FAST-FIT™ Metal Clad Jacketed Cable Connectors

advertisement

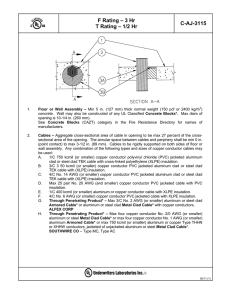

TB12 TB12 Armored/Metal Clad Cable Terminators FAST-FIT™ Metal Clad Jacketed Cable Connectors Type MCJ Malleable Iron Type MCJ-A Copper Free Aluminum Use: • To secure, ground and seal metal clad jacketed cable to enclosures or raceways. Features: • Fast installation without disassembly of fitting. • Wide cable range per fitting (requires less inventory) • Positive ground between cable armor and fitting • Neoprene grommet assures water and dust tight seal on jacket • Exceeds pull-out requirements on cable • Rugged construction in malleable iron and aluminum • For use with jacketed metal clad, teck, smooth or corrugated continuous or gas-blocked cables • Fits all armored cable regardless of convolution differences • Concrete tight Materials: Body and Nut - malleable iron or copper free aluminum Grounding Ring - stainless steel non-magnetic Grommet - neoprene Pressure Ring - aluminum Finish: Malleable Iron, Zinc Plated Aluminum Natural finish Optional Finish/Accessories: Malleable Iron - Mechanically Galvanized Finish available. All fittings can be supplied with neoprene gasket, locknut and Insulating bushing. Add Suffix “LGB”. Contact your local representative for price and availability. Third Party Certification: UL Listed: E-36853 Suitable for wet locations Applicable Third Party Standards: UL Standard: 514B National Electrical Code Article: 330, 501.4(B)(4), 501.5(E)(2), 501.5(E)(3); CSA Standards: C22.2 No.18 Fed. Spec: W-F-406B Suggested Specification: “A metal clad jacketed cable connector shall be used to secure, ground and seal jacketed metal clad cable to enclosures or raceways. These fittings shall be malleable iron or aluminum construction and allow installation without connector disassembly. Jacketed metal clad cable connectors shall be O-Z/Gedney Type MCJ or Type MCJ-A. Type MCJ Note: Suitable for use in the following hazardous locations: USA: Class I, Div. 2 Class II, Div. 2 Class III, Div. 1, 2 Canada: Class I, Div. 2; Class II, Div. 1, 2 Class III, Div. 1, 2 Sealing fittings may be required when entering explosion proof enclosures. Trade Size (inches) Malleable Iron Catalog Number Copper Free Aluminum Catalog Number Strip Armor Jacket Jacket Range Armor Range Max. Max. Thread Stop From Min. Max. Min. Max. Dia. Length Length I.D. Armor Dimensions in Inches ⁄2 ⁄2 1 ⁄2 MCJ-50-63 MCJ-50-75 MCJ-50-88 MCJ-50-63A MCJ-50-75A MCJ-50-88A .47 .59 .72 .54 .66 .79 13⁄4 13⁄4 13⁄4 25⁄16 25⁄16 25⁄16 9 ⁄4 ⁄4 MCJ-75-97 MCJ-75-111 MCJ-75-97A MCJ-75-111A .79 .97 .93 1.11 .70 .88 .84 1.02 21⁄8 21⁄8 27⁄16 27⁄16 9 1 1 MCJ-100-119 MCJ-100-136 MCJ-100-119A .99 1.19 .90 1.10 MCJ-100-136A 1.16 1.36 1.07 1.27 21⁄2 21⁄2 23⁄4 23⁄4 11 11⁄4 11⁄4 MCJ-125-156 MCJ-125-175 MCJ-125-156A 1.33 1.56 1.23 1.46 MCJ-125-175A 1.52 1.75 1.42 1.65 215⁄16 215⁄16 31⁄16 31⁄16 3 11⁄2 11⁄2 MCJ-150-176 MCJ-150-198 MCJ-150-176A 1.50 1.76 1.40 1.66 MCJ-150-198A 1.72 1.98 1.62 1.88 33⁄16 33⁄16 31⁄4 31⁄4 3 2 2 MCJ-200-222 MCJ-200-247 MCJ-200-222A 1.93 2.22 1.79 2.08 MCJ-200-247A 2.18 2.47 2.06 2.35 311⁄16 311⁄16 33⁄8 33⁄8 3 1 1 3 3 .63 .75 .88 .38 .50 .63 ⁄16 ⁄16 9 ⁄16 .35 .47 .60 3 ⁄16 ⁄16 .67 .81 3 ⁄16 ⁄16 .87 1.04 3 ⁄4 ⁄4 1.20 1.39 7 ⁄4 ⁄4 1.37 1.59 1 1 ⁄4 ⁄4 1.78 2.03 1 1 9 9 11 3 3 3 ⁄4 ⁄4 ⁄4 3 3 ⁄4 ⁄4 3 ⁄4 ⁄4 3 ⁄8 ⁄8 7 CSA Certified: 9795 Raintight Effective December, 2007 Copyright 2007 800-621-1506 www.o-zgedney.com