An ultra-low-voltage rectifier for PE energy harvesting applications

advertisement

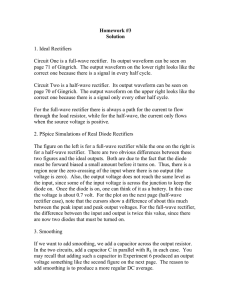

Vol. 37, No. 2 Journal of Semiconductors February 2016 An ultra-low-voltage rectifier for PE energy harvesting applications Wang Jingmin(王静敏), Yang Zheng(杨正), Zhu Zhangming(朱樟明) , and Yang Yintang(杨银堂) School of Microelectronics, Xidian University, Xi’an 710071, China Abstract: An ultra low voltage rectifier with high power conversion efficiency (PCE) for PE energy harvesting applications is presented in this paper. This is achieved by utilizing the DTMOS which the body terminal is connected to the gate terminal in a diode connected transistor. This implementation facilitates the rectifier with dynamic control over the threshold voltage. Moreover, we use input powered to take the place of output powered to reduce the power loss and thereby increasing the power conversion efficiency. Based on standard SMIC 0.18 m CMOS technology, the simulation results show that the voltage conversion efficiency and the power conversion efficiency can reach up to 90.5% and 95.5% respectively, when the input voltage equals to 0.2 V @ 100 Hz with load resistance 50 k. Input voltages with frequencies in the range of 10 Hz–1 kHz can be rectified. Key words: PE energy harvesting; DTMOS; input powered; active rectifier DOI: 10.1088/1674-4926/37/2/025004 PACS: 85.40.-e EEACC: 2570 1. Introduction With the increasing demand for portable electronic devices, replacement or recharging of batteries plays a significant role in the development of microelectronics. In this case, energy harvesting systems have been researched and developed in recent yearsŒ1 . Energy can be harvested from ambient environments such as mechanical, thermal, light, electromagnetic, the human body, and so on to replace traditional sources. One of the most popular and prominent methods of energy harvesting is by using piezoelectric material. Representative piezoelectric materials can be categorized into piezoceramics and piezopolymers. Piezoelectric vibration harvesting is attractive mainly due to the simplicity of piezoelectric transduction and the piezoelectric systems can be easily implemented into a wide variety of applications, especially in wearable healthcare applicationsŒ2 . Since the energy harvesting can generate mW or W level power, the output of the piezoelectric materials is usually an AC signal below 1 V. Therefore, a rectifier is needed to produce a dc supply source. The most common rectifiers for the PE energy harvesting systems are active rectifiersŒ3; 4 . The structure of an active rectifier is shown in Figure 1. The circuit consists of two stages: the MOS full wave rectifier and the active diode. The full wave rectifier converts the negative half waves of the input signal into positive ones. The active diode as a second stage is to control the current direction, which could be either a conventional diode connected PMOS or an active diode. For the low voltage and small reverse leakage current, the active diode is more appropriate. In Figure 1(a), an active diode is composed of one PMOS switch and one comparator. One problem for the PMOS switch is the high threshold voltage in the conducting mode, which is not available for the low voltage PE energy harvesting. To obtain high voltage gain and high power conversion with low leakage losses and fast switching, in our work, we use the DTMOS in the PMOS switch which can dynamically alter the threshold voltage. In this way the minimum input voltage could be as low as 0.18 V. Moreover, we use input powered to take the place of output powered to reduce the power loss and thereby increasing the power conversion efficiency. The structure of the proposed rectifier is shown in Figure 1(b). The paper is organized as follows: Section 2 investigates the principle of DTMOS architecture, Section 3 describes the analysis and design of the proposed rectifier, Section 4 shows the simulation results and discussion, and finally the conclusion is presented in Section 5. 2. The principle of DTMOS architecture In a standard CMOS process, a diode is commonly replaced with a diode-connected MOS transistor, which is easier to implement. The conventional way to implement the diode connected MOS (BTMOS) with parasitic diodes is shown in Figure 2(a), in which the gate terminal is connected to the drain terminal and the body terminal is tied to the source terminal. The drain current through the transistor is composed of a channel current plus the current through the parasitic diode D2 since diode D1 is shorted due to the body-source tie. This usual connection imposes a disadvantage during the OFF-state, since it allows the high reverse current, due to the direct current in the parasitic diode, which rises exponentially with the increase in reverse bias voltage. To overcome the limitation, one possible solution is to implement CMOS transistors with dynamic VTH . In DTMOS architectureŒ5 as shown in Figure 2(b), the gate and body of the device are connected together to dynamically change the threshold voltage of the transistor, by utilizing the relation in Equation (1). * Project supported by the National Natural Science Foundation of China (Nos. 61234002, 61322405, 61306044, 61376033) and the National High-Tech Program of China (No. 2013AA014103). † Corresponding author. Email: zmyh@263.net Received 9 June 2015, revised manuscript received 2 August 2015 © 2016 Chinese Institute of Electronics 025004-1 J. Semicond. 2016, 37(2) Wang Jingmin et al. Figure 1. The structure of an active rectifier. (a) Conventional active rectifier. (b) Proposed active rectifier. Figure 3. Schematic of the negative voltage converter (NVC) using DTMOS architecture. half waves of the input signal into positive ones. The active diode as a second stage is to control the current direction. 3.1. Negative voltage converter Figure 2. (a) BTMOS architecture. (b) DTMOS architecture. (c) PMOS threshold voltage variation with body-source voltage in SMIC 0.18 m CMOS process. p VTH D VTH0 C . j2F VBS j p j2F j/: (1) In DTMOS biasing parasitic diode D2 is short circuited due to the gate-body tie up. This not only improves the forward conduction current but also minimizes the reverse conduction leakage current. Figure 2(c) clearly shows that in the DTMOS biased transistor, the VTH varies more than 35% compared with the BTMOS biased transistor. 3. The proposed ultra low voltage rectifier circuit As shown in Figure 1(b), the structure of the proposed rectifier consists of two stages: the negative voltage converter (NVC) and the active diode. The NVC converts the negative The first stage is used to convert the negative half waves of the input wave into positive ones, which is achieved with only four standard CMOS transistors. Figure 3 shows the schematic of the negative voltage converter (NVC). During the positive half period of the input (VIN1 > VIN2 /, the transistors P1 and N2 will conduct when the input voltage increases and gets larger than jVTHP j and VTHN . Thus, current can flow from Vin1 over P1 and the A node to the output node and then back to Vin2 over the B node and N2. Similarly, for the negative half period of the input, P2 and N1 are conducted and terminal A is connected to Vin2 . Therefore, the high potential of VIN is always at node A, while the low potential of VIN is always at node B. In a standard CMOS process, the body terminal of the NMOS (N1 and N2) is connected to the ground and the body terminal of the PMOS (P1 and P2) uses DTMOS architecture. Compared with the NVCs in References [5, 6] which adopt a body bias technique, our negative voltage converter circuit is simple, and does not require other devices, which results in less chip area. 3.2. Active diode Once the input voltage exceeds the threshold voltage, current backflow occurs, and the storage capacitor directly connected to the rectifier will discharge. Therefore it is necessary to add a second stage to control the direction of the current. 025004-2 J. Semicond. 2016, 37(2) Wang Jingmin et al. Figure 4. Schematic of the active diode. (a) PMOS switch. (b) Input-powered comparator. Since the threshold voltage in a conventional diode connected MOS transistor will result in a low efficiency, so an active diode is adopted here. The conduction voltage drop of the DTMOS is smaller than the BTMOS diode, so the active diode uses DTMOS as an ideal switch. As shown in Figure 1(b), the active diode is composed of a comparator and a PMOS switch. The PMOS switch (PMS) is controlled by the comparator. Its drain and source terminals are equivalent to the anode and cathode terminals of a diode respectively. The comparator detects the voltage between these two terminals: when VOUT is higher than VNVC , the comparator outputs a high voltage to the gate terminal, which turns off the PMS to prevent the reverse current. Otherwise if VOUT is lower than VNVC , the comparator outputs a low voltage to turn on the PMS. To reduce the on resistance, a large size of PMS should be chosen, but it could increase the area and the gate capacitance accordingly. Therefore, the comparator should be sufficient to drive a large size PMOS transistor. In addition, a bypass PMOS diode, PMBD, in parallel with the PMS is added in the circuit to ensure that the active diode can be safe to open in all process corners, as Figure 4(b) shows. It enhances the reliability of the active diode under worst case conditions, although there will be some area overhead. After the active diode opens, PMBD will stop working and keep into a high impedance state. Compared with the PMOS switch in References [5, 6], which adopt the body bias technique, our PMOS switch is simple, and also does not require other devices, which results in less chip area. The comparator is the critical part for an active diode. In our rectifier, a bulk-driven comparator is used. Due to the fact that the power consumption of the comparator should be very low, the transistors of the comparator are working in the sub-threshold region. Moreover, compared with the common comparators, the differential pair is powered by the VNVC directly. When the input voltage of the comparator is not high enough, the comparator automatically stops working to save energy consumption and improve the system efficiencyŒ6 . The architecture of the comparator is shown in Figure 4(b). Figure 5. The simulation waveforms of the proposed rectifier at VIN D 200 mV. 100 Hz, the load resistance RL is 50 k, and capacitance CL is 10 F. For PE energy applications, the minimum input voltage with available voltage conversion efficiency and power conversion efficiency is very important. Figure 5 shows the overall simulation waveforms of the rectifier at VIN D 200 mV. As can be seen from Figure 5, the output voltage of the rectifier is 181 mV and the voltage drop of the rectifier is only 19 mV, thus the voltage conversion efficiency is as high as 90.5%. The voltage efficiency is expressed as v D (2) The voltage efficiency at different process corners is shown in Figure 6. As can be observed in Figure 6, the voltage efficiency can achieve 85.5% when the input voltage equals to 0.18 V under the TT corner, and changes little with different process corners. The power efficiency is expressed as 1 R t CT Vout .t / Iout .t/ dt t T 100%; P D 1 R tCT Vin .t / Iin .t/ dt T t 4. Simulation results Based on SMIC 0.18 m standard CMOS technology, the proposed rectifier is simulated and verified. Suppose the default input voltage amplitude is 200 mV and the frequency is vout 100%: vin (3) where VIN and IIN are the input voltage and current, VOUT is the output voltage and IOUT is the output current delivered to the load. 025004-3 J. Semicond. 2016, 37(2) Wang Jingmin et al. Figure 6. The voltage efficiency of the proposed rectifier at different process corners. Table 1. Performance summary and comparisons. Parameter Reference Reference This work* [3]* [4]* Technique (m) 0.35 0.18 0.18 Minimum input 0.3 0.25 0.2 voltage (V) Voltage effi- 90 90 90.5 ciency (%) Power effi- 90 80 95.5 ciency (%) RL D 50 k RL D 40 k RL D 50 k *The results are obtained through the simulation. Figure 7. (a) The power efficiency versus difference load resistance. (b) The power efficiency versus input voltage. 5. Conclusion The rectifiers should be able to extract the maximum power available from the PE harvester. According to the maximum power theory, maximum power transfer is realized when the load impedance is equal to the Thevenin impedance. Figure 7(a) reports the power efficiency with difference load resistance at different frequency. When the frequency is 100 Hz, the power efficiency can achieve the maximum power efficiency of 95.5% at the load resistance of 50 k. All the efficiency can reach up to 80% in a wide load range 10–300 k under 10 and 100 Hz. As can be observed in Figure 7(a), the voltage efficiencies at 10 and 100 Hz are nearly the same, which are higher than at 1 kHz. Since the higher frequency will result in more power loss in the large size transistors of NVC and the PMOS switch, the maximum frequency of our rectifier with a high efficiency is around 1 kHz and it is enough for most PE energy applications. Figure 7(b) shows the power conversion efficiency of the DTMOS and the BTMOS circuits. It can be seen from the figure that the DTMOS rectifier obtains higher power conversion efficiency than the BTMOS circuit. For the DTMOS circuit, it can be seen that the power efficiency reaches 85% when the input voltage equals to 0.16 V, and the maximum efficiency can be up to 95.5% when the input voltage equals to 0.2 V. In Table 1, the proposed rectifier is compared with the other reported rectifiers. It is difficult to make a fair comparison due to the differences in the PE transducer, design environments and processing technology; however, the overall performance of our rectifier is better, which can be seen from the Table 1. Based on SMIC 0.18 m standard CMOS technology, a low voltage rectifier with high power conversion efficiency (PCE) for PE energy harvesting applications is proposed in this paper. This is achieved by utilizing the DTMOS, which the body terminal is connected to the gate terminal in the diode connected transistor. This implementation facilitates the rectifier with dynamic control over the threshold voltage. Furthermore, the active diodes are used to reduce the voltage drop and thereby increase the power extraction and conversion capability. The simulation results show the voltage conversion efficiency and the power conversion efficiency can reach up to 90.5% and 95.5% respectively, when the input voltage equals to 0.2 V @ 100 Hz with load resistance 50 k. Input voltages with frequencies in the range of 10 Hz–1 kHz can be rectified. Although our paper only provides simulation results, we considered all the situations to compensate this weakness. So the results obtained are persuasive. Therefore, the proposed rectifier can be well suited to piezoelectric energy harvesting systems. References [1] Nguyen T T, Feng T, Häfliger P. Hybrid CMOS rectifier based on synergistic RF-piezoelectric energy scavenging. IEEE Trans Circuits Syst I: Regular Papers, 2014, 61(12): 3330 [2] Wahbah M, Alhawari M, Mohammad B. Characterization of human body-based thermal and vibration energy harvesting for wearable devices. IEEE J Emerging and Selected Topics in Circuits and Systems, 2014, 4(3): 354 [3] Peters C, Handwerker J, Maurath D, et al. A sub-500 mV highly 025004-4 J. Semicond. 2016, 37(2) Wang Jingmin et al. efficient active rectifier for energy harvesting applications. IEEE Trans Circuits Syst I: Regular Papers, 2011, 58(7): 1542 [4] Yang Zheng, Li Yani, Wang Jingmin, et al. A highly efficient interface circuit for ultra low voltage energy harvesting. IEICE ELEX, 2013, 10(24): 1 [5] Chouhan S S, Halonen K. The design and implementation of DTMOS biased all PMOS rectifier for RF energy harvesting. IEEE 12th International New Circuits and Systems Conference (NEWCAS), 2014: 444 [6] Rao Y, Arnold D P. An input-powered vibrational energy harvesting interface circuit with zero standby power. IEEE Trans Power Electron, 2011, 26(12): 3524 [7] Kim H S, Kim J H, Kim J. A review of piezoelectric energy harvesting based on vibration. International Journal of Precision Engineering and Manufacturing, 2011, 12(6): 1129 [8] Shen Jinpeng, Wang Bo, Liu Shan, et al A passive UHF RFID tag with a dynamic-Vth -cancellation rectifier. Journal of Semiconductors, 2013, 34(9): 095005 025004-5