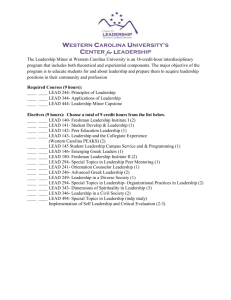

Option

advertisement