Implementation of Precision Full-Wave Rectifier using CNTFET

advertisement

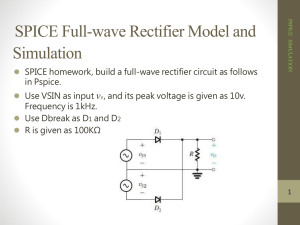

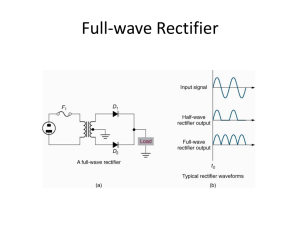

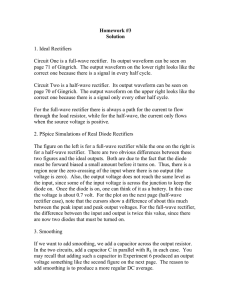

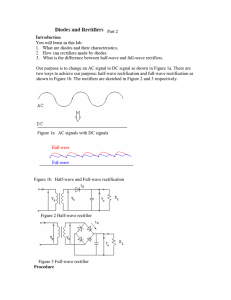

International Journal of Research in Electronics & Communication Technology Volume 1, Issue 2, October-December, 2013, pp. 76-80, © IASTER 2013 www.iaster.com, ISSN Online: 2347-6109, Print: 2348-0017 Implementation of Precision Full-Wave Rectifier using CNTFET Aatreya Vivek M*, P. Reena Monica** * M. Tech VLSI Design, **Assistant Professor (Sr.) SENSE, VIT University Chennai Campus, Chennai, Tamil Nadu, India ABSTRACT We are hitting a road block scaling down the conventional MOSFET devices because of the exponential increase in the sensitivity of the device parameters and the sophistication of the fabrication techniques. CNTFET is a promising alternative with low power consumption and better performance which will help us to prolong Moore’s law. In this paper, using CNTFET, a Precision Full-Wave Rectifier is implemented with the help of a DDCC (Differential Difference Current Conveyor) in Cadence Virtuoso tool. The implemented design has low design complexity, larger bandwidth of operation and higher packing density. Keywords: Amplifier, Cadence, CNTFET, DDCC, Rectifier. 1. INTRODUCTION Full-wave rectifier is used in RF demodulator, piecewise linear function generator, AC voltmeter, wattmeter, and various nonlinear analog signal processing circuits [1]. A typical rectifier realized by using diodes, cannot rectify signals whose amplitudes are less than the threshold voltage (approximately 0.7V for silicon diode and approximately 0.3 for germanium diode) [2]. Hence the diode based rectifiers are used in applications where the accuracy in the range of threshold voltage is not important. Moreover, the rectifiers based of operational amplifiers and resistors cannot be used as they are not suitable for IC fabrication because of their size. To overcome these obstacles, a precision full-wave rectifier using a DDCC (Differential Difference Current Conveyor) could be used. In the previous works on DDCC [3] with CMOS (350nm), the circuits suffer from the problem of leakage current. Hence to avoid this problem, CNTFETs can be used in the place of CMOS. Hence the DDCC implementation with CNTFETs shows better performance with higher packing density. 2. CARBON NANOTUBE A monolayer of graphite is called graphene, and a carbon nanotube (CNT) is a cylinder made of graphene. CNTs are broadly classified into two types namely single-walled carbon nanotubes (SWCNTs) and multi-walled nanotubes (MWCNTs) as shown in the figure 1. The way the graphene sheet is wrapped is represented by a pair of indices (n,m) called the chiral vector. The integers n and m denote the number of unit vectors along two directions in the honeycomb crystal lattice of graphene. SWCNT can further be classified into Arm-Chair, Zigzag and Chiral which can be described by the chiral vector (n, m), where n and m are the integers of the vector equation R = na1 + ma2. 76 International Journal of Research in Electronics & Communication Technology, Volume-1, Issue-2, October-December, 2013, www.iaster.com Graphene SWCNT ISSN (O) 2347-6109 (P) 2348-0017 MWCNT Fig 1. Three Types of Carbon Nano Tube The values of n and m determine the way the nanotube is folded into a cylinder. If m = 0, the nanotubes are called zigzag nanotubes, and if n = m, the nanotubes are called armchair nanotubes. Otherwise, they are called chiral. Moreover the chirality determines the diameter of the nanotube too and the differences in the chiral angle and the diameter cause the differences in the properties of the various carbon nanotubes. 3. CARBON NANOTUBE FIELD EFFECT TRANSISTOR A carbon nanotube field-effect transistor (CNTFET) refers to a field-effect transistor that utilizes a single carbon nanotube or an array of carbon nanotubes as the channel material instead of bulk silicon in the traditional MOSFET structure. The electronic transport in CNTs occurs ballistically (without scattering) over long lengths owing to their nearly one dimensional electronic structure. This enables nanotubes to carry high currents with negligible heating. Moreover, because of the lack of boundaries in the perfect and hollow cylinder structure of CNTs, there is no boundary scattering too. A carbon nanotube’s band-gap and the threshold voltage of the CNTFET are dependent on its chirality and diameter of the nanotube. The threshold voltage and the band gap energy are directly proportional to each other and both of them in turn are inversely proportional to the diameter of the carbon nanotube. The threshold voltage, band gap energy and the diameter of CNT are related as shown in the equation (1) [4] (1) where ɑ = 2.49Å is the carbon to carbon atom distance, Vπ=3.033eV is the carbon π- π bond energy in the tight bonding model, e is the unit electron charge, and DCNT is the diameter of the CNT which is calculated by the equation (2) (2) where ɑ 0 = 0.142 is the interatomic distance between each carbon atom and its neighbor. 77 International Journal of Research in Electronics & Communication Technology, Volume-1, Issue-2, October-December, 2013, www.iaster.com ISSN (O) 2347-6109 (P) 2348-0017 In this paper, we are using a Verilog-A formulation of the Stanford compact model of CNTFET [5] [6] in Cadence EDA tool to implement a precision full-wave rectifier in 32nm technology. 4. THE DDCC DEVICE A differential difference current conveyor combines features of a differential difference amplifier and a current conveyor. A differential difference amplifier is a fundamental amplifier circuit which is widely used in opamp circuits because of its simplified design process. But like the conventional opamp circuit, performance of the differential difference amplifier is limited by its finite gainbandwidth product, so it is unsuitable for application in high frequency circuits. A device called a current conveyor is a current mode amplifier which is quite appropriate for high frequency circuits. DDCC (differential difference current conveyor) is a device that combines the characteristics of both a differential difference amplifier and a current conveyor and hence has a superior finite gain-bandwidth product. Therefore it is suitable for high frequency applications. The electrical symbol of DDCC [7] and its input-output characteristics are shown in the figure 2. It has three voltage input terminals: Y1, Y2 and Y3, which have high input impedance. There is a low impedance current input terminal X and a high impedance current output terminal Z. Fig. 2. DDCC Circuit Symbol and its Input-Output Characteristics The circuit diagram for the DDCC device [2] using the Stanford compact model of CNTFET is implemented and is shown in the figure 3. Fig. 3. Circuit Diagram of DDCC 78 International Journal of Research in Electronics & Communication Technology, Volume-1, Issue-2, October-December, 2013, www.iaster.com ISSN (O) 2347-6109 (P) 2348-0017 The characteristics obtained for the DDCC device is shown in the figure 4 where Vx is plotted against Vy1 for different values of Vy2. Fig. 4. Input-Output Characteristics of DDCC 5. IMPLEMENTATION OF PRECISION FULL-WAVE RECTIFIER Basically a full wave rectifier converts an AC signal into a pulsating DC signal. Using the previously implemented circuit of DDCC as a basic building block, the full wave rectifier circuit [9] is constructed as shown in the figure 5. Fig. 5. Full-wave Rectifier Circuit In the full wave rectifier circuit shown in the figure 5, when the input signal Vin > 0, Vin is reflected at the output Vout by DDCC1 while the DDCC2 is turned off. And when Vin < 0, Vin is reflected at the output Vout by DDCC2 while the DDCC1 is turned off. Therefore the given circuit provides full-wave rectification. The characteristics obtained from the simulation of the given full-wave rectifier circuit is shown in the figure 6. Fig. 6. Response of Precision Full-wave Rectifier made using CNTFET 79 International Journal of Research in Electronics & Communication Technology, Volume-1, Issue-2, October-December, 2013, www.iaster.com ISSN (O) 2347-6109 (P) 2348-0017 The characteristics shown in the figure 6 is a response of a full-wave rectifier implemented using a CNTFET. The same procedure was repeated and the full-wave rectifier circuit was implemented using CMOS devices. The response obtained from a CMOS circuit is shown in the figure 6. From the obtained simulation results, we can observed that the rectifier implemented using CNTFETs can rectify any signal with amplitudes as low as 20mV whereas conventional rectifiers constructed using CMOS require minimum applied voltage to be above the knee voltage of the semiconductor material used. Fig. 6. Response of Precision Full-wave rectifier made using CMOS FET 6. CONCLUSION Carbon Nanotube Field Effect Transistor provides a vast field of research in the area of nanoelectronics and a number of different circuits can be implemented using CNTFETs. In this work, a precision full-wave rectifier circuit is implemented in Cadence using the Verilog-A model of CNTFET and the results show that they have better performance and higher device density when compared to the conventional CMOS counterparts. REFERENCES [1] [2] [3] [4] [5] [6] [7] [8] [9] S. J. G. Gift, ―A high-performance full-wave rectifier circuit‖ International Journal of Electronics, vol.89, pp.467-476, 2000. Gavendra Singh, Umesh Kumar, Rajeev Ranjan, ―CNTFET technology based Precision FullWave Rectifier using DDCC‖, International Journal of Engineering and Science, ISBN: 23196483, ISSN: 2278-4721, Vol. 2, Issue 1 (January 2013), PP 40-47. M. Kumngern and K. Dejhan, ―DDCC-based quadrature oscillator with grounded capacitors and resistors‖, Active and Passive Electronic Components, vol. 2009, pp. 1-5, 2009, doi:10.1155/2009/987304. M. S. Dresselhaus, G. Dresselhaus, R. Saito, ―PHYSICS OF CARBON NANOTUBE‖, 1995 Elsevier Science Ltd. J. Deng and H.-S. P. Wong, ―A compact SPICE model for carbon nanotube field effect transistors including non-idealities and its application—Part I: Model of the intrinsic channel region‖, IEEE Trans. Electron Devices, vol. 54, no. 12, pp. 3186–3194, Dec. 2007. J. Deng and H.-S. P. Wong, ―A compact SPICE model for carbon nanotubefield effect transistors including non-idealities and its application—Part II: Full device model and circuit performance benchmarking‖, IEEE Trans. Electron Devices, vol. 54, no. 12, pp. 3195–3205, Dec. 2007. Usa Torteanchai, Montree Kumngern, Kobchai Dejhan, ―A CMOS Log-Antilog Current Multiplier/ Divider Circuit Using DDCC‖, TENCON 2011 - 2011 IEEE Region 10 Conference. Stanford University CNFET Model website [Online 2008]. Available: http://nano.stanford.edu/model.php?id=23.compat1. Kumngern M, Saengthong P, Junnapiya S, ―DDCC-based full-wave rectifier‖ 5th International Colloquium on Signal Processing & Its Applications, 2009. CSPA 2009. 80