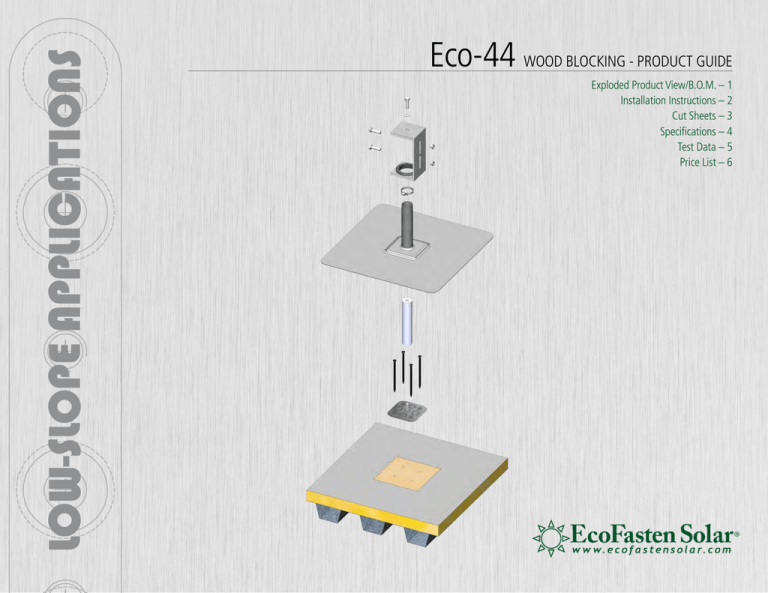

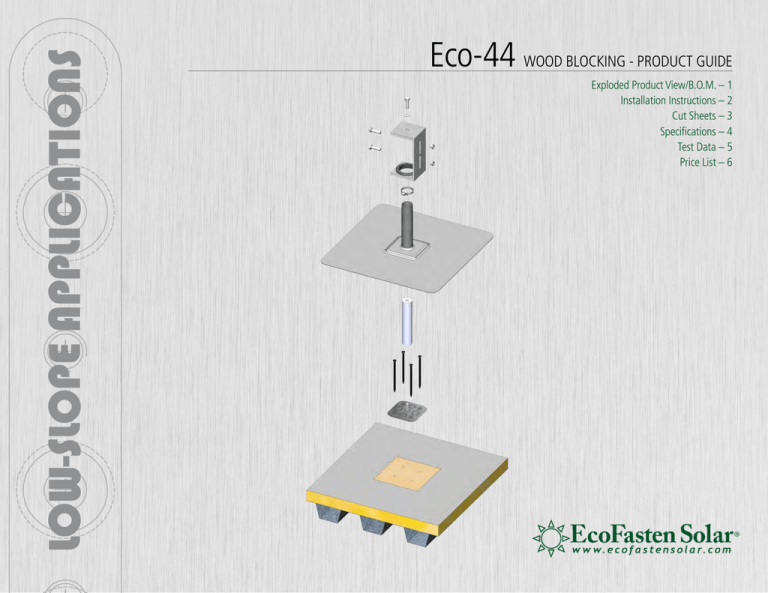

Low-Slope Applications

Eco-44 Wood blocking - Product Guide

Exploded Product View/B.O.M. – 1

Installation Instructions – 2

Cut Sheets – 3

Specifications – 4

Test Data – 5

Price List – 6

Eco-44 Wood Blocking – Product Guide

Exploded Product View, Bill of Materials

Materials Needed for Assembly

12

12

11

11

EcoFasten Solar

10

9

8

7

Item No.

Description of Material/Part

Quantity

1

Structural Steel Roof Deck

By Others

2

Insulation

By Others

3

Membrane

By Others

4

Wood Blocking

(Thickness TBD) (6” x Span 2 high ribs, use level)

By Others

5

Eco-44 Base Plate

1

6

Fastener (length to be determined)

4

7

P6-CSK (1-1/4” O.D.)

1

8

Pipe Flashing with 1” Boot (Must match roof material)

By Others

9

Stainless Steel Hose Clamp

By Others

10

C-102-6 Bracket

1

11

Hardware (3/8” bolt and nut)

2

12

Hardware (3/8” bolt and washer)

1

6

5

Required Tools

4

3

2

1

289 Harrel Street

Morrisville, VT 05661

Eco-44-6 WoodBlocking

877-859-3947 Committed to the Support of Renewable Energy © EcoFasten Solar® All content protected under copyright. All rights reserved. 11/01/2012

Toll Free Phone 1.877.859.3947

MATERIAL:

1.1

Eco-44 Wood Blocking – Product Guide

Installation Instructions

1.Determine the locations needed for the Eco-44 brackets.

2. Place base plate (#5) on finished roof deck material.

3.Trace around the base plate (#5) adding a one inch perimeter to the base plate

dimensions. Note: it may be helpful to make a tracing template to speed this process.

4. Set base plate (#5) aside.

12

12

11

11

EcoFasten Solar

5.Using a utility knife or scissors cut roof membrane from corner to corner diagonally across

the area marked in step three to form an “X”. This will allow the installer to fold the resulting

four triangular shapes of roof membrane back to expose the insulation below.

10

9

*Depending on the roof substructure, step six has two basic variations.

6.Cut out a section of the insulation equal to the hole cut in the roof membrane in

step five to expose the supporting substructure.

A. If the substructure is wood, gypsum, or concrete install wood blocking (#9) to

fill the void created by removing the insulation.

8

B. If the substructure is structural steel decking the installer will need to enlarge the opening in the membrane and remove enough insulation to allow the wood blocking

to be fully supported on at least two of the high points of the corrugation. The

dimensions of the wood blocking (#4) and the opening in the membrane will vary

depending on the amount of insulation that needs to be removed to allow for a

properly supported wood block.

7

6

7.Fill any voids around wood blocking (#4) in a manner that is approved by the roof membrane manufacturer to prevent thermal bridging.

5

8.Lay the four triangular roof membrane flaps back down over the wood block (#4).

9.Replace base plate (#5) over the roof membrane flaps and secure it to the wood blocking

using four fasteners (#6).

4

10.Install standoff (#7) by threading the post onto portion of the stud.

Torque to 50 inch-pounds.

11. Install acceptable roof membrane manufacturer’s plumbing / vent stack (#8)

over standoff (#7).

3

12.Secure stainless steel pipe clamp (#9) around top of plumbing vent stack flashing (#8)

with roof membrane manufacturer’s acceptable sealant, if required. It may be necessary

to trim the flashing so that it is flush with the top of the standoff.

2

1

.X = +/- .1

.XX = +/- .01

.XXX= +/- .005

877-859-3947 Committed to the Support of Renewable Energy © EcoFasten Solar® All content protected under copyright. All rights reserved. 07/26/2012

289 Harrel Street

Morrisville, VT 05661

Toll Free Phone 1.877.859.3947

Toll Free Fax 1.888.766.9994

2.1

MATERIAL:

Eco-44 Wood Blocking – Product Guide

Cut Sheets: Base Plate EF-44-SS

.77

.38

4.00

2.25

EcoFasten Solar

A

4.00

2.25

82.00°

.85

A

SECTION A-A

SCALE 1 : 1

.X = +/- .1

.XX = +/- .01

.XXX= +/- .005

289 Harrel Street

Morrisville, VT 05661

Toll Free Phone 1.877.859.3947

Toll Free Fax 1.888.766.9994

web www.ecofastensolar.com

e-mail info@ecofastensolar.com

EF-SS-44

MATERIAL:

SCALE: 1:1

877-859-3947 Committed to the Support of Renewable Energy © EcoFasten Solar® All content protected under copyright. All rights reserved. 07/26/2012

304 STAINLESS

1/26/2011

SHEET 1 OF 1

3.1

EcoFasten Solar

Eco-44 Wood Blocking – Product Guide

Cut Sheets: P-6-CSK

1 1/4"

6"

5/16"

1 1/2"

3/8-16 UNC

1 3/8"

5/16"

1 1/2

3/8-16 UNC

1 3/8"

7/8" X 82°

.X = +/- .1

.XX = +/- .01

.XXX= +/- .005

289 Harrel Street

Morrisville, VT 05661

Toll Free Phone 1.877.859.3947

Toll Free Fax 1.888.766.9994

web www.ecofastensolar.com

e-mail info@ecofastensolar.com

P-6-CSK

MATERIAL:

SCALE: 1:2

877-859-3947 Committed to the Support of Renewable Energy © EcoFasten Solar® All content protected under copyright. All rights reserved. 07/26/2012

6000 Series Aluminum

1/13/2012

SHEET 1 OF 1

3.2

Cut Sheets: Bracket Options C-102-6

1 3/16"

1 3/16"

1 1/2"

1 1/2"

1 1/2"

3 1/4"

6"

1 1/2"

EcoFasten Solar

3"

1 1/2"

2X 3/8"

Eco-44 Wood Blocking – Product Guide

RUBBER GROMMET

1 1/2"

2"

2 3/4"

5 1/8"

1 1/2"

3/8" THRU

.X = +/- .1

.XX = +/- .01

.XXX= +/- .005

289 Harrel Street

Morrisville, VT 05661

Toll Free Phone 1.877.859.3947

Toll Free Fax 1.888.766.9994 MATERIAL:

web copyright.

www.ecofastensolar.com

877-859-3947 Committed to the Support of Renewable Energy © EcoFasten Solar® All content protected under

All rights reserved. 07/26/2012

e-mail info@ecofastensolar.com SCALE: 1:2

C-102-6

6000 Series Aluminum

1/16/2012

SHEET 1 OF 1

3.3

Eco-44 Wood Blocking – Product Guide

Cut Sheets: Bracket Option SL-102-6

13/32"

7/16"

5/16"

2"

1/16"

1 1/2"

3/8"

3"

3 1/16"

3 5/8"

5 1/4"

L6 Extrusion

6"

R.01

1"

1/16"

45.00°

90.00°

7/16"

EcoFasten Solar

A

.X = +/- .1

.XX = +/- .01

.XXX= +/- .005

1 7/8"

5/8"

R.01

R.01

DETAIL A

SCALE 2 : 1

289 Harrel Street

Morrisville, VT 05661

Toll Free Phone 1.877.859.3947

Toll Free Fax 1.888.766.9994 MATERIAL:

web www.ecofastensolar.com

e-mail

info@ecofastensolar.com

1:2

877-859-3947 Committed to the Support of Renewable Energy © EcoFasten Solar® All content

protected

under copyright. All rights reserved.SCALE:

07/26/2012

SL-102- 6

6000 Series Aluminum

6/13/2012

SHEET 1 OF 1

3.4

Eco-44 Wood Blocking – Product Guide

PART 1 – GENERAL

EcoFasten Solar

1.1 SUMMARY

A. WORK INCLUDES

1. Eco-44 solar attachment bracket that

attaches directly to the roof deck.

2. Provide appropriate bracket and fasteners

for the roof system.

B. RELATED SECTIONS

1. Section 07600: Flashing and Sheet Metal

2. Section 07500: Membrane Roofing

3. Division 1: Administrative and procedural

requirements

4. Division 7: Thermal and Moisture Protection

1.2 SYSTEM DESCRIPTION

A. COMPONENTS:

1. Eco-44 system consists of aluminum bracket

and stainless steel base plate.

2. Fasteners

A. To be of metal compatible with base plate.

B. Fasteners should be selected for

compatibility with the roof deck

C. Fastener strength should exceed or be equal

to that of the allowable load of the system.

See test data at www.ecofastensolar.com

3. Sealant (if required by roof manufacturer):

to be membrane roof manufacturer approved.

4. Plumbing boot flashing of appropriate size and

material and method of installation to meet roof

manufacturer’s requirement for proper flashing.

5. Stainless steel pipe clamp

B. DESIGN REQUIREMENTS:

1. Bracket spacing to be recommended by project

engineer.

2. Install a minimum of four fasteners per base plate.

3. It is important to design new structures or

assess existing structures to make sure that

they can withstand retained loads.

Specifications

1.3 SUBMITTAL

A. S ubmit manufacturer’s written specifications.

B. S ubmit standard product cut sheets.

C. S ubmit installation instructions.

D. Submit

product specific load test data, showing ultimate and allowable load values.

1.4 QUALITY ASSURANCE

Installer to be experienced in the installation of

specified roofing material for not less than 5 years in

the area of the project.

1.5 DELIVERY / STORAGE / HANDLING

Inspect material upon delivery. Notify manufacturer within

24 hours of any missing or defective items. Keep material

dry, covered, and off the ground until installed.

D. W

ood blocking of appropriate size and thickness to

support base without splitting.

E. Plumbing boot, (may be supplied by others) to be

compatible with roofing material,roofing material

manufacturer’s acceptable installation technique,

and of an acceptable size to meet roof manufacturer’s

specifications.

F. 1 -1/4” I.D. Aluminum Post: Series 6000 aluminum

with 3/8-16” threaded hole in one end, countersink

in opposite end.

G. Stainless steel pipe clamp - 1-1/4” adjustable

(supplied by others)

2.3 FINISH – Mill Finish

PART 2 - PRODUCTS

PART 3 - EXECUTION

2.1 MANUFACTURER

EcoFasten Solar ®

289 Harrel Street, Morrisville, VT 05661

(877) 859-3947

www.ecofastensolar.com

3.1EXAMINATION

A. Substrate: Inspect structure on which brackets

are to be installed and verify that it will withstand

any additional loading that may be incurred.

2.2 MATERIALS

A. Attachment Bracket 6000 Series Aluminum

Required:P-6-CSK

Options: (choose one)

1. C-102-6

2. SL-102-6

3.Custom

B. Base Plate is 11 gauge material thickness.

304 Stainless Steel with one 3/8” 304 stainless steel

screw welded into embossed countersink.

B. Notify General Contractor of any deficiencies before

installing EcoFasten Solar brackets.

C. Verify that roofing material has been installed

correctly prior to installing solar attachment brackets.

3.2INSTALLATION

A. Comply with architectural drawings and project

engineer’s recommendations for location of system.

Comply with Manufacturer’s written installation

instructions for installation and layout.

C. F asteners (may be supplied by others) to be compatible

with chosen roof application and meet specified pull out

values as shown in load test data.

877-859-3947 Committed to the Support of Renewable Energy © EcoFasten Solar® All content protected under copyright. All rights reserved. 07/26/2012

4.1

Eco-44 Wood Blocking – Product Guide

Test Data: C-102-6

Engineer’s Test Report - C-102-6-B-44 Bracket

Engineer’s Test Report - C-102-6-B-44 Bracket

Page 2

EcoFasten Solar

Page 1

877-859-3947 Committed to the Support of Renewable Energy © EcoFasten Solar® All content protected under copyright. All rights reserved. 07/26/2012

5.1

Eco-44 Wood Blocking – Product Guide

Test Data: C-102-6

Engineer’s Test Report - C-102-6-B-44 Bracket

Engineer’s Test Report - C-102-6-B-44 Bracket

Page 4

EcoFasten Solar

Page 3

877-859-3947 Committed to the Support of Renewable Energy © EcoFasten Solar® All content protected under copyright. All rights reserved. 07/26/2012

5.2

Eco-44 Wood Blocking – Product Guide

Test Data: C-102-6

Engineer’s Test Report - C-102-6-B-44 Bracket

EcoFasten Solar

Page 5

877-859-3947 Committed to the Support of Renewable Energy © EcoFasten Solar® All content protected under copyright. All rights reserved. 07/26/2012

5.3

Eco-44 Wood Blocking – Product Guide

Test Data: Load Test

Load Test Report (for reference only)

EcoFasten Solar

Machine: Universal or tensile testing machine with a capacity of 5,000 lbs or

more. ASTM E74 certified load cell and display to measure load and a dial or

electronic indicator accurate to .001” to measure displacement.

Specimen: One solar bracket fastened according to the manufactures

installation instructions to a 12”x 12” or larger section of the roof substrate.

Sealants, flashings and other roofing materials that have no affect on bracket

strength may be omitted from the assembly.

Apparatus: A welded steel structure reinforced as necessary to prevent

buckling, warping or twisting while the specimen is under load. The apparatus

is securely fastened to the bed of the testing machine.

Setup: Attach the specimen to the apparatus using #14 or #15 self drilling

screws in sufficient quantity and spacing so as to prevent failure of the roof

substrate prior the failure of the snow guard bracket. Position the apparatus on

the test machine bed and connect the load cell to the bracket so that the load

is applied as it would be during normal service.

Procedure: Photograph the specimen and apparatus prior to testing. Load the

bracket slowly with an upward pull until failure. Photograph the specimen after

testing. Do a minimum of three tests using a new specimen for each test. If

after three tests the results are inconsistent, conduct two additional tests.

Failure: Any of the following occurrences shall be considered failure.

Test Data

Substrate:

1 ½” Spruce Board

Product: EF-SS-44

Fastener:

2” Olympic XHD

Failure: Any of the following occurrences shall be considered failure.

A. Fastener failure (fracture or withdrawal).

B. Structural failure of bracket.

Test #

Ultimate Load

(lbs)

Mode of

Failure

1

4452.8

A

Fasteners withdrew from board

2

4144.9

A

Fasteners withdrew from board

3

4304.5

A

Fasteners withdrew from board

Mean

4300.7

Description

A. Fastener failure (fracture or withdrawal).

B. Structural failure of bracket.

Reporting: On the data sheet, record the ultimate load (in pounds) and

mode of failure for each test. Calculate and record the mean load for all

tests conducted. Note any unusual observations during testing as well as a

description of the specific failure observed for each test. Fill out all requested

information on the data sheet.

877-859-3947 Committed to the Support of Renewable Energy © EcoFasten Solar® All content protected under copyright. All rights reserved. 07/26/2012

5.4

Eco-44 Wood Blocking – Product Guide

Test Data: Load Test

Fastener Pull-Out Comparison

EcoFasten Solar

To determine the Eco-44 ultimate pull out capacity for your project you will first need

to know the single fastener pull out capacity of the fastener you plan to use when

fasted in to your roof deck. The best way to determine this is to do an on site pull test.

If an on site test is not possible contact the fastener manufacturer and ask for their

published pull out data. The estimated Eco-44 ultimate load will be 4 times the single

fastener pull out capacity.

(Single Screw Pullout Capacity) x 4 = Eco-44 Ultimate Pullout Capacity (No safety factor)

For example:

Fastener = Triangle #14-13 Concealer

Roof Deck = 5/8” CDX Plywood

Single Fastener Ultimate Pullout

Capacity in 5/8” CDX Plywood = 483 lbs

Eco-44 Estimated Ultimate Pullout Capacity =

483 lbs x 4 = 1546 lbs

This process determines the expected ultimate load; appropriate safety factor must still

be applied. Each plate must be fastened with four fasteners.

877-859-3947 Committed to the Support of Renewable Energy © EcoFasten Solar® All content protected under copyright. All rights reserved. 07/26/2012

5.5

Test Data: Load Test

EcoFasten Solar

Eco-44 Wood Blocking – Product Guide

877-859-3947 Committed to the Support of Renewable Energy © EcoFasten Solar® All content protected under copyright. All rights reserved. 07/26/2012

5.6

Eco-44 Wood Blocking – Product Guide

Leak Test Report

EcoFasten Solar tested the EcoFasten roof mount system so you can be sure your

roof penetrations won’t leak, even when under standing water.

®

Test Data: Leak Test

Our test apparatus encapsulates the entire bracket and seals against the

membrane flashing which allows us to flood the bracket and pressurize the

system.

EcoFasten Solar

A paper towel was inserted above and below the base plate in this mock installation to provide a visual indication if any of the green water leaks past the flashing.

The membrane is a 45mil reinforced EPDM from Carlisle.

877-859-3947 Committed to the Support of Renewable Energy © EcoFasten Solar® All content protected under copyright. All rights reserved. 07/26/2012

5.7

Eco-44 Wood Blocking – Product Guide

Leak Test Report

The apparatus is pressurized to 30psi and left to stand for over 10

minutes. This is equivalent to nearly 70ft of standing water. The green

water leaks past the flashing. The membrane is a 45mil reinforced EPDM

from Carlisle.

Test Data: Leak Test

The patented compression fitting between the cone shape of the base plate

and the countersink in the bracket makes the EcoFasten system water tight.

Water finds its way between the bracket and membrane but stops at the base

of the compression fitting and can go no further.

EcoFasten Solar

Neither of the paper towels shows any indication of leaking. The EcoFasten

system is 100% water tight.

877-859-3947 Committed to the Support of Renewable Energy © EcoFasten Solar® All content protected under copyright. All rights reserved. 07/26/2012

5.8

Eco-44 Wood Blocking – Product Guide

Price List

12

12

11

11

5

10

EcoFasten Solar

$ 9.12

6

Fasteners

OMG XHD: #15 self drilling, phillips drive

XHD002B

2” length

$ 0.26

XHD003B

3” length

$ 0.32

XHD004B

4” length (shown)

$ 0.43

XHD005B

5” length

$ 0.56

XHD006B

6” length

$ 0.73

7

Standoff - required to maintain most membrane roof warranties

P-6-CSKincludes one 3/8-16 x 1” bolt and

stainless washer (shown) $ 6.49

5

8

Pipe Boot Flashing - Must match roof manufacturer and roof type;

to be supplied by others

4

9

Pipe clamp - To be supplied by others

3

10

9

/- .1

+/- .01

+/- .005

Base Plate - required, includes one 3/8” ID bonded washer

and one 3/8” hex nut (No. 11,12 in illustration)

EF-44-SS

Stainless steel (shown)

8

7

6

2

1

Attachment Brackets - optional, used to bring the attachment

point closer to the roof surface

C-102-6includes two 3/8-16 x 1-1/4” bolts

and flange nuts (shown)

$15.70

SL-102-6includes two 3/8-16 x 1-1/4” bolts

and flange nuts (use with P-6-CSK only) $13.94

List cost of assembly shown above

EF-44-SS

Stainless steel

$ 9.12

XHD004B

4: 4” length

fasteners

$ 1.72

289 Harrel Street

Eco-44-6 WoodBlocking

Morrisville,

P-6-CSKincludes

one 3/8-16VT

x 1”05661

bolt and

Toll

Freewasher

Phone 1.877.859.3947

stainless

$ 6.49

Toll Free Fax 1.888.766.9994 MATERIAL: Assembly

C-102-6includes

two

3/8-16

x

1-1/4”

bolts

web www.ecofastensolar.com

e-mail

info@ecofastensolar.com

SCALE:$15.70

1:10

SHEET 1 OF 1

1/16/2012

and flange

nuts

$33.03

877-859-3947 Committed to the Support of Renewable Energy © EcoFasten Solar® All content protected under copyright. All rights reserved. 02/27/2013

6.1