Winches and High Capacity Hoists

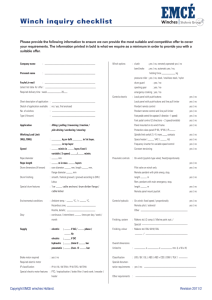

advertisement