Multilayer Bus-Bar Conductor Rails

advertisement

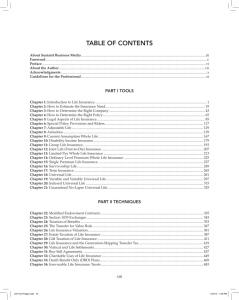

ae-Stromschienen-04-multilang.indd 1 14.05.14 20:19 to uc nd Co ls rib ist ar s-B Bu ai rR er E fo ffec r e ti le ve ct an ro d ni fl c c ex om ib po le e ne ne nt rg s yd til ay ul M n io ut er ay til ul M s-B Bu ar Cutting insulations to customer specification ae-Stromschienen-04-multilang.indd 2 14.05.14 20:19 Conductor rails such as the multilayer bus-bar have become indispensible in today‘s electronics. They create the possibility of a cost-efficient and sound basis for power distribution in power electronics. Our development team will gladly attend to your project needs to find an efficient and sustainable solution together with you. We can perform individual cutting, bending and assembly work as part of our in-house production. Using plotter cutting devices we supply fitting insulation films besides offering the assembly, pressing and soldering of electrical components to the conductor rails. The quality standards required have been demonstrated and documented within the scope of different test methods. Technologies applied stamping technology surface finishing pressing and heating technology various assembly techniques different test methods ae-Stromschienen-04-multilang.indd 3 Assembling and soldering electronic components 14.05.14 20:19 Technology Mulitlayers (bus-bars, low-inductive bus-bars) serve the purpose of power distribution especially for high power electronics and/or high frequencies. They are made up of singleand/or multi-pole plate-type electric conductors separated from one another by insulation films. In order to compensate parasitic inductance, they are layered on top of each other with little distance inbetween and are ‚baked together‘ like a sandwich. Copper or aluminium plates of up to 6.0 mm thickness with surfaces that are either untreated, tinned or nickel-plated are best suited for use as electric conductors. They give the mulitlayer such stability as to allow mounting other components on it. Stamp plate as intermediate layer ae-Stromschienen-04-multilang.indd 4 Stamp holes to customer specifications Stamping and bending 14.05.14 20:19 Copper stamp plate with a thick ness of 6 mm Multilayer, copper conductor rail stamped and bent Multilayer, copper conductor rail as stamped and bent part with flexible connections Rightangled version ae-Stromschienen-04-multilang.indd 5 14.05.14 20:19 Technical Data Advantages power conductor made of copper or aluminum with a thickness from 0.5 to 6.0 mm low inductive resistance surface finish: untreated, tinned, nickel-plated insulation film depending on temperature reduced impedance improved electromagnetic shielding operating voltage up to 6 kV optimized heat distribution and dissipation current up to 1,500 A space-saving design temperature tolerance of -40 °C up to + 110 °C (+300 °C) customized solutions RoHS-compliance Combinations with different turned parts possible ae-Stromschienen-04-multilang.indd 6 Connection variant with pressnuts 14.05.14 20:19 Fields of application Mulitlayers are applied whenever significant amounts of electrical power have to be transferred safely within small spaces, for example: for industrial applications (frequency converters, etc.) electrical drive engineering (railroad, electromobility, building services) industrial power supply (converters, inverters) renewable energy (wind power, solar, etc.) telecommunications Conductor rail with connection variant to customer specification Angled multilayer bus bar with flexible connection lugs ae-Stromschienen-04-multilang.indd 7 Conductor rail with premounted and soldered electronics possible 14.05.14 20:19 Conductor rail with connections above inserts Angled conductor rail with flexible connection lugs austerlitz electronic GmbH Ludwig-Feuerbach-Straße 38 D-90489 Nürnberg Telefon: Telefax: E-Mail: Internet: ae-Stromschienen-04-multilang.indd 8 +49 (0)9 11/5 97 47-0 +49 (0)9 11/5 97 47-89 info@austerlitz-electronic.de www.austerlitz-electronic.de 14.05.14 20:19