Catalog - NK Technologies

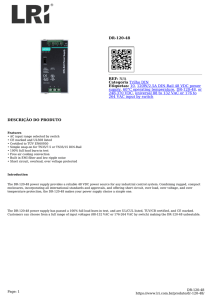

advertisement