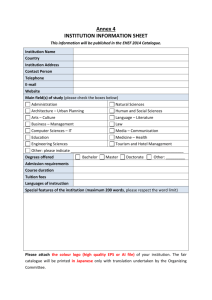

advertisement

Track Fastening Systems User Guide - Edition 8 Other PANDROL publications available Pandrol FASTCLIP system literature Pandrol FASTCLIP ‘FE’ system Provides detailed information on installing PANDROL FASTCLIP. The literature describing the new generation of FASTCLIP. Pandrol VANGUARD Pandrol ‘Re’ system Provides detailed information on Pandrol’s very resilient track form for the highest vibration mitigation. Literature describing the new ‘Re’ system for re-railing applications on older sleepers. Pandrol VIPA Pandrol SFC baseplates Provides detailed information on Pandrol’s noise and vibration isolation system. Pandrol FASTCLIP Track Installation Guide Providing practical instructions for the safe installation of the FASTCLIP system. 01 Pandrol Track Fastening Systems User Guide - Edition 8 Provides detailed information about SFC single resilience baseplates. Track Report 2011 The journal of Pandrol Rail Fastenings 2011. This technical magazine contains authoritative articles written by railway experts from around the world about high-profile rail projects. It is published every 12 to 18 months. Contents Introduction 03 Clip Applications & Colour Coding 04 Insulator Applications & Colour Coding 09 Pad Identification 15 Baseplates for Timber Sleepers 18 Concrete & Steel Sleeper Assemblies 19 Special Applications 22 Identification of Pandrol Hand-Tools 27 Use of Hand-Tools 36 Machines for automated installation and extraction of FASTCLIP systems. 40 Track Support baseplates for Noise & Vibration mitigation 41 Anchorage Systems for Pandrol Baseplates 45 Identification Chart for Anchorage Components 47 www.pandrol.com 02 Introduction and how to contact PANDROL This guide is intended for use by all those involved in the specification, installation and maintenance of Pandrol products for Network Rail in the UK. The products and systems are not applicable to other railways as system details vary between customers. History of the Company Pandrol is owned by the Delachaux Group and has been established in the business of resilient rail fastenings since 1937. Our first rail fastening was the Elastic Rail Spike, the very first resilient rail fastening for timber sleepers. This was manufactured at Worksop, largely for export, with factories being opened in South Africa and Australia in the early 1950’s. In the early 1960’s European railways began to move to concrete sleepers fitted with continuous welded flat bottom rail. The classic ‘Pandrol’ PR clip was introduced at this time, firstly in the UK and then around the world. In the mid 1970’s the Pandrol ‘e’ clip was introduced offering a higher clamping force at a lower component cost due to more effective use of the steel section. During this period the number of factories world wide increased to twelve. In the early 1990’s the Pandrol FASTCLIP system was introduced which combined the traditional virtues of the Pandrol system with pre-assembly of the fastening at the sleeper factory. This has led to major productivity gains wherever it has been introduced in particular with the new generation of automated track relaying equipment such as the TRT and NTC machines. New information since Edition 7 This edition of the booklet has been revised and many new products and systems have been added, including: 1. Pandrol ‘Re’ system 2. ZLR systems for ‘rail free’ applications 3. Glue-in and replacement shoulders 4. Clips around IBJ’s. 5. Clips around ‘Balise’ units 6. More efficient and safer hand-tools for FASTCLIP 7.Expanded section on vibration mitigation baseplates for slab track and steel bridges This booklet is intended to answer the most frequently asked questions relating to our products. However, if further information is needed, Pandrol’s Customer Support Engineers can be contacted for advice on: T. 01909 476101 F. 01909 500004 03 E. support@pandrol.com www.pandrol.com Pandrol Track Fastening Systems User Guide - Edition 8 Clip Applications & Colour Coding FINISHES: Clips are available with either STANDARD or CORROSION PROTECTION (previously called SHERARDISED) finishes. CORROSION PROTECTION (CP) finish should be used in the following areas: • Wet tunnels • Coastal areas Note: 10kN = 1 Tonne • Level crossings • Adjacent to heavily salted roads and platforms Standard Finish: Green 57/48048 CP Finish: Purple 57/48055 Type: FC 1504 Used on G44 and EG47 concrete sleepers also Series 560, 560H, 600, HH10, Mk2 and HH12 steel sleepers. Nominal toe load per clip = 10kN Standard Finish: Red 57/48033 CP Finish: Grey Gloss 57/48056 Type: FC 1501 Used on F41 and EF36 concrete sleepers and Series 500 steel sleepers. Nominal toe load per clip = 10kN Standard Finish: Cat. No. not allocated. CP Finish: Blue 57/02029 Type: FC 1503 Used only for Pandrol Type SFC baseplates for slab track. Nominal toe load per clip = 10 kN www.pandrol.com 04 Clip Applications & Colour Coding FINISHES: Clips are available with either STANDARD or CORROSION PROTECTION (previously called SHERARDISED) finishes. CORROSION PROTECTION (CP) finish should be used in the following areas: • Wet tunnels • Coastal areas Note: 10kN = 1 Tonne • Level crossings • Adjacent to heavily salted roads and platforms Type: e-Plus - eP20127 Standard Finish: Red 57/48237 CP Finish: Grey Gloss 57/48307 Standard Finish: Green 57/48236 CP Finish: Blue Gloss 57/48308 Standard Finish: Yellow 57/48252 CP Finish: Purple Gloss 57/48309 Standard Finish: Red 57/48469 CP Finish: Matt Grey Cat No. Not allocated Used on F27, EF28 and W402 sleepers where extra resilience and insulator durability is required. Fitted with integral Type 9903 toe insulator. Nominal toe load per clip = 12.5kN Type: e-Plus - eP20129 Used on NR60 S&C, also on EG49 sleepers with 60E1 rail. Nominal toe load per clip = 12.5 kN Type: e-Plus - eP20130 Left hand version of eP20129. Nominal toe load per clip = 12.5kN Type: Re Clip - Re1609 Used on F23 to F27, EF28, 5EF28, W402 sleepers for re-railing operations, used in conjunction with pad type 14229. Clip is fitted with integral toe insulator not separately available. Nominal toe load per clip = 9 kN 05 Pandrol Track Fastening Systems User Guide - Edition 8 Standard Finish: Red 57/48255 CP Finish: Matt Grey 57/48031 Type: e1809 For use in F40 sleepers with a Blue (HVN) insulator. For use in all other sleepers with an Orange (Nylon) insulator. Must not be used with Grey Cast Iron ‘PAN’ Type Baseplates. Nominal toe load per clip = 9kN Standard Finish: Yellow 57/48256 CP Finish: Black Gloss 57/48043 Type: e1810 Left handed version of e1809. Used in IBJ’s in various situations, see page 25. Nominal toe load per clip = 9kN Standard Finish: Purple 57/48247 CP Finish: Bright Red Gloss: 57/48044 Type: e2001 High toe load clip for F27/EF28 sleepers, used in difficult areas where insulator crushing or creep is occurring. Must be used with white insulator, either type 2433 or type 6924. Nominal toe load = 12.5 kN Standard Finish: Blue 57/48248 CP Finish: Grey Gloss 57/48045 Type: e2007 High toe load clip which is interchangeable with either PR401A or e1809 clip types. Should NOT be used in applications fitted with orange insulator type 724a. Also used with IBJ’s in NR60 S&C. See page 25. Nominal toe load = 12.5 kN CP Finish: Green 57/48587 Type: e2071 Clip only used for Zero Longitudinal Restraint (ZLR), to convert the following sleeper types to ‘rail free’ assemblies: F23 to F27, EF28, 5EF28, W402, F40 & 5F40, with other specialist components. (See separate section on page 23) www.pandrol.com 06 Clip Applications & Colour Coding FINISHES: Clips are available with either STANDARD or CORROSION PROTECTION (previously called SHERARDISED) finishes. CORROSION PROTECTION (CP) finish should be used in the following areas: • Wet tunnels • Coastal areas Note: 10kN = 1 Tonne • Level crossings • Adjacent to heavily salted roads and platforms Type: PR401A Standard Finish: Red 57/48239 CP Finish: Matt Grey 57/48253 Standard Finish: Blue 57/48243 CP Finish: Grey Gloss 57/48234 Standard Finish: Purple 57/48245 CP Finish: Bright Red Gloss 57/48242 Standard Finish: Green 57/48244 CP Finish: Yellow Gloss 57/48249 For concrete sleepers and all PAN plates EXCEPT obsolete PAN1 to PAN5 where PR303 clips were used. Nominal toe load per clip = 6.5kN Type: PR402A Left handed version of PR401A. Nominal toe load per clip = 6.5kN Type: PR427A Maintenance replacement for PR303 in PAN 1 to PAN5 baseplates. NOT suitable for other types of baseplate. Nominal toe load per clip = 6.5kN Type: PR428A Maintenance replacement for left handed PR304 in PAN 1 to PAN5 baseplates. NOT suitable for other types of baseplate. Nominal toe load per clip = 6.5kN 07 Pandrol Track Fastening Systems User Guide - Edition 8 Left-Handed Clips Non-symmetrical clips (‘PR’, ‘e’, ‘e-PLUS’, & ‘Re’) are normally ‘right-handed’ and should be inserted into the shoulder anchor point from the right-hand side of the shoulder, when facing the rail. Left-handed variants are required in areas of restricted access around the shoulders, and are fitted from the opposite end of the shoulder (i.e the left-hand side of shoulder). Left-handed clips are typically needed around IBJ’s and S&C layouts. The equivalence chart below shows which clips are interchangeable between the standard right-handed and left-handed variants. Right-Handed Clips Equivalent Left-Handed Clips PR401A PR402A PR427A PR428A e1809 e1810 eP20129 eP20130 Standard Finish: Red 57/48450 CP Finish: Matt Grey 57/48046 Type: PANLOCK Clip for Bull Head Rail Catalogue No. 57/48781 A1 Spike Original A1 Elastic Rail Spike. Elastic spikes are only supplied in Standard finish. The A1 spike is red colour. Catalogue No. 57/48785 AL23 Maintenance Spike Maintenance replacement for A1 Spike Elastic spikes are only supplied in Standard finish. The AL23 spike is supplied in two parts. The inner part is black and the outer part is red, and fit together as shown. www.pandrol.com 08 Insulator Applications & Colour Coding FASTCLIP Type 8582 Catalogue Number: 57/48064 Sidepost Insulator (Blue) 16.4mm sidepost thickness. For use on the FIELD side of the 56E1 rail when fitted to G44, EG47, Series 560, 560H, 600, HH10 Mk2 and HH12 sleepers. Also used to replace obsolete insulator type 9373 previously used for hook-in shoulders with steel sleepers. FASTCLIP Type 7551 Catalogue Number: 57/48021 Sidepost Insulator (White) 8mm sidepost thickness. Used on G44, EG47, Series 560, 560H, 600, HH10 Mk2 and HH12 sleepers with 60E1 rail. Used on F41, 5F41, 5EF36 and Series 500 steel sleepers with 56E1 rail. Also used to replace obsolete insulator type 8914 previously used for hook-in shoulders with steel sleepers. FASTCLIP Type 8690 Catalogue Number: 57/48066 Sidepost Insulator (Black) 10mm sidepost thickness. For use on the GAUGE side of the 56E1 rail when fitted to G44, EG47, Series 560, 560H, 600, HH10 Mk2 and HH12 sleepers. Also used to replace obsolete insulator type 9374 previously used for hook-in shoulders with steel sleepers. FASTCLIP Type 8691 Catalogue Number: 57/48067 Sidepost Insulator (Green) 6mm sidepost thickness. Used in limited areas where oversize 60E1 rail was supplied. Used in place of the GAUGE side Type 7551 sidepost Insulator. 09 Pandrol Track Fastening Systems User Guide - Edition 8 Catalogue Number: 57/48118 FASTCLIP Type 8277 Side post insulator (Yellow) 13mm sidepost thickness, for use on HH10 Mark 1 sleepers with Type 9922 hook in shoulders. Catalogue Number: 57/48111 e-PLUS Type 9132 Sidepost Insulator (Blue) Used with eP20127 clip on F27, EF28, W402 sleepers and NR56V S&C. Catalogue Number: 57/48294 e-PLUS Type 9875 Sidepost Insulator (White) Used with eP20129 clips on F40 sleepers and NR60 S&C. Catalogue Number: 57/48114 e-PLUS Type 9877 Gauge Management Insulator (Black) 10mm sidepost insulator, used for NR60 S&C. Catalogue Number: 57/48115 e-PLUS Type 9876 Gauge Management Insulator (Green) 6mm sidepost insulator, used for NR60 S&C www.pandrol.com 10 Insulator Applications & Colour Coding FASTCLIP Type 8494 Catalogue Number: 57/48020 Toe Insulator (White) For use on all sleeper types fitted with the FASTCLIP system. e-PLUS Type 9903 Catalogue Number: 57/48113 Toe Insulator (White) Previously coloured blue. Not supplied separately, always supplied already fitted to the e-PLUS clip types Orange (Nylon) Type 724a Catalogue Number: 57/48424 5mm sidepost thickness x 5mm blade thickness. Used for: F23 , F24 series, EF25, F27, EF28, EF29, EF32, EF33, F34, F35 concrete sleepers and 400 series, steel sleepers with 56E1 or BS110A or BS110A rails. Blue (Nylon) Type 724a Catalogue Number: 57/48423 5mm sidepost thickness 5mm blade thickness used where 98lb and 109lb rail is installed. Used for concrete sleeper types: F23, F24, EF25, F27, EF28, EF29, EF33, F34, & F35, as well as steel sleepers 400 Series. NOTE: This insulator is not commonly available, and can be replaced with Pandrol type 6924 provided this is used with clip type e2001. 11 Pandrol Track Fastening Systems User Guide - Edition 8 Catalogue Number: 57/48027 Blue (GRN) Type 4452. 8mm sidepost thickness x 8mm blade thickness used on: F40 and 5F40 sleepers Catalogue Number: 57/48436 White (GRN) Type 2433 5mm sidepost x 8mm blade thickness (previously coloured black) used with e2001 clip. Also used on F40 & 5F40 sleepers as part of the range of gauge management insulators to adjust the track gauge, by moving the rail across the rail seat. This insulator can be upgraded to use HVN by substituting insulator type 6924, which is an identical size. Catalogue Number: Not allocated White Type 6924 White (HVN) type 6924, 5mm side post x 8mm blade thickness used with e2001 clip. Also can be used with NR56V S&C to replace composite insulators. This HVN insulator is sufficiently flexible to be used as a replacement for Blue nylon insulator Catalogue No. 57/48423 with either 98lb or 109lb rail, but can ONLY be used with e2001 clips Catalogue Number: 57/48434 Brown(HVN) Type 7583 12mm sidepost x 8mm blade thickness. Used as part of the range of Pandrol insulators to provide gauge management by adjusting the position of the rail in the rail seat. A separate data-sheet is available to advise the methods and adjustment range achievable. Gauge management can be provided for concrete sleeper types: F40, & 5F40. www.pandrol.com 12 Insulator Applications & Colour Coding Red (HVN) Type 10274 Catalogue Number: 57/48082 Insulator for 56E1 rail on FIELD side of: 1. NRS1/NRS2/Combi baseplates 2. EG49 concrete sleepers Yellow (HVN) Type 10275 Catalogue Number: 57/48081 Insulator for 56E1 on GAUGE side of: 1. NRS1/NRS2/Combi baseplates. 2. EG49 concrete sleepers Green (HVN) Type 5720 Catalogue Number: 57/48060 Insulator for use with 60E1 rail using: 1) NRS1/NRS2/Combi baseplates with 60E1 rail. 2) 6 Hole IBJ’s on NR60 S&C 3) EG49 Concrete sleepers Composite Catalogue Number: 57/48427 (Nylon with cast iron cover plate) for: 1. Concrete S&C bearers. 2. As a substitute for ORANGE (Nylon) insulators where the wear rate is unacceptable. NOTE. This insulator is not commonly available, and can be replaced with Pandrol type 6924 provided this is used with clip type e2001. 13 Pandrol Track Fastening Systems User Guide - Edition 8 Catalogue Number: 57/48166 Composite (Black) Type 2786/1 6mm sidepost thicknesses Catalogue Number: 57/48167 Composite (Blue) Type 2786/2 7.5mm sidepost thicknesses Catalogue Number: 57/48168 Composite (Red) Type 2786/3 9mm sidepost thicknesses Catalogue Numbers: 4mm = 57/48169 8mm = 57/48170 12mm = 57/48171 Composite Cover Plates Composite cover plates Type 2787, to provide 4, 8 and 12mm blade thicknesses Catalogue Number depends upon insulators and cover plates selected Composite Insulators For level and gauge adjustment on slab track installations. Plastic insulators and metal cover plates are combined to give a variety of blade and sidepost thicknesses. www.pandrol.com 14 Pad Identification PANDROL pads are an important part of the rail fastening system. Rail pads provide a conforming layer between the rail seat and the rail, provide electrical resistance, and protect concrete sleepers from impact loading. Modern pads are 10mm thick. Low stiffness studded rubber pads are used for 25t axle loads on concrete sleepers. Stiffened pads are used for 30t axle loads on concrete sleepers to prevent excessive dynamic gauge widening. Steel sleepers use hard EVA pads of 10mm thickness. Pad No. 14229 Catalogue Number: 057/48470 Studded EVA rail pad 8mm thick bonded to HVN side insulators of 5.5mm thick. Used with ‘Re1609’ clip for ‘re-railing’ to replace orange insulators on older sleeper types F23 to F27, EF28, 5EF28, W402, HH10 (Mk1). Pad No. 2061/3 Catalogue Number: 57/48521 Thickness: 5mm Material: Flat EVA Used with W402 sleepers and PAN baseplates. Can also be used with concrete sleeper types: F23, F24 ,EF25, F27, EF28, EF32, EF33, F34, F35. Pad No. 9970 Catalogue Number: 57/48077 Thickness: 10mm Material: Studded EVA Used on FASTCLIP steel sleepers with 60E1 rail. Supersedes / interchangeable with 7850. 15 Pandrol Track Fastening Systems User Guide - Edition 8 Catalogue Number: 57/48278 Pad No. 8531 Thickness: 10mm Material: Studded EVA Used on FASTCLIP steel sleepers 56E1 rail. Catalogue Number: 57/48028 Pad No. 4548 Thickness: 10mm Material: Studded Rubber Used on F40 and 5F40 sleepers. Catalogue Number: 57/48271 Pad No. 6650 Thickness: 10mm Material: Studded Rubber Used on FASTCLIP concrete sleepers with 56E1 rail. Catalogue Number: 57/48254 Pad No. 8854 Thickness: 10mm Material: Studded Rubber Used on FASTCLIP concrete sleepers with 60E1 rail. www.pandrol.com 16 Pad Identification Pad No. 9286 Catalogue Number: 57/48441 Thickness: 8mm Material: Studded Rubber Used on F27 and EF28 sleepers when fitting the e-Plus system. Pad No. 9328 Catalogue Number: 57/48293 Thickness: 10mm Material: Studded Rubber Used on e-Plus RT60 and NR60 layouts. Pad No. 5197 Catalogue Number: 57/48088 Thickness: 10mm Material: Studded Rubber Used on EG49 sleepers with either 56E1 or 60E1 rails. Pad No. 7031 Catalogue Number: 57/48613 Thickness: 10mm Material: Studded Rubber Used on NRS1, NRS2, and Combi baseplates. 17 Pandrol Track Fastening Systems User Guide - Edition 8 Baseplates for Timber Sleepers Baseplate Types Pandrol Clips Used Originally fitted with PAN 1 to PAN 5 PR303, can be fitted with PR427A x 2 PAN 1 to PAN PR401A x 2 12 and PAN 14 Number of Pandrol Housings 4 Either 2 or 4 CC PAN 1 - 44 PR401A x 1 PR402A x 1 2 HO PAN PR401A X 1 PR402 X 1 2 PAN 14SG e1809 x 2 4 Various other baseplates including: V, VN, CV, RCV PR401A x 2 Either 2 or 4 NRS1 & NRS2, or Combi baseplates e2007 The Vortok Coil is used to refurbish timber sleepers with worn screw spike holes. The coils restore 90% of both the original pull-out strength and the torque of the screw to improve the positioning and dynamic gauge performance of the baseplates. 2 Comments Baseplates no longer available. Only 2 housings and clips should be used Only 2 housings and clips should be used in any of these baseplates. Note the extra housings should only be used in the event of the first housings wearing or failing Check rail baseplates Only 2 housings should be used. Only use ‘e’ clips with SGI grade cast-iron. Only 2 housing should be used in any of these baseplates. Dual rail baseplate for either 56E1 or 60E1/2. Other components: • Pad Type 7031 • Insulator Types: 60E1 = 5720 56E1 = 10274 & 10275 Catalogue No’s: S tandard Coil 057/048034 Large Coil 057/048298 www.pandrol.com 18 Concrete & Steel Sleeper Assemblies Sleeper Type(s) Clip Insulators Pad Design Track Gauge Current CONCRETE sleepers G44, EG47 for 56E1 rails FC1504 with 8494 toe G44, EG47 for 60E1/2 rails FC1504 with 8494 toe Pad 6650, except: • Curves less than 400m radius, fit EVA type 8531 FIELD side: 8582 (Blue) GAUGE side: 8690 (Black) • Low line speed, fit EVA type 8531 Pad 8854, except: • Curves less than 400m radius , fit EVA type 9970 Both sides: 7751 (White) • Low line speed, fit EVA type 9970 1436mm 1438mm Current STEEL sleepers 560H for 56E1 rails NOTE. This sleeper is fitted with hook-in shoulder type 9482. 560H for 60E1 / 2 rails NOTE. This sleeper is fitted with hook-in shoulder type 9482. 19 FC1504 with 8494 toe FIELD side: 8582 (Blue) Pad 8531 GAUGE side: 8690 (Black) 1436mm FC1504 with 8494 toe Both sides: 7751 (White) Pad 9970 1438mm Pandrol Track Fastening Systems User Guide - Edition 8 Concrete & Steel Sleeper Assemblies Sleeper Type(s) Clip Insulators Pad Design Track Gauge Discontinued / serviceable older CONCRETE sleeper types EG49 for 56E1 rails e2007 FIELD side: 10274 (Red) GAUGE side: 10275 (Yellow) Pad 5197 1436mm EG49 for 60E1/2 e2007 Both sides: 5720 (Green) Pad 5197 1438mm F41 & EF36 FC1501 with 8494 toe Both sides: 7751 (White) Pad 6650, except: • Curves less than 400m radius, fit EVA type 8531 • Low line speed, fit EVA type 8531 1435mm e1809 Both sides: 4452 (Blue) Pad 4548 1432mm 1435mm F40 5F40 Alternative assemblies for F23 to F27, EF28, EF29, EF33 sleepers: Pad 5mm rubber, or 7.5mm rubber maintenance pad, or EVA Pandrol type 2061/3. 1. S tandard toe-loads PR401A or e1809 56E1 rail: Both sides: 724a (Orange) 98lb or 109lb rails: Both sides: 724a (Blue) 2. I ncreased toe-loads e2001 56E1 rails: Pad 5mm rubber or EVA Both sides: 2433 (GRN White), pad type 2061/3 or 6924 (HVN White) 1432mm 3. e-PLUS system eP20127 56E1 rails: Both sides: 9132 Pad 9286 1432mm 4. Pandrol ‘Re’ system 56E1 rails: No separate insulator Composite pad type 14229 1432mm Re1609 1432mm www.pandrol.com 20 Concrete & Steel Sleeper Assemblies Sleeper Type(s) Clip Insulators Pad Design Track Gauge Discontinued / serviceable older STEEL sleeper types HH10 (Mk 2), HH12, for 56E1 rails FC1504 with Shoulder types: 8494 toe • HH10 = shoulder 9922 • HH12 = shoulder 9482 FIELD side: 8582 (Blue) GAUGE side: 8690 (Black) Pad 8531 1436mm HH10 (Mk 2), HH12, FC1504 with for 60E1/2 rails • HH10 = shoulder 9922 8494 toe • HH12 = shoulder 9482 Both sides: 7751 (White) Pad 9970 1438mm 500 Series FC1501 with 8494 toe Both sides: 7751 (White) Pad 8531 1435mm W402 Series HH10 (Mk1) for 56E1 rail PR401A or e1809 56E1 rail: Both sides: 724a (Orange) Pad 5mm EVA 1435mm Pandrol type 2061/3. Both sides: 8277 (Yellow) Pad 8531 Alternative assembly converting HH10 (Mk1) FC1504 with to FASTCLIP system 8494 toe using shoulder type 9922 1435mm Conversion of obsolete fastenings on very old concrete sleepers The following obsolete sleepers may be converted to Pandrol ‘e’ clip assemblies: • F10 using BJB fastenings • RNB6 also known as KENITRA sleepers • HEYBACK sleepers 21 Whilst conversions have been available and undertaken in large volumes in the past, the components are no longer readily available, generally regarded as uneconomic, and anyone attempting this process should contact Pandrol directly for advice. Pandrol Track Fastening Systems User Guide - Edition 8 Special Applications 1. Replacement shoulders for concrete and steel sleepers, and concrete slab track. This identifies the shoulders to be used for replacement in the unlikely event of damage in track. Shoulder Type Shoulder type 8888R Sleeper Type(s) Catalogue No. Not allocated Modification of standard shoulder. Shoulder type 9922 Comments G44, and EG47 HH10 This shoulder is ONLY available as part of a complete supply and replacement service provided through the approved specialist subcontractor HOLEMASTERS. Hook-in shoulder for 10mm thick steel sleepers. Catalogue No. 057/048072 Shoulder type 9482 HH12, 560H Series. Hook-in shoulder for 12mm steel sleepers. Catalogue No. 057/048073 Shoulder type 7250 Concrete slab track Standard finish: Catalogue No. 057/048071 For slab track in tunnels: Sherardised finish Catalogue No. 057/048063 For use with 10mm pads and either: ‘e’ clip assembly using GRN insulator type 4452 (blue) Or e-PLUS assembly using eP20129 www.pandrol.com 22 Special Applications 2. Zero longitudinal restraint (ZLR) assemblies to provide ‘rail free’ longitudinal movement of the rail. Used to provide differential movement between the rails and long bridge structures, or stressing relief for ground subsidence due to mining activities. ZLR assemblies use normal toe-load clips, but divert the clamping force in other directions providing a gap over the rail foot and allowing the rail to slide longitudinally in the gap. In the event of the rail moving to close gap (such as ‘rail roll’) the nominal toe-load is immediately available to prevent further overturning movement. The components below can be used with existing sleeper configurations to alter the fastening assembly into a ZLR assembly. Sleeper Type(s) Pandrol Assembly No. F23 to F27, EF28 5EF28, and W402 15206 (covers all sleeper types) F40 and 5F40 23 15207 (covers all sleeper types) Components & Catalogue Nos. EVA 5.5mm pad type 2061 Cast-iron cover plate type 7015 Clip type e2071 NOTE: Sherardised finish ONLY Catalogue Number: 057/048521 Catalogue Number: 057/048586 Catalogue Number: 057/048587 EVA 10mm pad type 12697 Cast-iron cover plate type 7015 Clip type e2071 NOTE: Sherardised finish ONLY Catalogue Number: 057/0485588 Catalogue Number: 057/048586 Catalogue Number: 057/048587 Pandrol Track Fastening Systems User Guide - Edition 8 Special Applications Sleeper Type(s) Pandrol Assembly No. G44, EG47 and EG47-3R 15208 for 56E1 rail 15229 for 60E1 / 2 rail Components & Catalogue Nos. EVA 10mm pad type 8531 Sub-assembly 15227 comprising clip type FC1504 with ZLR insulator Catalogue Number: 057/048287 Catalogue Number: 057/048589 NOTE: The ZLR insulator is BLACK EVA 10mm pad type 9970 Sub-assembly 15227 comprising clip type FC1504 with ZLR insulator Catalogue Number: 057/0485587 Catalogue Number: 057/048589 NOTE: The ZLR insulator is BLACK www.pandrol.com 24 Special Applications 3. Insulated Block Joints FASTCLIP with IBJ’S 6-hole IBJ on concrete sleeper type EG47. 6-hole IBJ on steel sleepers, showing standard FASTCLIP components. The clips fit snuggly into the recesses of the IBJ, and clip extraction is carried out using a rear-arch FASTCLIP extractor. ‘e’ Clips with older concrete sleepers 6-hole IBJ on older types of concrete sleepers. The clips should be: Right handed locations: e1809 Left handed locations: e1810 Both clip types are used with orange or composite insulators , except for F40 sleepers which use blue GRN type 4452 insulators. Other clips with S&C layouts NR60 details in e-PLUS (eP20129) layout. NOTE: e-PLUS clips do not fit beneath the IBJ bolts. The clips should be: Right handed locations: e2007 Left handed locations: e1810 Both clip types are used with green insulator type 5720 In layouts to NR56V design the IBJ will be mounted on 8mm thick pads, and the clips should be: Right handed locations: e2001 Left handed locations: e1810 Both clip types are used with orange or composite insulators. 25 Pandrol Track Fastening Systems User Guide - Edition 8 Special Applications 4. Anchorage for ‘Balise’ mounting frames. Vortok Balise Mounting System (BMS) The Vortok BMS is fitted to either concrete or steel sleepers using the rail clips to hold the beams in place between the shoulders of the sleepers. The beams are used with either ‘e’ clip or FASTCLIP as shown below. Balise units on FASTCLIP sleepers TYPES G44 / EG47, F41 & EF36 The frame sits beneath the rear arch of the standard FASTCLIP in each sleeper type. ‘e’ Clips with older concrete sleepers The frame is anchored in position using Pandrol clip type e2001. The new clip should replace the original clip on the GAUGE side of the rail seat, and is usually supplied as part of the BMS system by Vortok. www.pandrol.com 26 Identification of Pandrol Hand-Tools The new range of FASTCLIP tools also for VIPA-SFC The new tools, which react from the rail, are more efficient, faster and safer because they are not prone to slipping from the shoulder reaction points. Additionally, the tools offer compatibility with a wide range of Pandrol systems, including FASTCLIP ‘FC’ & FASTCLIP ‘FE’ and the Pandrol baseplate types VIPA-SP & SFC baseplate. Finally, because the reaction point for the installation tool has been moved to the head of the rail, the installer is able to lift sleepers (about 20mm) as part of the normal action of the tool, lifting from the rear arches of the clip before driving the clip into the installed position. Installer (FASTCLIP ‘FC’, ‘FE’, VIPA-SP, SFC) FASTCLIP Installer LP18681 Catalogue No. 39/47850 Extractor (FASTCLIP ‘FC’, ‘FE’, VIPA-SP, SFC) FASTCLIP Installer LP18679 Catalogue No. 39/47851 The original version of the sleeper lifter can still be used in conjunction the new installer where sleepers need to be lifted more than 20mm. The rear arch extractor remains available to extract clips around IBJ’s. Sleeper lifter for FASTCLIP ‘FC’, & ‘FE’ PANDROL No. LP12608 Catalogue No. 39/47852 27 Pandrol Track Fastening Systems User Guide - Edition 8 Rear arch extractor for FASTCLIP ‘FC PANDROL No. LP15177 Catalogue No. not allocated Discontinued FASTCLIP and VIPA-SP tools. The original versions of the FASTCLIP hand-tools are illustrated below, and these remain suitable for use. Pandrol has discontinued the original versions from sale. The original FASTCLIP tools have now been superseded with new tools which are more efficient, faster to use and safer. Both of the new tools look different from the earlier tools, because they react from the rail instead of from the shoulder in the sleepers. See the section on the opposite page. The original versions of the VIPA-SP & SFC hand-tools are illustrated below, and these remain suitable for use. Pandrol has discontinued the original versions shown below. The original VIPA-SP tools have now been superseded with new tools which are more efficient, faster to use and safer. See FASTCLIP hand-tools on the opposite page The new tools are compatible with FASTCLIP ‘FC’ and FASTCLIP ‘FE’ systems, as well as VIPA-SP & SFC baseplates, reducing the risk of the selecting the incorrect tools. www.pandrol.com 28 Hydraulic tools for VANGUARD and FASTCLIP Vanguard Hydraulic Tool PANDROL No. LP15647 Catalogue No. Not Allocated Vanguard Installer & Extractor Refer to separate Pandrol instructions for the use of the VANGUARD hydraulic tool. FASTCLIP Hydraulic Tool RAILTECH TYPE CDH 16 Catalogue No. Not Allocated Rosenqvist Handy Clipper (Network Rail Acceptance Certificate PA05/03211) A versatile lightweight clipping/unclipping machine dedicated to Pandrol FASTCLIP. With one man operation, the Handy Clipper is easily transported to site and will fit in the back of an estate car. It incorporates automatic sleeper lifting of up to 10mm. At maximum output 10 sleepers a minute can be achieved. 29 Pandrol Track Fastening Systems User Guide - Edition 8 Identification of Pandrol Hand-Tools Catalogue Number: Not Allocated PANPULLER Type D For PR, & e Clips PANDROL No. LP7632 Especially for e2001 and e2007clips but NOT for 4-shoulder baseplates. NOTE hook positions for max efficiency: Upper pivot: Clip installation Lower pivot: Clip extraction Catalogue No. 39/42748 PANPULLER Type C for PR, & e Clips PANDROL No. LP1180 And for 4 shoulder baseplates Catalogue No. Not allocated e-PLUS PANPULLER LP12717 PANDROL No. LP12717 Colour: Red working head (matches the appropriate e-PLUS clip type), and yellow handle. For use with eP20127 clips for retrofitting to sleeper types: F27, EF28, 5EF28, and for the new S&C designs to NR56V. Catalogue No. 39/42749 e-PLUS PANPULLER LP15923 PANDROL No. LP15923 Colour: White The tool is used with the eP20129 green or eP20130 yellow e-PLUS clips, mostly with RT60 and NR60 S&C layouts. www.pandrol.com 30 Replacement Hook for Types C and D PANPULLER Catalogue No. 39/42743 PANDROL No. 3-P2260 Replacement Hooks e-Plus PANPULLER’S LP12717 - Catalogue Number: Not Allocated LP15923 - Catalogue Number: 39/42742 PANDROL No. LP12717 use replacement hook type 2P5931 PANDROL No. LP15923 use replacement hook type 3P16127 PANPULLER Hook Wear - Gauge Catalogue No. 39/30100 PANDROL No. 3-P6536 Use of Wear Gauges • Place curve of gauge into hook. Gauge can be used with out removing the hook from the PANPULLER. • Surfaces ‘A’ and ‘C’ in contact and gap at ‘B’ Hook suitable for use. • Surfaces ‘B’ and ‘C’ in contact and gap at ‘A’ Hook unsuitable for use. Replacement Hooks for e-Plus PANPULLER: Catalogue Number 39/42742 Pandrol Number 3P16127 Replacement Hooks for Standard PANPULLER: Catalogue Number 39/42743 Pandrol Number 3P2260 It is recommended for safety reasons that contractors should formally check and record the wear of the hooks at intervals of 6 months using the wear gauge described above. The gauge is suitable for all types of PANPULLER or e-PLUS PANPULLER. The wear gauge provides easy Go / No-Go assessment of when to replace the hook. Worn hooks have a tendency to slip off the clips, which can present a significant risk to operators. 31 Pandrol Track Fastening Systems User Guide - Edition 8 Identification of Pandrol Hand-Tools Catalogue No. 39/42900 PANSETTER for PR, e, e-PLUS & Re clips PANDROL No. 2-P9559 THE PANSETTER is suitable for all Network Rail Sleepers fitted with PR, e & e-PLUS Optional Handles Catalogue Nos. for tools with straight insulated handles. All Pandrol hand-tools can be supplied with optional insulated handles, which have recently been upgraded to 35mm diameter cylindrical handles with ‘T’ cross bars for improved ergonomic and safer use. The photograph shows a typical handle attached to a FASTCLIP sleeper lifter. PANPULLER type ‘C’: Catalogue No. 39/40129 PANSETTER: Catalogue No. 39/40133 PANLOCK Puller: Catalogue No. 39/40135 FASTCLIP installer: Catalogue No. not allocated FASTCLIP extractor: Catalogue No. not allocated FASTCLIP lifter: Catalogue No. not allocated Tools with cranked handles for operation in the 4-foot. A further option is available on Pandrol hand-tools for operation whilst standing in the 4-foot, typically needed through platform areas, or in track with 3rd rail electrification. Cranked handles alter the swept arc of the handle to operate safely whilst standing in the 4-foot. All the FASTCLIP tools have optional cranked handles. www.pandrol.com 32 Identification of Pandrol Hand-Tools Hand-tools for PANLOCK and Elastic Spikes Hammers should NEVER be used for either insertion or extraction of PANLOCK. Hammers may be used for the loosening of rusty PANLOCK, but NOT to fully extract. Hammers can be used for the insertion of elastic spikes. PANLOCK Puller Catalogue No. 40/60549 PANDROL No. LP8452 Elastic Spike Extractor Catalogue No. 39/17090 Elastic Spike extractor available from Tool and Steel; Product code: TASTE112 33 Pandrol Track Fastening Systems User Guide - Edition 8 Identification of Pandrol Hand-Tools Vortok Stressing Roller (VSR) The VSR is a multi function stressing roller. It combines both the side and under roller requirements for stressing rail. It also incorporates a lift function removing the need for track jacks. The Vortok Stressing Roller is available for: • FASTCLIP (0094/018014) • ‘e’ clip (0094/018013) • FASTCLIP ‘FE‘ (Application Pending) Catalogue No. 094/018014 Catalogue No. 94/018013 Side Roller LP16668 for Pandrol Vipa Under Roller LP17469 for Pandrol Vipa Hooks over the shoulder on the inside of the track curve, and tightens using the screw to adjust the ball-bearing to touch the web of the rail. Use at least one roller every 10 rail seats, depending upon the severity of the curve. This simple wire roller fits on top of the rail pad once the rail has been lifted out of the rail seat. It is a low friction roller designed to provide an even distribution of the tension from the hydraulic stressing jacks. Catalogue No. Not allocated Catalogue No. Not allocated www.pandrol.com 34 Identification of Pandrol Hand-Tools Discontinued Rollers for FASTCLIP PANDROL UNDER-ROLLER Type 1P10385 is now obsolete and should NOT be used for stressing with FASTCLIP. Pandrol side rollers for dual rail sleeper types have been discontinued. However the original side rollers should only be used with conventional under-rollers. Therefore the recommendation for stressing is to use VSR equipment detailed on page 34. Cat No. 0039/47855 Side Roller FC1500l - 56 Cream with BLUE handle for 113A rail on FIELD side. Cat No. 0039/47856 Side Roller - FC1500l - 44 Cream with BLACK handle for 113A rail on GAUGE side. Cat No. 0039/47857 Side Roller FC1500l - 52 Cream all over for CEN60 rail on either side of rail seat. 35 Pandrol Track Fastening Systems User Guide - Edition 8 Use of Hand-Tools PANDROL PR and e-CLIP & Re clip types Installation Instructions Instructions for PANPULLER LP1180 and e-Plus PANPULLER LP12717 • I nsert centre leg of clip into housing. • P lace pivoted hook over the inside of the front arch of clip with foot of PANPULLER behind clip housing and ensure lip of the hook is under the front arch. • Taking up a natural stance behind the PANPULLER, with both hands on tee handle at top of PANPULLER, pull strongly towards chest until refusal. • The PANPULLER automatically pulls clip to the correct position e-Plus PANPULLER -eP20129 Catalogue No. 39/42749 • e-Clip and ‘Re’ Clips • e-Plus Clip Pandrol Number - LP15923 Pull until refusal. PANPULLER does not act as a stop due to shorter centre leg of clip. When correctly installed the centre leg of ALL types of e-PLUS clips, protrude beyond the shoulder to hold the side-insulator in the correct position. For instructions on the use of FASTCLIP tools and methods, refer to the separate booklet entitled: PANDROL FASTCLIP Track Installation Guide www.pandrol.com 36 Use of Hand-Tools PANDROL PR and e-CLIP & Re type clips Extraction Instructions Reverse the PANPULLER. • Taking up a natural stance on the same side as for installation, place hook on the outside of the front arch of the clip, the foot of the PANPULLER resting on the baseplate/housing just above the centre leg of clip (as illustrated). • Standing behind PANPULLER with both hands on the tee handle at the top of PANPULLER, give a strong firm push away from your chest. • If clips have been in situ for many years, it may be necessary to use a hammer to loosen them taking safety precautions. If the clips will not move then use the Rusty Clip Extractor can be used for PR clips. NOTE. It is mandatory to wear eye protection when removing or fitting any clips where hammer assistance might be necessary. Soft-faced hammers Soft-faced hammers can be used to extract ‘PR’, ‘e’‘e-PLUS’ and ‘Re’ type clips, provided the following has been agreed on each site. The use of hammers should only be attempted with the agreement of Network Rail, using suitably trained and supervised track teams. The risks of the inappropriate use of soft faced hammers fall into 2 categories. ‘PR’, ‘e’ and ‘e-PLUS’ & Re type clips can generally withstand the use of hammers so the risks are: 1. ‘PR’, ‘e’ and ‘e-PLUS’ & Re type clips MUST be caught at the point of extraction to prevent clips flying. See the boot of the operator in the photograph. 2. Poorly controlled hammers can injure personnel and damage other components The photograph shows the typical use of a soft faced hammer to extract any of the following clip types: PR, e, Re, e-PLUS. For instructions on the use of FASTCLIP tools and methods, refer to the separate booklet entitled: PANDROL FASTCLIP Track Installation Guide 37 Pandrol Track Fastening Systems User Guide - Edition 8 Use of Hand-Tools PANDROL PR , e, e-PLUS and Re Clips Pansetter Used for lifting the sleeper to the rail foot. It pushes the rail over, leaving the correct gap between the rail foot and the Pandrol housing, so that the insulator can be easily placed in the correct position. Catalogue Number 39/42900 Pandrol Number 2P9559 PANDROL PR Rusty Clip Extractor If the clips have not been disturbed for a long time, rust can develop between the centre leg of the clip and the inner face of the housing. This problem has mainly occurred with concrete sleepers in tunnels. With this situation, considerable force may be needed to remove the clips from their housings. By using such force the concrete around the housing may break away, making the sleeper unserviceable. To overcome this difficulty, Pandrol has developed the Rusty Clip Extractor to remove whole clips. If the clip has broken then the tool will remove the clip centre leg. • Suitable for PR401A clips only. • NOT suitable for use on slab track. For instructions on the use of FASTCLIP tools and methods, refer to the separate booklet entitled: PANDROL FASTCLIP Track Installation Guide www.pandrol.com 38 Use of Hand-Tools Pandrol Rail Fastenings for Bull Head Rail PANDROL PANLOCK PANLOCK Puller: Catalogue Number 40/60549 Pandrol Number LP8452 Insulated PANLOCK Puller: Catalogue Number 39/040135 Installation Instructions • P lace PANLOCK in chair from right hand side with open curled end to rail web. • P lace PANLOCK-Puller head against rail head and on top of chair jaw with lower arm under rail foot. • E nsure curved toe of handle enters leading curve of PANLOCK. • Take up a firm stance with both hands on the tee handle and pull until PANLOCK is fully installed when PANLOCK-Puller toe will disengage from PANLOCK. • Remove tool. • Check PANLOCK is located centrally in chair. PANDROL PANLOCK IMAGE REQUIRED Extraction Instructions • P lace PANLOCK-Puller head against rail head and on top of chair jaw with lower arm under rail foot. • E nsure curved toe of handle enters right hand curve of PANLOCK behind centre section. • Take up a firm stance with both hands on the tee handle and pull until PANLOCK is driven through the chair and out. • Remove tool. If the PANLOCK has been installed for a long time, it may be necessary to loosen the fastening with a hammer prior to extraction with the PANLOCK Puller. • NOTE. It is mandatory to wear eye protection when removing or fitting any clips where hammer assistance might be necessary. • For maximum effectiveness PANLOCKS should not be mixed with other bull head rail fastenings. Also ensure the chair is square to the rail. For instructions on the use of FASTCLIP tools and methods, refer to the separate booklet entitled: PANDROL FASTCLIP Track Installation Guide 39 Pandrol Track Fastening Systems User Guide - Edition 8 Machines for automated installation and extraction of FASTCLIP systems. Most track renewal sites now use FASTCLIP machines to insert or remove the clips and achieve significant productivity and efficiency gains. FASTCLIP Clipping Machine Mark 4A: • Petrol or Diesel Engine • Sleeper Lifting Device • Optional Unclipping Module • Self Propelled • Umbilical Remote Control • Suitable for Concrete or Steel Sleepers • Clipping Module (4 clips simultaneously) • Clipping Rates about 8 Sleepers per minute with Sleeper Lifting Rosenqvist CD500 High Output Clip Driver: • Self-propelled high speed clipping machine • Clipping and unclipping actions • On & off tracking is self-powered. • Clipping / Unclipping rate: up to 75 slprs/min for stressing. • Sleeper lifting capability for renewal work. Rosenqvist CD400 Clip Driver: • Sleeper lifter • Clipping / Unclipping action • Hydraulically operated attachment or self propelled • Ideal for track renewal and stressing • Clipping rates: 12 sleepers per Min for renewals. 25 sleepers per Min for stressing. • Suitable for concrete or steel sleepers • Fits 3rd rail conductor systems without removing conductor rails Rosenqvist CD200: • Clipping and unclipping action. • Sleeper lifting option • Clipping and unclipping rates up to 12 sleepers per Min www.pandrol.com 40 Track Support baseplates for Noise & Vibration mitigation. 1. Baseplates and Modular Assemblies Pandrol provides 3 different baseplate systems incorporating different levels of resilience for different required levels of vibration mitigation. The stiffness can be engineered to achieved different levels of resilience within limits, but generally Pandrol VANGUARD is the softest possible system, followed by VIPA-SP then SFC baseplates the firmest. All of these systems can be supplied in different variants, most of which are already Product Accepted by Network Rail. The baseplates can be installed on concrete slab track or steel structures using a range of anchorage systems shown on the following pages. Pandrol SFC: Catalogue No. 057/001958 Assembly 14903 for 56E1 Pandrol SFC: Catalogue No. 057/001959 Assembly 15082 for CEN60 Pandrol VANGUARD: Not relevant to loose components Assembly No. 10395 for CEN60 See pages 43 and 44 for description of loose components Pandrol VANGUARD: Assembly No. 10853 for 56E1 See pages 43 and 44 for description of loose components 41 Pandrol Track Fastening Systems User Guide - Edition 8 Not relevant to loose components Catalogue No. 057/001960 Pandrol VIPA-SP: Assembly 11308 for 56E1 Catalogue No. 057/001961 Pandrol VIPA-SP: Assembly 10435 for CEN60 Catalogue No. 057/001955 Pandrol VIPA-SP: Assembly 11321 for 56E1 Catalogue No. 057/001956 Pandrol VIPA-SP: Assembly 13788 for 56E1 Catalogue No. 057/001957 Pandrol VIPA-SP: Assembly 10601 for CEN60 www.pandrol.com 42 Track Support baseplates for Noise & Vibration mitigation. 1. Vanguard Components These tables depict the differing components needed for the most frequently used variant of the VANGUARD range being the baseplate variant. Network Rail has formally accepted this variant for either 56E1 or 60E1 or 2 rails but the components are different to reach the differing rail sizes. The Network Rail Product Acceptance certificate is: PA05/00569. This explains and illustrates the differing components. Common Components for Both Rails Baseplate Type 10396 Hook-In Shoulder Type 9705 Catalogue No. 057/060022 Catalogue No. 057/060023 Bump-Stop Pad Type 9766 VANGUARD Locking Wedge Type 9242 Catalogue No. 057/060024 Catalogue No. 057/0060026 VANGUARD Retention Clip Type 7920 Catalogue No. 057/048335 43 Pandrol Track Fastening Systems User Guide - Edition 8 Remaining Components Unique to Each Rail Size Rail Size 56E1 Rail Size 60E1 or 60E2 Rubber Wedge Assembly 9456 Rubber Wedge Assembly 9769 Catalogue No. 057/048334 Catalogue No. 057/060027 Side Arm Type 9413 Side Arm Type 9765 Catalogue No. 057/048350 Catalogue No. 057/060025 www.pandrol.com 44 Anchorage Systems for Pandrol Baseplates 3. Anchorage Assemblies The choice of anchorage assembly is determined by the installation method selected by the contractor. The methods listed below describe the techniques used by contractors. The corresponding anchorage should be specified as part of the Pandrol scope of supply to maintain the Product Acceptance validity. Components List for Each Hold-Down Assembly ‘Bottom-up’ Method Bottom-up method on concrete slab track 24 Stud Type: M24 Nut Type: 2 Qty. Flat Washers: 2 Qty. Disc Springs: 11249 11368 11244 11242 Top-Hat Bush: 11032-24 Serrated Washer: 9978 Conforming Pad: 10401 Heights Adjusting Shims Type: 10854 (Thickness available: 3, 5, 10mm) Pandrol does NOT supply grout for the anchor stud ‘Top-Down’ Method Drilled and grouted anchors, with poured grout pad beneath baseplate The ‘Top-down’ method uses the same components as above, with the exception of swapping the Conforming pad, for a: Construction shim: 11361 Pandrol does NOT supply grout for the anchor stud, NOR the grout for beneath the construction shim ‘Bottom-up’ Method Bottom-up method on steel deck M24 Bolt Type: M24 Nut Type: 2 Qty. Flat Washers: 2 Qty. Disc Springs: 45 13110 11368 11244 11242 Top-Hat Bush: 11032-24 Serrated Washer: 9978 Conforming Pad: 10401 Heights Adjusting Shims Type: 10854 (Thickness available: 3, 5, 10mm) Pandrol Track Fastening Systems User Guide - Edition 8 The anchorage assemblies shown below can be used with either method of top-down construction. Installation and the choice is determined by other factors such as track curvature or height adjustment limits required. Generally plastic inserts can used for track where curvature is greater than 400 metres, and height adjustments less than 15mm. ‘Top-Down’ Method Assemby with M24 bolt, and cast-iron insert. Slab track concrete poured to beneath the baseplate or set with concrete sleepers. M24 Bolt Type: 9978 13110 Serrated Washer: Cast Iron Insert: 11361 9744 Construction Shim: Top-Hat Bush: 11032-24 (wet poured concrete) 2 Qty. Flat Washers: 11244 Conforming pad: 10401 2 Qty. Disc Springs: 11242 (on sleepers) Height adjusting shims are NOT required using this method, unless downward adjustment is later required ‘Top-Down’ Method Assemby with Anchor Screww and plastic insert. Slab track concrete poured to beneath the baseplate or set with concrete sleepers. Anchor Screw 9978 Serrated Washer: 22mm ø Type: 11361 10886 Construction Shim: Plastic Insert: 10887 (wet poured concrete) Top-Hat Bush: 10401 11032-23 Conforming pad: 2 Qty. Flat Washers: 11244 (on sleepers) 2 Qty. Disc Springs: 11242 Height adjusting shims are NOT required using this method, unless downward adjustment is later required NOTES. 1. The lengths of anchor studs, bolts, and screws can be calculated with the aid of separate data-sheets from Pandrol. 2. The factors of safety for the various Pandrol anchorage systems can be calculated by Pandrol from track and site parameters. Contact Pandrol for details. www.pandrol.com 46 4. Identification Chart for Anchorage Components The anchorage components identified below form part of the scope of supply only with the relevant Pandrol baseplates. These components are NOT supplied separately, and can only be warranted when used within the defined Pandrol assembly. Bolts, Studs and Nuts Catalogue No. 57/01962 M24 Anchor Stud Type 11249 Lengths from 225mm to 320mm Catalogue No. 57/01970 M24 Bolts Type 13110 Lengths from 140mm to 210mm Catalogue No. 57/01972 Anchor Screw Type 10886 For use with plastic inserts Catalogue No. 57/01963 M24 Nut Type 11368 NOTE: The standard finish on bolts, anchor studs, screws, and nuts is spun galvanised. 47 Pandrol Track Fastening Systems User Guide - Edition 8 Inserts Catalogue No. 57/01971 Cast-Iron Type 9744 Note: The blue epoxy finish is optional. Standard finish is natural cast-iron Catalogue No. 57/01973 Plastic Insert Type 10887 Washers and Disc Springs Catalogue No. 57/01964 M24 Flat Washer Type 11244 For use with plastic inserts Catalogue No. 57/01965 M24 Disc Spring Type 11242 NOTE: Washers are zinc plated, and disc springs are additionally passivated yellow colour. www.pandrol.com 48 Identification Chart for Anchorage Components Bushes and Serrated Washers Catalogue No. 57/01947 Top-Hat Type 11032-23 Catalogue No. 57/01966 Top-Hat Type 11032-24 Catalogue No. 57/01998 Serrated Washer Type 9978 (Top) Serrated Washer Type 9978 (Bottom) 49 Pandrol Track Fastening Systems User Guide - Edition 8 Pads and Shims Catalogue No. 57/01968 Catalogue No. 57/01969 Conforming pad Type 10401 Height Adjusting Shim 3mm thick for preformed concrete and steel decks Type 10854-3 3mm thick Catalogue No. 57/01974 Construction Shim Catalogue No. 57/01948 Height Adjusting Shim Type 11361 Type 10854-5 10m thick for poured concrete and grout 5mm thick 1mm - Catalogue No. 57/01950 2mm - Catalogue No. 57/01951 Catalogue No. 57/01949 Steel Half-Shim with Slotted Holes Type 14954 Height Adjusting Shim Range:1,2mm thick Type 10854-10 HDPE Half Shim with Slotted Holes 3mm - Catalogue No. 57/01952 Type 14953 Range: 3, 5 10mm thick 10mm thick 5mm - Catalogue No. 57/01953 10mm - Catalogue No. 57/01954 www.pandrol.com 50 www.pandrol.com Design by Andy Marsden: t. 07960 085647 e. andy.marsden76@gmail.com Pandrol UK Limited Gateford Road Worksop Notts S81 7AX T. 01909 476101 F. 01909 500004