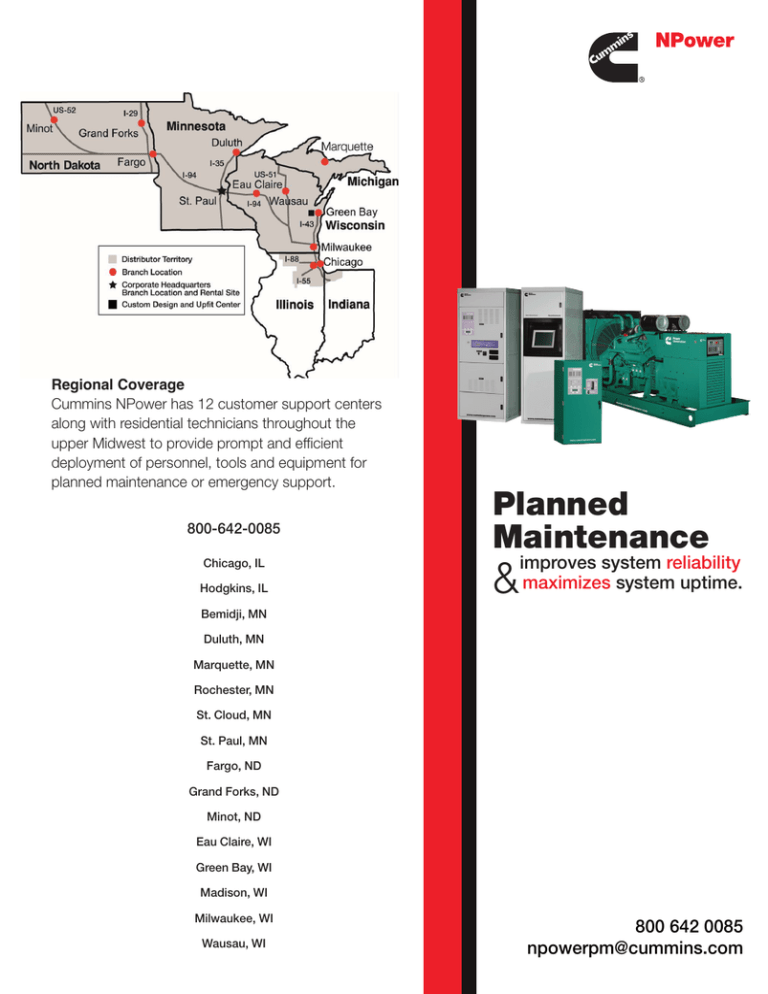

Planned Maintenance

advertisement

Regional Coverage Cummins NPower has 12 customer support centers along with residential technicians throughout the upper Midwest to provide prompt and efficient deployment of personnel, tools and equipment for planned maintenance or emergency support. 800-642-0085 Planned Maintenance & Chicago, IL Hodgkins, IL improves system reliability maximizes system uptime. Bemidji, MN Duluth, MN Marquette, MN Rochester, MN St. Cloud, MN St. Paul, MN Fargo, ND Grand Forks, ND Minot, ND Eau Claire, WI Green Bay, WI Madison, WI Milwaukee, WI 800 642 0085 npowerpm@cummins.com Wausau, WI Menu of Planned Maintenance Services Offered Planned maintenance improves system reliability & maximizes system uptime. Your emergency power system is designed to protect your business from interruption and costly downtime. A planned maintenance program from Cummins NPower helps keep your power generation equipment up and running, providing your business with an extra measure of protection. About planned maintenance Planned Maintenance is a site specific program of scheduled maintenance, equipment inspections, and performance tests. Our program is not only designed to keep the equipment in proper working condition, but also to gain early knowledge of items that may require unscheduled maintenance and repair, further improving system reliability. Truly comprehensive maintenance Our complete knowledge of power generation equipment and applications enables us to offer the most comprehensive system maintenance programs to meet your needs. We provide customized packages for each unique application and overall performance goals of the system. Cummins NPower offers the best value for your planned maintenance needs Certified Technicians – Cummins NPower has trained and certified power generation technicians that have the experience and knowledge to meet planned and unplanned service support. Our field technicians use reliable support vehicles to provide service where you need it. Flexibility – Cummins NPower is capable of meeting your unique scheduling needs 24 hours a day. Quality – Cummins NPower has adopted best in class processes and procedures for each maintenance event to ensure that work is done systemically to uncover problems and correct them before they affect system reliability. Price – Our fixed price guarantee allows you to know the cost of your maintenance plan up front with no surprise fees. Oil / Performance Testing Load Fluid Bank Sampling 2Coolant hour Oil 4Fuel hour Coolant Fuel Load Bank / Performance Testing 56 Point Inspection 2 hour Monthly Load Bank / Performance Testing 4 hour Quarterly 2 hour Semi-annual 4 hour 56 Point Inspection Semi-annual (with fluid filter change, no oil) Monthly 56 Point Inspection Load Management Inspection (no open test) Quarterly Monthly Load Management Inspection (with run test) Semi-annual Quarterly (with fluid filter change, no oil) EngineSemi-annual Service Semi-annual Load Management Inspection (no open56 test) Replace oil and all fluid filters (includes point check) Semi-annual (with fluid filter change, no oil) Load Management Inspection (with run56 test) Replace all fluid filters, no oil (includes point check) Load Management Inspection (no open test) Load Management Inspection (with run test) Engine Service Battery Replacement Replaceengine oil andstarting all fluid batteries filters (includes 56years) point check) Replace (every 2 Engine Service Replacesystem all fluidstation filters, batteries no oil (includes 56years) point check) Replace (every 2 Replace oil and all fluid filters (includes 56 point check) Replace allMaintenance fluid filters, no oil (includes 56 point check) Battery Replacement Cooling System Replacereplacement engine starting (every 2 years) Coolant withbatteries flush Battery Replacement Replacereplacement system station batteries Coolant without flush(every 2 years) Replace engine starting batteries (every 2 years) Replace coolant and hoses Replace system station batteries (every 2 years) Cooling System Maintenance Full cooling system maintenance Coolant replacement with flush – coolant, and belts Cooling Systemhoses Maintenance Coolant replacement without flush Coolant replacement with flush Replace coolant and hoses Remote Monitoring Coolant replacement without flush Full cooling system maintenance Equipment installand with full monitoring capabilitiesReplace coolant hoses –provided coolant, hoses and belts by Cummins NPower Full cooling system maintenance – coolant, hoses and belts Equipment install – customer monitors Remote Monitoring Equipment install with full monitoring capabilitiesGenerator Warranty Remote Monitoring provided5 by Cummins NPower warranty Extended year comprehensive Equipment install with full monitoring capabilitiesEquipment install – customer monitors provided by Cummins NPower Fuel System Generator Warranty Fuel tank cleaning conditioning Equipment install –/customer monitors Extended 5 year comprehensive warranty Biocide or winterizer Generator Warranty Fuel tank replacement Extended 5 year comprehensive warranty Fuel System – includes day tank filter if applicable Fuel tank cleaning / conditioning Fuel System PI / Megohmeter Biocide or Test winterizer Fuel tank cleaning / conditioning Validate integrity of the insulation Fuel tankthe replacement Biocide or winterizer – includes tank filter if applicable coating the day electrical windings within generator Fuel tank replacement PI / Megohmeter Test – includes day tank filter if applicable Tune-up Gas Engines Validatespark the integrity of the insulation Replace plugs and wires PI / Megohmeter Test coating the electrical windings within generator Replace distributor cap and rotor Validate the integrity of the insulation coating the electrical windings within generator Tune-up Gas Engines Valve / injector set with flush Replace spark plugs and wires Valve injector adjust and flush Tune-up Gasand Engines Replace distributor cap and rotor Replace spark plugs and wires cap and rotor Valve Replace / injectordistributor set with flush and injector adjust and flush Valve / Valve injector set with flush Valve and injector adjust and flush Menu of Services • Cooling System Maintenance Experience – Cummins has been a worldwide leader in the power generation industry for over 75 years. Cummins NPower, a premier engine and power generation systems distributor serving the upper Midwest, is committed to delivering fast, proven solutions to its customers. Cummins NPower has adopted best in class processes and procedures for each maintenance event to ensure that work is done systemically to uncover problems and correct them before they affect system reliability. Fluid Sampling Menu ofOilPlanned Maintenance Services Offered Coolant Menu ofFuel Planned Maintenance Services Offered Fluid Sampling Engine Full Service Recommended every 5 years for reliability: Recommended Annually • Engine Service Drain and refill cooling system with Fleetguard hybrid extended life coolant. • Replace all coolant hoses including engine block heater hoses. • Replace engine thermostats and test for proper operation. • Replace all drive belts. Note: Cummins NPower disposes of all waste per Environmental Protection Agency (EPA) regulations. • Replace engine oil and filters (oil, fuel, water) and dispose per Environmental Protection Agency (EPA) specifications. • Recycle batteries per Environmental Protection Agency (EPA) specifications. Semi-Annual Inspection • Inspect engine, transfer switch, and generator components including: battery(ies) and battery charger, engine cooling system (coolant testing optional), controls and accessories, main alternator, fuel system (fuel testing optional), intake and exhaust systems, and the engine and lubrication system (oil sampling when recommended). • Perform system operational tests with and without load. • Provide data analysis of service event along with a quote for any recommendations or repairs needed on equipment. Additional Services Record Retention – Each service event is documented and a copy of each report is presented to the customer. We also maintain records for performance analysis and to meet record retention requirements for local authorities. Extended Warranty Coverage – Didn’t buy extended warranty coverage at the time of purchase? We can research the availability of 2, 5 or 10 year extended warranty coverage for Cummins products. Fluid Sampling • Test oil, coolant, and fuel for contaminants that may affect the operation of equipment. • Proactive approach to respond to early warning signs of wear, contamination, and fluid breakdown. Engine Full Service • Inspection • Fluid Sampling Cooling System Maintenance Load Banking Performance Testing Battery Program Recommended yearly for standby applications Recommended every 24 months • Test rated output capacity of the generator to the manufacturer’s specifications. Verify sub-systems overall reliability to perform in an emergency power situation (during a 2 or 4 hour durability test). • System is monitored during the course of the load test producing a detailed report of its output and operating parameters noting any abnormal conditions that may exist. • Provide follow up quote for any recommendations or repairs needed on equipment. Remove and replace the engine-starting battery/batteries and the transfer switch batteries. • Recycle batteries per Environmental Protection Agency (EPA) specifications. Battery Program • Load Bank Performance Testing • •