the kirchhoff group magazin

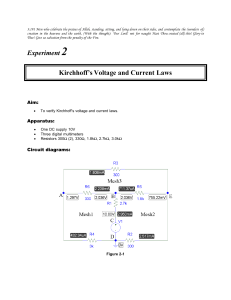

advertisement