TB9057FG

advertisement

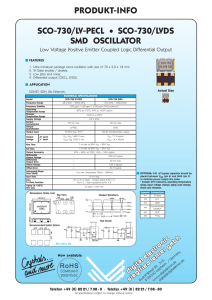

TB9057FG TOSHIBA Bi-CMOS Integrated Circuit Silicon Monorithic TB9057FG Automotive GATE-driver for DC brushed motor driver TB9057FG is Pre-Driver IC for DC Brushed Motor. Motor Speed is controlled by Input PWM signal Duty. Charge Pump, Motor Current Detection circuit, Motor drive direction detection circuit and Oscillator are built in. And also, build-in Miscellaneous Abnormal Detection circuit which can decide detection condition by external setting. LQFP48-P-0707-0.50C Features Weight: 0.186g (typ.) Motor Speed control by Input PWM signal Duty Build-in Charge Pump High response Current Detection circuit Motor Drive Direction Detection circuit Miscellaneous Abnormal Detection circuit (Over Temp / Low Voltage / Short Detection)) Operating Voltage :5 to 21V Operating Temperature : −40 to 125°C Package : LQFP48-P-0707-0.50C (0.5mm Pitch) The product(s) is/are compatible with RoHS regulations (EU directive 2011 / 65 / EU) as indicated, if any, on the packaging label ("[[G]]/RoHS COMPATIBLE", "[[G]]/RoHS [[Chemical symbol(s) of controlled substance(s)]]", "RoHS COMPATIBLE" or "RoHS COMPATIBLE, [[Chemical symbol(s) of controlled substance(s)]]>MCV"). 1 ⓒ2014 TOSHIBA Corporation TB9057FG VCC5A2 PCCO PCCD2 PCC2 PCCD1 PCC1 V B1 V B2 INTERNAL BLOCK DIAGRAM Charge pump VCC5A1 VDD1 VDD2 PGND1 VDD under voltage detection SO1 SO2 CRESET HO1 DR1 VB under voltage detection HO2 DR2 Pre-Driver NC IN1 IN2 IN3 IN4 ENA LO1 LO2 PGND2 Motor direction detection MR1 MR2 Short detection SEL PD2 PD1 LS IN5 TEST1 TEST2 Current sensor TSD AMPP1 AMP2 DG1 AMP1 AMPM1 CS1 AMPP2 AMPM2 CS2 AGND2 NC AGND1 Error logic DG2 *1: Some of the functional blocks,circuit,or constants in the block diagram may be omitted or simplified for explanatory purpose. *2: Install the product correctly. Otherwise, it may result in break down, damage and/or deterioration to the product or equipment. 2 TB9057FG VB1 VB2 DR1 SO2 SO1 PCC1 PCCO PCC2 TEST2 PCCD2 TEST1 PCCD1 36 35 34 33 32 31 30 29 28 27 26 25 PACKAGE PIN LAYOUT (Top View) IN5 43 18 AMPP1 VDD2 44 17 AMPM1 IN1 45 16 CS1 IN2 46 15 AMPP2 NC 47 14 AMPM2 IN3 48 13 CS2 3 12 AGND1 LS 19 11 42 AGND2 CRESET 10 LO2 DG1 20 9 41 DG2 VDD1 8 HO2 VCC5A1 21 7 40 PD1 MR2 6 PGND2 PD2 22 5 39 VCC5A2 MR1 4 LO1 SEL 23 3 38 ENA PGND1 2 HO1 NC 24 1 37 IN4 DR2 TB9057FG PIN DESCRIPTION PIN No. Symbol 1 2 3 4 5 6 7 8 9 10 11 12 13 14 15 16 17 18 19 20 21 22 23 24 25 26 27 28 29 30 31 32 33 34 35 36 37 38 39 40 41 42 43 44 45 46 47 48 IN4 NC ENA SEL VCC5A2 PD2 PD1 VCC5A1 DG2 DG1 AGND2 LS CS2 AMPM2 AMPP2 CS1 AMPM1 AMPP1 AGND1 LO2 HO2 PGND2 LO1 HO1 PCCD1 TEST1 PCCD2 TEST2 PCC2 PCCO PCC1 SO1 SO2 DR1 VB2 VB1 DR2 PGND1 MR1 MR2 VDD1 CRESET IN5 VDD2 IN1 IN2 NC IN3 Definition Pre-Driver Direct Control 4 Non Connection Pin Pre-Driver Enable Signal Pre-Driver Select Signal Power Supply for Analog 2 Short Detection Ref. 2 Short Detection Ref. 1 Power Supply for Analog 1 Abnormal Detection Information Output 2 Abnormal Detection Information Output 1 Analog GND 2 Pre-Driver Low-side Source Input 2nd AMP. Output for Current Sensor 2nd AMP. - Input for Current Sensor 2nd AMP. + Input for Current Sensor 1st AMP. Output for Current Sensor 1st AMP. - Input for Current Sensor 1st AMP. + Input for Current Sensor Analog GND 1 Pre-Driver Output LO2 Pre-Driver Output HO2 Power GND 2 Pre-Driver Output LO1 Pre-Driver Output HO1 1st Charge Pump Drive Output TEST PIN 1 2ndCharge Pump Drive Output TEST PIN 2 2nd Charge Pump Output Final Charge Pump Output 1st Charge Pump Output Pre-Driver High-side Drain Input 1 Pre-Driver High-side Drain Input 2 Motor Connect PIN 1 Power Supply(Battery 12V) 2 Power Supply(Battery 12V) 1 Motor Connect PIN 2 Power GND 1 Motor drive direction detection signal 1 Motor drive direction detection signal 2 Power Supply for Logic 1 Charge pump reset signal Setting Filtering time for Short Detection Power Supply for Logic 2 Pre-Driver Direct Control 1 Pre-Driver Direct Control 2 Non Connection Pin Pre-Driver Direct Control 3 IN/OUT Internal circuit I I I I I O O I O I I O I I O O O O O I O I O O O I I I I O O I I I I I Pull-up Pull-down Pull-up Pull-down Pull-down Pull-down Pull-down Pull-up Pull-up Pull-up Pull-up Notes Please use OPEN Please use OPEN Please use OPEN Please use OPEN *1: Install the product correctly. Otherwise, it may result in break down, damage and/or deterioration to the product or equipment. 4 TB9057FG FUNCTIONAL DESCRIPTIONS TB9057FG is Pre-Driver IC for DC Brushed Motor. TB9057FG build in Charge pump for Pre-Driver and it can control external Nch MOSFET directly. TB9057FG build in Motor Current Detection circuit which can detect motor current from PIN”CS1, CS2”. And also, build-in Miscellaneous Abnormal Detection circuit which can decide detection condition by external setting. (1) Charge Pump TB9057FG build in Charge pump for Pre-Driver and it can control external Nch MOSFET directly. Also Charge Pump Output Voltage Detection circuit is built-in. When Output voltage of Chareg Pump (PCCO) is over SO+12V or 36V(typ.), Charge Pump is stopped. When this voltage is dropped to SO+11.9V or 35.5V, Charge Pump re-start the operation. And Charge Pump Operation can be stopped by using external PIN “CRESET”. ・CRESET is “High”: Normal operation. ・CRESET is “Low”: Charge Pump operaion is stopped. When charge pump is stopped, PCCO voltage become “VB-3VF”. Battery VB1 VDD OSC VB2 PCC1 CRESET PCCD1 PCC2 PGND PCCD2 VDD Under Voltage Detection PGND PCCO Comp. for VB+12V Detection SO Comp. for 36V Detection Charge Pump Stop Charge Pump Stop CRESET SO+12V 36V Charge Pump Re-start Charge pump Stop 35.5V SO+11.9V Charge Pump Re-start Charge pump Re-start POO OUTPUT *1: Charge Pump is clampped by 36V(typ.). But when VB is over 40V, even Charge Pump is stopped the operation, the voltage of PCCO is over 40V. VB need to keep max. 40V. *2: Some of the functional blocks, circuits, or constants in the block diagram may be omitted or simplified for explanatory purpose. 5 TB9057FG (2) Pre-Driver Circuit The Output of Pre-Driver (HO1,HO2.LO1.LO2) are contorlled by PIN”IN1 to IN4” , and Charge pump output voltage is used for Pre-Driver power supply. And Pre-Driver Operation can be stopped by using external PIN “ENA”. NC Battery PCCO VDD HO1 IN1 VDD HO2 IN2 Control Logic (inc. Dead Time) VDD Clamp Circuit M IN3 LO1 VDD IN4 LO2 ENA VDD PGND1 SEL VDD Under voltage detection VB Under voltage detection Short Detection PGND2 *1: Some of the functional blocks, circuits, or constants in the block diagram may be omitted or simplified for explanatory purpose. Truth Table Input Signal Output Signal IN1 IN2 IN3 IN4 ENA HO1 HO2 LO1 LO2 L * L * H L L L L * L * L H L L L L L L H H H H H L L L H H L H H L L H H L L H H L H H L H H L L H L L H H L H H H H H L L L H L H H H L H L L H H L H H L L H L H H H L H L L L H H H H H H L L L L * * * * L L L L L * : Don’t care. 6 TB9057FG * DEAD TIME Operation TB9057FG automatically generate DEAD TIME to protect the short circui of Hi-side/Lo-side on the same Half-Bridge as the follows. Driver Hi-side Input ON Driver Lo-side Input OFF OFF ON ON ON Driver Hi-side Gate signal Driver Lo-side Gate signal Tdt Tdt *1:Timing charts may be simplified for explanatory purpose. (3) Motor Current Sensor Circuit TB9057FG build-in Motor Current Sensor Circuit and Motor Current sensing is done by external Shunt Resistor. Amp. rate of Differential Amp. is set by external Resistor as shown the below. VCC5A1 VCC5A2 VCC5A1 AMPP1 AMP2 AMP1 VCC5A2 CS1 AGND1 AMPP2 AMPM2 CS2 AGND2 AMPM1 *1:Some of the functional blocks, circuits, or constants in the block diagram may be omitted or simplified for explanatory purpose. 7 TB9057FG (4) Motor Drive Direction Detection Circuit TB9057FG build in the motor drive direction detection circuit to detect whether external MOSFET turns on or turn off normally. Battery SO1 SO2 VB VDD HO1 + MR1 DGND VDD DR1 AGND HO2 VB + MR2 DGND DR2 M LO1 AGND LO2 *1:Some of the functional blocks, circuits, or constants in the block diagram may be omitted or simplified for explanatory purpose. Truth Table Input Signal Output Signal HO1 HO2 LO1 LO2 DR1 DR2 L L L L Hi-Z(Open) Hi-Z(Open) H H L L H H H L L H H L L H H L L H L L H H L L H L L L H Hi-Z(Open) L H L L Hi-Z(Open) H L L H L L Hi-Z(Open) L L L H Hi-Z(Open) L Input Signal Output Signal DR1 DR2 MR1 MR2 Hi-Z(Open) Hi-Z(Open) L L H H H H H L H L L H L H L L L L H Hi-Z(Open) H L Hi-Z(Open) H L H L Hi-Z(Open) L L Hi-Z(Open) L L L 8 TB9057FG (5) Miscellaneous Abnormal Detection Circuit TB9057FG build-in Miscellaneous Abnormal Detection Circuit, such as Low Voltage Detection of VB and VDD, Over Temperature Detection, external MOSFET Short Detection and Motor Line Short Detection. In case of under voltage detection, DG1=Low,DG2=Low. In case of under over temperature detection, DG1=High, DG2=High. In case of short detection, DG1=Low, DG2=High. And if return to normal operation, DG1=High, DG2=Low. PIN”DG1” H PIN”DG2” L L L L H Short Detection H H Over Temp. Detection Abnormal Phenomenon Normal (No Abnormal Detection) VB Low Voltage or VDD Low Voltage Detection Priority of each detection is as follow. * When both Short Detection and Over Temp. Detection are occur, DG1=High, DG2=High. * When both Short Detection and Low Voltage Detection are occur, DG1=Low, DG2=Low. * When both Low Voltage Detection and Over Temp. Detection are occur, DG1= Low, DG2= Low. (5-1) VB Low Voltage Detection / VDD Low Voltage Detection (5-1-1) VB Low Voltage Detection When VB is dropped to lower than 4V(typ.), PIN”DG1” and “DIG2” are changed to “L”. When VB is increased over 4.5V, these Diagnosis Information singal change to PIN”DG1”=”H”, “DG2”=”L”.The Output of Pre-driver at the abnormal detetction can be selectable by PIN”SEL”. When PIN”SEL”=”L”, all of Pre-driver are changed to “L” at the abnormal detection. When PIN”SEL”=”H”, all of Pre-driver Output keeps normal operation even at abnormal detection. SEL = Low VB 4V Low V Detect SEL = High 4.5V Low V Detect Off VB 4V DG1 DG1 DG2 DG2 Low V Detect 4.5V Low V Detect Off HO1 or HO2 Control by input signal Pre-Driver =L Control by input signal HO1 or HO2 Control by input signal LO1 or LO2 Control by input signal Pre-Driver =L Control by input signal LO1 or LO2 Control by input signal *1:Timing charts may be simplified for explanatory purpose. 9 TB9057FG (5-1-2)VDD Low Voltage Detection TB9057FG monitor the voltage of Logic Power Supply(VDD) and detect Low Voltage by internal Band Gap circuit. When VDD is dropped to 2.8V(typ.),TB9057FG reset internal Logic circuit and Pre-Driver Output(PIN”HO1”,”HO2”,”LO1”,”LO2”) are changed to “L” and Charge pump operation is stopped. When VDD increase to be over 2.9V(typ), internal reset is off and return to normal operation. This internal Reset signal has the protection circuit for Chataring to prevent miss-reset. Normal Operation Power On Voltage Drop Voltage Up 2.9V Reset off VDD Normal Operation 2.9V Reset off 2.8V Reset on 0V Internal Reset Signal HO1,2 LO1,2 Control by input signal Control by input signal PCCO Control by CRESET Control by CRESET *1:Timing charts may be simplified for explanatory purpose. (5-2) Over Temperature Detection TB9057FG build-in CHIP Temperature Detection circuit. When CHIP Temp. is over 170 ℃ , Diagnosis signals change to PIN”DG1”=”H”, ”DG2”=”H”. But, Pre-Driver Output keeps normal operation signal. When CHIP Temperature is dropped to lower than 160 ℃, Diagnosis signals return to PIN”DG1”=”H”, ”DG2”=”L”. 170℃ Temp. Over Temp. detection Over Temp. reset 160℃ DG1 DG2 Control by input signal HO1 or HO2 LO1 or LO2 Control by input signal *1:The Absolute maximum Temperature of TB9057FG is 150℃. This Over Temperature Detection function does not intend to limit the CHIP temperature. Thus, the above Absolute Maximum Temperature never is over to use TB9057FG. If any of these rating would be exceeded during operation, the device electrical characteristics may be irreparably altered and the reliability and lifetime of the device can no longer be guaranteed. Moreover, these operations with exceeded ratings may cause break down, damage and/or degradation to any other equipment. Applications using the device should be designed such that each maximum rating will never be exceeded in any operating conditions. Before using, creating and/or producing designs, refer to and comply with the precautions and conditions set forth in this documents. This Over Temp. Detection is worded over the Max. Rating Temperature and shipping test does not perform at the Max. Rating Temp. 10 TB9057FG (5-3) Short Detection TB9057FG build-in MOSFET Short Detection and MOTOR Short detection by monitoring voltage of Source PIN and Drain PIn of external Driver. If detected Short, Diagnosis signals change to PIN”DG1”=”L”, ”DG2”=”H”. And when release Short detection, Diagnosis signals return to PIN”DG1”=”H”, ”DG2”=”L”. During Short Detection(“DG1”=”L” and “DG2”=H), the Output of Pre-Driver (PIN”HO1”,”HO2” “LO1”,” LO2”) are decided by PIN”SEL” setting. When PIN”SEL”=”L”, all of Pre-Driver are “L” during Short Detection. When PIN”SEL”=”H”, Pre-Driver keeps normal operation during. Short Detection circuit has filter to prevent miss-detecion by noise. This Filtering time is decided by external connection of PIN”IN5”. In addition, even if PIN”ENA”=”L” and inputed inhibit logic, Short Detection cirsuit operate normally. ENA IN5 VCC5A1 IN4 IN3 IN2 IN1 PD1 PD2 Pre-Dr VCC5A2 Pre-Dr SO2 Pre-Dr Pre-Dr HREF + Battery SO1 Bias Circuit HO1 DR1 COMP4 + HO2 COMP3 To Error Logic Circuit Filter (Filter time is selectable) - DR2 COMP2 + - LO1 COMP1 M LREF + LO2 LS *1:Some of the functional blocks, circuits, or constants in the block diagram may be omitted or simplified for explanatory purpose. *2:If SO voltage become over 18V, there is possible to reverse Error logic output. Comparator Input Comparator output PWM Input Abnormal Phenomenon DR1 > LREF COMP2 = H IN3 = L HO1 external MOSFET Short or Motor Line Short DR2 > LREF COMP1 = H IN4 = L HO2 external MOSFET Short or Motor Line Short DR1 < HREF COMP4 = H IN1 = L LO1 external MOSFET Short or Motor Line Short DR2 < HREF COMP3 = H IN2 = L LO2 external MOSFET Short or Motor Line Short ※HREF = (SO voltage)-(PD1 voltage), LREF = (LS voltage)+(PD2 voltage) < MOSFET Short Detection > ・SEL = Low <Low-side MOSFET Short> ENA <High-side MOSFET Short> ENA Short Detection Off IN1 or IN2 IN1 or IN2 IN3 or IN4 IN3 or IN4 Low-side Short Detection Short Detection Off Hi-side Short Detection DR1 or DR2 DR1 or DR2 Filter time Filter time DG1 DG1 DG2 DG2 Driver Off Driver Off HO1 or HO2 HO1 or HO2 Driver Off Driver Off LO1 or LO2 LO1 or LO2 11 TB9057FG ・SEL = High <Low-side MOSFET Short> ENA <High-side MOSFET Short> ENA Short Detection Off IN1 or IN2 IN1 or IN2 IN3 or IN4 IN3 or IN4 Low-side Short Detection Short Detection Off High-side Short Detection DR1 or DR2 DR1 or DR2 Filter time Filter time DG1 DG1 DG2 DG2 HO1 or HO2 HO1 or HO2 LO1 or LO2 LO1 or LO2 < MOTOR Short Detection > SEL = Low ENA SEL = High ENA Short Detection Off IN1 or IN2 IN1 or IN2 IN3 or IN4 IN3 or IN4 MOTOR Short Detection Short Detection Off MOTOR Short Detection DR1 or DR2 DR1 or DR2 Filter time Filter time DG1 DG1 DG2 DG2 Driver Off HO1 or HO2 HO1 or HO2 Driver Off LO1 or LO2 LO1 or LO2 *1:Timing charts may be simplified for explanatory purpose. 12 TB9057FG Reference Circuit Diagram Battery + + PCCO PCCD2 PCC2 PCCD1 PCC1 V B1 V B2 + VCC5A2 VCC5A1 5V Reg . PGND1 Charge pump VDD1 SO1 VDD2 VDD under voltage detection + SO2 + HO1 DR1 CRESET HO2 VB under voltage detection DR2 Pre-Driver NC IN1 IN2 IN3 IN4 ENA LO1 LO2 PGND2 MR1 Motor direction detection MR2 MCU M VCC5A2 VCC5A1 Short detection SEL PD2 PD1 LS IN5 TEST1 VCC5A1 TEST2 Current sensor TSD AMPP1 AMP2 DG1 AMP1 AMPM1 Error logic DG2 CS1 AMPP2 AMPM2 CS2 AGND2 AGND1 NC VCC5A2 *1:Some of the functional blocks, circuits, or constants in the block diagram may be omitted or simplified for explanatory purpose. *2: The equivalent circuit diagrams may be simplified or some parts of them may be omitted for explanatory purpose. *3: Timing charts may be simplified for explanatory purpose. *4: Install the product correctly. Otherwise, it may result in break down, damage and/or deterioration to the product or equipment. *5: The application circuits shown in this document are provided for reference purposes only. Especially, a thorough evaluation is required on the phase of mass production design. Toshiba dose not grant the use of any industrial property rights with these examples of application circuits. 13 TB9057FG PACKAGE LQFP48-P-0707-0.50C Unit: mm Weight: 0.186g (typ.) 14 TB9057FG RESTRICTIONS ON PRODUCT USE Toshiba Corporation, and its subsidiaries and affiliates (collectively "TOSHIBA"), reserve the right to make changes to the information in this document, and related hardware, software and systems (collectively "Product") without notice. This document and any information herein may not be reproduced without prior written permission from TOSHIBA. Even with TOSHIBA's written permission, reproduction is permissible only if reproduction is without alteration/omission. Though TOSHIBA works continually to improve Product's quality and reliability, Product can malfunction or fail. Customers are responsible for complying with safety standards and for providing adequate designs and safeguards for their hardware, software and systems which minimize risk and avoid situations in which a malfunction or failure of Product could cause loss of human life, bodily injury or damage to property, including data loss or corruption. Before customers use the Product, create designs including the Product, or incorporate the Product into their own applications, customers must also refer to and comply with (a) the latest versions of all relevant TOSHIBA information, including without limitation, this document, the specifications, the data sheets and application notes for Product and the precautions and conditions set forth in the "TOSHIBA Semiconductor Reliability Handbook" and (b) the instructions for the application with which the Product will be used with or for. Customers are solely responsible for all aspects of their own product design or applications, including but not limited to (a) determining the appropriateness of the use of this Product in such design or applications; (b) evaluating and determining the applicability of any information contained in this document, or in charts, diagrams, programs, algorithms, sample application circuits, or any other referenced documents; and (c) validating all operating parameters for such designs and applications. TOSHIBA ASSUMES NO LIABILITY FOR CUSTOMERS' PRODUCT DESIGN OR APPLICATIONS. PRODUCT IS NEITHER INTENDED NOR WARRANTED FOR USE IN EQUIPMENTS OR SYSTEMS THAT REQUIRE EXTRAORDINARILY HIGH LEVELS OF QUALITY AND/OR RELIABILITY, AND/OR A MALFUNCTION OR FAILURE OF WHICH MAY CAUSE LOSS OF HUMAN LIFE, BODILY INJURY, SERIOUS PROPERTY DAMAGE AND/OR SERIOUS PUBLIC IMPACT ("UNINTENDED USE"). Except for specific applications as expressly stated in this document, Unintended Use includes, without limitation, equipment used in nuclear facilities, equipment used in the aerospace industry, medical equipment, equipment used for automobiles, trains, ships and other transportation, traffic signaling equipment, equipment used to control combustions or explosions, safety devices, elevators and escalators, devices related to electric power, and equipment used in finance-related fields. IF YOU USE PRODUCT FOR UNINTENDED USE, TOSHIBA ASSUMES NO LIABILITY FOR PRODUCT. For details, please contact your TOSHIBA sales representative. Do not disassemble, analyze, reverse-engineer, alter, modify, translate or copy Product, whether in whole or in part. Product shall not be used for or incorporated into any products or systems whose manufacture, use, or sale is prohibited under any applicable laws or regulations. The information contained herein is presented only as guidance for Product use. No responsibility is assumed by TOSHIBA for any infringement of patents or any other intellectual property rights of third parties that may result from the use of Product. No license to any intellectual property right is granted by this document, whether express or implied, by estoppel or otherwise. ABSENT A WRITTEN SIGNED AGREEMENT, EXCEPT AS PROVIDED IN THE RELEVANT TERMS AND CONDITIONS OF SALE FOR PRODUCT, AND TO THE MAXIMUM EXTENT ALLOWABLE BY LAW, TOSHIBA (1) ASSUMES NO LIABILITY WHATSOEVER, INCLUDING WITHOUT LIMITATION, INDIRECT, CONSEQUENTIAL, SPECIAL, OR INCIDENTAL DAMAGES OR LOSS, INCLUDING WITHOUT LIMITATION, LOSS OF PROFITS, LOSS OF OPPORTUNITIES, BUSINESS INTERRUPTION AND LOSS OF DATA, AND (2) DISCLAIMS ANY AND ALL EXPRESS OR IMPLIED WARRANTIES AND CONDITIONS RELATED TO SALE, USE OF PRODUCT, OR INFORMATION, INCLUDING WARRANTIES OR CONDITIONS OF MERCHANTABILITY, FITNESS FOR A PARTICULAR PURPOSE, ACCURACY OF INFORMATION, OR NONINFRINGEMENT. Do not use or otherwise make available Product or related software or technology for any military purposes, including without limitation, for the design, development, use, stockpiling or manufacturing of nuclear, chemical, or biological weapons or missile technology products (mass destruction weapons). Product and related software and technology may be controlled under the applicable export laws and regulations including, without limitation, the Japanese Foreign Exchange and Foreign Trade Law and the U.S. Export Administration Regulations. Export and re-export of Product or related software or technology are strictly prohibited except in compliance with all applicable export laws and regulations. Please contact your TOSHIBA sales representative for details as to environmental matters such as the RoHS compatibility of Product. Please use Product in compliance with all applicable laws and regulations that regulate the inclusion or use of controlled substances, including without limitation, the EU RoHS Directive. TOSHIBA ASSUMES NO LIABILITY FOR DAMAGES OR LOSSES OCCURRING AS A RESULT OF NONCOMPLIANCE WITH APPLICABLE LAWS AND REGULATIONS. 15