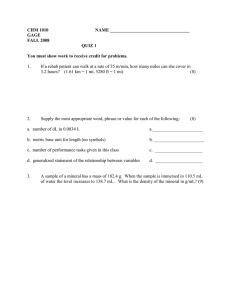

Estimation of Mineral Resource and Mineral

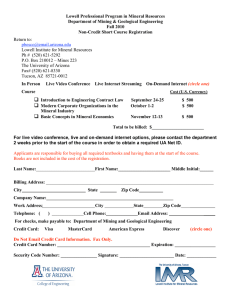

advertisement