Engineering Manual - Heatcraft Worldwide Refrigeration

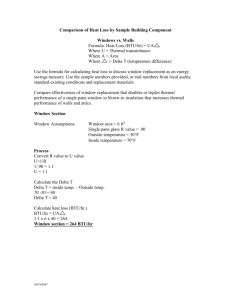

advertisement