily removed to provide access into the tank. The integral 10” relief valve provides emergency pressure relief and meets the 1 liter surge leakage limit imposed by 49CFR178.345-10(b)(3)(ii). The relief valve also serves as a 10” latch style fill which can be easily opened to provide access for filling the tank or for inspection. Relief valves contain an adjustment feature to allow for fine-tuning of set pressure in the field. Other standard features include a heavy duty clamp ring, secondary safety latch and model 6238ALB pressure-vacuum vent mounted in the 10” relief valve cover. Manholes are available with a self-latching feature that allows the 10” relief valve/fill cover to drop and securely latch upon movement of the tank if the cover is inadvertently left open. For self-latching model substitute R463 for R420 in assembly number. Cover Plate Relief Valve Steel Zinc Plt. Stnls 304 Stnls 316 Alum. Alum. Alum. Clamping Ring, Bolt, Washer, Strongback, & Latch Steel Zinc Plt. Stnls 304 Stnls 304 Clamping Ring Nut Brass Stnls 304 Stnls 304 Normal Vent Wt. (lb.) Alum. Alum. Alum. 30.5 31.0 31.0 Assembly No. FVAR420BXB FVAR420CXB FVAR420DXB Note: Manhole assemblies, as listed above, have Buna-N gaskets (suffix “B”). For variation in gasketing change last letter of assembly number as follows. Suffix “V” indicates Viton collar gasket & Viton 10” fill gasket Suffix “W” indicates White Hypalon collar gasket & White Hypalon 10” fill gasket Suffix “T” indicates Teflon envelope collar gasket & Tef-Sil 10” fill o-ring Manhole collars are available in aluminum, steel, and stainless steel. Please see parts page for correct numbers. When welding collars to tank, care should be exercised to insure collar remains flat and round. TM INDUSTRIES, INC. WARREN, PA. Nov 1999 Section 86 Page 20A PARTS LIST 20” PAF 306-98 MANHOLE No. 1 1a Description Fill Cover Fill Cover (O-Ring Grvd.) 2 Gasket Integral Relief Valve 2a O-Ring 3 Bolt-Clamp Ring 4 Nut-Clamp Ring 5 Washer-Clamp Ring 6 Clamping Ring 7 Manhole Gasket Channel Type 8 Manhole Collar Channel Type Material Alum/E-Coated Alum/E-Coated Buna-N Viton Wh. Hypalon Tef-Sil Steel Zinc Plt. Stnls 304 Brass Stnls 304 Steel Zinc Plt. Stnls 304 Steel Steel Zinc Plt. Stnls 304 Buna-N Viton Wh. Hypalon Teflon Env. w/ Wh. Hypalon Steel Aluminum Stnls 304 Stnls 316 Part No. 8317ALEY 8317ALEY389 3119BN 3119VT 3119WH 3902TS 3029ZC 3029SL 3030BR 9Q5809 3031ZC 3031SL 3036MS 3036ZC 3036SL 3560BN 3560VT 3560WH 3033TF 3176MS 3176AE 3176SL 3176SS No. 9 10 11 12 13 14 15 16 17 18 19 20 21 22 23 24 25 Description Vent Assembly Gasket Cylinder Assembly Piston Stem Spring 1 /2” NPT Plug Zinc Plt. Stem O-Ring -112 Cylinder O-Ring –137 Piston O-Ring –137 O-Ring Retainer Retainer Ring Bellows 7 Lockwasher Ext. Tooth /16” 7 Nut Hex /16x20 Plastic Plug 3 /8-16 Hex Nut w/ Insert Material Aluminum Buna-N Aluminum Aluminum Stnls 303 Steel Steel Zinc Plt. Buna-N Buna-N Tef-Sil Alum/E-Coated Stnls 304 BUNA Stnls 304 Stnls 304 Polyethylene Steel Zinc Plt. Gasket Maximum Temperature Buna-N (Nitrile) Viton White Hypalon Teflon-Silicone Teflon Envelope w/ White Hypalon Insert Part No. 6238ALB 3716BN 6657AL 6654AL 6720SL 4173MS 9V4907 4118BN 4015BN 4015TS 4117ALEY 9Q4961 3998BU 9Q5961 9Q5960 9Z6163 9Q5896 250°F 400°F 250°F 400°F 250°F Replace oil cylinder using Automatic Transmission Fluid Dexron III/Mercon, SAE 5W-20 with viscosity of 177 SUS at 100°F and a pour point of no greater than –45°F. MAINTENANCE: Manhole assemblies should be inspected with sufficient frequency to insure 10” Integral Relief Valve functions properly. Any worn, damaged or missing parts must be replaced. Gaskets should be replaced if their effectiveness to insure a liquid tight seal is impaired in any way. Replacement gaskets must be compatible with products carried. WARNING Consult PAF406-98 maintenance manual prior to disassembly of this relief valve. Use only genuine Betts Industries Inc. replacement parts. Use of substitute parts can impair the proper functioning of this product. TM INDUSTRIES, INC. WARREN, PA. Nov 1999 Section 86 Page 20B R 20” PAF306-98 OFFSET MANHOLE With Integral Relief Valve/10” Fill • LESS THAN 1 LITER LEAKAGE • SECONDARY SAFETY LATCH CT-0040 INTEGRAL 10” FILL/PRESSURE RELIEF VALVE WITH MC306 SET PRESSURE COVERED BY PATENTS ISSUED AND PENDING • BETTS INDUSTRIES, INC. WARREN, PA. U.S.A. REPLACEMENT FOR PAF9000 MODELS MEETS DOT 178.345-5 TEST PRESSURE 36 PSIG • Pressure Relief Valve setting 3.0 psig Rated Pressure Actuated Emergency Venting: 250,000 cu. ft. free air per hour @ 5.0 psig Rated Liquid Flow Capacity 1012 gpm @ 5.0 psig PAF manholes with integral latch style surge suppression relief valves are designed for use as a replacement for PAF9000 model manhole assemblies on MC306 tanks. Manholes are certified and marked in accordance with 49CFR178.345-5 with a test pressure of 36 psig. Manhole covers are 7 gage steel or stainless and are secured to the tank weld collar with a clamp ring and bolt which can be easily removed to provide access into the tank. The integral 10” relief valve provides emergency pressure relief and meets the 1 liter surge leakage limit imposed by 49CFR178.345-10(b)(3)(ii). The relief valve also serves as a 10” latch style fill which can be easily opened to provide access for filling the tank or for inspection. Relief valves contain an adjustment feature to allow for fine-tuning of set pressure in the field. Other standard features include a heavy duty clamp ring, secondary safety latch and model 6238ALB pressure-vacuum vent mounted in the 10” relief valve cover. Manholes are available with a self-latching feature that allows the 10” relief valve/fill cover to drop and securely latch upon movement of the tank if the cover is inadvertently left open. For self-latching model substitute R563 for R520 in assembly number. Note: 31/2” Vent and Liquid Level Switch not included in assembly. Clamping Ring, Clamping Ring Cover Relief Bolt, Washer, Nut Plate Valve Strongback, & Latch Steel Zinc Plt. Alum. Steel Zinc Plt. Brass Stnls 304 Alum. Stnls 304 Stnls 304 Stnls 316 Alum. Stnls 304 Stnls 304 Normal Vent Wt. (lb.) Assembly No. Alum. Alum. Alum. 29.7 30.2 30.2 FVAR520BXB FVAR520CXB FVAR520DXB Note: Manhole assemblies, as listed above, have Buna-N gaskets (suffix “B”). For variation in gasketing change last letter of assembly number as follows. Suffix “V” indicates Viton collar gasket & Viton 10” fill gasket Suffix “W” indicates White Hypalon collar gasket & White Hypalon 10” fill gasket Suffix “T” indicates Teflon envelope collar gasket & Tef-Sil 10” fill o-ring Manhole collars are available in aluminum, steel, and stainless steel. Please see parts page for correct numbers. When welding collars to tank, care should be exercised to insure collar remains flat and round. TM INDUSTRIES, INC. WARREN, PA. Nov 1999 Section 86 Page 21A A B C D E F G H PARTS LIST 20” PAF 306-98 MANHOLE No. 1 1a Description Fill Cover Fill Cover (O-Ring Grvd.) 2 Gasket Integral Relief Valve 2a O-Ring 3 Bolt-Clamp Ring 4 Nut-Clamp Ring 5 Washer-Clamp Ring 6 Clamping Ring 7 Manhole Gasket Channel Type 8 Manhole Collar Channel Type Material Alum/E-Coated Alum/E-Coated Buna-N Viton Wh. Hypalon Tef-Sil Steel Zinc Plt. Stnls 304 Brass Stnls 304 Steel Zinc Plt. Stnls 304 Steel Steel Zinc Plt. Stnls 304 Buna-N Viton Wh. Hypalon Teflon Env. w/ Wh. Hypalon Steel Aluminum Stnls 304 Stnls 316 Part No. 8317ALEY 8317ALEY389 3119BN 3119VT 3119WH 3902TS 3029ZC 3029SL 3030BR 9Q5809 3031ZC 3031SL 3036MS 3036ZC 3036SL 3560BN 3560VT 3560WH 3033TF 3176MS 3176AE 3176SL 3176SS No. 9 10 11 12 13 14 15 16 17 18 19 20 21 22 23 24 25 PLAN VIEW DIMENSIONS 1 4 /4” Dia. (107.95mm) 7 8 Holes-.390 Dia. (9.90mm) on 4 /8” (123.83mm) B.C. 3 2 /8” Dia. (60.325mm) Hole 1 /4” N.P.T. Coupling 7” Rad. (177.8mm) 3 6 /8” (161.93mm) 3 4 /4” (120.65mm) 1 3 /4” (82.55mm) Description Vent Assembly Gasket Cylinder Assembly Piston Stem Spring 1 /2” NPT Plug Zinc Plt. Stem O-Ring -112 Cylinder O-Ring –137 Piston O-Ring –137 O-Ring Retainer Retainer Ring Bellows 7 Lockwasher Ext. Tooth /16” 7 Nut Hex /16x20 Plastic Plug 3 /8-16 Hex Nut w/ Insert Material Aluminum Buna-N Aluminum Aluminum Stnls 303 Steel Steel Zinc Plt. Buna-N Buna-N Tef-Sil Alum/E-Coated Stnls 304 BUNA Stnls 304 Stnls 304 Polyethylene Steel Zinc Plt. Gasket Maximum Temperature Buna-N (Nitrile) Viton White Hypalon Teflon-Silicone Teflon Envelope w/ White Hypalon Insert Part No. 6238ALB 3716BN 6657AL 6654AL 6720SL 4173MS 9V4907 4118BN 4015BN 4015TS 4117ALEY 9Q4961 3998BU 9Q5961 9Q5960 9Z6163 9Q5896 250°F 400°F 250°F 400°F 250°F Replace oil cylinder using Automatic Transmission Fluid Dexron III/Mercon, SAE 5W-20 with viscosity of 177 SUS at 100°F and a pour point of no greater than –45°F. MAINTENANCE: Manhole assemblies should be inspected with sufficient frequency to insure 10” Integral Relief Valve functions properly. Any worn, damaged or missing parts must be replaced. Gaskets should be replaced if their effectiveness to insure a liquid tight seal is impaired in any way. Replacement gaskets must be compatible with products carried. WARNING Consult PAF406-98 maintenance manual prior to disassembly of this relief valve. Use only genuine Betts Industries Inc. replacement parts. Use of substitute parts can impair the proper functioning of this product. TM INDUSTRIES, INC. WARREN, PA. Nov 1999 Section 86 Page 21B