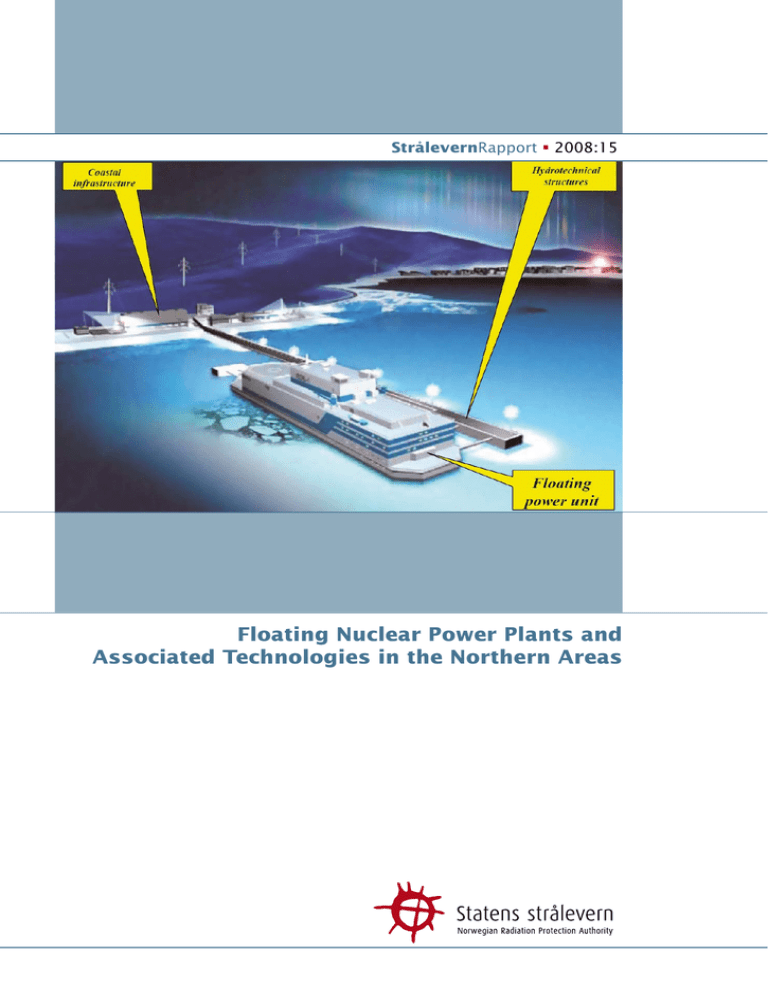

Floating Nuclear Power Plants and Associated

advertisement