Final Report I. Problem Statement In underdeveloped countries

advertisement

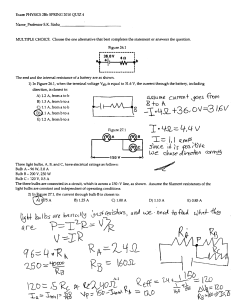

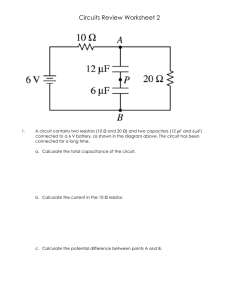

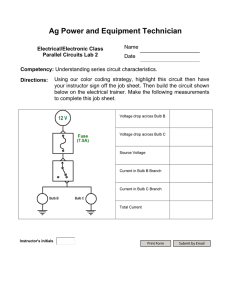

Final Report I. Problem Statement In underdeveloped countries, surgery light bulbs are expensive to replace and not always locally available. There is a need for a universal, low-cost alternative that is suitable to the environment and has a long lifetime. In preparation for this project, we as a team did a lot of background research on current surgical light bulbs, conditions in underdeveloped countries, as well as pre-existing and ongoing universal surgery light bulb projects. One of the main problems with the current surgical bulbs is that they are too expensive. One surgical bulb can cost hundreds of dollars and then the cost of shipping to these underdeveloped countries makes it impossible for them to afford. In searching for this low cost alternative, we found that LEDs are starting to replace the original fluorescent bulbs and decided to bring our design in that direction as well. In conjunction with this finding, we came upon a group performing our same project at Duke and they too used a LED as their light source. Since this current project is so similar to what we want to develop, we have decided to recreate their project as a starting point. II. Background and Prior Art for Instrumentation An extensive research on surgical lights and living conditions in developing countries helped us choose our design and components. Moreover, our meeting with Ben Fleishman from EWH was very rewarding since we were able to obtain additional information, discuss our design, and receive feedback from him. For example, based on the information we got from our research, we decided to use LED lights. While doing some background search, we came across a team that has undertaken the same project at another university. We decided to make a replica of their LED circuit and modify it to meet our design specifications. Moreover, while exploring another website, we came upon a frame for an LED light bulb built with a single sheet of metal. We decided to build a similar frame that can be used with any lamp in developing countries. Our design specifications include the following: calibration to different voltages (the power grid in developing countries is unreliable and inconsistent), universality (the surgical light should be able to adapt to different lamps), the overall cost should be low (less or equal to $100?), sustainability (easy to maintain with replaceable parts locally available), long lifetime, user friendly. The components of our chosen design are: LED light, LED circuit made of resistors, capacitors, inductors, op-amps, diodes, and power supply, frame made of metal sheet. The table below lists the most common surgical procedures practiced in Rwanda at district hospitals. This kind of information can help us determine the size of the area needed for illumination on the surgical table in case of a complete power outage. Table 1: List of most common operational procedures performed in district hospitals in Rwanda Source: Petroze R.T., East and Central African Journal of Surgery, Vol. 16, No. 2, July/August, 2011, pp. 102-111 The table was provided to the Ministry of Health in Rwanda from 40 district hospitals over the period from January 2008-September 2010. Comparable to the global literature, the majority of procedures performed at the District Hospital level in Rwanda are caesarian sections. III. Project Accomplishments We gained background knowledge regarding developing countries and the need for a universal surgery light bulb replacement to reduce the high cost of replacing light bulbs for varying surgical lamps. The team determined that LEDs are a long-lasting and relatively cheap light source. We found similar projects online and incorporated ideas from their projects towards our goals for our team’s design. In groups, we built a basic flashlight circuit and developed soldering skills to gain knowledge of a light source circuit. We had the opportunity to meet with Ben Fleishman, from Engineering World Health, who made us aware of various possible problems such as varying voltages due to unstable power grids. An independent and stable power source is a desirable factor in our final design. We bought parts in order to assemble our design. A schematic of an ideal prototype can be seen in the figure below. It would have a flat metal frame with a clamp to attach it to surgery lamp framework. There would be a four LED arrangement for light intensity distribution over the surgical table. We need an independent power source such as batteries to power the LEDs. The circuitry and wires can be hidden above the frame. Perforated metal sheeting may ease shipping and manufacturing overseas. Figure 3: CAD drawing exhibiting mock surgical light IV. Building and Testing Plan After the design was decided on, building and testing was the next step. Fortunately, the chosen design also had a parts list so it was easier to order the needed parts since we knew exactly what they needed to be. The challenge faced in this area was the availability of the exact parts needed. Some of the parts that were needed were found and other were either out of stock or impossible to find. For the parts that were out of stock, we looked through the site for similar parts that could be used in place of the parts. After getting all the parts together, testing was the next step. We tested the parts for their functionality. Using a AAA battery, the LEDs were tested for their brightness and also to determine how many of it would be needed for the light bulb. Our quest to design a universal surgery light bulb involved and continues to involve significant amount of research regarding not only the bulb itself but also background information about Rwanda. From our research, we have concluded the LEDs solve several problems. LEDs are relatively cost efficient and long-lasting and certain LEDs have environmental advantages as well. After we decided to work with LEDs, we started to focus more on the constructing a design for the bulb. We first looked at the work of various other research groups and gathered preliminary ideas. We also began working in the lab and constructed a basic circuit consisting of a battery and an LED bulb, seen in the figure below. Figure 9: LED flashlight constructed for circuit design development and learning proper soldering technique The lab allowed us to practice soldering materials together, which will be important in the construction of the final product. In our research to find preliminary ideas, we noticed that a research group at Duke University was constructing a LED apparatus similar to our own. We then decided to recreate the apparatus in order to better understand how to create our own bulb. We first went to a university supply store and bought several materials; the rest of the materials were ordered online. We are currently in the process of gathering the materials together and constructing the apparatus. V. Conclusion Over the course of this semester, we have laid the groundwork for assembly of a universal surgery light bulb prototype. After understanding the need for this light bulb in underdeveloped countries, we developed a list of design properties and constraints that would make the ideal universal surgery light bulb, as detailed in our project proposal. With the help of Ben Fleishman, online research, and collaboration of prior art and design concepts, we have agreed on the preliminary LED-design and acquired the necessary parts for assembly. In the spring semester, we plan to build the prototype and test it, taking environmental constraints into account, and thus making modifications where needed.