PEH-7/8/10MYB Air Cooled Split

advertisement

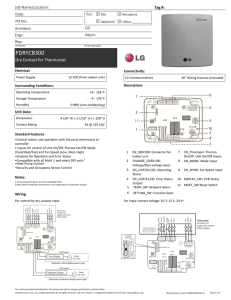

AIR COOLED SPLIT-TYPE DUCTED AIR CONDITIONERS Series HEAT PUMP PEH-7, 8, 10 PEH-7 PEH-8 PEH-10 Cooling capacity (kW) 18.8 22.0 28.8 Heating capacity (kW) 19.4 22.0 28.8 High Efficiency, Powerful Heating and Cooling 7/8/10HP Models Lined Up for Commercial & Residential Application Indoor Unit Outdoor Unit New Model Outdoor Unit Dramatically Reduces the Installation Space 550 New MYF model Affordable External Static Pressure The installation space for each outdoor unit, including service space, has been reduced to 0.65m2. Quiet Operation The low operating noise of the newly designed outdoor units (8/10HP) marks the industry leading level. Noise level (dB) New model (Cooling/Heating) PUH-7MYF 59/59 65 PUH-8MYF 59/59 65 PUH-10MYF 59/60 65 Previous model Saltproof Fin Treatment of Outdoor Unit Meets Various Installations Newly developed Fan Controller expands the operating ambient temperature. By introducing new 2-stage Fan Motor in the indoor unit, the fan speed can be changed (Hi/Lo) by the controller for extra comfort. (PEH-10 Fan speed is preset at high speed.) To provide flexibility for duct extension, branching and outlet configuration. 1180 Wide Operation Range Enable to Change Fan Speed (7/8HP) External static pressure (Pa) 7 8 10 125 125 150 Automatic Cooling/Heating Changeover Operation for More Comfort Extra Quiet Operation Along with the innovative noise suppression features found on other Mitsubishi Electric air conditioners, the PEH Series incorporates an improved sirrocco fan to reduce noise. Noise level (dB : at Lo-notch) 7 8 10 55 56 59 Operating ambient temp. (Outdoor) Limitations on Piping Length 50 40 30 20 Cooling 10 -5 Indoor Heating L ≤ 50m H ≤ 20m L ≤ 50m H ≤ 30m Outdoor -10 -15 Outdoor H Standard Finguard at Air Intake Side Enhances the Product Safety H L Indoor L Enhanced System Control and Operation Ease Wiring Needs Halved–Remarkable Saving in Cost and Labor Interactive system management, incorporated using an original technology we call "A-Control," is provided by a single 3-wire power/control cable connecting system components. In addition, a non-polarized, dual core wire employed for the remote control line further facilitates installation work. Full System Diagnosis "A-Control" interactivity between indoor and outdoor units enables the system's self-diagnostic function to be used for examining the entire system; even abnormalities in the outdoor unit will be shown on the remote controller display. Imporvements in display details make more accurate and timely responses for maintenance and repair possible. Remote display alternately shows error code and corresponding model number Power supply wiring to indoor unit LED PEH-7, 8 : Single phase PEH-10 : 3-phase CLOCK CLOCK CHECK MODE ERROR CODE OA UNIT ADDRESS Power supply wiring to outdoor unit (3-phase) Alternate display ERROR CODE OA UNIT ADDRESS NOT AVAILABLE Error delection article Error code CHECK MODE NOT AVAILABLE Corresponding model number Self diagnostic target unit address Transmission line (2-core) 3-core transmission cable Remote controller Flexible Function Setting from Remote Controllers Prepared as Standard Remote Controllers can now be used for the selection and setting of functions such as fan speed, air outlets, etc. which were previously set from the indoor unit base board. Setting changes can also be made very easily at the installation stage. Set temperature display Building Management System Compatibility "A-Control" technology offers compatibility so that systems of the series can operate as part of the MELANS building air conditioning management system. Once connected by a special adapter (optional), the systems respond to commands given from the MELANS control center. The remote controller can also be used for general system control. M-NET (MELANS) connection Man machine interface (G-50A) City Multi Y outdoor unit Power supply unit PAC-SC50KUA (optional) Adapter PAC-SF48MA-E (optional) Indoor unit Local remote controller Indoor unit Indoor unit Local remote controller Outdoor unit Indoor unit A-cotrol remote controller Room temperature display Operation lamp Filter sign reset switch Test run switch Check switch Operation mode switch Ventilation (Lossnay) mode setting switch (Control linked operation with Lossnay) Wired remote controller < PAR-20MAA-E > Efficient Lossnay Ventilation Management The Lossnay ventilation system can be easily connected to and controlled by the interactive "A-Control" system using an adapter. The combined interlocking system offers the ability to remove unclean air from indoor environments while adding 25% savings in operating costs for ventilation compared to conventional systems. Independent control of the Lossnay is also possible. Lossnay operation managed by "A-Control" Use of Two Remote Controllers per Group Thanks to the employment of "A-Control", the remote controller can be installed up to two sets per system. This greatly upgrades operability in residential and commercial application. LGH-++RS PZ-53ADF-E Indoor unit 2 Lossnay connecting cable (PZ-53ADF-E Accessories) Remote controller Specifications Model name Service reference Power supply Indoor Outdoor Total cooling capacity (Gross) Sensible cooling capacity (Gross) Total cooling capacity (Net) Total heating capacity (Net) Capacity step Refrigerant Refrigerant charge Refrigerant control Indoor unit kW BTU/h kcal/h kW BTU/h kcal/h kW BTU/h kcal/h kW BTU/h kcal/h % kg Model name Service reference External finish Dimension Height Width Depth Net weight Indoor coil Indoor fan Indoor fan motor No. x Motor output Indoor fan airflow (Lo-Hi) External static pressure Sound pressure level Drain connection Outdoor unit mm mm mm kg kW CMM CFM L/S mmAq Pa dB(A) mm Model name Service reference External finish Color Dimension Net weight Compressor No. x Motor output Outdoor coil Outdoor fan Outdoor fan motor No. x Motor output Height Width Depth mm mm mm kg kW kW CMM Outdoor fan airflow CFM L/S Sound pressure level (Cooling/Heating) dB(A) Protection devices PEH-7MYB PEH-8MYB PEH-10MYB PEH-7MYB-EU PEH-8MYB-EU PEH-10MYB-EU ~ 220~240V 50Hz 3N~ 380~415V 50Hz 3N~ 380~415V 50Hz 18.8 22.0 28.8 64,200 75,100 98,300 16,200 19,000 24,800 16.2 18.7 24.8 55,300 63,800 84,600 14,000 16,100 21,400 18.1 21.1 27.7 61,800 72,000 94,500 15,600 18,200 23,900 20.1 22.0 28.8 68,600 75,100 93,800 17,300 19,000 24,800 0 – 100 R-22 5.7 6.6 9.9 Capillary tube PEH-7MYB PEH-8MYB PEH-10MYB PEH-7MYB-EU PEH-8MYB-EU PEH-10MYB-EU Galvanized steel 428 1,380 1,580 650 67 70 84 Cross fin coil Centrifugal (plastic) – Direct drive 1-pahse induction motor 3-phase induction motor 1 x 0.21 1 x 0.4 1 x 1.0 48/60 56/70 90 1,695/2,119 1,978/2,472 3,179 800/1,000 933/1,167 1,500 12.5 15 125 150 55 56 59 25.4 PUH-7MYF PUH-8MYF PUH-10MYF PUH-7MYF-EUS PUH-8MYF-EUS PUH-10MYF-EUS Acrylic resin coating MUNSELL 5Y 8/1 1,480 1,180 550 (642) 188 (193) *5 221 (226) *5 Hermetic line start 1 x 5.0 1 x 5.5 1 x 7.5 Cross fin coil (Saltproof treatment) Propeller-direct drive 3-phase induction motor 2 x 0.09 2 x 0.15 167 190 5,898 6,711 2,783 3,167 59/59 59/60 High pressure switch, Freeze & frost protection fuse, Overcurrent relay (compressor& indoor fan), Internal thermostat (compressor, indoor fan & outdoor fan) Note : 1. Cooling and heating capacities are based on the following conditions; Cooling : Indoor: 27˚CDB, 19˚CWB, Outdoor: 35˚CDB Heating : Indoor: 20˚CDB, Outdoor: 7˚CDB, 6˚CWB Cooling and heating capacities are based on 5m pipe length. 2. Refrigerant charge volumes are factory charged (at 5m piping length). Refrigerant is enclosed in the outdoor unit. 3. The measuring point of the sound pressure level is 1m from the unit surface. 4. Specifications subject to change without notice. 5. Figure in ( ) indicates the dimension with built-in air outlet guide. Outline Dimensions (Unit : mm) 24- φ 3.1 holes Model PEH-7, 8MYB 104 1102 130 31 130 130 Air inlet duct flange 34 130 130 130 130 31 199 100 40 130 1280 423 20 200 Control box 20 131 22- φ 3.1 holes 4- φ 12 holes (For hanging bolt M10) (Field supply) 45 130 130 130 130 Air inlet sensor 130 130 130 45 15 5 Air outlet duct flange 1380 650 1320 70 562 40 120 1000 98 156 46 250 Connect wire (PEH-PUH) wiring hole φ 27 (Air inlet side) 14 25 100 100 Air outlet 25 42 33 Refrigerant pipe φ 15.88 (5/8 braze) 1240 120 382 116 210 130 130 152 344 Controller wiring hole φ 27 (Air inlet side) 95 Air inlet 15 42 20 15 40 428 530 55 55 50 156 Refrigerant pipe φ 25.4 (1 braze) 1264 Duct earth point (Both duct side) Drain : Rc 1 Power supply wiring hole φ 27 (Air inlet side) 26- φ 3 holes 104 Model PEH-10MYB 1102 130 130 130 130 34 130 130 130 66 130 Air inlet duct flange 100 40 130 66 1480 423 20 20 131 22- φ 3 holes 4- φ 12 holes (For hanging bolt M10) (Field supply) 45 130 130 130 Air inlet sensor 130 130 130 130 45 15 5 Air outlet duct flange 200 Control box 1580 650 1520 70 33 562 46 Drain : Rc 1 250 14 Connect wire (PEH-PUH) wiring hole φ 27 (Air inlet side) 1464 Duct earth point (Both duct side) Power supply wiring hole φ 27 (Air inlet side) 490 (Bolt pitch) 20 Air inlet Air inlet 4-10x20 holes (For mounting anchor bolt M8) (Field supply) 10 20 (1212) 30 30 30 4- φ 15 holes (Hanging) 20 20 550 Detail B Control box 1480 66 30 142 Refrigerant pipe φ 15.88(5/8 flare) Refrigerant pipe 7, 8MYF : φ 25.4(1 flange) 10MYF : φ 28.6(1-1/8 flange) Wiring hole 95 Detail A B Air outlet 1212 (Bolt pitch) 1180 170 (490) (490) (1212) 10 A 30 Model PUH-7, 8, 10MYF 20 40 220 1000 98 156 25 100 100 Air outlet 25 42 Refrigerant pipe φ 15.88 (5/8 braze) 220 428 116 210 130 130 156 152 344 Controller wiring hole φ 27 (Air inlet side) 95 Air inlet 1440 40 15 42 20 15 55 55 530 382 Refrigerant pipe φ 28.6 (1 braze) 50 20 Outline Dimensions Model PUH-7, 8, 10MYF (with optional air outlet guide) (Unit : mm) 30 490 (Bolt pitch) (1212) 20 4- φ 15 holes (Hanging) Air inlet 30 4-10x20 holes (For mounting anchor bolt M8) (Field supply) 20 (490) 30 10 Air inlet A B 20 Air outlet 1212 (Bolt pitch) 20 Detail A 20 1180 20 92 30 (490) 550 Air outlet 10 Control box (1212) 1480 20 Detail B 66 30 142 95 Air outlet 170 Refrigerant pipe (Field supply) φ 15.88(5/8 flare) Refrigerant pipe (Field supply) 7, 8MYF : φ 25.4(1 flange) 10MYF : φ 28.6(1-1/8 flange) Accessory pipe (with flange) Wiring hole Main Optional Parts Model PAR-20MAA-E PAC-SF48MA PAC-YT32PTA PAC-SE41TS-E PAC-SF40RM-E PAC-SE55RA-E Description Standard remote controller M-A transmission converter Program timer Remote sensor Remote operation adapter Remote ON/OFF adapter Guaranteed Operation Range Heating 15 40 10 30 Range for continuous operation 20 10 0 Outdoor temp. (˚CWB) Outdoor temp. (˚CDB) Cooling 50 46 5 0 Range for continuous operation -5 -10 Note: As an applicable humidity outside standard for both indoors and outdoors, we recommend use within a range of 35-80% relative humidity. However, it is a condition that there is no be dewy in surfaces of electric parts. -15 -5 -10 10 15 20 24 25 30 Indoor temp. (˚CWB) 10 15 20 25 27 30 Indoor temp. (˚CDB) HEAD OFFICE: MITSUBISHI DENKI BLDG., 2-2-3, MARUNOUCHI, CHIYODA-KU, TOKYO 100-8310, JAPAN P 2003 E-1 Prepared in Japan (KMC) New publication, effective July 2003 Specifications subject to change without notice.