Platinum-RTD-based circuit provides high performance

advertisement

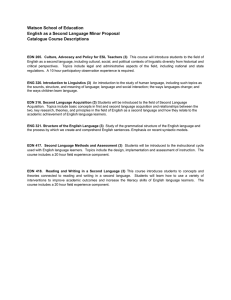

designideas Edited By Martin Rowe and Fran Granville readerS SOLVE DESIGN PROBLEMS Platinum-RTD-based circuit provides high performance with few components Equations for DI4264 (5 − 29) D Is Inside 72 Proportional-ac-power controller Equation 1 doles out whole cycles of ac line 78 Extend monolithic program- Jordan Dimitrov, Toronto, ON, Canada mable-resistor-adjustment range Y1 VOwith = VREF × negative × active resistance The standard way of using an additional current to the sensor that Y2 RTD (resistance-temperature- relates to the temperature you are mea- R (Y78+1-YWire � Y �Y network Equations for DI4264 (5 − 29) Θ 0 2 3 Y4 )�1 controls remote , detector) sensor is to include it in a suring. With proper Equations for DIdesign, 4264 (the 5 − circuit 29) R [ Y + SPI peripherals bridge followed by a differential am- can provide good linearity and stabil-Θ 1 Y3�R 2Y4 (Y0 + Y1)] + 1 EWhat are your design problems plifier. The problem is that two non- ity over a wide range of input tempera2 1 and solutions? Publish them here linearities—one from the sensor and tures. TheEquation output voltage, VO, depends Equation Equation 1 and receive $150! Send your another from the bridge—affect the on circuit components in the followDesign Ideas to edndesignideas@ transfer function. Some approaches ing way: are available that attempt to avoid the Y1 R Θreedbusiness.com. = R 0 (1 + α × Θ + β × Θ2), VO = VREF × problem, but they tend to be bulky and Y1 × ETo see all of EDN's Design VO = VREF × × Y2 expensive (references 1, 2, and 3). Y2 Ideas, visit www.edn.com/design R Θ (Y0 + Y2�Y3�Y Y4 )�1 An alternative circuit proposes add, ideas. R Θ (Y0 + Y2�Y3�Y Y4 )�1 ing only one extra resistor to the difR Θ [ Y1 + Y3�R 2Y4 (Y0 + Y1)] , +1 R [ Y + Y � R Y ( Y + Y )] + 1 Equation 3 ferential amplifier but provides neither Θ 1 3 2 4 0 1 design guidelines nor results (Refer- where YI51/R and I=0 to 4. in the first and doing some rearrangeEquation 2 I Equation ence 4). This Design Idea fills the gap. For positive 2temperatures, a second- ments, you get: Although circuit analysis is somewhat degree polynomial of the following form Θ�B V0 = 2 × K × Θ = f (Θ)KΘ, complex, performance is good, and the can approximate RTD characteristics:2 Θ � B Θ � C R = R ( 1 + α × Θ + β × Θ ), Θ 0 circuit uses few components. R Θ = R 0 (1 + α × Θ + β × Θ2), Besides the platinum RTD, RU, the where B, C, and K are constants and circuit features only six precision resis- where R0 is sensor resistance at 08C, f(U) is a function of temperature. Figtors, an op amp, and a voltage refer- a and b are coefficients, and U is the ure 2 shows the general shape of f(U). ence (Figure 1). R4, the extra resistor measuredEtemperature. The output voltage depends linearly quation 3 for the differential amplifier, delivers After replacing Equation 3 the second equation on temperature when f(U) is as close as possible to a conVREF stant. This situation R2 Θ�B is most true around V0 =Θ�B × K × Θ = f ( Θ ) K Θ , V0 = 2 Θ2�BΘ×�KC× Θ = f (Θ)KΘ, R1 R1 the minimum point Θ �Bf(�) Θ�C of f(U). � Some additional VO �/� relations provide � that the output volt�, �C age is 0V at temperature 08C, the conR4 R0 R� R3 version coefficient is 10 mV/8C, the minimum of function f(U) is in the Figure 1 This generic RTD circuit needs few Figure 2 The general shape of function f(U) middle of the meacomponents. varies with temperature. surement span, and edn080529di42641 DIANE edn080529di42642 DIANE september 4, 2008 | EDN 71 designideas the current through RU causes adjustment at 5508C to match TABLE 1 experimental results negligible self-heating of the the magnitudes of the posiMeasurement range 1100 to 1600°C sensor. tive and the negative errors. Figure 3 shows the circuit Nominal sensitivity You can also extend the tem10 mV/°C that meets these requirements. Basic accuracy (nonlinearity) perature range to start from Well below 61°C The sensor is a DIN-IEC 751 21008C instead of 08C withAmbient-temperature effect 0.05°C/10°C platinum RTD. Microsoft (www. out exceeding the basic non0.1°C/V microsoft.com) Excel software Power-supply effect linearity. The three-lead confits 13 points of 0 to 6008C in Cable effect (three-lead connection) nection to the sensor signifi0.7°C/V steps of 508 from the RTD’s cal- Power-supply range cantly reduces the influence of 612 to 618V ibration table. The spreadsheet connection-cable resistance, 9 and 13 mA software determined R0 to have Consumption (600°C input) RC, on accuracy. 140 to 185°C a value of 100V, a to have a Operating temperature Table 1 shows the results of value of 3.908310238C21, and evaluating this circuit’s perb to have a value of 25.801310278C22 coefficient is 50 ppm/8C. You can use formance with a calibrated, precisionwith an R2 factor of one. two trimming potentiometers, VR1 and decade resistance and a calibrated, All the circuit’s resistors have toler- VR2, to independently adjust zero and 4.5-digit multimeter with readings ances of 0.02%, and the temperature span readings. You should perform span at ambient temperatures of 24 and 688C; power supplies of 612, 615, R2 VR1 and 618V; and cable resistances of 0 2.46k 100 and 5V.EDN 15V 2 REF01H R1 10k 6 5 VR2 100k � OP07C R0 100 4 RC 15V R1 10k R e fe r e nce s VO � RC RC R� R3 2.67k �15V R4 28.4k Figure 3 The full circuit needs trimming potentiometers VR1 and VR2 to adjust zero and span, respectively, and a three-lead cable for sensor connection. RC is the cable’s resistance. EDN080529DI42643 DIANE Proportional-ac-power controller doles out whole cycles of ac line Richard Rice, Oconomowoc, WI In industrial and process control, it is often necessary to accurately control the temperature of a process. You control most heating elements using the “bang-bang” method—turning the power to them on and off at a predetermined setpoint. The temperature of the heated substance constantly hunts back and forth around the setpoint. You can achieve much 72 EDN | september 4, 2008 Bryant, James, Walt Jung, and Walter Kester, Op Amp Applications, Analog Devices, 2002. 2 Villanucci, Robert S, “Design an RTD interface with a spreadsheet,” EDN, Feb 7, 2008, pg 57, www.edn. com/article/CA6526816. 3 Moghimi, Riza, “Low-error platinum RTD circuit has shutdown capability,” EDN, Sept 14, 2000, pg 186, www. edn.com/article/CA47186. 4 Gutnikov, VS, Integrated Electronics in Measuring Devices, Leningrad, 1980. 1 greater temperature precision using proportional power control. With this method, the controller monitors the temperature, proportionally varying the heater power to keep the temperature as close as possible to the setpoint. A PID (proportional-integral-derivative) control loop usually accomplishes this function. Varying the ac power to the heating element in a linear-proportion- al manner is neither easy nor simple. This Design Idea borrows from the delta-sigma-modulator concept. The controller sends cycles of the ac line to the load as the delta-sigma modulator determines. For example, when the input-control voltage is 15% of fullscale, only 15 of 100 ac cycles arrive at the load. Likewise, at 85%, 85 of 100 arrive (Figure 1). The control-voltageinput stage, IC1A, is an inverting amplifier with a gain of negative one. This stage makes the control-voltage range over the positive side of 0V. In this example, the control-voltage input ranges from 0 to 2V full-scale. The control designideas R2 100k VIN R1 100k � CONTROL VOLTAGE 0 TO 2V R3 49.9k VCC C1 0.22 �F IC1A ½TL072 � OP AMP R4 100k � IC R5 71.5k VCC R14 1k R8 100k ½TL072 � IC2A ½LM319W VCC OP AMP 4 R18 1k � 2 2 1 COMPARATOR VCC D1 � 7 IC3A Q1 74HCT74 D FLIP-FLOP 1 R1 4 S1 C1 D3 120V AC + 8V AC 4 IC4 MOC3011 Q1 2N3906 SCR1 C2 0.1 �F 250V LINE 2 VCC 5V IN D1 2 COMPARATOR C3 470 �F D2 6 R10 100 R13 180 60-Hz CLOCK 6 + 16V AC CT 500 mA T1 8V AC Q1 5 R12 180 6 3 IC2B ½LM319W 9 R11 180 1 LED1 3 � 8 � R16 4.7k LINE 1 R23 390 R9 1k R7 100 1B R17 100k R15 100k LINE 1 TO AC LOAD (HEATER) VCC R6 249k D4 LINE 2 C6 220 �F IC4 OUT LM317 ADJ R19 750 R20 243 R21 750 ADJ IC5 OUT IN LM337 + C4 33 �F + R22 243 C7 33 �F C5 0.1 �F C8 0.1 �F VEE �5V Figure 1 This ac controller borrows from a sigma-delta converter to output a number of whole cycles of ac-line power according to an input-control voltage. voltage’s input impedance is 100 kV. The next stage, IC1B, is an integrator. The integrator output ramps either up or down depending on the polarity of the input current. The speed at which it ramps depends on the magnitude of the input current. The integrator is the heart of the delta-sigma modulator. It forces a balance, on the average, between the control-voltage current in R4 and the feedback current in R6. In other words, the duty cycle of the output of IC3A, a CMOS D-type flip-flop, must match the control-voltage percentage of full-scale. Comparator IC2A detects whether the integrator’s output is positive, thus requiring more feedback current, or negative, thus requiring less feedback to maintain the balance. The output of the comparator switches between 0 and 5V. The flip-flop latches the comparator’s decision on the next rising edge of the 60-Hz clock. 76 EDN | september 4, 2008 PNP transistor Q1 and optoisolated SCR (silicon-controlled rectifier) IC4 drive load-switching SCR1 into conduction whenever the flip-flop provides feedback current to the integrator. Indicator LED1 lights when the load SCR is on. The secondary of transformer T1 detects the zero crossings of the acpower line; these crossings provide the 60-Hz clock. The output of comparator If you turn off the SCR too late, its self-latching nature may cause it to stay on for an extra half-cycle when it should have been off. IC2B switches high during the positive half-cycles of the ac line and low during the negative half-cycles. Resistor R15 provides a small positive bias, causing the edges of the 60-Hz clock to occur slightly early—which is better than late in this case. If you turn off the SCR too late, its self-latching nature may cause it to stay on for an extra half-cycle when it should have been off. Both comparators IC2A and IC2B use a small amount of hysteresis to promote fast, clean switching. The remaining components generate the regulated 5 and 25V power supplies. Transformer T1 and optoisolator IC4 provide isolation from the ac-power line. This Design Idea works well for an application such as a spa-heater control but does not work for light-dimming or motor-speed control because the output power is pulsating in nature. You can easily adapt the design for 240V-ac or 50-Hz operation.EDN designideas Extend monolithic programmableresistor-adjustment range with active negative resistance W Stephen Woodward, Chapel Hill, NC A variety of solid-state, in-circuit-programmable replacements exist for the traditional electromechanical trimmer potentiomHGND eter. These replacements have many obvious advantages, such as automatic adjustability, miniaturization, and immunity to vibration. But these R1ADJ e REFFECTIVE = R�RC =R�RM. R R1 R1 V RM=MINIMUM PROGRAMMED RESISTANCE. I �I VC RF � VM�VC=0, IF RC=RM. � RF VC=IC�RC. RC �IC VREF Figure 1 This circuit uses an op amp in a negative-resistance topology that, in effect, subtracts the minimum programmable resistance from the total programmed resistance. edn080515di42591 DIANE 1-Wire network controls remote SPI peripherals Michael Petersen, Maxim Integrated Products, Colorado Springs, CO Many 1-Wire-compatible peripherals are available, but, for those that lack the 1-Wire capability, the circuit in Figure 1, pg 80, illustrates one way to implement it. The example controls a remote LED display by the 1-Wire network through an SPI (serial-peripheral-interface)-compatible display controller. To produce the three-wire SPI that a MAX7221 display controller requires for the CS (chip-select), DIN (serial-data), and CLK (clock) signals, the 1-Wire network serially addresses three DS2405 1-Wire switches. The first switch directly creates CS; the second switch directly creates DIN; and the third switch, aided by three 78 EDN | september 4, 2008 devices, unlike humble mechanical potentiometers, have relatively large minimum programmable resistance. Although you can adjust a typical trimming potentiometer down to a fraction of 1V, solid-state-potentiometer substitutes usually bottom out at 10s, 100s, or even 1000s of ohms. This limitation can sometimes be problematic and frequently precludes use of the solid-state option in some design applications. The Rejustor family of devices, which Microbridge (www.mbridgetech.com) recently introduced, provides an extreme example of this effect. You can program a typical Rejustor over only a narrow span of 30%. For example, you can program a 10‑kV Rejustor to no lower than 7 kV, imposing a serious and obvious obstacle to generalpurpose application of these devices. Figure 1 suggests a generally applicable workaround that works not only with Rejustors, but also with all adjustable resistances. It uses an op amp in a negative-resistance topology that, in effect, subtracts RMIN (minimum programmable resistance) from the total programmed resistance.EDN exclusive-OR gates, creates CLK. The edge detector and one-shot IC4A, IC4B, and IC4C combine the outputs of IC2 and IC3—Data 1 and Data 0—to create a clock signal for the SPI. This one-shot clock-generation circuit improves the data rate by requiring only a single 1-Wire transaction per SPI bit, instead of the three transactions—data, clock low, and clock high—that would be necessary if you directly use the IC3 output as a clock signal. To transmit data to the SPI inputs, first set the output of IC1 low. Then, transmit the data bits using the following rules: If the current data bit differs from the previous bit, set IC2’s Data 1 output accordingly. If the current data bit is the same as the previous bit, toggle IC3’s Data 0 output. The circuit automatically generates a clock pulse each time and requires only one 1-Wire command for each data bit sent. When data transmission is complete, send a final 1-Wire command to set the IC1 output high. This circuit allows a 1-Wire network to control a remote temperature display, but similar techniques can provide an interface to I2C (inter-integrated-circuit)-compatible devices and to other SPI peripherals, such as ADCs and DACs. You can also produce a bidirectional-data capability by adding a fourth DS2405. Note that the SPI data rate and updates to the peripheral are relatively slow, but speed is not an issue for many remote-monitoring applications.EDN designideas 5V R1 4.7k R2 4.7k PIO IC2 DS2405 DATA GND IC4B IC4A DATA 0 DATA 1 CS PIO IC1 DS2405 DATA GND R3 4.7k R4 100 74HCT86 PIO IC3 DS2405 DATA GND 74HCT86 IC4C 74HCT86 C1 0.01 �F 1-WIRE 5V DIGIT ZERO CS DIN CLK DIGITS ONE TO SIX DIGIT SEVEN SEG A V+ SEG B R5 SEG C ISET SEG D IC5 MAX7221 SEG E SEG F SEG G SEG DP GND GND DIG 7 DIG 6 . . . DIG 1 DIG 0 Figure 1 Three 1-Wire switches—IC1, IC2, IC3; three XOR gates, IC4; and the associated components enable a 1-Wire network to control this display through the SPI peripheral IC5. edn080710di42871 DIANE (placed in the 8-21 folder) 80 EDN | september 4, 2008