advertisement

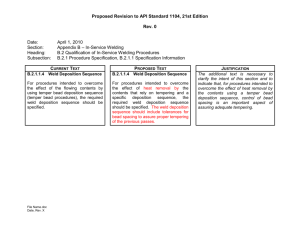

PRODUCTION & MANUFACTURING | RESEARCH ARTICLE Influence of heat input on weld bead geometry using duplex stainless steel wire electrode on low alloy steel specimens Ajit Mondal, Manas Kumar Saha, Ritesh Hazra and Santanu Das Cogent Engineering (2016), 3: 1143598 Page 1 of 14 Mondal et al., Cogent Engineering (2016), 3: 1143598 http://dx.doi.org/10.1080/23311916.2016.1143598 PRODUCTION & MANUFACTURING | RESEARCH ARTICLE Influence of heat input on weld bead geometry using duplex stainless steel wire electrode on low alloy steel specimens Received: 24 October 2015 Accepted: 09 January 2016 First Published: 28 January 2016 *Corresponding author: Santanu Das, Department of Mechanical Engineering, Kalyani Government Engineering College, Nadia, Kalyani, 741235, West Bengal, India Email: sdas.me@gmail.com Reviewing editor: Zude Zhou, Wuhan University of Technology, China Additional information is available at the end of the article Ajit Mondal Ajit Mondal1, Manas Kumar Saha1, Ritesh Hazra1 and Santanu Das1* Abstract: Gas metal arc welding cladding becomes a popular surfacing technique in many modern industries as it enhances effectively corrosion resistance property and wear resistance property of structural members. Quality of weld cladding may be enhanced by controlling process parameters. If bead formation is found acceptable, cladding is also expected to be good. Weld bead characteristics are often assessed by bead geometry, and it is mainly influenced by heat input. In this paper, duplex stainless steel E2209 T01 is deposited on E250 low alloy steel specimens with 100% CO2 gas as shielding medium with different heats. Weld bead width, height of reinforcement and depth of penetration are measured. Regression analysis is done on the basis of experimental data. Results reveal that within the range of bead-onplate welding experiments done, parameters of welding geometry are on the whole linearly related with heat input. A condition corresponding to 0.744 kJ/mm heat input is recommended to be used for weld cladding in practice. ABOUT THE AUTHORS PUBLIC INTEREST STATEMENT Ajit Mondal is an Assistant Professor of Mechanical Engineering in Camellia Institute of Technology, Madhyamgram, Kolkata and a Visiting Faculty in Kalyani Government Engineering College, Kalyani. He is currently working in GMAW based cladding process. Manas Kumar Saha is a Lecturer in Mechanical Engineering at Engineering Institute for Junior Executives, Howrah, India. He is doing research work on weld cladding at Kalyani Government Engineering College, Kalyani. He served in Hindustan Motors Ltd., Kolkata, and Nazrul Centenary Polytechnic, Burdwan, India. Ritesh Hazra did B.Tech and M.Tech from Kalyani Govt. Engineering College, Kalyani, India. He is currently working on GMAW based cladding process. Dr. Santanu Das is Professor and Head of Mechanical Engineering Department, Kalyani Government Engineering College, Kalyani. He did his Bachelors and Masters from Jadavpur University, Kolkata and obtained Ph.D. from Indian Institute of Technology, Kharagpur. His area of research includes machining, grinding, tool condition monitoring, welding, production management, etc. This article deals with gas metal arc welding performance with regard to depositing duplex stainless steel on a low alloy steel base plate. For any arc welding process, heat input to the process plays an important role to achieve good weld material deposition. In this work, weld beads are formed on base plate with varying heat input. Investigation is made to find out the condition to have high weld bead reinforcement above the base plate with large bead width maintaining small depth of penetration. Large reinforcement and bead width cause thick and wide covering of stainless steel onto the base plate. Process parameters are, therefore, needed to choose in such a way that this kind of corrosion-resistant stainless steel would be used to cover a less costly, corrosion prone steel to render prolonged service life of an equipment or structure subjected to highly corrosive atmosphere. © 2016 The Author(s). This open access article is distributed under a Creative Commons Attribution (CC-BY) 4.0 license. Page 2 of 14 Mondal et al., Cogent Engineering (2016), 3: 1143598 http://dx.doi.org/10.1080/23311916.2016.1143598 Subjects: Manufacturing & Processing; Manufacturing Engineering; Manufacturing Technology Keywords: GMAW; heat input; weld bead; bead geometry; regression analysis 1. Introduction In recent times, costly materials having good surface-dependent properties like corrosion resistance is overlaid on relatively cheap corrosion-prone material to increase its performance in severe service conditions for relatively long period. Cladding is one such process called surfacing technique where a relatively thick coating up to several milimetres is applied (Nadkarni, 1988; Parmar, 2010). Different types of surfacing techniques are used by means of depositing different materials and, metallic materials, in particular. The methods used are coating, plating, buttering, cladding, metal spraying, etc. Cladding is a surfacing technique that involves improvement of surface strength of mother metal considerably to increase service life of the parent material without changing the microstructure of the base material (Rao, Reddy, & Nagarjuna, 2011). Cladding creates a new surface layer with different compositions which, in general, is harder than the base material. Comparing with other techniques used for surface treatment by means of material deposition, cladding has some distinct advantages, such as it provides high hardness, corrosion and/or erosion resistance, good bonding and favourable microstructure (Funderburk, 1999). Nowadays, weld cladding processes are used in numerous industries and plants, such as chemical and fertilizer plant, aviation industry, mining industry, agriculture, sea water application (Wilson, Kelly, & Kiser, 1987), power generation, food processing and photochemical industries as a cost-effective engineering solution against corrosion attack (Kang & Lee, 2014). Among various welding processes employed for cladding, gas metal arc welding (GMAW) is widely utilized in industry due to some advantages (Lucas, 1994). GMAW cladding has high reliability, all position capability, ease of use, low cost, high productivity, suitability for both ferrous and nonferrous metals and alloys, high deposition rate, absence of flux, cleanliness and ease of mechanization (Kannan & Murugan, 2005). One point to note is that any good-quality weld cladding needs minimum dilution (Shahi & Pandey, 2008). Mechanical strength of GMAW clad metal is influenced not only by the composition of the metal but also by the clad bead shape and its geometry. The acceptable clad bead geometry depends (Jha, Bhardwaj, Bhagatand, & Sharma, 2014; Khara, Mondal, Sarkar, & Das, 2011; Murugan & Parmar, 1994; Verma et al., 2013) on arc voltage, welding current, gas flow rate (Saha, Das, Bandyopadhyay, & Bandyopadhyay, 2012), wire feed rate, welding speed, torch angle, tip-to-nozzle distance, etc. Hence, the relationship between input process parameters and bead parameters is necessary to explore (Kumar, Singh, & Yusufzai, 2012). In some recent investigations, properties of duplex stainless steel cladding on lower grade steel by GMAW were investigated using CO2 as the shielding gas (Chakrabarti, Das, Das, & Pal, 2013; Kumar et al., 2012; Sreeraj, Kannan, & Maji, 2013a; Verma et al., 2012). In particular, the influence of heat input and shielding gas composition in GMAW on weld deposit geometry were studied (Palani & Murugan, 2006; Senthilkumar & Kannan, 2013; Shahi & Panday, 2008; Sreeraj & Kannan, 2012). Various mathematical models have been successfully developed among heat input and weld geometry parameters in specific welding atmosphere (Kannan & Yoganandh, 2010; Palani & Murugan, 2005; Rajkumar & Murugan, 2014a, 2014b; Sreeraj, Kannan, & Maji, 2013b, 2013c). At the end, the claddings should offer enough erosion and/or corrosion resistance. In the present work, GMAW experiments are conducted to find out the influence of process parameters and corresponding heat inputs on weld bead geometry under 100% CO2 gas shield. Duplex Page 3 of 14 Mondal et al., Cogent Engineering (2016), 3: 1143598 http://dx.doi.org/10.1080/23311916.2016.1143598 Table 1. Composition of base plate (E250) %C %Si %Mn %P %S %Ni %Mo %Nb %Pb %Sn %As %Fe 0.199 0.14 0.498 0.06 0.03 0.025 0.038 0.01 0.01 0.014 0.066 Rest Table 2. Composition of duplex stainless steel filler wire (E2209 T01) %C %Si %Mn %P %S %Cr %Mo %Ni %N %Fe 0.02 0.76 1.01 0.018 0.009 22.52 2.91 9.09 0.125 Rest stainless steel wire electrode is used to make bead-on-plate made of low alloy steel. Regression analysis is done for evaluating relations among different parameters of weld bead geometry and heat input. 2. Experimental procedure Bead-on-plate experiments are performed using ESAB, India made Auto K400 GMAW machine having voltage and current capacity of 0–75 V and 0–400 A, respectively. 100% CO2 gas with a constant gas flow rate of 16 l/min is used as shielding gas throughout the experiment. E250 low alloy steel base plates are of size 55 mm × 45 mm × 25 mm. These thick specimens are used to avoid any distortion in it. Composition of E250 steel base plate and E2209 T01 duplex stainless steel wire electrode are given in Tables 1 and 2. Carbon Equivalent, Ceqv of the base metal is found to be 0.29, and that of the duplex stainless steel filler wire is 5.88 signifying this in the pro-eutectic zone. Process parameters chosen for bead-on-plate experiments performed and corresponding heat input values are detailed in Table 3. Heat input serves a significant role in welding. Proper heat input provides greater penetration, favourable fusion and sufficient bonding in cladding. Cooling rate, weld size and material properties may all be influenced by the heat input (Chakrabarti et al., 2013; Funderburk, 1999; Nadkarni, 1988; Verma et al., 2013) which is calculated using Equation (1). Q= (60 × V × I) ×𝜂 (1000S) (1) where Q is the heat input (kJ/mm), V is the welding voltage (V), I is the welding current (A), and S is the welding torch travel speed (mm/min), and η is the efficiency for the welding process (in this work on GMAW, it is taken to be 0.8 (Nadkarni, 1988)). Photographs of bead-on-plate samples obtained through second replication of experiments are shown in Figure 1. Top views of the weld beads on plate are depicted in Figure 1(a), while Figure 1(b) indicates front views of these nine weld beads. Weld bead geometry, such as reinforcement (R), depth of penetration (P) and weld bead width (W) are measured under tool makers’ microscope after polishing of cut crosswise samples. A typical weld bead geometry is schematically shown in Figure 2. Reinforcement form factor (RFF) and penetration shape factor (PSF) are evaluated next from the bead geometry parameters following Equations (2) and (3). RFF = W R (2) PSF = W P (3) where W is the weld bead width (mm), R is the height of reinforcement (mm), and P is the depth of penetration (mm). Page 4 of 14 Mondal et al., Cogent Engineering (2016), 3: 1143598 http://dx.doi.org/10.1080/23311916.2016.1143598 Table 3. Parameters of bead-on-plate experiment Sample no. Voltage (V) Current (A) Travel speed (mm/min) Heat input (kJ/mm) S1 22.5 120 390 0.332 S2 25 160 390 0.358 S3 24 160 390 0.472 S4 24 140 450 0.492 S5 26 180 450 0.499 S6 28 190 450 0.567 S7 29 200 480 0.580 S8 30 220 480 0.660 S9 31 240 480 0.744 3. Results and discussion 3.1. Visual inspection Table 4 shows results of visual inspection of bead-on-plate experiments. No blow hole is obtained in the present experiment. Deposition of weld pool is found to be continuous in the cases. Occasional spatter is observed in some of experiments. On the whole, good consistency within the two replicated experiments is apparent. Small spatter seen in experiments No. 7 and 9 may be due to high weld current used under CO2 gas shield. However, no spatter is detected in experiment No. 8 with the same high weld current in both the replications that could not be explained. 3.2. Observation on weld bead geometry Figure 1 depicts views of weld beads of experiments of second replication. Weld bead geometry parameters (as shown in Figure 2), such as height of reinforcement, width of weld bead and depth of penetration are shown in Table 5 that are also clearly visible in the front view of the weld bead section (Figure 1(b)). The RFF and PSF are evaluated following Equations (1) and (2). Tables 5 and 6 show evaluated RFF and PSF values of bead-on-plate experiments for the two replicated sets of experiments. Graphical representations of different weld bead geometry parameters obtained from first and second replications of bead-on-plate experiments as detailed in Tables 5 and 6 are shown in Figure 3 through Figure 7. The effect of heat input on reinforcement as observed in bead-on-plate experiments is shown in Figure 3. The plot is constructed with the average value of reinforcement as obtained from the two replications of experiments. Dispersion of reinforcement indicating the higher and smaller values is also indicated at each point of experimental observation. The figure shows that on the whole, reinforcement increases with increasing heat input. Less dispersion as seen in Figure 3 indicates consistency in replicated experiments. Maximum value of reinforcement height is obtained at a heat input of 0.66 kJ/mm. However, at a higher heat input of 0.744 kJ/mm, reinforcement shows a slight decrease. Small spatter observed at this condition may have resulted in this. Increase in heat input Figure 1. Photographs of beadon-plate samples obtained through second replication of experiments ((a) top view of the weld beads on plate and (b) front view of weld beads). Page 5 of 14 Mondal et al., Cogent Engineering (2016), 3: 1143598 http://dx.doi.org/10.1080/23311916.2016.1143598 Figure 2. A typical weld bead geometry schematic. Table 4. Visual inspection of bead-on-plate experiments Sample no. Voltage, V (V) Current, I (A) Travel speed, S (mm/min) Heat input (kJ/mm) Blow hole in both replication Continuity in deposition in both replication 1st replication 2nd replication 22.5 120 390 0.332 Nil Continuous Nil Nil 1 Spatter 2 25 160 390 0.358 Nil Continuous Nil Nil 3 24 160 390 0.472 Nil Continuous Very few Nil 4 24 140 450 0.492 Nil Continuous Nil Nil 5 26 180 450 0.499 Nil Continuous Nil Nil 6 28 190 450 0.567 Nil Continuous Nil Nil Very few 7 29 200 480 0.580 Nil Continuous Very few 8 30 220 480 0.660 Nil Continuous Nil Nil 9 31 240 480 0.744 Nil Continuous Very few Very few corresponding to hike in weld current or voltage, or reduction in weld torch speed, causes higher heat energy input to the weld zone causing higher volume of melting of electrode material and enlarged volume of weld zone. It is also known that weld current imparts greater influence on heat input than voltage. Travel speed influences welding time and heat accumulation occurs corresponding to heat conduction property of the work material. Naturally, larger reinforcement height, R with higher heat input is expected in general in these tests on bead-on-plate welding. Table 5. RFF and PSF of bead-on-plate experiments of first replication Sample no. 1 Voltage, V (V) Current, I (A) Travel speed, S (mm/min) Heat input (kJ/ mm) Height of reinforce ment, R (mm) Weld bead width, W (mm) Depth of penetra tion, P (mm) RFF = (W/R) PSF = (W/P) 22.5 120 390 0.332 2.445 7.775 1.355 3.179 5.738 2 24 140 450 0.358 2.43 8.775 1.485 3.611 5.909 3 24 160 390 0.472 2.665 9.543 1.555 3.580 6.136 4 25 160 390 0.492 2.785 9.785 1.6 3.513 6.115 5 26 180 450 0.499 3 10.6 1.78 3.533 5.955 5.937 6 28 190 450 0.567 3.1 10.985 1.85 3.543 7 29 200 480 0.580 3.15 12 1.95 3.809 6.153 8 30 220 480 0.660 3.295 13.385 1.899 4.062 7.048 9 31 240 480 0.744 3.215 14.33 1.985 4.457 7.219 Page 6 of 14 Mondal et al., Cogent Engineering (2016), 3: 1143598 http://dx.doi.org/10.1080/23311916.2016.1143598 Table 6. RFF and PSF of bead on plate experiments of second replication Sample no. 1 Voltage, V (V) Current, I (A) Travel speed, S (mm/min) Heat input (kJ/ mm) Height of reinforce ment, R (mm) Weld bead width, W (mm) Depth of penetra tion, P (mm) RFF = (W/R) PSF = (W/P) 22.5 120 390 0.332 2.49 7.83 1.35 3.144 5.8 2 24 140 450 0.358 2.59 8.885 1.41 3.430 6.301 3 24 160 390 0.472 2.455 9.01 1.4 3.670 6.435 4 25 160 390 0.492 2.699 9.83 1.525 3.642 6.445 5 26 180 450 0.499 2.899 10.599 1.599 3.656 6.628 6 28 190 450 0.567 3.01 11.105 1.685 3.689 6.590 7 29 200 480 0.580 3.233 12.785 1.83 3.954 6.986 8 30 220 480 0.660 3.33 13.33 1.85 4.003 7.205 9 31 240 480 0.744 3.265 14.35 1.999 4.395 7.178 The effect of heat input on width of weld bead is shown in Figure 4. The plot is constructed with the average value of reinforcement as obtained from the two replications of experiments. Dispersion of width of weld bead (indicating the higher and smaller values) is also indicated at each point of experimental observation. Less dispersion is depicted in Figure 4 showing consistency of replicated experiments. The figure shows that width of weld bead has a clear tendency to increase with increasing heat input. Higher heat input is related to higher volume of weld pool. As it is bead-on-plate welding, molten electrode material is expected to spread on the base plate. Therefore, higher heat input causes higher spread of weld material on base plate and hence, higher width of weld bead. In line with this, for a high value of 0.744 kJ/mm of heat input, width of weld bead is found to be quite high. The effect of heat input on depth of penetration as observed in bead-on-plate experiments is shown in Figure 5. Similar to Figures 3 and 4, Figure 5 is plotted with the average value of depth of penetration as obtained from the two replications of experiments, and its dispersion indicating the higher and smaller values is also indicated at each point of experimental observation. Depth of penetration shows an overall increase with increasing heat input with small deviations. High heat input is expected to transfer large amount of heat into the weld zone, and therefore, large depth of penetration is imminent. For this, higher value of 0.744 kJ/mm of heat input gives high depth of penetration of weld bead. Slight decrease in penetration between 0.58 and 0.66 kJ/mm heat input may be seen for experiments done in the first replication. However, increasing trend is observed in second replication as usual. Difference in trend in first replication may be the result of experimental deviation that is often experienced. In Figure 3, minimum slope between experimental points 2 and 3 is observed compared to the other points. The slope within 8 and 9 points is negative. This may be due to high heat input (0.744 kJ/ 3.5 Reinforcement (mm) Figure 3. Plot of variation of reinforcement with heat input as obtained from first and second replications of bead-onplate experiments. 3.25 3 2.75 2.5 2.25 2 0.3 0.35 0.4 0.45 0.5 0.55 0.6 0.65 0.7 0.75 0.8 Heat Input (kJ/mm) Page 7 of 14 Figure 4. Plot of variation of weld bead width with heat input as obtained from first and second replications of bead on plate experiments. Weld Bead Width (mm) Mondal et al., Cogent Engineering (2016), 3: 1143598 http://dx.doi.org/10.1080/23311916.2016.1143598 15 14 13 12 11 10 9 8 7 0.3 0.35 0.4 0.45 0.5 0.55 0.6 0.65 0.7 0.75 0.8 Heat Input (kJ/mm) 2 Depth of Penetration (mm) Figure 5. Plot of variation of depth of penetration with heat input as obtained from first and second replications of bead-onplate experiments. 1.9 1.8 1.7 1.6 1.5 1.4 1.3 1.2 0.3 0.35 0.4 0.45 0.5 0.55 0.6 0.65 0.7 0.75 0.8 Heat Input (kJ/mm) 4.6 4.4 4.2 4 RFF Figure 6. Plot of variation of RFF with heat input as obtained from first and second replications of bead-on-plate experiments. 3.8 3.6 3.4 3.2 3 0.3 0.35 0.4 0.45 0.5 0.55 0.6 0.65 0.7 0.75 0.8 Heat Input (kJ/mm) 7.5 7.25 7 6.75 PSF Figure 7. Plot of variation of PSF with heat input as obtained from first and second replications of bead-on-plate experiments. 6.5 6.25 6 5.75 5.5 0.3 0.35 0.4 0.45 0.5 0.55 0.6 0.65 0.7 0.75 0.8 Heat Input (kJ/mm) Page 8 of 14 Mondal et al., Cogent Engineering (2016), 3: 1143598 http://dx.doi.org/10.1080/23311916.2016.1143598 mm) caused by high weld current and voltage even when weld torch travel speed is high. High torch travel speed means low time of welding and hence, high heat input taking less time naturally causes wide weld bead and deep penetration but less height of reinforcement. This is evident from Figures 3 to 5. At point 3, the travel speed is lesser than point two and weld current is higher keeping the same weld voltage. For this, heat accumulation remains for longer period creating lesser increase in reinforcement, bead width and penetration. Variation of change in weld bead geometry with heat input indicates change in deviation from their linear relationship. It may be the result of usual experimental deviations observed in any experimental investigation. The effect of heat input on RFF (=weld bead width (W)/height of reinforcement (R)) as observed in bead-on-plate experiments is shown in Figure 6. In line with previous plots, the plot of Figure 6 is constructed with the average value of RFF as obtained from the two replications of experiments against different heat inputs. Dispersion of RFF is indicated at each point of observation. RFF is seen to increase with increasing heat input on the whole with some deviations. Quite low RFF value is obtained for minimum heat input of 0.332 kJ/mm used in this work. On the other hand, maximum RFF is obtained for 0.744 kJ/mm heat input condition. Less dispersion is seen in Figure 6 showing good consistency of replicated experiments. Large volume of molten material corresponding to large heat input is expected to cause large spread of weld material due to good wettability of it on low alloy steel base plate than causing large reinforcement. The effect of heat input on PSF (=width of weld bead (W)/depth of penetration (P)) as observed in bead-on-plate experiments is shown in Figure 7. The plot is constructed with the average value of PSF as obtained from the two replications of experiments. Dispersion of PSF (indicating the higher and smaller values) is also indicated at each point of experimental observation. The figure shows that PSF has wide dispersion within 0.5 and 0.6 kJ/mm heat input. Otherwise it increases with increasing heat input. Quite low PSF is obtained for minimum heat input of 0.332 kJ/mm used in this work. Maximum PSF is obtained for 0.744 kJ/mm heat input condition. Due to large quantity of heat input and large volume of molten material depositing on base plate in this bead-on-plate experiments, spread of weld pool on base plate is more than the depth of penetration. This condition would be helpful for doing weld cladding successfully. The result shows that nature of all graphs (Figure 3 through Figure 7) of first and second replication of bead on plate experiments is somewhat close, barring few deviations. Results of bead-onplate experiments clearly indicate that reinforcement, weld bead width, depth of penetration, RFF and PSF are significantly influenced by heat input. Maximum reinforcement is obtained in the present experiment at a heat input of 0.660 kJ/mm. At a higher heat input of 0.744 kJ/mm, reinforcement height drops a bit and some spatter is observed. However, depth of penetration and weld bead width are increased when heat input increases from 0.660 to 0.744 kJ/mm. Considering the above, it may be recommended that the condition for imparting a heat input of 0.660 kJ/mm can be adopted in weld cladding practice. In this case, a welding voltage of 30 V, weld current of 220 A and weld torch travel speed of 480 mm/min are chosen to achieve this heat input condition. Table 7. ANOVA table on regression analysis relating heat input to weld bead width df SS MS F Significance F Regression 1 71.68677 71.68677 253.2943 3.13E−11 Residual 16 4.52828 0.283018 Total 17 76.21505 Coefficients Standard error t Stat p-value Lower 95% Intercept 2.483818 0.539069 4.607609 0.000291 1.341044 X Variable 1 15.96442 1.003091 15.91522 3.13E-11 13.83796 Page 9 of 14 Mondal et al., Cogent Engineering (2016), 3: 1143598 http://dx.doi.org/10.1080/23311916.2016.1143598 3.3. Regression analysis Regression analysis is carried out on the observed data to evaluate the relationship between heat input and different weld bead geometry parameters. First, weld bead width is tried to express in terms of heat input. The relation between heat input, Q and weld bead width, W is found out as given in Equation (4). A simple straight line relation is obtained that signifies increase in weld bead width with the increase in heat input. This is quite natural a phenomenon in arc welding. Analysis of variance (ANOVA) is done on the regression analysis results and is detailed in Table 7. In this table, Df stands for degree of freedom, SS is for sum of squares, MS means mean of squares. F corresponds to F-statistics used in the ANOVA. Clearly high degree of significance at 95% confidence level is found with respective to regression equation developed. W = Q × 15.96442 + 2.483818 (4) Regression equation relating heat input to depth of penetration is developed similar to the previous case, and the relationship is given as Equation (5). In this case also, simple linear relationship exists between depth of penetration and heat input to the system during GMAW that is naturally expected. High heat energy input during arcing is responsible for higher degree of heating and subsequent melting of electrode material and the portion of base plate. Therefore, higher volume of melting or weld zone is likely to occur resulting in higher penetration, width or even reinforcement. The procedure of computing significance level of the regression equation evaluated is given in Table 8. High level of significance is found out regarding the regression equation computed at 95% confidence level. The relation between heat input, Q to depth of penetration, P becomes: P = Q × 1.607342 + 0.832507 (5) Table 9 shows the ANOVA on regression analysis done to relate heat input with height of reinforcement. At a standard confidence level of 95%, regression equation (Equation 6) is observed to be remarkably significant that means it relates well among heat input and reinforcement. The linear relationship evaluated is naturally expected. The relation between height of reinforcement, R and heat input, Q is: R = Q × 1.824867 + 1.896434 (6) PSF which is the ratio of weld bead width W, and depth of penetration P, also shows a linear relationship with heat input as par Equation (7). It indicates that with the increase in heat input, weld bead width increases at a higher rate than the increase in depth of penetration. The test being bead-onplate welding, widening of weld bead is more likely with the increased heat input and increased melting zone. Table 10 also shows the analysis to be significant at 95% confidence level. The relation between heat input and PSF becomes: PSF = Q × 3.278704 + 4.718442 (7) Regression analysis relating RFF to heat input and its level of significance at 95% confidence level is shown in Table 11. The regression equation derived as shown in Equation (8) is found to be quite significant. The relationship is straight linear. It means increase in RFF, that is, the ratio of bead width to reinforcement height, with heat input to signify higher rate of increase in weld bead width than reinforcement. This condition is desirable for weld cladding where more bead width than reinforcement or penetration is better related to bond strength and better welding due to more wetting of weld material to base plate. Relation between RFF and heat input, Q is given in Equation (8): Page 10 of 14 Mondal et al., Cogent Engineering (2016), 3: 1143598 http://dx.doi.org/10.1080/23311916.2016.1143598 Table 8. ANOVA table on regression analysis relating heat input to depth of penetration df SS MS F Significance F Regression 1 0.72669 0.72669 86.27938 7.59E−08 Residual 16 0.13476 0.008423 Total 17 0.86145 Coefficients Standard error t Stat p-value Lower 95% Intercept 0.832507 0.092995 8.952194 1.25E-07 0.635367 X Variable 1 1.607342 0.173043 9.288669 7.59E-08 1.240506 Table 9. ANOVA table on regression analysis relating heat input to height of reinforcement df SS MS F Significance F Regression 1 0.94736 0.94736 17.63854 0.000678742 Residual 16 0.859354 0.05371 Total 17 1.806714 Coefficients Standard error t Stat p-value Lower 95% Intercept 1.896434 0.243262 7.795855 7.74E-07 1.380741654 X Variable 1 1.824867 0.43451 4.199826 0.000679 0.903746708 Table 10. ANOVA table on regression analysis relating heat input to PSF df SS MS F Significance F Regression 1 3.023688 3.023688 34.31366 2.43E−05 Residual 16 1.409905 0.088119 Total 17 4.433594 Coefficients Standard error t Stat p-value Lower 95% Intercept 4.718442 0.300796 15.6865 3.9E-11 4.080782 X Variable 1 3.278704 0.559717 5.857786 2.43E-05 2.092156 Table 11. ANOVA table on regression analysis relating heat input to RFF df SS MS F Significance F Regression 1 1.795407 1.795407 88.25544 6.5E−08 Residual 16 0.325493 0.020343 Total 17 2.1209 Coefficients Standard error t Stat p-value Lower 95% Intercept 2.394495 0.144527 16.56784 1.71E−11 2.088112 X variable 1 2.526476 0.268933 9.394437 6.5E−08 1.956363 RFF = Q × 2.526476 + 2.394495 (8) In all the regression analyses, straight linear relationships are found that have high degree of significance at 95% confidence level. This justifies the physical understanding that high heat input Page 11 of 14 Mondal et al., Cogent Engineering (2016), 3: 1143598 http://dx.doi.org/10.1080/23311916.2016.1143598 Table 12. Per cent error in estimation of bead geometry parameters Sample no. % Error in height (R) % Error in width (W) % Error in depth (P) % Error in RFF % Error in PSF 1st repl 2nd repl 1st repl 2nd repl 1st repl 2nd repl 1st repl 2nd repl 1st repl 2nd repl 1 −2.34 −0.49 −0.12 0.59 −0.82 −1.95 −1.71 −2.84 −1.20 −0.12 2 −4.94 1.55 6.56 7.72 5.19 0.15 8.64 3.82 0.284 6.49 3 −3.48 −12.3 −4.98 −11.2 −2.33 −13.6 −0.19 2.26 −2.19 2.63 4 −0.33 −3.53 −5.65 −5.17 −1.46 −6.45 −3.54 0.12 −3.54 1.76 5 6.44 3.17 1.41 1.41 8.17 −2.22 −3.46 0.02 −6.71 4.22 6 5.45 2.62 −5.01 −3.87 5.34 −3.49 −8.02 −3.74 −10.8 0.19 7 6.19 8.60 2.14 8.15 9.49 3.56 −1.34 2.38 −7.59 5.24 8 5.89 6.88 2.72 2.32 0.3 −2.34 0.01 −1.47 2.317 4.47 9 −1.22 0.33 −0.72 −0.08 −2.19 −1.47 4.10 2.75 0.848 0.28 generates higher pool of weld material that contributes to higher spread or width of weld bead on the base material. Reinforcement and penetration also increase with heat input, but at a lower rate than width of weld bead. Therefore, RFF and PSF also show an increasing tendency with the increase in heat input. The error analysis on the estimated weld bead geometrical parameters evaluated through regression analysis has been carried out. Their results are shown in Table 12. It is seen that percentage error is appreciably less in most of the cases, and somewhat high percentage estimation errors come to be −12.3, −11.2 and −13.6% in case of experiment No. 3 for height of reinforcement, bead width, and depth of penetration, respectively. Apart from it, in experiment No. 6, only while estimation of PSF, −10.8% error is observed. So, the regression analysis giving somewhat high estimation error for mainly a particular replication of experiment beyond 10% can be considered to be a fairly good one. 4. Conclusion From the observations and regression analysis on the data obtained from bead-on-plate experiments with duplex stainless steel electrode on low alloy steel base plate using GMAW under 100% carbon dioxide gas shield, the following inferences may be made. (1) Geometric shape parameters of weld bead like weld bead width, height of reinforcement, depth of penetration, PSF and RFF are greatly affected by heat input within the range of welding experiments done. In all of the cases, weld bead geometry parameters have linear relationships with heat input. (2) Higher heat input results in larger quantity of molten weld material, and as it is bead-on-plate welding, increase in weld bead width in this case is higher due to more spread of weld material on base plate by good wetting than reinforcement height and depth of penetration. (3) Heat input of 0.660 kJ/mm may be recommended for adopting in weld cladding practice, as this condition gives the maximum reinforcement with no spatter and wide weld bead width. Funding The authors received no direct funding for this research. Author details Ajit Mondal1 E-mail: mondalajit830@gmail.com Manas Kumar Saha1 E-mail: manassaha71@gmail.com Ritesh Hazra1 E-mail: zudezhou@whut.edu.cn Santanu Das1 E-mail: sdas.me@gmail.com ORCID ID: http://orcid.org/0000-0001-9085-3450 1 Department of Mechanical Engineering, Kalyani Government Engineering College, Nadia, Kalyani, 741235, West Bengal, India. Page 12 of 14 Mondal et al., Cogent Engineering (2016), 3: 1143598 http://dx.doi.org/10.1080/23311916.2016.1143598 Citation information Cite this article as: Influence of heat input on weld bead geometry using duplex stainless steel wire electrode on low alloy steel specimens, Ajit Mondal, Manas Kumar Saha, Ritesh Hazra & Santanu Das, Cogent Engineering (2016), 3: 1143598. Cover image Source: Authors. References Chakrabarti,B., Das, S., Das, H., & Pal, T. K. (2013). Effect of process parameters on clad quality of duplex stainless steel using GMAW process. Transactions of the Indian Institute of Metals, 66, 221–230. doi:10.1007/s12660-013-0246-x Funderburk, R. S. (1999). Key concepts in welding engineering. Welding Innovation, XVI, 1–4. Retrieved October 22, 2015, from http://www.jflf.org/pdfs/papers/keyconcepts4.pdf Jha, T. K., Bhardwaj, B., Bhagatand, K., & Sharma, V. (2014). Investigating to the effect of gas metal arc weld arc weld parameters on the weld bead height using D.O.E., International Journal of Science, Engineering and Technology, 2, 1482–1488. Retrieved October 22, 2015, from http://www.ijset.in/wp-content/uploads/2014/10/ IJSET.0920140941.1011.2709_TARUN_P2_1482-1488.pdf Kang, D. W., & Lee, H. W. (2014). Study of pitting resistance of duplex stainless steel weldment depending on the Si content. International Journal of Electrochemical Science, 14, 5864–5876. Retrieved October 22, 2015, from http:// www.electrochemsci.org/papers/vol9/91105864.pdf Kannan, T., & Murugan, N. (2005). Effect of flux cored arc welding process parameters on duplex stainless steel clad quality. Journal of Materials Processing Technology, 176, 230–239. doi:10.1016/j.jmatprotec.2006.03.157 Kannan, T., & Yoganandh, J. (2010). Effect of process parameters on clad bead geometry and its shape relationships of stainless steel claddings deposited by GMAW. International Journal for Advanced Manufacturing Technology, 47, 1083–1095. doi:10.1007/ s00170-009-2226-1 Khara, B., Mondal, N. D., Sarkar, A., & Das, S. (2011). On cladding performance of austenite stainless steel over low alloy steel plates using metal arc welding. In Proceedings of the National Welding Seminar (pp. 51–62). Bhilai. Kumar,V., Singh, G., & Yusufzai, M .Z. K. (2012). Effect of process parameters of gas metal arc welding on dilution in cladding of stainless steel on mild steel, MIT International Journal of Mechanical Engineering, 2, 127–131. Retrieved October 22, 2015, from http://mitpublications.org/yellow_ images/1361593787_logo_10.pdf Lucas, W. (1994). Arc surfacing and cladding processes to enhance performance in service and to repair worn components. Welding and Metal Fabrication, 62, 55–60. Retrieved October 22, 2015, from http://trid.trb.org/view. aspx?id=445588 Murugan, N., & Parmar, R. S. (1994). Effects of MIG process parameters on the geometry of the bead in the automatic surfacing of stainless steel. Journal of Materials Processing Technology, 41, 381–398. doi:10.1016/0924-0136(94)90003-5 Nadkarni, S. V. (1988). Modern arc welding technology. New Delhi: Oxford & IHB Palani, P. K., & Murugan, N. (2005). Development of mathematical models for prediction of weld bead geometry in cladding by flux cored arc welding. International Journal for Advanced Manufacturing Technology, 30, 669–676. doi:10.1007/s00170-005-0101-2 Palani, P. K., & Murugan, N. (2006). Sensitivity analysis for process parameters in cladding of stainless steel by flux cored arc welding. Journal of Manufacturing Process, 8, 90–100. doi:10.1016/S1526-6125(06)80004-6 Parmar, R. S. (2010). Welding engineering and technology. New Delhi: Khanna. Rajkumar, G. B., & Murugan, N. (2014a). Development of regression model and optimization of FCAW process parameter of 2205 duplex stainless steel. Indian Journal of Engineering and Material Science, 21, 149–154. Retrieved October 22, 2015, from http://nopr.niscair.res. in/bitstream/123456789/28781/1/IJEMS%2021(2)%20 149-154.pdf Rajkumar, G. B., & Murugan, N. (2014b). Influences of the heat input on a 2205 duplex stainless steel weld. Materiali in Tehnologije, 48, 761–763. Retrieved October 22, 2015, from http://mit.imt.si/Revija/izvodi/mit145/gnanasun.pdf Rao, N. V., Reddy, G. M., & Nagarjuna, S. (2011). Weld overlay cladding of high strength low alloy steel with austenitic stainless steel–structure and properties. Materials and Design, 32, 2496–2506. doi:10.1016/j.matdes.2010.10.026 Saha, M. K., Das, S., Bandyopadhyay, A., & Bandyopadhyay, S. (2012). Application of L6 orthogonal array for optimal selection of some process parameters in GMAW process. Indian Welding Journal, 45, 41–50. Senthilkumar, B., & Kannan, T. (2013). Sensitivity analysis of flux cored arc welding process variables in super duplex stainless steel claddings. Procedia Engineering, 64, 1030– 1039. doi:10.1016/j.proeng.2013.09.180 Shahi, A. S., & Panday, S. (2008). Effect of auxiliary preheating of the filler wire on quality of gas metal arc stainless steel cladding. Journal of Materials Engineering and Performance, 17, 30–36. doi:10.1007/ s11665-007-91321-1 Shahi, A. S., & Pandey, S. (2008). Modelling of the effects of welding conditions on dilution of stainless steel claddings produced by gas metal arc welding procedures. Journal of Materials Processing Technology, 196, 339–344. doi:10.1016/j.jmatprotec.2007.05.060 Sreeraj, P., & Kannan, T. (2012). Modelling and prediction of stainless steel clad bead geometry deposited by GMAW using regression and artificial neural network models. Advances in Mechanical Engineering, 2012, 1–12. Retrieved October 22, 2015, from http://ade.sagepub. com/content/4/237379.full Sreeraj, P., Kannan, T., & Maji, S. (2013a). Sensitivity analysis of process parameters in cladding of stainless steel by GMAW. Journal of Machine Design, 5, 1–10. Retrieved October 22, 2015 from http://www.mdesign.ftn.uns.ac.rs/ pdf/2013/no5/001-010.pdf Sreeraj, P., Kannan, T., & Maji, S. (2013b). Simulation and parameter optimization of GMAW process using neural networks and particle swarm optimization algorithm. International Journal of Mechanical Engineering & Robotics Research, 2, 130–146. Retrieved October 22, 2015, from http://www.ijmerr.com/ uploadfile/2015/0409/20150409110142990.pdf Sreeraj, P., Kannan, T., & Maji, S. (2013c). Optimization of process parameters of stainless steel clad bead geometry deposited by GMAW using integrated SA-GA, 1, 26–52. Retrieved October 22, 2015, from http://www. researchinventy.com/papers/v3i5/D03503041.pdf Verma, A. K., Biswas, B. C., Roy, P., De, S.¸Saren, S., & Das, S. (2012). On the effectiveness of duplex stainless steel cladding deposited by gas metal arc welding. In e-Proceeding of International Conference of the International Institute of Welding, Seoul. Verma, A. K., Biswas, B. C., Roy, P., De, S., Saren, S., & Das, S. (2013). Exploring quality of austenite stainless steel clad layer obtained by metal active gas welding. Indian Science Cruiser, 27, 24–29. Wilson, R. K., Kelly, T.J., & Kiser, S. D. (1987). The effect of iron dilution on Cu–Ni weld deposits used in seawater. Welding Journal, 66, 280s–287s. Retrieved October 22, 2015, from https://app.aws.org/wj/supplement/WJ_1987_09_s280.pdf Page 13 of 14 Mondal et al., Cogent Engineering (2016), 3: 1143598 http://dx.doi.org/10.1080/23311916.2016.1143598 © 2016 The Author(s). This open access article is distributed under a Creative Commons Attribution (CC-BY) 4.0 license. You are free to: Share — copy and redistribute the material in any medium or format Adapt — remix, transform, and build upon the material for any purpose, even commercially. The licensor cannot revoke these freedoms as long as you follow the license terms. Under the following terms: Attribution — You must give appropriate credit, provide a link to the license, and indicate if changes were made. You may do so in any reasonable manner, but not in any way that suggests the licensor endorses you or your use. No additional restrictions You may not apply legal terms or technological measures that legally restrict others from doing anything the license permits. Cogent Engineering (ISSN: 2331-1916) is published by Cogent OA, part of Taylor & Francis Group. Publishing with Cogent OA ensures: • Immediate, universal access to your article on publication • High visibility and discoverability via the Cogent OA website as well as Taylor & Francis Online • Download and citation statistics for your article • Rapid online publication • Input from, and dialog with, expert editors and editorial boards • Retention of full copyright of your article • Guaranteed legacy preservation of your article • Discounts and waivers for authors in developing regions Submit your manuscript to a Cogent OA journal at www.CogentOA.com Page 14 of 14