technical data - Instituto de Artes

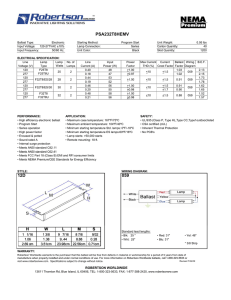

advertisement