Smart Structures

Technology Laboratory

July 2010

Smart Structures

Technology Laboratory

July 2010

Main Topics of APSS

Advanced Sensor Technology

Sensor Informatics

Asia--Pacific Summer School

Asia

on

Smart Structures Technology

Wavelet Domain

s1 s2

105

97

sp

Scale

89

81

Output

73

65

hidden

II

57

49

41

33

hidden I

25

17

200

300

400

500

600

700

Time Step (No. of poiint)

B F

B.

F. Spencer,

S

Jr.

J

Nathan M. and Anne M. Newmark Endowed Chair

of Civil Engineering

University of Illinois at Urbana-Champaign

0 .1 0

Acceleration (m/s )

0 .0 5

0 .0 0

-0 .0 5

C o n tr o l le d b y

H M D m ode

-0 .1 0

20

40

60

80

100

120

140

T im e ( s e c )

Structural Control

Application of SHM

Smart Structures

Technology Laboratory

July 2010

Outline

Conservation of energy yields:

• Trends in Structural Control

E = Ek + Es + Eh + Ed

• Trends in Structural Health Monitoring

• Sensors,

S

D

Data

t A

Acquisition,

i iti

and

d Di

Digital

it l

Signal Processing

• E = total energy

gy input

p to the structure from

f

excitation

• Ek = kinetic energy of the structure

• Es = elastic strain energy of the structure

• Eh = energy dissipated due to inelastic

deformation

• Ed = energy dissipated by supplemental damping

devices

Implementations

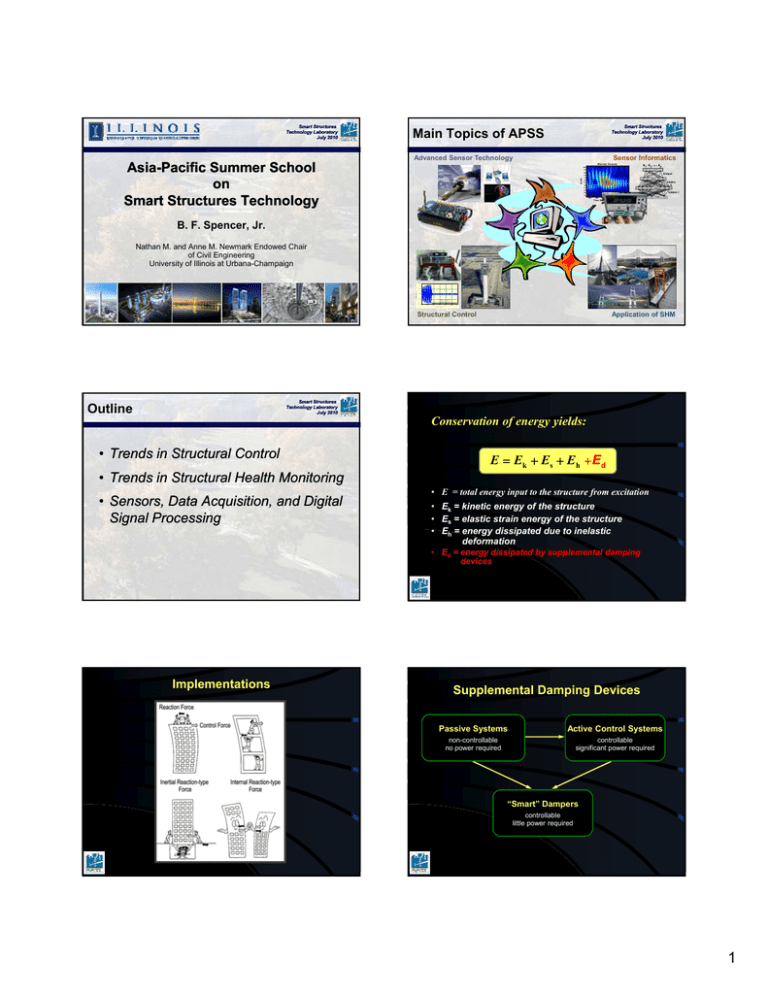

Supplemental Damping Devices

Passive Systems

Active Control Systems

non-controllable

no power required

controllable

significant power required

“Smart” Dampers

controllable

little power required

1

Conventional Structure

Passive Control Systems

PED

Structure

Excitation

Response

Excitation

Structure

Response

m

M

M

Tuned Mass Damper

Passive Control Systems

M

M

M

Base Isolation

Passive Damper

World Trade Center in New York

•10,000 Visco-elastic dampers

in each tower

•Evenly distributed from 10th

to the 110th floor

•Damping: 2.5%~3%

•

•

•

•

Dampers

Base Isolation

Tuned Mass Damper

Tuned Liquid Damper /

Tuned Liquid Column Damper

• Aerodynamic Shaping

Visco-elastic

Viscodamper

Visco--elastic Damper

Visco

Steel Damper

Visco-elastic

ViscoMaterial

Low-yield strength steel

Tennozu Project

Brace Type

Visco-elastic Material

ViscoSteel

Steel

鋼

粘

Plate

Plate

板

弾

Shear

鋼

性

Force Q(Q) 板

体

C Building

Shear

Force (Q)

Q

v(速度)

deformation

せん断ひずみ γ=δ/d

(d)

Thickness (d)

Shear Strain g = d/d

d(厚さ)

Wall Type

M Department Store

Copyright 2008 Shimizu Corporation, All Rights Reserved

42-story high-rise RC condominium

Copyright 2008 Shimizu Corporation, All Rights Reserved

2

Steel Dampers in 42-story RC

condominium

Use of Dampers

in High-rise Building

R.J. Smith and M. R. Willford, The damped outrigger concept for tall buildings

Dissipate energy of

relative vertical

motion between

perimeter columns

and outriggers

Vertically acting

dampers between

coupled shear walls

Copyright 2008 Shimizu Corporation, All Rights Reserved

Beam-type Steel Dampers in RC

Core Walls

Typical Layout at outrigger levels

R.J. Smith and M. R. Willford, The damped outrigger concept for tall buildings

2525

超高強度RCコアウォール

(最大強度80N/mm2)

4650

4650

23650

4650

4650

境界梁型制震ダンパー

2525

3450

6000

6000

6000

6000

3450

30900

超高強度

RCコアウォール

境界梁型

制震ダンパー

Copyright 2008 Shimizu Corporation, All Rights Reserved

Passive Control System

•

•

•

•

Dampers

Base Isolation

Tuned Mass Damper

Tuned Liquid Damper /

Tuned Liquid Column Damper

• Aerodynamic Shaping

Seismic Isolation Methods for

High-rise RC Condominiums

Base Isolation

Device (A total of

32)

Mat slab

35 story RC condominium

Copyright 2008 Shimizu Corporation, All Rights Reserved

3

Seismic Isolation Methods for

High-rise RC Condominiums

Oakland City Hall

Dual-Layer Core Seismic Isolation Method

Earthquake Response

Fixed Base

Base Isolated

Copyright 2008 Shimizu Corporation, All Rights Reserved

21

Base-isolation of LNG Tanks

Base-Isolated Display-Table

for Museum

(Y. S. Kim & S. J. Joo : TS Solution)

Display-Tables on Shaking Table

(Hyundai E&C)

Performance of Base Isolation

2D El Centro Record

fBI

fSLIDING

fNON

NON--BI

(PGA=0.6g)

Without

Base-isolator

Laminated Rubber Bearings

Passive Control Systems

With

Base-isolator

Petronas Towers: TMD

• Supplementary damping

•

•

•

•

Dampers

Base Isolation

Tuned Mass Damper

Tuned Liquid Damper /

Tuned Liquid Column Damper

• Aerodynamic Shaping

– Towers: not necessary

– Sky bridge: 3 TMDs per each leg. (73 kg ea)

– Pinnacles: simple chain impact dampers

TMD

4

Taipei 101: TMD

Taipei 101: Building TMD

• Building TMD

Pinnacle TMDs

– 660 ton. (0.24% of building mass)

Worlds largest.

– TMD and its support occupy five upper

floors.

– Visible from a mezzanine level.

– $3.5-million

$3 5 million turnkey contract.

contract

• Includes Dampers and 60m tall

pinnacle.

• Additional $800k for the damper ball.

– Made of 12.5cm thick steel plate.

– Peak acceleration of the top was reduced

from 7mili-g to 5 milli-g.

– The damper will not have any role during

earthquakes

Building TMD

PARK TOWER

HOTEL & RESIDENCES

Taipei 101: Pinnacle TMDs

CSA

• Pinnacle TMDs

– Two 4.5 ton dampers

– Flat steel masses tuned by springs are able to move horizontally in

any direction.

– To reduce cumulative fatigue damage due to wind-induced motion.

PARK TOWER

HOTEL & RESIDENCES

CSA

• Chicago, Illinois, United States

• 70 story multi-use building

– 48 stories of condos over 18 story hotel

• 824 ft. tall tower

• 5 story parking garage

• Building was designed with a tuned mass

damper to control lateral accelerations

PARK TOWER

HOTEL & RESIDENCES

CSA

• Modified structure

– Initial structural properties:

• T = 7.26 sec

• Drift = 13” = h/700

• Acceleration = 35 mg

– Fi

Finall structurall properties

i without

ih

damper:

• T = 5.18 sec

• Drift = 9.7 in. = h/940

• Acceleration = 20.7 mg

– With addition of damper:

• Acceleration = 15 mg

5

Passive Control System

Random House: TLCD

• Tuned Liquid Column Damper

– Two TLCDs at the roof level (290 tons and

430tons)

– Large U-shaped tanks at right angles.

– Moving water mass is 550 tons (0.33% of

building weight) in each tank.

– Cost effective. Cheaper than a pendulum

TMD.

•

•

•

•

Dampers

Base Isolation

Tuned Mass Damper

Tuned Liquid Damper /

Tuned Liquid Column Damper

• Aerodynamic Shaping

Application of Super Sloshing

Damper in High-rise hotels

Super Sloshing Damper

Tokyo Dome

Hotel

Shin-Yokohama

Prince Hotel

Copyright 2008 Shimizu Corporation, All Rights Reserved

Copyright 2008 Shimizu Corporation, All Rights Reserved

Tuned Mass Dampers for

Tall Buildings

Supplementary Damping System

(Y. S. Kim & S. J. Joo

Joo,, TS Solution)

•

•

•

•

6

5.18

4.95

4.87

Centum Park Apartments

(Busan

Busan,, Korea)

acceleration[gal]

5

3.41

4

2.98

3.12

3.41

3.41

Dampers

Base Isolation

Tuned Mass Damper

Tuned Liquid Damper / Tuned Liquid

Column Damper

• Aerodynamic Shaping

2.94

3

2

1

0

No.101

without TMD

No.103

with TMD

No.105

ISO6897

6

Burj Dubai:

Aerodynamic Shaping

Wind Tunnel Testing at RWDI

•

•

•

•

Rowan Williams Davies & Irwin – Ontario, Canada

1:500 Scale Aero-elastic Model

Structural damping ratio of 1.5% for sway modes 1 and 2

Mounted on turntable

• 36 wind directions at

10 d

degree iinterval

t

l

• Wind speeds between

0.5 and 1.3 times of the

50 year design wind

speed

• Burj Dubai

–

–

–

–

Height: 818m (world’s tallest structure)

Floor: 160

Completion date: Jun 2010

334,000 m2 space

• Damping system

– Conceptual designs for sloshing water and water

column damper systems were developed by

Motioneering

– Shape refinements and structural measures can keep

building sway motions to acceptable levels

– Space for sloshing dampers

Comparison of

Wind Tunnel Results

Wind Tunnel Testing at RWDI

Wind Tunnel #1 Results

Wind Tunnel #3 Results

F = Ma

Disorganized Vortex Shedding

over the height of the tower

Active Control Systems

Active Control Systems

u

x

m

Excitation

Structure

Response

Consider the SDOF system

&&(t ) + cx& (t ) + kx (t ) = bu (t ) + γ w (t )

mx

c,k

with linear state feedback / feedforward

Feedforward

Li k

Link

Control Actuators

Feedback

Li k

Link

w

u = − g1 x − g 2 x& − g 3w

Thus, the closed-loop dynamics are

Sensors

Computer

Sensors

&&(t ) + [c + bg2 ]x& (t ) + [ k + bg1 ]x (t ) = [γ − bg3 ]w (t )

mx

The closed-loop stiffness, damping, and load factor

may be arbitrarily assigned

7

Active Mass Damper (AMD) Experiment:

Acceleration Feedback Control Strategies

Active Control Systems

Actuator

Sensors

Actuator

M

M

Sensor

Sensor

m

M

zact (t )

z&&a3 (t )

Actuator

z&&a2 (t )

Active Mass Damper

Active Base Isolation

Active Bracing

z&&a1(t )

Control

Computer/

DSP Board

z&&g (t )

Control Computer

Kyobashi Seiwa Building (1989)

Rainbow Bridge Tower (1991)

AMD-1

Sensor

AMD-2

Control

Computer

Sensor

Sensor

Yokohama Landmark Tower

(1993): AMD

Sendagaya INTES Building (1992)

8

Shinjuku Park Tower (1994)

Hybrid Mass Damper

ORC200 at Osaka

Roller

2 ×100 ton

Hybrid Mass Dampers for Tower

Floor count: 50, Basement

floor: 2

Shimizuand

Corporation,

MadeCopyright

with2008

SRC

S All Rights Reserved

Shanghai World Financial Center: HMD

(Incheon Int’l Airport)

• Active tuned mass damper

Air Traffic Control Tower: 100. 4 m

Natural Frequency: 0.71 Hz

y

– Two dampers on the 90th floor.

– Sensors are used to measure the building

sway with a computer to control

x

HMD2

HMD1

Hybrid Mass Damper (HMD)

0 .1 0

0 .0 5

0 .0 5

Acceleration (m/s )

0 .1 0

2

Acceleration (m/s )

Location of HMDs: 19th Floor

(80 m above ground)

0 .0 0

-0 .0 5

TM D

m ode

• Shape

0 .0 0

- 0 .0 5

C o n t r o l le d b y

H M D m ode

U n c o n tr o ll e d

-0 .1 0

- 0 .1 0

20

40

60

80

100

120

140

20

40

60

80

100

T im e ( s e c )

T i m e (s e c )

Signal w/o HMD

Signal w/ HMD

120

140

– The Hole in the building reduces vortexshedding induced force.

Harumi Island Triton Square

Next Steps …

• Smart damping strategies can effectively

address a number of these challenges –

devices are low power, fail-safe.

• Studies show that smart dampers can

potentially achieve the majority of the

performance of fully active systems.

9

Smart (Semiactive) Control Systems

Structure

Excitation

Smart Damping?

Response

PED

Control Actuators

Sensors

Computer

Sensors

Smart Damping?

Kajima Shizuoka Building:

Observations from the

May 7, 1999 M4.9

Earthquake

K-Building

R-Building

238.05m, 54 story

172 m, 38 story

Hybrid mass

damper 2

Semi-active

hydraulic

damper 88

356

semi-active

semihydraulic

dampers

10

Magnetorheological Fluid Damper

Smart Base Isolated Building

Using Variable-Orifice Dampers

at Keio University

Magnetic Choke

MR Fluid

x

F

Magnetorheological Fluids

Magnetorheological Fluids

What are they?

• Micron-sized, polarizable, iron particles in oil

What do they do?

•

•

•

•

Magnetorheological Fluid Damper

Newtonian in the absence of applied field

Develop yield strength when field applied

Bingham Model: τ = τ (u) + ηγ&

Provide reliable means for a low-power,

rapid response interface between

electronic controls and mechanical

devices

Force - Velocity Envelope for

MR Fluid Damper

Large force at small or zero

velocity is possible

F

Magnetic Choke

MR Fluid

x

Constant current

operating curve

Zero current

x&

F

F = μ (u ) sgn( x& ) + c p x&

μ (u )

F = μ (u ) sgn( x& ) + c p x&x, F

Maximum current

Extension

Any arbitrary curve within

operational envelope is

possible

Compression

cp

11

Prototype 20-Ton MR Fluid Damper

Thermal Expansion

Accumulator

3-Stage Piston

Wire

Coils

Prototype 20-Ton MR Fluid Damper

MR Fluid

LORD

RheoneticTM Seismic Damper

MR-9000

LORD

RheoneticTM Seismic Damper

MR-9000

Diameter: 20 cm

Stroke: 16 cm

Power: < 50 watts, 22 volts

Diameter: 20 cm

Stroke: 16 cm

Power: < 50 watts, 22 volts

Performance Testing at the

University of Notre Dame

Performance Testing

2A

Maximum Current

1A

Fo

orce (kN)

0.5 A

Zero Current

0A

Displacement

Velocity (cm/s)

(cm)

Experimental Setup

MR Dampers in a Building

Measured Response

Triangular Displacement

Base Isolation Implementation

Nihon-Kagaku-Miraikan, Tokyo

National Museum of Emerging Science

and Innovation

Two 30-ton, MR Fluid dampers

built by Sanwa Tekki using

Lord MR fluid are installed

between 3rd and 5th floors

12

Tider MRD-160-100 in

JZ20-2NW Offshore Platform (China)

Smart Structures

Technology Laboratory

July 2010

Outline

• Trends in Structural Control

• Trends in Structural Health Monitoring

• Sensors,

S

D

Data

t A

Acquisition,

i iti

and

d Di

Digital

it l

Signal Processing

Why Monitor Infrastructure?

Structural Health Monitoring of

Infrastructure

Smart Structures

Technology Laboratory

July 2010

• To monitor and control the construction process

• To validate the structural designs and characterize

performance (e.g., develop database)

• To characterize loads in situ

g

g maintenance

• To assist with building/bridge

• To detect and localize damage before it reaches a

critical level, thus increasing the safety to the public

• To reduce the costs and down-time associated with

repair of damage

• To assist with emergency response efforts, including

building evacuation and traffic control

Ordinary

situation

Emergency

situation

Strong Wind

Building

Brain

Brain

プチッ

Bridge

・

ボキッ

Pipeline

バキッ

sensor

Earthquake

Structural

Damage & Deterioration

Structural

Performance

Owner, Designer,

Engineer

Smart Structures

Technology Laboratory

July 2010

Smart Structures

Technology Laboratory

July 2010

Data

Management

Server

Lantau Fixed Crossing

Database

Owner,

Administrator,

User

Smart Structures

Technology Laboratory

July 2010

Bridges

77

The Hong Kong Polytechnic University

13

Smart Structures

Technology Laboratory

July 2010

Tsing Ma Bridge

Measurements in Four Phases

Phase 1 : Free - standing tower

Smart Structures

Technology Laboratory

July 2010

Phase 2 : Tower - cable system

Structural Health Monitoring

System

•

•

300 Sensors

•

Data acquisition system

Data processing and analysis system

•

Cabling network system

•

$7.8 M

Phase 3 : Tower - cable - deck system

The Hong Kong Polytechnic University

Phase 4 : Completed bridge

The Hong Kong Polytechnic University

Decade of free vibration studies:

Republic Plaza (280M), Singapore

Smart Structures

Technology Laboratory

July 2010

Smart Structures

Technology Laboratory

July 2010

Buildings Applications

•

•

•

•

•

81

Smart Structures

Static+dynamic monitoring through Technology

Laboratory

July 2010

construction tracked modal frequencies

70

7

60

storeys,

mass/106kg

6

50

5

40

4

30

3

20

2

10

1

Frequency measurements 1994-1995

AVT conducted 1995

Monitoring since 1996

Originally for wind data

Building used as wind and earthquake

super-sensor’

• Dual rover GPS operational until 3/2005

• Now reverts to seismometer array

Permanent Monitoring

Smart Structures

Technology Laboratory

July 2010

Building

mode

period/sec

Roof level FBA

Basement FBA

‘sonic’ anemometer

GPS antenna

Logger

0

0

200

days

400

0

600

core w all

core Slab

office Slab

CFT Column

curtain Wall

mass

mode A1

mode B1

14

Smart Structures

Technology Laboratory

July 2010

Typical Earthquake Recording

Smart Structures

Technology Laboratory

July 2010

Design Spectrum

L65A acc/mm.s-2

Bengaft5 Lat -4.0 Long 101.7 (619km) Ms 6.7 tremor 13:25:00 16/01/01 GMT

10

0

-10

2

4

6

8

10

12

14

16

18

Hence there is enough information for a local

design spectrum based on tremor

recordings

B1A acc/mm.s-2

10

1

0

-1

2

4

6

8

10

12

14

16

18

800

900

1000

3

2

1

0

B1A F/Hz

Normalised A-dir 1% spectra

2

2

time /minutes since 21:22:30 16 Jan 2001

65A F/Hz

(Aftershock of

Bengkulu

subduction

zone event in

2000), triggered

b strong

by

t

mode

d

2 response

100

200

300

400

500

600

Time

700

Normalised

to peak

ground

acceleration

10

10

3

1

0

0

0.5

1

1.5

2

2

frequency /Hz

2.5

3

1 Sunda

2 SSumat 4

3 NSumat 2

4 Aceh

5 SSumat 3

7 SSumat 1

9 SSumat 5

10 CSumat

11 SSumat 7

12 Sulawesi

13 Bengkulu

14 Bengaftr

15 SSumat 8

16 Bengaft3

17 Bengaft4

18 Sunda 2

20 Bengaft6

21 SSumat 8

22 SSumat 9

23 SSumat10

25 Aceh 2

composite

3.5

4

1

0

100

200

300

400

500

600

time /s

Chicago Full-Scale

Monitoring Program

700

800

900

1000

Smart Structures

Technology Laboratory

July 2010

• Established in 2001 (windycity.ce.nd.edu)

• Partnership between Notre Dame, SOM and the

Boundary Layer Wind Tunnel Laboratory

• Currently monitors 4 signature tall buildings in

Chicago and Korea, with Phase II expansion of

p to three additional buildings

g worldwide

up

• Major Objectives:

– Document level of response, impacts on

habitability and reliability of wind-tunnel response

predictions

– Document in-situ dynamic properties and

correlations with FEM/design assumptions

Smart Structures

Technology Laboratory

July 2010

Monitoring Technologies

• Response:

– Sub-Centimeter Accuracy GPS

– Force Balance Accelerometers

– Digital Accelerometers

• Wind Environment

– Ultrasonic anemometers/met. stations

• Hub & Spoke Data Acquisition:

– Wired datalogger systems

– DAQ over LAN, real-time systems

Sponsors: NSF CMS 00-85109,

CMMI 06-01143, CCHRB,

SEAOI

The R-SHAPE System

Caltech Millikan Library Building (2002)

Smart Structures

Technology Laboratory

July 2010

Example of Mode Shape

Determined From R-SHAPE Data

Smart Structures

Technology Laboratory

July 2010

st

Millikan Library 1 E-W Mode

10

9

8

Story Levell

7

6

5

Data

4

Rigid Body Rotation

3

Bending (Core)

2

Shear (Core and Frame)

1

Total Calculated

0

0

0.2

0.4

0.6

0.8

1

Normalized Displacement

W. D. Iwan - Some Milestones in Strong Motion Monitoring - EERI, February 9, 2008

W. D. Iwan - Some Milestones in Strong Motion Monitoring - EERI, February 9, 2008

15

Smart Structures

Technology Laboratory

July 2010

University of Tokyo

Guangzhou New TV Tower (610 m in height)

Smart Structures

Technology Laboratory

July 2010

measurement

of ambient

motion

0.4

Seismic retorfit

RMS値(0.1gal)

0.35

RMS

In ambient

motion

0.3

0.25

耐震補強済

耐震補強前

0.2

0.15

Not retrofitted

0.1

0.05

Effectiveness of retrofit

0

x西

x東 x(西

-東)

y西

y東 y(西

-東)

First step of vulnerability

測定位置

assessment

The Hong Kong Polytechnic University

Guangzhou New TV Tower (610 m in height)

Smart Structures

Technology Laboratory

July 2010

Guangzhou New TV Tower (610 m in height)

Smart Structures

Technology Laboratory

July 2010

Photos taken on 30 December 2007

上

下

The Hong Kong Polytechnic University

Guangzhou New TV Tower (610 m in height)

No.

1

2

3

4

5

6

7

8

9

10

11

12

13

14

15

16

Total

Type

Monitored Data

Temperature, humidity,

rain, air pressure

Wind speed and direction

Wind pressure

Inclination, leveling,

Total Station

elevation

Z ith l Telescope

Zenithal

Tl

I li ti off tower

Inclination

t

Tiltmeter

Inclination of tower

Level Sensor

Leveling of floors

Theodolite

Elevation

GPS

Displacement

Vibrating Wire Gauge Strain, shrinkage and creep

Thermometer

Temperature of structure

Digital Video Camera Displacement

Seismograph

Earthquake

Corrosion Sensor

Corrosion of reinforcement

Accelerometer

Acceleration

Fiber Optic Sensor

Strain and temperature

Smart Structures

Technology Laboratory

July 2010

The Hong Kong Polytechnic University

http://www.cse.polyu.edu.hk/benchmark

Smart Structures

Technology Laboratory

July 2010

Number of Sensors

In-Construction In-Service

Stage

Stage

Weather Station

1

1

Anemometer

Wind Pressure Sensor

2

2

4

1

2

2

2

2

2

416

96

3

527

2

60

60

3

1

3

22

120

280

The Hong Kong Polytechnic University

The Hong Kong Polytechnic University

16

Smart Structures

Technology Laboratory

July 2010

Structural Health Monitoring (SHM)

Smart Structures

Technology Laboratory

July 2010

• SHM requires more than just data

–

–

–

–

Future Directions

Pertinent information

Timely reporting

Has the structure sustained damage?

The number of sensors required to If so, where?

adequately

adequately monitor civil infrastructure monitor

infrastructure

• F

Fact:

t D

Damage

iis an iintrinsically

t i i llcivilllocally

ll phenomena

h

cannot be sufficiently realized with • Fact: Civil infrastructure

is large and complex

traditional approaches

traditional approaches

• Result: Dense arrays of sensors are required to

effectively monitor civil infrastructure

• Current monitoring systems are expensive with much of

the cost derived from cabling and installation

97

Intelligent Sensory System

Stonecutters Bridge in Hong

Kong (2007)

Smart Structures

Technology Laboratory

July 2010

Smart Structures

Technology Laboratory

July 2010

WI

M

Anemometer

Accelerometer & Seismometer

Temperature Sensor

4E

3E

Strain Gauge

The key to development of the

next generation of SHM systems is

embedded computing and sensing.

sensing

2E

GPS Rover Station

1E

Displacement Transducer

Diagnostics

Prognostics

Corrosion Sensor

Digital Video Camera

WI

M

Sensory

System

Safety

Performance

Life-Cycle Cost

East

Tower

Barometer, Rain Gauge, Hygrometer

Sensory

System

Weigh-In-Motion System

Total Number of

Sensors : >1200

@

$11K / sensor

WIM

1W

West

Tower

2W

3W

4W

Seoul

Daejeon (KAIST)

US-Korea-Japan Test Bed on

Smart Wireless Monitoring of the

Second Jindo Bridge

Environmentally Hardened Enclosure

(September 2008 – present)

Antenna Extension Cable

2nd Jindo Bridge

Haenam

(Inland)

Jindo

Bridges

External Antenna

- Range up to 200m

- Cover longer than midspan

Jindo

Jeju Island

Wireless sensor kit

- Battery board

- Imote2

- SHMa sensorboard

Modified battery board

- 3 D-cell batteries

2nd Jindo Bridge

Type

Cable-stayed bridge

Spans

70+344+70 = 484m

Girder

Steel box (12.55m width)

Design velocity

70 km/hr

Designed by

Yooshin cooperation (2000, Korea)

Constructed by

Hyundai construction (2006, Korea)

Owner

Iksan Regional Construction and

Management Administration

Special feature

Twin bridge

10

101

1

AirLock

- Water proof

102

17

Measured Time‐history Data

• Sensors on Pylon

• Sensors on Cable

Cable : 8

Deck : 26

Pylon : 3

Total : 37

P-HE2 : Time-history Acceleration

C-JE7 : Time-history Acceleration

In total, 420 channels of sensors

Z-axis

Y-axis

X-axis

0

0

Y

20

40

60

time(sec)

80

0

20

40

60

time(sec)

80

0

-10

0

20

100

40

60

time(sec)

80

0

5

10

time(sec)

15

Z

X

• Sensors on Deck

D-JE5 : Time-history Acceleration

D-JE8 : Time-history Acceleration

0

-10

-20

0

20

40

60

time(sec)

80

100

-20

10

Z-axis

Y-axis

X-axis

5

0

-5

-10

0

D-HE2 : Time-history Acceleration

10

Z-axis

Y-axis

X-axis

10

amplitude (mg)

amplitude (mg)

Sensor

powered by

solar cell

D-HE13 : Time-history Acceleration

20

Z-axis

Y-axis

X-axis

-10

0

20

40

60

time(sec)

80

100

Z-axis

Y-axis

X-axis

5

amplitude (mg)

20

10

Sensor

3 D-cell

powered by

Batteries

D-cell batteries

100

amplitude (mg)

SHM-A Board

w/ Imote2

[Base Stations are installed on pylons of 1st

Jindo Bridge, parallel to 2nd Jindo Bridge]

Manager node

Base Station

w/ Antenna

(Industrial PC, UPS, ADSL

Internet, Enclosure w/

ventilation)

0

-50

X-axis

Y-axis

Z-axis

5

-5

-5

-10

4 reference sensors

to construct global mode

information

10

X-axis

Y-axis

Z-axis

5

amplitude (mg)

0

-50

P-HT1 : Time-history Acceleration

10

50

Z-axis

Y-axis

X-axis

amplitude (mg)

C-JE2 : Time-history Acceleration

50

amplitude (mg)

Cable : 8

Deck : 22

Pylon : 3

Total : 33

amplitude (mg)

Sensor Deployment

0

-5

0

20

40

60

time(sec)

80

-10

0

20

40

60

time(sec)

103

80

104

Smart Structures

Technology Laboratory

July 2010

Modal Information

• Test Specification

• Result of FDD (Jindo

(Jindo--side)

Result for Singluar Value Decomposition

3

System: Jindo-side Sensor Network

10

[Singular Values]

Date : July 21, 2009

2

No. of collected data: 5000 data points

Sampling frequency: 50Hz

Singular Values

10

1

10

0

10

LPF : 20Hz (by Programmable Filter)

-1

10

0

0.5

1

1.5

2

2.5

Frequency (Hz)

3

3.5

4

4.5

5

l

lessons

from

f

a smartt fish

fi h

0.647Hz

1st vertical mode

: 0.439Hz

0.442Hz

2nd vertical mode

: 0.641Hz

4th vertical mode

: 1.404Hz

1.247Hz

5th vertical mode

: 1.569Hz

1.001Hz

3rd vertical mode

: 1.025Hz

1.735Hz

1.349Hz

6th vertical mode

: 1.837Hz

Smart Structures

Technology Laboratory

July 2010

105

Principle of Active

Electrolocation

Smart Structures

Technology Laboratory

July 2010

Smart Sensing Strategies in Electric Fish

Prof. Mark E. Nelson

Beckman Institute, UIUC

18

Smart Structures

Technology Laboratory

July 2010

Electroreceptors

Something to Ponder …

Smart Structures

Technology Laboratory

July 2010

• Electrosensory images are low resolution, so

why is the sensor density so high?

~15,000 individual sensors

1 nerve fiber per sensor

up to 1000 temporal pulses per sec per nerve fiber

RAW DATA RATE: ~15 Mbps

MacIver, from

Carr et al., 1982

Why so many sensors?

Smart Structures

Technology Laboratory

July 2010

Virtual Sensor Arrays

Smart Structures

Technology Laboratory

July 2010

Virtual Sensor Arrays:

Multi-scale Filtering

Smart Structures

Technology Laboratory

July 2010

• Facts: Individual electro-sensory sensors are

– relatively low resolution devices

– do not provide reliable event detection

– are easy to replicate (developmental biology)

• Solution: Nervous system creates arrays of

VIRTUAL SENSORS with desired resolution

and sensitivity

Smart Structures

Technology Laboratory

July 2010

Virtual Sensor Arrays

Array Name

# virtual

sensor nodes

Skin Sensors

15,000

--

CMS Map

M

2 800

2,800

40

BRAIN PROCESSING

skin sensors

per node

Centromedial map

- High spatial acuity

- Low temporal acuity

SKIN

SENSORS

INPUT

CLS Map

LS Map

1,400

200

900

1000

(from skin receptors)

both

Centrolateral map

- Inter spatial acuity

- Inter temporal acuity

Lateral map

- Low spatial acuity

- High temporal acuity

19

Smart Structures

Technology Laboratory

July 2010

Prey capture behavior

Smart Structures

Technology Laboratory

July 2010

Outline

• Trends in Structural Control

• Trends in Structural Health Monitoring

• Sensors,

S

D

Data

t A

Acquisition,

i iti

and

d Di

Digital

it l

Signal Processing

Prey capture behavior

Outline

Smart Structures

Technology Laboratory

July 2010

Smart Structures

Technology Laboratory

July 2010

• What is a sensor?

• Typical sensors for measuring dynamic

structural response

• Collecting

C ll ti Di

Digital

it l D

Data

t

– Quantization and Aliasing

• Digital Signal Processing

Smart Structures

Technology Laboratory

July 2010

Pendulum Response

Vibration Sensor

Smart Structures

Technology Laboratory

July 2010

Can be read

and recorded

M

M

Accelerometers

20

Smart Structures

Technology Laboratory

July 2010

Vibration Sensor

Smart Structures

Technology Laboratory

July 2010

Displacement Meter

For undamped oscillator:

δ&& + ω 2δ = −u&&

If u = A sin pt

We have δ = B sin pt

(1)

(2)

(3)

Carrying out differentiations, and dividing out common terms,

we find a necessary condition for the form (3)

Accelerometer

Smart Structures

Technology Laboratory

July 2010

Smart Structures

Technology Laboratory

July 2010

Pendulum Response

M

M

Accelerometers

Piezoelectric Accelerometer

Smart Structures

Technology Laboratory

July 2010

Piezoelectric Accelerometer

Smart Structures

Technology Laboratory

July 2010

Typical Specification: 5~1000Hz, ±10g

21

Smart Structures

Technology Laboratory

July 2010

Vibration Sensor

Influence of natural frequency of the sensor

Specification of sensors

Sensitivity:

S=

Smart Structures

Technology Laboratory

July 2010

Output ( voltage)

Input (vibration)

Resolution: the minimum quantity which can cause

the variation of output.

Frequency range: the range over which the sensitivity

of the transducer does not vary more than

a stated percentage from the rated sensitivity.

Specification of sensors

Smart Structures

Technology Laboratory

July 2010

Ground Loops

Smart Structures

Technology Laboratory

July 2010

Linearity:

Output

y

f (x)

x

Input

⎛ y − f ( xi ) ⎞

⎟⎟ %

max ⎜⎜ i

⎝ f ( xi ) ⎠

Ground Loops

Smart Structures

Technology Laboratory

July 2010

Before and after coupling

Smart Structures

Technology Laboratory

July 2010

22

Smart Structures

Technology Laboratory

July 2010

Ground-loop coupling

Smart Structures

Technology Laboratory

July 2010

Typical Sensors for

Measuring Dynamic

Response

Smart Structures

Technology Laboratory

July 2010

Resistive Accelerometers

• Operating Principle

• Operating Principle

– Voltage output of resistor bridge changes proportionally with applied

acceleration

+ Signal

+ Power - Power

– Utilizes frequency modulation technique through varying capacitor

bridge

Power

- Signal

Fixed Capacitors

Fixed

Resistors

Sensing Resistor

#1

Flexure

Sensing Resistor

#2

Resistive/Capacitive

Accelerometers

•

•

•

•

•

Ground

Signal

Built-In Electronics

~

Insulator

Sensing Capacitor

#1

Mass

Flexure

Mass

Sensing Capacitor

#2

Insulator

Smart Structures

Technology Laboratory

July 2010

Typical Characteristics

•

•

•

•

Smart Structures

Technology Laboratory

July 2010

Capacitive Accelerometers

Measure down to 0 Hz (DC response)

Limited dynamic range (<80 dB = 10,000:1)

Limited high frequency range (<10 kHz)

p frequency

q

y response

p

((0.7% of

Often a damped

critical)

Sensitivity may vary with input (mV/g/V)

Traditionally fragile (limited shock protection)

Operates multi-conductor cable (at least 3 wires)

Micro-machined versions are small and lightweight

Performance matches cost ($10 to $1000 USD)

Piezoelectric

Accelerometers

Smart Structures

Technology Laboratory

July 2010

• Piezoelectric

– Force on self-generating crystal provides charge output proportional to

acceleration

Signal/Power

Ground

Voltage or Charge Amplifier

Preload Ring

Mass

Piezoelectric

Crystal

Base

23

Smart Structures

Technology Laboratory

July 2010

Piezoelectric Materials

• Piezoelectric Effect

Smart Structures

Technology Laboratory

July 2010

Piezoelectric Materials

• Piezoelectric Materials

– Word origin comes from the greek work

“piezen” which translates “to squeeze”.

– The generation of an electrical signal by a

dielectric material as it is subjected to a

mechanical stress.

F

– Naturally Piezoelectric

• Rochelle Salt

– One of first materials used to make sensors

• Tourmaline

T

li

– Sensitive to hydrostatic pressure

• Exotic, “Man-Made” Materials

+

+

-

+

-

+

-

+

-

+

-

+

-

Piezoelectric

Material

– Langasite

– Lithium Niobate

• Cultured Quartz

-

F

Smart Structures

Technology Laboratory

July 2010

Piezoelectric Materials

Smart Structures

Technology Laboratory

July 2010

Mechanical Design

• Piezoelectric Sensing Element

• Piezoelectric Materials

– Mechanical transduction mechanism as

important as piezoelectric material selection

– The key is to design the sensor so that it only

meas res the parameter of interest and

measures

minimizes the affects of any outside

environmental conditions

– Types

– Artificially Polarized

• Piezofilm

– Made of a special polymer - PVDF

• Piezoceramics

Pi

i

– Lead Zirconate Titanate (PZT)

– Bismuth Titanate

• Compression Mode

• Flexural Mode

• Shear Mode

Smart Structures

Technology Laboratory

July 2010

Mechanical Design

• Compression Mode

• Flexural Mode

– Original sensors utilized this approach;

however, it is not commonly used today

except for special applications

Seismic

Mass

Electrode

Smart Structures

Technology Laboratory

July 2010

Mechanical Design

Preload Stud

- + +

- + +

+- +-

+

- +-

Piezoelectric

Crystal

(d11-Quartz)

(d33-Piezoceramic)

– Utilized only in a few low cost sensor designs

as performance limitations minimize its

widespread use

Piezoelectric

Seismic

Mass

+ + + + +

- - - - -

Crystal

y

(d12-Quartz)

(d31-Piezoceramic)

Fulcrum

Signal (+)

Ground (-)

Signal (+)

Ground (-)

Optional Built-In

Electronics

Optional Built-In

Electronics

24

Smart Structures

Technology Laboratory

July 2010

Mechanical Design

– Most commonly utilized design based on

overall performance

+

+

+

+

-

-+

-+

-+

-+

Preload Ring

Piezoelectric

Crystal

(d26-Quartz)

(d15-Piezoceramic)

Center

Post

Signal (+)

Ground (-)

Optional Built-In

Electronics

Smart Structures

Technology Laboratory

July 2010

Strain Gages

Transverse

strain

Axial

strain

e T = −ν e L

Poisson’s

ratio

Smart Structures

Technology Laboratory

July 2010

Typical Characteristics

• Shear Mode

Seismic

Mass

Piezoelectric

Accelerometers

•

•

•

•

•

Dynamic events only (>0.2 Hz)

Wide dynamic range (>100dB = 100,000:1)

Wide frequency bandwidth (<1 Hz to >10 kHz)

Solid-state ((No moving

gp

parts))

Self-generating piezoelectric elements require no

power

• Operates over two conductors

• Rugged (5,000 g’s)

• High temperature charge versions operate to

1000 F (537 C)

Smart Structures

Technology Laboratory

July 2010

Gage Factor

eT

eL

F

l

Δl

Elastic Modulus:

F

A

E=

σ (stress)

(t

)

e (strain)

Because:

Δl

= eL ;

l

ΔA

ΔD

=2

= 2 e T = 2 (−υ e L )

A

D

Poisson’s

ratio

Material resistivity

Then:

R=

The resistance of a strain gage:

Relative change in resistance:

ρl

Element length

A

Cross section area

Define a Gage factor G:

G=

ΔR

R

eL

When a strain gage is strained, the change in resistance is:

∂R

∂R

⎛ ∂R ⎞

ΔR = ⎛⎜ ⎞⎟Δl + ⎛⎜ ⎞⎟ΔA + ⎜ ⎟Δρ

⎝ ∂l ⎠

⎝ ∂A ⎠

⎝ ∂ρ ⎠

Example of Strain Gage

Specifications

Smart Structures

Technology Laboratory

July 2010

Temperature Range

Normal: -100 to +350 F

Short-Term: -320 to +400 F

Strain Range

+3% for gage lengths under 1/8 in

+5% for 1/8 in and over

Fatigue Life

105 cycles at +1500 microstrain

106 cycles at +1500 microstrain

with low modulus solder.

Gage factor of a strain gage:

Wheastone Bridge

Smart Structures

Technology Laboratory

July 2010

Sensitive instrumentation is

required to measure the small

changes in resistance

produced by strain gauges.

Wheatstone bridge is

typically used to measure

resistances accurately and

dynamically over a very large

range (1 to 1,000,000 Ω).

25

Common Strain Gage

Arrangements

Smart Structures

Technology Laboratory

July 2010

Smart Structures

Technology Laboratory

July 2010

Strain-Type Load Cells

F

R1

R2

+

Strain gages are used

in pillar type load cells

VS

-

+

VS

R2

-

R1

R4

R4

R3

R3

R3 , R1

eT

R2 , R4

R1

R2

eL

+

R2

VS

-

+

VS

-

R1

R4

R4

R3

R3

Single point

Platform scales

1-1000 Kg

S-type

F

Smart Structures

Technology Laboratory

July 2010

Strain-Type Load Cells

σ

F

=−

A⋅E

E

υ⋅F

eT = +

= −υ e L

A⋅E

eL = −

Piezoelectric Load Cells

Poisson’s

ratio

Smart Structures

Technology Laboratory

July 2010

Bending beam

Low profile: load and

pallet scales

5-500

5

500 Kg

Compression

Silos, tanks and weighbridges

5,000-60,000 Kg

Shear beam

(tension-compression)

Low profile: load and pallet scales

500-5000 Kg

Can not measure static loads

Hanging scales 50 – 5000 Kg

Smart Structures

Technology Laboratory

July 2010

LVDT

LVDT

Smart Structures

Technology Laboratory

July 2010

Linear Voltage Differential Transformer

(LVDT)

Coil Assembly

Core

26

Smart Structures

Technology Laboratory

July 2010

LVDT

•

•

•

•

•

•

•

•

•

•

Friction-Free Operation

Infinite Resolution

Unlimited Mechanical Life

Overtravel Damage Resistant

Single Axis Sensitivity

Separable Coil And Core

Environmentally Robust

Null Point Repeatability

Fast Dynamic Response

Absolute Output

Core at Center, Eout is Zero

+

SECONDARY 1

Smart Structures

Technology Laboratory

July 2010

Eout -

PRI

PRIMARY

SECONDARY 2

Smart Structures

Technology Laboratory

July 2010

-

+

Ein

-

Eout

Ein

Core

SEC2

SECONDARY 2

Cable Extended Transducer

PRIMARY

Core right-of-center

Eout Non-Zero and Out-of-Phase with Input

Eout

Eout

Core

SEC1

SECONDARY

1

-

LVDT Operation

+

-

-

Core

Core Left-of-Center

Eout Non-Zero and In-phase with input

+

Eout

+

LVDT Operation

+

Smart Structures

Technology Laboratory

July 2010

LVDT

SECONDARY 1

Smart Structures

Technology Laboratory

July 2010

PRIMARY

SECONDARY 2

Cable Extended Transducer

Smart Structures

Technology Laboratory

July 2010

CETs are ideal in many instances:

• Where Large Displacements are Expected

• Up to 100” for Laboratory Models

• Up to 1750” (145ft) for Industrial Models

Cable is wound around a precision

machined spool attached to either a:

• Potentiometer (variable resistor,

analog)

• Incremental Encoder ((optical,

p

, digital)

g )

• Where Perfect Alignment is Not Possible

A spring provides controlled recoil of

the cable.

• Cannot use LVDT Here!

27

Smart Structures

Technology Laboratory

July 2010

Optical Encoder

Quadrature (or Incremental)

Encoder

Smart Structures

Technology Laboratory

July 2010

Channel A

Channel B

Photo Detector

Channel I

Light

Source

Code Track on Disk

Channel A

Shaft

Code Track

Channel B

90

Rotating Disk

Channel I

Digital Output

Smart Structures

Technology Laboratory

July 2010

Collecting Digital Data

Collecting Digital Data

Smart Structures

Technology Laboratory

July 2010

• Because analysis, results, and conclusions

are only as good as the data on which it is

based, special care must be taken to

ensure that high quality data are obtained.

• The quality of the data often depends on

the purpose for which the data will be

used.

The Measurement Process

Smart Structures

Technology Laboratory

July 2010

• Data Acquisition: The process of representing

an analog signal as a series of digital values is a

basic requirement of modern digital signal

processing analyzers. In practice, the goal of the

analog to digital conversion (ADC) process is to

obtain the conversion while maintaining sufficient

accuracy in terms of frequency, magnitude, and

phase.

• Two basic related concepts dictate accuracy:

Sampling and Quantization

Smart Structures

Technology Laboratory

July 2010

• Primarily, sampling considerations alone affect

the frequency accuracy.

• Both sampling and quantization considerations

affect magnitude

g

and p

phase accuracy.

y

• The dynamic range of the ADC (84 dB for 14

bits, 96 dB for 16 bits, etc.) is only meaningful if

the quantization of an input signal of interest

involves all of the bits of the ADC.

– Sampling and Quantization

28

The Measurement Process

Smart Structures

Technology Laboratory

July 2010

Sampling and Quantization

Sensors (e.g., Accelerometers,

LVDT, strain gage, etc.) all

produce analog voltage signals

that must be calibrated with

physical response.

A/D

Converter

Sensor

Δt

Sensor Volta

age

Physical

Response

Digital

Computer

1. Sample and Hold

2. Quantize

Sampling and Quantization

t

Output Code

Smart Structures

Technology Laboratory

July 2010

Smart Structures

Technology Laboratory

July 2010

Quantization

Δt

Sensor Volta

age

Smart Structures

Technology Laboratory

July 2010

Physical

Response

Sensor

Gain

S

Sensor

t

A/D

Converter

Digital

Computer

Output Code

Smart Structures

Technology Laboratory

July 2010

Aliasing

1

0.4

0.2

0

-0.2

-0.4

-0.6

-0.8

0

Measure

ed Frequency

0.6

-1

Nyquist Frequency Nf = fs/2

• Consider a 48 Hz signal

• What if the signal is

sampled at 50 Hz?

• The resulting measured

signal has an apparent

frequency of 2 Hz

0.8

After a signal is

sample the aliasing

sample,

Aliasing

problem cannot be

?

◊ Cannot have significant energy resolved!

above the Nyquist frequency (f /2)

0.05

0.1

0.15

0.2

0.25

0.3

Time (sec)

0.35

0.4

0.45

Smart Structures

Technology Laboratory

July 2010

Aliasing

0.5

Nf

Nf

fs

Excitation Frequency

s

◊ Anti‐aliasing filters must be used in dynamic measurements to preserve signal integrity

Illustration of Aliasing in the frequency Domain

fN

fs

29

Smart Structures

Technology Laboratory

July 2010

Antialiasing Filters

Aliased Square Wave

Smart Structures

Technology Laboratory

July 2010

Calibration of System

Smart Structures

Technology Laboratory

July 2010

Physical

Response

Sensor

Sensor

Gain

Antialiasing

Filters

A/D

Converter

Unaliased Square Wave

Digital

Computer

Smart Structures

Technology Laboratory

July 2010

Physical

Response

S

Sensor

Sensor

Gain

A/D

Converter

Other ADC Issues

Smart Structures

Technology Laboratory

July 2010

• Differential Nonlinearity: If the round-off that occurs to

cause quantization error is not regular (some of the spacing

between counts varies) this type of error results. This causes

the “noise” from quantization error to be biased.

• Bit Dropout: One bit in the ADC may never be set.

Obviously, any sample requiring this bit in the ADC word to be

set will be in error and the error will be biased. A similar

problem exists if one bit of the ADC word is always set.

• Reference Voltage: The reference voltage used by the ADC

may drift within or between sample periods. Since this drift is

not known or measured, this error will cause a bias in any

resulting estimate of the dependent variable.

Other ADC Issues

Digital

Computer

Smart Structures

Technology Laboratory

July 2010

• Overload and Overload Recovery: When the ADC is

overloaded, it may take several sampling increments to

recover. This is normally only a problem under severe

overloads but if it occurs the result will be a bias in the

estimate of the amplitude.

• Aperture Error - Clock Jitter: The value of the amplitude

recorded does not correspond to the assumed instant in time,

t. This type of error will result in a bias in the estimate of time

and frequency parameters.

• Digitizer Noise: The random setting of plus or minus one bit

when the input is zero is referred to as digitizer noise. This

error may become dominant in transient excitation since a

large pert of the observed histories may be very small or

actually zero as in the case of impact testing. This error can

be controlled to some extent by averaging and the use of

special window functions.

30

Smart Structures

Technology Laboratory

July 2010

Smart Structures

Technology Laboratory

July 2010

Spectrum analysis

Digital Signal Processing

Smart Structures

Technology Laboratory

July 2010

Frequency Response Function

• One of the most important

measurements to be made is the

frequency response function.

• But,

But what is the frequency response

function?

• Another important function

impulse response function:

1

1/ m

=

− mω 2 + icω + k −ω 2 + i2ζωnω + ωn2

Smart Structures

Technology Laboratory

July 2010

• Recall that the forward Fourier transform and

the inverse Fourier transform are defined by

X (ω ) = F

∞

{ x (t )} = ∫

is

the

&&(t ) + cx& (t ) + kx (t ) = f (t )

mx

h(t ) =

&&(t ) + cx& (t ) + kx (t ) = f (t )

mx

H (ω ) =

Smart Structures

Technology Laboratory

July 2010

The Impulse Response Function

1 − ωnt

sin(ωdt )

e

mωd

Extraction of Modes

#1

Smart Structures

Technology Laboratory

July 2010

#2

#3

x (t )e -iωt dt

−∞

x (t ) = F

-1

1

{ X (ω )} =

2π

∞

∫ X (ω )e

iω t

dω

−∞

• The Frequency Response Function and the

Impulse Response Function form Fourier

Transform pairs

H (ω ) = F {h(t )} , h(t ) = F

-1

Mode 1

2.38 Hz

0.36%

{H (ω )}

31

Extraction of Modes

#1

Smart Structures

Technology Laboratory

July 2010

#2

Extraction of Modes

#3

#1

Smart Structures

Technology Laboratory

July 2010

#2

#3

Mode 2

6.57 Hz

0.4%

Smart Structures

Technology Laboratory

July 2010

Mode 1

2.38 Hz

0.36%

Mode 2

6.57 Hz

0.4%

Smart Structures

Technology Laboratory

July 2010

Frequency Response Function

u (t )

Single-Input,

Hvu (f )

v (t )

Single-Output

Hvu (f ) =

• There are several methods to

experimentally obtain the Frequency

Response Function:

H1 Frequency Response Function

• Including noise:

V (f ) V (f ) Gvv (f )

=

V * (f ) U (f ) Gvu (f )

+

Hvu (f )

m (t )

x (t )

Gxy (f )

Gxx (f )

+

y (t )

v (t )

+

+

H1(f ) =

Smart Structures

Technology Laboratory

July 2010

n(t )

u (t )

V (f )

Hvu (f ) =

U (f )

U * (f )V (f ) Guv (f )

Hvu (f ) = *

=

U (f ) U (f ) Guu (f )

*

Smart Structures

Technology Laboratory

July 2010

Frequency Response Function

– Swept-Sine

– Random Excitation

– Impulse Excitation

– Step-Relaxation Excitation

Mode 3

11.3 Hz

1.68%

• For the

system:

Mode 3

11.3 Hz

1.68%

=

Cov [ m (t ), n(t )] = 0

Guv (f )

Hvu (f )

=

Guu (f ) + Gmm (f ) 1 + Gmm (f )

Guu (f )

32

Smart Structures

Technology Laboratory

July 2010

H2 Frequency Response Function

• Including noise:

n(t )

u (t )

+

y (t )

x (t )

+

H2 (f ) =

Gyy (f )

Gxy (f )

u (t )

v (t )

+

=

Smart Structures

Technology Laboratory

July 2010

n(t )

+

Hvu (f )

m (t )

AA-Filter Effect on the

Transfer Function

Cov [ m (t ), n(t )] = 0

Gvv (f ) + Gnn (f )

G (f )

= Hvu (f ) + nn

Guv (f )

Guu (f )

Smart Structures

Technology Laboratory

July 2010

Digital Signal Processing

+

Hvu (f )

+

y (t )

H AA2 (f )

If the AA

filters onvthe

(t ) input and

+

m (t )

y AA (t )

output are amplitude

and phase

H AA1(f )

+

x

(

t

)

x (tthen

)

matched,

they will

AA not affect

the signal in the frequency range

Gx y of

(f )interest.

H AA1(f )H AA 2 (f )Gxy (f )

H1(f ) =

=

AA AA

Gx AA x AA (f )

H AA1(f )H AA1(f )Gxx (f )

Digital Signal Processing

Smart Structures

Technology Laboratory

July 2010

• The Discrete Fourier Transform is a

discretized, finite time-interval,

approximation of the Fourier Transform

integral.

N −1

X (fk ) = Δt ∑ x (t n )e

⎛ kn ⎞

− i 2π ⎜

⎟

⎝ N ⎠

n=0

N −1

x (t n ) = Δf ∑ X (fk )e

⎛ kn ⎞

i 2π ⎜

⎟

⎝ N ⎠

k =0

Spectral Leakage

Smart Structures

Technology Laboratory

July 2010

Leakage Experiment

Smart Structures

Technology Laboratory

July 2010

• Leakage is probably the most common and,

therefore, the most serious digital signal processing

error. Unlike aliasing and many other errors, the

effects of leakage can only be reduced, not

completely eliminated.

• Leakage is basically due to a violation of an

assumption of the discrete Fourier transform

algorithm (i.e., the true signal is periodic within the

sample period used to observe the sample function).

• Common ways of reducing leakage include: (i)

windowing or weighting functions, (ii) periodic

excitation, and (iii) increase in frequency resolution.

• Effect on coherence function

• Transient vs. Stationary signals

33

Actual Power Spectrum

Smart Structures

Technology Laboratory

July 2010

Power Spectrum:

Boxcar Window

Smart Structures

Technology Laboratory

July 2010

Power Spectrum:

Hanning Window

Smart Structures

Technology Laboratory

July 2010

Power Spectrum:

Flattop Window

Smart Structures

Technology Laboratory

July 2010

Power Spectrum:

Zoom w/ Flattop Window

Smart Structures

Technology Laboratory

July 2010

Windows Scorecard

Smart Structures

Technology Laboratory

July 2010

For more information, see:

http://www.lds-group.com/docs/site_documents/AN014%20Understanding%20FFT%20Windows.pdf

34

Conclusions

Smart Structures

Technology Laboratory

July 2010

• Use appropriate sensors for the job and know their

limitations.

• Obtaining accurate data requires high quality data

acquisition equipment, and the system must be calibrated.

• Generally

Generally, more bits in the A/D converter is better (e

(e.g.,

g 16

bits). Preamplify the sensor signal so that it uses the

maximum span of the A/D converter.

• Always use high-quality antialiasing filters, typically 8-pole

elliptic filters are generally the best for experimental modal

analysis.

• Spectral leakage is a critical problem that must be

addressed in experimental structural dynamics

35