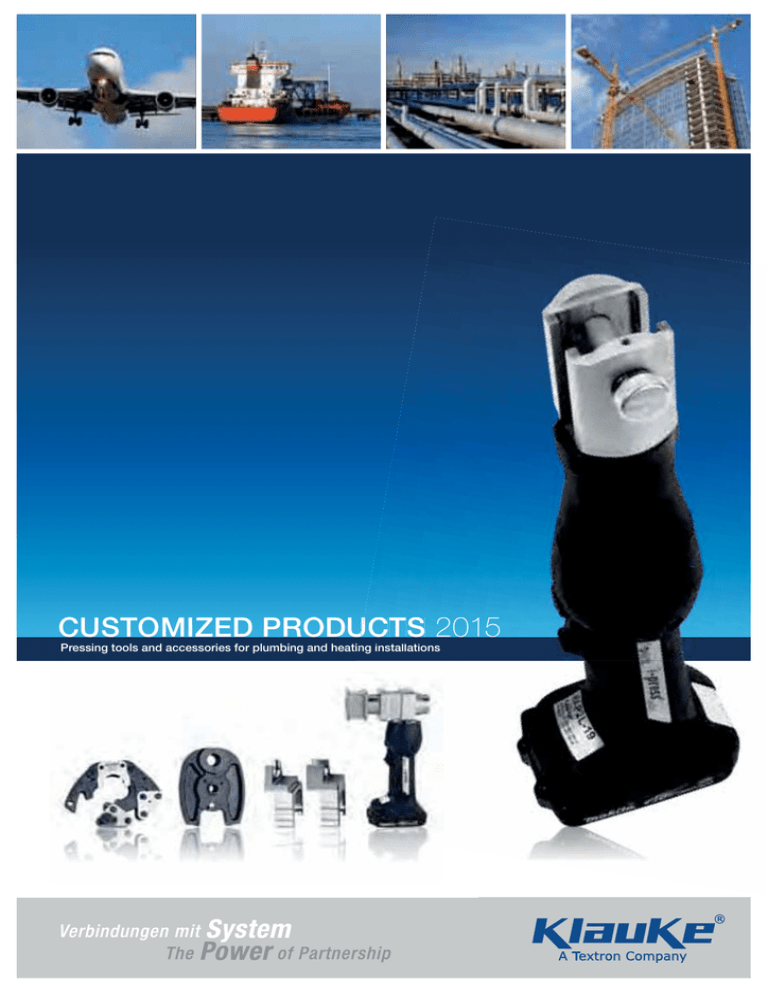

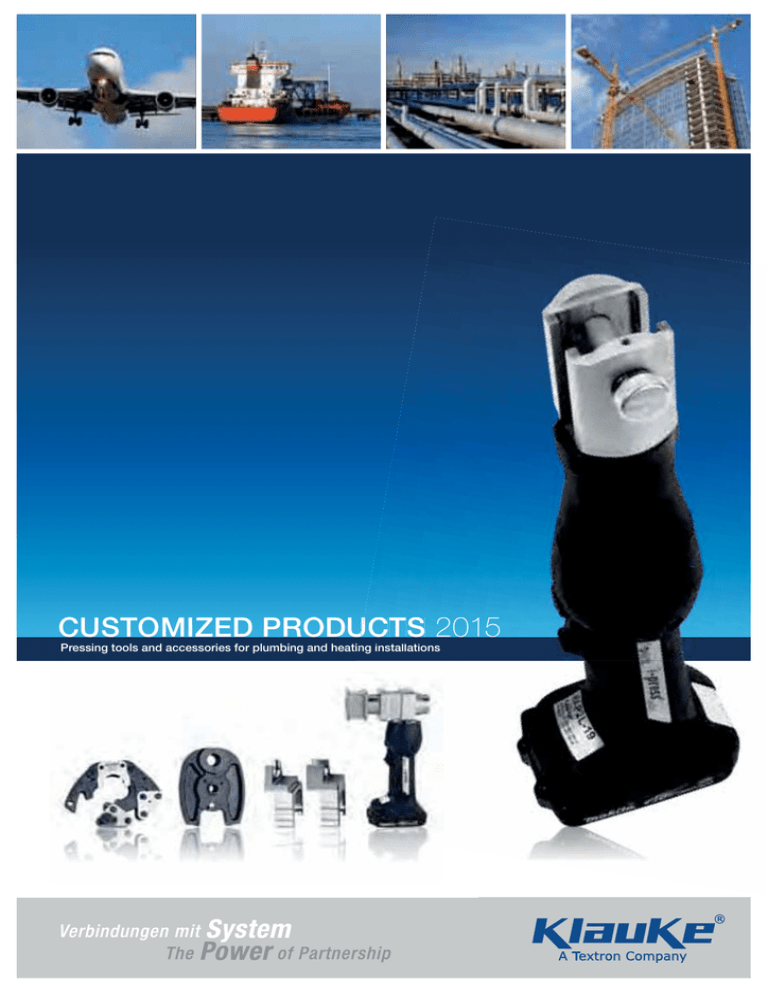

CUSTOMIZED PRODUCTS

UCTS 2015

Pressing tools and accessories for plumbing and heating

ng installations

Contents

About us

4

i-Press

12

Hydraulic pressing tools

16

radial

________16

19 kN___18

______20

UNP2 ___________22

______24

_________26

AHP700LS _______28

Pressing heads ___30

HPU2 ___________32

HPU32 __________34

Pressing profiles __36

Pressing jaws,

Universal pressing jaws,

Interchangeable dies 40

Pressing chains ___46

Quick Click Chains _50

axial

________52

Mechanical pressing tools

56

MP32 ___________56

MP20 ___________57

Accessories

Deburring tools ___58

Battery chargers __58

58

Spare Batteries ___59

Mains units ______61

General

Worlwide Service __62

System partners __64

62

Customized tools__68

Zeichenerklärung

Weight

mm

Dimensions

Pressings per battery

charge

40 min

Charging time

32 NW

15 kN

Li-Ion

2-segment pressing

3-segment pressing

350°

4-segment pressing

Automatic retraction

Audible signal

Nominal size

Quick stop

Hydraulic Pressure Check

Linear thrust

Autostop

Environmentally-friendly

hydraulic oil

Li-Ion battery

2K

2-component housing

NiMH battery

Workplace illumination

Rotating pressing jaw

holder

LED maintenance

indicator

3

At Klauke we have always

been committed to the future.

Familiar with the market for over

130 years

Since being established in 1879, we have been committed to systematically developing and producing innovative,

user-oriented solutions. Our origin lies in the traditions of

tool production in our region; the focus being on watchmaking tools. By the end of the 1950s, we were specialising in cable lugs for the electrical industry and tools for

solderless crimping technology.

Since 1994, we have also been applying our know-how

to plumbing and heating technology and are the world‘s

leading manufacturer of pressing tools.

We meet your requirements backed by our 800-strong

highly trained team. Every year, over 30 hours of training

and development per worker qualify our team to apply rationalisation potentials using SIX SIGMA and Lean Management methodologies.

Our consistent progress is set apart by future-oriented investment in personnel, production, development and service. This guarantees first-class processes, professional

quality and unprecedented customer-satisfaction.

Medium-sized German business meets

global player

The close cooperation with a Group of 32,000 employees

has generated important development impetus for both

our customers and ourselves. As an example, we combine the virtues of a German medium-sized company with

the strengths and global presence of a large corporation.

This enables us to continuously optimise our processes

and product quality, to remain a technological leader and

to operate in future markets. Developing the future has always been our primary objective.

4

Our recipe for success:

Klauke quality for global markets.

For more than 130 years now, „Made in Germany“ has

been a certificate of origin, a claim to quality and the key to

the success of our products. Klauke‘s long and successful history began with pliers production at our headquarters in Remscheid. From that acorn we have continued to

grow. We are now an international organisation.

All over the world, „Made by Klauke“ is synonymous with

outstanding quality products. Of that we are proud.

Worldwide presence with

local solutions

Currently, more than 800 employees develop, produce and distribute the Klauke range from ten locations in Europe and

Asia-Pacific and via Greenlee in North and

South America. Backed by a global distribution network and Authorised Service Centers in over 50 countries,

we are close to our customers and their needs throughout

the world. Allowing us to create local solutions for regional

markets and their special requirements.

5

Solutions for the requirements of

today and tomorrow.

Klauke develops tailored solutions for the trade, commerce and industry. Our comprehensive expertise in the Electrical

Distribution, Automotive Connector Solutions, Customized Tools and Assembly Solutions sectors enables us to meet

the high requirements of our target groups efficiently and to the right quality.

Electrical Distribution

The Klauke and Greenlee brands stand for innovation, safety and

cost-effectiveness in installation technology - unconditionally

and uncompromisingly. Both in electrical connection systems as well as in the case of tools and measuring devices, professional users all over the world trust in our

products and application-orientated solutions.

Klauke:

Electrical connection systems,

crimping, cutting and hand tools

Greenlee: Holemaking tools, cable pulling

technology, test and measurement

instruments

Automotive

Connector Solutions

Klauke develops and produces electrical

connection systems and special tools for the

automotive industry, certified according to ISO/

TS 164494:2009. Our solutions are used, for example, in vehicle electrical systems, engine and

electro mobility concepts. Based on knowledge

and experience attained over decades we incorporate the latest manufacturing processes to produce

special tools.

6

Customized Tools

Our battery hydraulic pressing tools are market leaders for solder

free connections solutions. Furthermore, Klauke‘s professional

pressing and cutting tools provide the technological basis

for customer specific solutions in many fields. In close collaboration with our customers, our tool experts develop

innovative products that eventually lead to production

stage and then manufacturing.

Assembly Solutions

Industrial products often call for customerspecific punched parts, connecting materials,

connectors and pre-assembled cables. Assembly Solutions from Klauke offer specific and

highly-flexible solutions. Due to our in-house design and manufacturing expertise in electrical connection systems, we can also undertake unconventional requirements and small production runs quickly,

reliably and economically.

7

From a single source –

advice, development and production.

As a full-service partner, our customers have been trusting Klauke‘s expertise for advice – development – application

technology – prototyping – production – testing – after-sales for decades. And all that from one source!

Our diversification into several industrial applications has developed a creativity potential, which is the basis of individual innovations. Following project implementation, our customers can continue to concentrate fully and

completely on their core business. We take care of preparatory inspections for certification and

ensure the continuous support of our sales team.

First-class processes of our quality management also quickly made us a partner in the

automotive and aviation sectors.

Advice

1

Our team is very close to the customer and

hence to market developments. We also receive feedback from the worldwide Service

Centers, on the basis of which we realise

innovations and meet market requirements again and again.

1

Individual Development...

2

The broad diversification of Klauke

products in the various industries and

the tight integration with Textron, the

parent company, gives us unparalleled

innovative strength.

The synergies ensuing from the various development teams are used to full

effect, especially for individual product

development.

2

3

...and construction

3

8

Through our prototyping strategy, which is integrated deep

into development, we guarantee our customers short routes in

concept implementation.

After-Sales-Management

Benefit from our extensive range of services.

As a specialist within the Textron group, we are always close

to the action. We react to changes on the international

and local markets immediately, and act together with

our partners.

We recognise the demands and are available at all

times with our know-how as an expert point of

contact.

The Service Center in Remscheid and the

Authorised Service Centers (ASC) offer you

comprehensive worldwide technical support

for our tools.

6

5

6

The latest technology for

optimised quality

4

Besides the carefully selected highquality raw materials and components,

and with due consideration for environmental guidelines, we ensure the highest levels of precision during our manufacturing processes. Use of the latest

methods in manufacture and logistics guarantees an optimised value creation process. This ensures high quality, low costs

and high availability.

5

Application technology and test

laboratories

You are always well advised with our proprietary application

technology and test laboratories. We are able to carry out countryspecific preliminary tests for system providers.

4

9

The solution for

your application.

The focus is very much on the system concept. The Klauke range has the right pressing tool in its range for your

fitting. The result is pressing jaws, dies and mechanical

and hydraulic tools that are matched to the fitting.

From the requirement to the product

System development starts by exchanging information

with the users. Our engineers use their requirements and

needs to create new, future-facing products and solutions.

They make day-to-day activities simpler, safer and more

efficient, exceeding expectations for performance, convenience and cost-effectiveness.

AHP 700-L: Systematic innovation

An example par excellence of system integration is the

AHP 700-LS, the battery powered drive unit for pressing.

Compatible with all Klauke presing heads on the one hand,

and on the other, based on the same 18V Li-Ion technology as the battery powered tools of the i-press generation.

The integrated pressure sensor determines the oil pressure required for each pressing operation. The Hydraulic

Pressure Check - HPC for short - reports any deviations to

the user immediately via visual and audible signals.

The identical batteries, the optional NG2 power supply and

the diagnostics facility via USB adapter and I-press analysis software increase flexibility in practical use. The crossmodel use of important technologies is part of Klauke‘s

system concept: Everything matches, for improved safety

and efficiency in day-to-day use.

10

Tools need service and

users need advice.

In workaday life, Klauke pressing and cutting tools are exposed to hot and cold temperatures and fouling from the

harsh conditions prevailing on construction sites.

Sometimes it rains, sometimes the sun burns down and

dust is often widespread - a durability test for our tools.

As with all high-tech solutions, they must therefore be inspected on a regular basis and serviced from time to time.

Worldwide service you can rely on

With an unbeatable technical maintenance and repair service, our company Service Centers along with the Service

Centers (ASC) that are authorised worldwide ensure that

Klauke tools retain their full functionality and guarantee reliable connections.

Services range from regular tool inspection to service and

repair work.

▸ Worldwide repair and maintenance service through

over 50 authorised Service Centers (Klauke ASC).

11

Intelligent solutions for efficient

pressing technology.

The innovative

pressing tools maximise quality

and reliability in use. The integrated intelligent electronics

provide support when crimping. This generation of tools is

technically and ergonomically state-of-the-art at all times.

12

Optimum ergonomics

and convenience

▸ Comfortable and secure grip, no slipping or pressure

points around the hand thanks to the 2-component

plastic housing

▸ Uninterrupted and effortless working – even when continuously assembling overhead – enabled by optimised

position of centre of gravity

Targeted illumination

▸ Integrated work area illumination of the

tools

for accurate detection of pressing location and safe

work

▸ Optimum illumination, safety and efficiency with low

power consumption thanks to LED light

Precision pressing with

Hydraulic Pressure Check

▸ Consistent quality pressings through controlled oil

pressure in the oil circuit with Hydraulic Pressure

Check (HPC)

▸ Optimised safety during use through continuous monitoring of the pressing pressure reached via a pressure

sensor

▸ Visual and audible warning signal on deviation from the

specified working pressure allows faulty pressings to

be detected immediately

▸ Additional protection from faulty pressings

13

Motor stop as required

during and after use

▸ „Quickstop“ permits an immediate shut-down of

device after releasing the power button, and hence a

fast reaction, for example with incorrect use of fittings

or pressing jaws

▸ The automatic switch off „Autostop“ after pressing

signals the end of the pressing process to the user,

reduces tool wear and increases the battery life

Optimum use of the

electronic control

▸ The construction site-compliant, robust electronics of

the tool gives the user all important information at a

glance

▸ The device status can be seen instantly via a light

diode or an audible signal: Remaining battery power at

20%, service message and pressure deviation

▸ All key data are electronically recorded by the devices: Information such as year of manufacture, serial

number, revision status of the integrated machine

parts, as well as number of pressing cycles allows the

Klauke Service Centers to provide the best possible

maintenance

Sustainable synthetic

oils to protect the

environment and sustain

quality

▸ The use of biologically degradable, water conserving

hydraulic oils meets the most stringent standards

14

MAP2L19

18 V/1.5 Ah with constant thrust

for system-related nominal sizes to

40 mm

from page 18

The world of intelligent pressing technology.

The appropriate battery powered pressing tool for your application:

UAP3L

UAP4L

18 V/3.0 Ah with constant thrust

for system-related nominal sizes to

110 mm

from page 20

18 V/3.0 Ah with constant thrust

for system-related nominal sizes to

110 mm

from page 24

UAP100L

MAPAXL

18 V/3.0 Ah with constant thrust for system-related nominal sizes from 76.1 mm

to 108 mm, PN16 approved

from page 26

18 V/3.0 Ah with constant thrust for

system-related sliding connections to

32 mm

from page 52

15

Pressing tools

Hydraulic

Radial

MAP2L Battery-powered pressing tool 18 V/1,5 Ah, to 32 mm

Flexible and cost-effective

thanks to interchangeable

Klauke Mini pressing jaws

Compact design for

optimum access to the

installation Effortless working

thanks to low weight and

ergonomic design

Tool information shown

via LED display

Secure grip due to innovative 2-component housing

Illumination for

working safely

High-quality, powerful

Makita Li-Ion technology for

lasting, battery-powered

pressing

Very quick pressing thanks to

short pressing cycle of 3-4 seconds

16

Easy 1-handed

operation

Very high safety factor based on

“Quickstop” function

Precise pressing force thanks to HPC

pressure monitoring with audible signal

Pressing tools

Hydraulic

Radial

MAP2L Battery-powered pressing tool 18 V/1.5 Ah to 32 mm

MAP2Lgrp

Scope of supply

`

Very quick pressing thanks to short pressing cycle of 3-4 seconds

`

Extremely short charging time of just 15 minutes (1.5 Ah)

`

Pressing jaws compatible with MAP1 tool

Characteristics

▪ Time saved when multiple pressing by means of automatic piston return

▪ Very high safety factor based on “Quickstop” function

▪ Precise pressing force thanks to HPC pressure monitoring with audible signal

▪ Long battery and tool servicelife thanks to “Autostop” after the pressing operation

▪ Flexible and cost-effective thanks to interchangeable Klauke Mini pressing jaws

▪ Tool information shown via LED display

▪ Illumination for working safely

▪ Compact design for optimum access to the installation

▪ Effortless working thanks to low weight and ergonomic design

▪ Secure grip due to innovative 2-component housing

▪ Easy 1-handed operation

▪ High-quality, powerful Makita Li-Ion technology for lasting, battery-powered pressing

▪ Makita i-press batteries and chargers available worldwide

Suitable for

▪ Stainless steel, steel max. NS22* (NS28 upon request)

▪ Copper, copper alloys: max. NS28*

▪ Multi-layer composite pipe/PEX pipe: max. NS32*

▪ * These values are system-related. Please contact your system supplier for binding

information.

Order info

▪ Country-specific chargers and power packs available. Tool and case available with

customised labelling (optional extra)

Accessories

Technical data

Crimping force

Linear thrust of approx. 15 kN

Number of crimps

1.5 Ah approx. 150 (for NS20) 3.0 Ah approx. 300 (for NS20)

Battery capacity

High-power Makita 1.5 Ah Li-Ion battery (3.0 Ah optional)

Charging time

1.5 Ah 15 min. 3.0 Ah 22 min.

Weight incl. battery

without jaw 1.7 kg incl. jaw 2.3 kg

Dimensions

377 x 75 x 116 mm

Revolving/rotatable

approx. 350° rotating pressing jaw holder

Item

MAP2L Battery-powered pressing tool 18 V/1.5 Ah to 32 mm

Scope of supply

RAL1

Description

Battery 18 V / 1.5 Ah, Li-Ion (27 Wh)

LGL1

Quick-charger for 18V Li-Ion batteries, 230 V

KKMAP2S

Rigid plastic case

Accessories

SBM

Description

Pressing jaw Mini

Part No.

MAP2L

Page

59

58

Page

41

UWM32N

Universal jaw Mini for interchangeable dies, Size 2

41

WE 2

Interchangeable dies, Size 2 for univ.-interchang. jaw Standard for

universal jaw Mini

44

NG2230

18 V mains adapter for 230 V Voltage

61

RAL2

Battery 18 V / 3.0 Ah, Li-Ion (54 Wh)

59

17

Pressing tools

Hydraulic

Radial

MAP2L19 Battery-powered pressing tool 18 V/1,5 Ah, to 40 mm, 19 kN

Flexible and cost-effective

thanks to interchangeable

Klauke Mini pressing jaws

Compact design for

optimum access to the

installation Effortless working

thanks to low weight and

ergonomic design

Tool information shown

via LED display

Secure grip due to innovative 2-component housing

Illumination for

working safely

High-quality, powerful

Makita Li-Ion technology for

lasting, battery-powered

pressing

Very quick pressing thanks to short pressing

cycle of 3-4 seconds

18

Easy 1-handed

operation

Very high safety factor based on “Quickstop”

function

Precise pressing force thanks to HPC

pressure monitoring with audible signal

Pressing tools

Hydraulic

Radial

MAP2L19 Battery-powered pressing tool 18 V/1.5 Ah to 40 mm

MAP2L19grp

Scope of supply

`

Very quick pressing thanks to short pressing cycle of 3-4 seconds

`

Extremely short charging time of just 15 minutes (1.5 Ah)

Characteristics

▪ Time saved when multiple pressing by means of automatic piston return

▪ Very high safety factor based on “Quickstop” function

▪ Precise pressing force thanks to HPC pressure monitoring with audible signal

▪ Long battery and tool servicelife thanks to “Autostop” after the pressing operation

▪ Flexible and cost-effective thanks to interchangeable Klauke Mini pressing jaws

▪ Tool information shown via LED display

▪ Illumination for working safely

▪ Compact design for optimum access to the installation

▪ Effortless working thanks to low weight and ergonomic design

▪ Secure grip due to innovative 2-component housing

▪ Easy 1-handed operation

▪ High-quality, powerful Makita Li-Ion technology for lasting, battery-powered pressing

▪ Makita i-press batteries and chargers available worldwide

Suitable for

▪ Stainless steel, steel max. NS35*

▪ Copper, copper alloys: max. NS35*

▪ Multi-layer composite pipe/PEX pipe: max. NS40*

▪ * These values are system-related. Please contact your system supplier for binding

information.

Order info

▪ Country-specific chargers and power packs available. Tool and case available with

customised labelling (optional extra)

Accessories

Technical data

Crimping force

Linear thrust of approx. 19 kN

Number of crimps

1.5 Ah approx. 150 (for NS20) 3.0 Ah approx. 300 (for NS20)

Battery capacity

High-power Makita 1.5 Ah Li-Ion battery (3.0 Ah optional)

Charging time

1.5 Ah 15 min. 3.0 Ah 22 min.

Weight incl. battery

without jaw 1.8 kg incl. jaw 3.1 kg

Dimensions

370 x 75 x 116 mm

Revolving/rotatable

approx. 350° rotating pressing jaw holder

Item

MAP2L Battery-powered pressing tool 18 V/1.5 Ah to 32 mm

Part No.

MAP2L19

Scope of supply

RAL1

Description

Battery 18 V / 1.5 Ah, Li-Ion (27 Wh)

Page

59

LGL1

Quick-charger for 18V Li-Ion batteries, 230 V

KKMAP2S

Rigid plastic case

Accessories

SBMX

Description

Pressing jaw Mini

RAL2

Battery 18 V / 3.0 Ah, Li-Ion (54 Wh)

59

NG2230

18 V mains adapter for 230 V Voltage

61

58

Page

42

19

Pressing tools

Hydraulic

Radial

UAP3L Battery-powered pressing tool 18 V/3,0 Ah, to 110 mm

Flexible and costcosteffective thanks

to interchangeable

standard pressing jaws

Effortless working

thanks to low weight

and ergonomic design

Illumination for

working safely

Tool information shown

via LED display

High-quality, powerful

Makita Li-Ion technology

for lasting,

battery-powered pressing

Easy 1-handed

operation Secure grip

due to innovative

2-component housing

Very high safety factor based on

“Quickstop” function

20

Quick pressing due to short pressing cycle

Precise pressing force thanks to HPC

pressure monitoring with audible signal

Pressing tools

Hydraulic

Radial

UAP3L Battery-powered pressing tool 18 V/3.0 Ah to 110 mm

UAP3Lgrp

Scope of supply

`

Quick pressing due to short pressing cycle of 3-4 seconds

`

Extremely short charging time of just 22 minutes

Characteristics

▪ Time saved when multiple pressing by means of automatic piston return

▪ Very high safety factor based on “Quickstop” function

▪ Precise pressing force thanks to HPC pressure monitoring with audible signal

▪ Flexible and costeffective thanks to interchangeable standard pressing jaws

▪ Effortless working thanks to low weight and ergonomic design

▪ Secure grip due to innovative 2-component housing

▪ Easy 1-handed operation

▪ High-quality, powerful Makita Li-Ion technology for lasting, battery-powered pressing

▪ Worldwide availability of i- press Makita batteries and chargers

Suitable for

▪ Stainless steel, steel: max. NS54*

▪ Copper, copper alloys: max. NS54/108/4“*

▪ Multi-layer composite pipe max. NS75/110*

▪ PEX pipe: max. NS75*

▪ * These values are system-related. Please contact your system supplier for binding

information.

Order info

▪ Country-specific chargers and power packs available. Tool and case available with

customised labelling (optional extra).

Technical data

Crimping force

Linear thrust of approx. 32 kN

Number of crimps

approx. 300 (for NS20)

Battery capacity

High-power Makita 3.0 Ah Li-Ion battery

Charging time

22 min.

Weight incl. battery

3,5 kg

Dimensions

366 x 81 x 317 mm

Revolving/rotatable

approx. 360° rotating pressing jaw holder

Item

UAP3L Battery-powered pressing tool 18 V/3.0 Ah to 110 mm

Accessories

Part No.

UAP3L

Scope of supply

RAL2

Description

Battery 18 V / 3.0 Ah, Li-Ion (54 Wh)

Page

59

LGL1

Quick-charger for 18V Li-Ion batteries, 230 V

KKUAP3L

Rigid plastic case

Accessories

SB 1

Description

Pressing jaw, Size 1

Page

42

SB 2

Pressing jaw, Size 2

43

SB 3

Pressing jaw, Size 3

43

UW32N

Universal jaw Standard for interchangeable dies, Size 2

44

WE 2

Interchangeable dies, Size 2 for univ.-interchang. jaw Standard for

universal jaw Mini

44

SBS

Axial jaw

45

58

UW63NK

Pressing element for interchangeable dies

51

SSK

Pressing chain SSK

49

QC

Pressing chain SSK

50

SBK4254

Adapter jaw for pressing chains SSK and QC

49

NG2230

18 V mains adapter for 230 V Voltage

61

21

Pressing tools

Hydraulic

Radial

UNP2 Mains operated pressing tool 230 V, to 110 mm

Flexible and cost-effective

thanks to interchangeable

standard pressing jaws

Effortless working

thanks to low weight

Easy 1-handed

Operation

Mains operation with

230 V / 110 V, optional

Quick pressing thanks to short

pressing cycle

22

Time saved when multiple pressing

by means of automatic piston return

High safety factor based on

“Quickstop” function

Pressing tools

Hydraulic

Radial

UNP2 Mains operated pressing tool 230 V to 110 mm

UNP2grp

Scope of supply

`

Quick pressing thanks to short pressing cycle

Characteristics

▪ Time saved when multiple pressing by means of automatic piston return

▪ High safety factor based on “Quickstop” function

▪ Flexible and cost-effective thanks to interchangeable standard pressing jaws

▪ Effortless working thanks to low weight

▪ Easy 1-handed operation

▪ Mains operation with 230 V / 110 V, optional

Suitable for

▪ Stainless steel, steel: max. NS54*

▪ Copper, copper alloys: max. NS54/108/4“*

▪ Multi-layer composite pipe: max. NS75/110*

▪ PEX pipe: max. NS75*

▪ * These values are system-related. Please contact your system supplier for binding

information.

Order info

▪ Tool and case available with customised labelling (optional extra).

Technical data

Crimping force

Linear thrust of approx. 32 kN

Weight

3.5 kg

Dimensions

350 x 81 x 260 mm

Revolving/rotatable

approx. 350° rotating pressing jaw holder

Item

UNP2 Mains operated pressing tool 230 V to 110 mm

Part No.

UNP2

Scope of supply

MKUNP2

Description

Rigid steel case

Page

Accessories

SB 1

Description

Pressing jaw, Size 1

Page

42

SB 2

Pressing jaw, Size 2

43

SB 3

Pressing jaw, Size 3

43

UW32N

Universal jaw Standard for interchangeable dies, Size 2

44

WE 2

Interchangeable dies, Size 2 for univ.-interchang. jaw Standard for

universal jaw Mini

44

SBS

Axial jaw

45

UW63NK

Pressing element for interchangeable dies

51

SSK

Pressing chain SSK

49

QC

Quick-Click-Chain

50

SBK4254

Adapter jaw for pressing chain SSK and QC

49

Accessories

23

Pressing tools

Hydraulic

Radial

UAP4L Battery-powered pressing tool 18 V 3,0 Ah, to 110 mm

Flexible and cost-effective

thanks to interchangeable

standard pressing jaws

Effortless working thanks to

low weight and ergonomic

design

Illumination for

working safely

Tool information shown

via LED display

High-quality, powerful Makita

Li-Ion technology for lasting,

battery-powered pressing

Secure grip due to innovative 2-component housing

Very high safety factor based on

“Quickstop” function

24

Broad application range from NS12 to NS110

(4“) including steel and stainless steel systems

Long battery and tool servicelife thanks to

“Autostop” after the pressing operation

Pressing tools

Hydraulic

Radial

UAP4L Battery-powered pressing tool 18 V 3.0 Ah, to 110 mm

UAP4Lgrp

Scope of supply

`

Extremely short charging time of just 22 minutes

`

Broad application range from NS12 to NS110 (4“) including steel and

stainless steel systems

`

Quick change from pressing jaws to chains with adapter jaw

Characteristics

▪ Time saved when multiple pressing by means of automatic piston return

▪ Very high safety factor based on “Quickstop” function

▪ Precise pressing force thanks to HPC pressure monitoring with audible signal

▪ Long battery and tool servicelife thanks to “Autostop” after the pressing operation

▪ Flexible and cost-effective thanks to interchangeable standard pressing jaws

▪ Tool information shown via LED display

▪ Illumination for working safely

▪ Effortless working thanks to low weight and ergonomic design

▪ Secure grip due to innovative 2-component housing

▪ High-quality, powerful Makita Li-Ion technology for lasting, battery-powered pressing

▪ Makita i-press batteries and chargers available worldwide

Suitable for

▪ Stainless steel, steel: max. NS108 (4“)*

▪ Copper, copper alloys: max. NS108 (4“)*

▪ Multi-layer composite pipe/PEX pipe: max. NS75 (110)*

▪ * These values are system-related. Please contact your system supplier for binding

information.

Order info

▪ Country-specific chargers and power packs available. Tool and case available with

customised labelling (optional extra).

Technical data

Crimping force

Linear thrust of approx. 32 kN

Number of crimps

approx. 300 (for NS20)

Battery capacity

High-power Makita 3.0 Ah Li-Ion battery

Charging time

22 min.

Weight incl. battery

4.3 kg

Dimensions

512 x 81 x 317 mm

Revolving/rotatable

approx. 350° rotating pressing jaw holder

Item

UAP4L Battery-powered pressing tool 18 V 3.0 Ah to 110 mm

Accessories

Part No.

UAP4L

Scope of supply

RAL2

Description

Battery 18 V / 3.0 Ah, Li-Ion (54 Wh)

Page

59

LGL1

Quick-charger for 18V Li-Ion batteries, 230 V

KKUAP4L

Rigid plastic case

NG2230

18 V mains adapter for 230 V Voltage

Accessories

SB 1

Description

Pressing jaw, Size 1

Page

42

SB 2

Pressing jaw, Size 2

43

SB 3

Pressing jaw, Size 3

43

58

61

UW32N

Universal jaw Standard for interchangeable dies, Size 2

44

WE 2

Interchangeable dies, Size 2 for univ.-interchang. jaw Standard for

universal jaw Mini

44

SBS

Axial jaw

45

UW63NK

Pressing element for interchangeable dies

51

SSK

Pressing chain SSK

49

QC

Quick-Click-Chain

50

SBK4254

Adpater jaw for pressing chain SSK and QC

49

BPLP

Pressing chain LP (to 48 bar)

48

SBKUAP4

Adapter jaw for pressing chain LP

48

25

Pressing tools

Hydraulic

Radial

UAP100L Battery-powered pressing tool 18 V/3,0 Ah, from 76,1 mm to 108 mm

PN 16 approved

Reliable pressing chain

adaptation thanks to new

pressing head concept

Comfortable operation

thanks to additional handle

Illumination for

working safely

Tool information shown

via LED display

High-quality, powerful

Makita Li-Ion technology

for lasting battery powered

pressing

Secure grip due to

innovative 2-component

housing

Very high safety factor based on

“Quickstop” function

26

Time saved when multiple pressing by

means of automatic piston return

Precise pressing force thanks to HPC

pressure monitoring with audible signal

Pressing tools

Hydraulic

Radial

UAP100Lgrp

UAP100L Battery-powered pressing tool 18 V/3,0 Ah, from 76,1 mm to 108 mm

Scope of supply

`

Extremely short charging time of just 22 minutes

Characteristics

▪ Time saved when multiple pressing by means of automatic piston return

▪ Very high safety factor based on “Quickstop” function

▪ Precise pressing force thanks to HPC pressure monitoring with audible signal

▪ Long battery and tool service-life thanks to “Autostop” after the pressing operation

▪ Reliable pressing chain adaptation thanks to new pressing head concept

▪ Tool information shown via LED display

▪ Illumination for working safely

▪ Secure grip due to innovative 2-component housing

▪ Comfortable operation thanks to additional handle

▪ High-quality, powerful Makita Li-Ion technology for lasting, battery-powered pressing

▪ Makita i-press batteries and chargers available worldwide

Suitable for

▪ Stainless steel, steel: NS76.1; 88.9; 108; 2.1/2“; 3“, 4“ *

▪ Copper, copper alloys: NS76.1; 88.9; 108; 2.1/2“; 3“, 4“ *

▪ * These values are system-related. Please contact your system supplier for binding

information.

Order info

▪ Country-specific chargers and power packs available. Tool and case available with

customised labelling (optional extra).

Technical data

Crimping force

Linear thrust of approx. 120 kN

Number of crimps

approx. 20 (for NS108)

Battery capacity

High-power Makita 3.0 Ah Li-Ion battery

Charging time

22 min.

Weight incl. battery

12.7 kg

Dimensions

567 x 81 x 359 mm

Item

UAP100L Battery-powered pressing tool 18 V/3.0 Ah from 76.1 mm to 108 mm,

PN16 approved

Scope of supply

RAL2

Description

Battery 18 V / 3.0 Ah, Li-Ion (54 Wh)

LGL1

Quick-charger for 18V Li-Ion batteries, 230 V

MKUAPA4-100L

Rigid sheet steel case

NG2230

18 V mains adapter for 230 V Voltage

Accessories

BP

Description

Pressing chain HP (to 64 bar)

Accessories

Part No.

UAP100L

Page

59

58

61

Page

47

27

Pressing tools

Hydraulic

AHP700LS Battery powered drive unit 700 bar, to 110 mm

High-quality, powerful Makita

Li-Ion technology for lasting,

battery powered pressing

High-capacity motor for

continuous and maximum

working speed

LED for maintenance

control

Large display serves

monitoring operations with

pressure reading and analysis

Shock proof housing made

of fiberglass reinforced

polyamid

Compact and handy

design for independent use

Safe working on scaffolds and ladders

thanks to upholstered carrying belt

28

Remote control for comfortable use

Precise pressing force thanks to HPC

pressure monitoring with audible signal

Pressing tools

Hydraulic

AHP700LS Battery powered drive unit 700 bar, to 110 mm

AHP700LSgrp

Scope of supply

`

High-capacity motor for continous and maximum working speed

`

Compact and handy design for independent use

Characteristics

▪ Time saved when multiple pressing by means of automatic piston return

▪ Precise pressing force thanks to HPC pressure monitoring with audible signal

▪ LED for maintenance control, charge level indicator of batteries and for data

transmission via USB adapter

▪ Compact and handy design for independent use

▪ High-quality powerful Makita Li-Ion technology for lasting, battery powered pressing

▪ Worldwide availability of i-press Makita batteries and chargers

▪ Remote control with cable for easy operation of the battery-operated pump

▪ Shoulder strap with padding for high wearing comfort

▪ Environmentally-friendly hydraulic oil, quickly biodegradable

▪ All high-pressure hoses have coupling plug and coupling sleeve, oil filled To connect

bus bar tool centre

Suitable for

▪ Stainless steel, steel: max. NW108 (4“)*

▪ Copper, copper alloys: max. NW108 (4“)*

▪ Multilayer composite pipe/PEX pipe: max. NW75 (110)*

▪ * These values are system-related. Please contact your system supplier for binding

information.

Order info

▪ Country-specific chargers and power packs available.

Technical data

Battery capacity

High-power Makita 3,0 Ah Li-Ion batteries

Charging time

22 min.

Weight incl. battery

6.4 kg

Dimensions

330 x 160 x 280 mm

Number of crimps

approx. 300 (NS20) / approx 20 (NS 108)

Item

Battery powered drive unit 700 bar for system-related nominal sizes to 110 mm

Scope of supply

RAL2

Description

Battery 18 V / 3.0 Ah, Li-Ion (54 Wh)

LGL1

Quick-charger for 18V Li-Ion batteries, 230 V

TT2

Carrying bag

HTA4

Remote control for hydraulic pump with 1.5 m cable

Part No.

AHP700LS

Amount

2

Page

59

58

HSOEL2

Hydraulic hose, 2m, oil filled

TG3

Carrying strap with shoulder padding

Accessories

PKMAP2

Description

Pressing head PKMAP2

Page

30

PKUAP3

Pressing head PKUAP3

30

PKUAP4

Pressing head PKUAP4

31

PK100

Pressing head PKUAP100

31

PKMAPAX

Pressing head PKMAPAX

HSOEL4

Hydraulic hose, 4m, oil filled

HSOEL6

Hydraulic hose, 6m, oil filled

FTA4

Foot switch for battery powered hydraulic pump AHP 700-L

29

Pressing head

PKMAP2grp

PKMAP2

Pressing head

Scope of supply

Characteristics

▪ Time saved when multiple pressing by means of automatic piston return

Suitable for

▪ Stainless steel, steel: max. NS22* (NS28 on request)

▪ Copper, copper alloys: max. NS28*

▪ Multilayer composite pipe/PEX pipe: max. NS32*

▪ * These values are system related. Please contact your system supplier for binding

information.

Order info

▪ Special dimensions on request.

Accessories

Item

Pressing head PKMAP2

Part No.

PKMAP2

Accessories

SBM

Description

Pressing jaw Mini

Page

41

UWM32N

Universal jaw Mini for interchangeable dies, Size 2

41

WE 2

Interchangeable dies, Size 2 for univ.-interchang. jaw Standard for

universal jaw Mini

44

PKUAP3grp Pressing head

PKUAP3

Scope of supply

Characteristics

Pressing tools

▪ Time saved when multiple pressing by means of automatic piston return

Suitable for

▪ Stainless steel, steel: max. NS54*

▪ Copper, copper alloys: max. NS54/108/4“*

▪ Multilayer composite pipe: max. NS75/110*

▪ PEX pipe: max. NS75*

▪ * These values are system related. Please contact your system supplier for binding

information.

Order info

▪ Special dimensions on request.

Accessories

Item

Pressing head PKUAP3

30

Part No.

PKUAP3

Accessories

SB 1

Description

Pressing jaw, Size 1

Page

42

SB 2

Pressing jaw, Size 2

43

SB 3

Pressing jaw, Size 3

43

UW32N

Universal jaw Standard for interchangeable dies, Size 2

44

WE 2

Interchangeable dies, Size 2 for univ.-interchang. jaw Standard for

universal jaw Mini

44

SBS

Axial jaw

45

UW63NK

Pressing element for interchangeable dies

51

SSK

Pressing chain SSK

49

QC

Quick-Click-Chain

50

SBK4254

Adapter jaw for SSK and QC

49

Pressing tools

Pressing head

PKUAP4 Pressing head

PKUAP4grp

Scope of supply

Characteristics

▪ Time saved when multiple pressing by means of automatic piston return

Suitable for

▪ Stainless steel, steel: max. NS108 (4“)*

▪ Copper, copper alloys: max. NS108 (4“)*

▪ Multilayer composite pipe/PEX pipe: max. NS75 (110)*

▪ * These values are system related. Please contact your system supplier for binding

information.

Order info

▪ Special dimensions on request.

Item

Pressing head PKUAP4

Part No.

PKUAP4

Accessories

SB 1

Description

Pressing jaw, Size 1

Page

42

SB 2

Pressing jaw, Size 2

43

SB 3

Pressing jaw, Size 3

43

UW32N

Universal jaw Standard for interchangeable dies, Size 2

44

WE 2

Interchangeable dies, Size 2 for univ.-interchang. jaw Standard for

universal jaw Mini

44

SBS

Axial jaw

45

UW63NK

Pressing element for interchangeable dies

51

SSK

Pressing chain SSK

49

QC

Quick-Click-Chain

50

SBK4254

Adapter jaw for SSK and QC

49

BPLP

Pressing chain LP (to 48 bar)

48

SBKUAP4

Adapter jaw for pressing chain LP

48

Accessories

PK100 Pressing head

PK100grp

Scope of supply

Characteristics

▪ Time saved when multiple pressing by means of automatic piston return

Suitable for

▪ Stainless steel, steel max. NS76.1; 88.9; 108 2.1/2“; 3“, 4“

▪ Copper, copper alloys max. NS76.1; 88.9; 108 2.1/2“; 3“, 4“

▪ * These values are system related. Please contact your system supplier for binding

information.

Order info

▪ Special dimensions on request.

Item

Pressing head PKUAP100

Accessories

BP

Description

Pressing chain HP (to 64 bar)

Part No.

PK100

Accessories

Page

47

31

Pressing tools

Hydraulic

Radial

HPU2 Manual hydraulic pressing tool to 110 mm

Flexible and cost-effective

thanks to interchangeable

standard pressing jaws

Optimum pump lever

position for all requirements

thanks to approx.

350° rotating head

Compact design thanks to

the integrated oil tank in the

handle

Effortless working thanks to low weight

32

Secure grip due to

ergonomic handles

Quick infeed of the piston due

to 2-stage hydraulics

Forced pressing cycle thanks

to valve control

Pressing tools

Hydraulic

Radial

HPU2 Manual hydraulic pressing tool, to 110 mm

HPU2grp

`

Quick infeed of the piston due to 2-stage hydraulics

`

With manual/hydraulic force transmission, it also meets fire and explosion

protection requirements

Scope of supply

Characteristics

▪ Time saved when multiple pressing by means of automatic piston return

▪ Broad application range from NS12 to NS108 (4“)

▪ Forced pressing cycle thanks to valve control

▪ Flexible and cost-effective thanks to interchangeable standard pressing jaws

▪ Compact design thanks to the integrated oil tank in the handle

▪ Effortless working thanks to low weight

▪ Secure grip due to ergonomic handles

▪ Optimum pump lever position for all requirements thanks to approx. 350° rotating

head

Suitable for

▪ Stainless steel, steel: max. NS54*

▪ Copper, copper alloys: max. NS54/108/4“*

▪ Multi-layer composite pipe: max. NS75/110*

▪ PEX pipe: max. NS75*

▪ * These values are system-related. Please contact your system supplier for binding

information.

Order info

Technical data

Crimping force

Linear thrust of approx. 32 kN

Weight

3.1 kg

Dimensions

500 x 81 x 150 mm

Revolving/rotatable

approx. 350° rotating pressing jaw holder

Accessories

Item

HPU2 Manual hydraulic pressing tool, to 110 mm

Part No.

HPU2

Scope of supply

TT32

Description

Fabric bag

Page

Accessories

SB 1

Description

Pressing jaw, Size 1

Page

42

SB 2

Pressing jaw, Size 2

43

SB 3

Pressing jaw, Size 3

43

UW32N

Universal jaw Standard for interchangeable dies, Size 2

44

WE 2

Interchangeable dies, Size 2 for univ.-interchang. jaw Standard for

universal jaw Mini

44

SBS

Axial jaw

45

UW63NK

Pressing element for interchangeable dies

51

SSK

Pressing chain SSK

49

QC

Quick-Click-Chain

50

SBK4254

Adapter jaw for pressing chain SSK and QC

49

33

Pressing tools

Hydraulic

Radial

HPU32 Manual hydraulic pressing tool to 32 mm

Optimum pump lever

position for all requirements

thanks to approx.

350° rotating head

Flexible and cost-effective

thanks to interchangeable

Klauke Mini pressing jaws

Compact design thanks to

the integrated oil tank in the

handle

For use in tight spaces due

to 55° pump lever opening

34

Secure grip due to

ergonomic handles

Quick infeed of the piston due

to 2-stage hydraulics

Effortless working thanks to low weight

Pressing tools

Hydraulic

Radial

HPU32 Manual hydraulic pressing tool to 32 mm

HPU32grp

`

Quick infeed of the piston due to 2-stage hydraulics

`

With manual/hydraulic force transmission, it also meets fire and explosion

protection requirements

Scope of supply

Characteristics

▪ Time saved when multiple pressing by means of automatic piston return

▪ For use in tight spaces due to 55° pump lever opening

▪ Low force requirement upon pressing

▪ Forced pressing cycle thanks to valve control

▪ Flexible and cost-effective thanks to interchangeable standard pressing jaws

▪ Compact design thanks to the integrated oil tank in the handle

▪ Effortless working thanks to low weight

▪ Secure grip due to ergonomic handles

▪ Optimum pump lever position for all requirements thanks to approx. 350° rotating

head

Suitable for

▪ Stainless steel, steel: max. NS22 (NS28* available on request)

▪ Copper, copper alloys: max. NS28*

▪ Multi-layer composite pipe/PEX pipe: max. NS32*

▪ * These values are system-related. Please contact your system supplier for binding

information.

Order info

Technical data

Crimping force

Linear thrust of approx. 16 kN

Weight

2.7 kg

Dimensions

510 x 60 x 150 mm

Revolving/rotatable

approx. 350° rotating pressing jaw holder

Accessories

Item

Manual hydraulic pressing tool for system-related nominal sizes to 32 mm

Part No.

HPU32

Scope of supply

TT32

Description

Fabric bag

Page

Accessories

SBM

Description

Pressing jaw Mini

Page

41

UWM32N

Universal jaw Mini for interchangeable dies, Size 2

41

WE 2

Interchangeable dies, Size 2 for univ.-interchang. jaw Standard for

universal jaw Mini

44

35

Pressing profiles

The usages for which dimensions, profiles and machine types are relevant can be found

in the application and assembly instructions from the system supplier.

KSP 0

Uponor

Dimension-related for

Pressing jaws

;

Interchangeable dies

Pressing chains

Machine and system-related for

Uponor UNIPIPE

KSP 1

B

Dimension-related for

Pressbacken

;

Interchangeable dies ;

Pressing chains

Machine and system-related for

ALPHATECH

Begetube

KSP 2

Emmeti Gerpex

F.I.V. Fivpress

Fränkische Ibérica

Ivar

Megaro

F

Dimension-related for

Pressbacken

;

Interchangeable dies ;

Pressing chains

Machine and system-related for

Fränkische Rohrwerke

KSP 3

M

alpex-duo

Dimension-related for

Pressbacken

;

Interchangeable dies ;

Pressing chains

;

Machine and system-related for

Airbel Sertinox / Pressclim

AMCO HI-TECH INTERNATIONAL

Aschl

Bonfix

CARO-SUPERSAN Installationstechnik GmbH

Chibro

Comisa

Emcal PRESSO NOX

Esta Simplesta

Eurotubi Europa

Filtube Instalpres

HEBEI GUANGDE STAINLESS

HSF

Inoxpres

Isotubi

KAN

Kohler InoxPres

LK Systems

Lombarda Raccordi InoxPres

Maincor

MARINE EQUIPMENT INT.

KSP 4

V

Oteraccordi

Pegler Yorkshire

Pipelife Austria

Raccorderie Metalliche InoxPres

Sabelita

Seppelfricke GmbH

Simplex

VSH

W&O Supply

Dimension-related for

Pressbacken

;

Interchangeable dies ;

Pressing chains

;

Machine and system-related for

ABM Kupral

Alnoco (SAPA)

AMCO HI-TECH INTERNATIONAL

Comap Sudopress CU

KSP 5

Comisa

Emmeti

Frabo

IBP B-Press

LK Systems B-Press

Megaro

Metallwerke Möllersdorf B-Press

Nibco

Seppelfricke GmbH

Tzanos B-Press

U

Dimension-related for

Pressbacken

;

Interchangeable dies ;

Pressing chains

;

Machine and system-related for

Aquatecnic

BRASS FORM

CO.E.S Coesclima

FAR

Fränkische Rohrwerke

Intermalia

Jupiter Heizsysteme

36

Ke kelit

KISAN

Maincor

Mr. Pex

Multec

Nikkai KMO

Nupi

Pipelife Austria

Polytherm Española

Rifeng

Saneper SaperXPress / Multisaper

SPK INDUSTRIES

TWEETOP

Wavin Trigris K1 + M1

Pressing profiles

The usages for which dimensions, profiles and machine types are relevant can be found

in the application and assembly instructions from the system supplier.

HTH

KSP 6

H

KSP 7

Dimension-related for

Pressbacken

;

Interchangeable dies ;

Pressing chains

Machine and system-related for

Thermtec

Dimension-related for

Pressbacken

;

Interchangeable dies ;

Pressing chains

Machine and system-related for

BRASS FORM

FAR

Friatec

Haka HAKAPRESS

Mair M-Press /Gomafix

Prandelli Multyrama

Simplex

Tzanos

Wefa Plastic WEFATHERM-PRESS

ZHEJIANG SEJIN

HR

KSP 7(A)

THH

KSP 8

TH

KSP 11

Dimension-related for

Pressbacken

;

Interchangeable dies ;

Pressing chains

Machine and system-related for

Roth

Dimension-related for

Pressbacken

;

Interchangeable dies ;

Pressing chains

;

Machine and system-related for

HENCO

NW32-40

Dimension-related for

Pressbacken

;

Interchangeable dies ;

Pressing chains

;

Machine and system-related for

ABM Kupral

APE

Auspex Duopex

Becker Plastics

BRASS FORM

Comap SudoPress Multiskin

COMFORTPRO SYSTEMS

Comisa

Dalpex

Diwa Rohrsysteme

Egoplast

Emcal PRESSO

FAR

Fränkische Ibérica

Fränkische Rohrwerke

Gabo Systemtechnik

General Fittings

Giacomini

Golan

Henco

Herz IPANAPRESS

Industrielle du Plastique & Accessoires

IP Produkter

IPA IPANAPRESS

Kermi X-Press

KISAN

Klimit

LK Systems PressPex

MA.S.TER SYSTEM

Megaro

Nicoll

Nikkai KMO

ONDA MFG.

PB Tub

Pedotherm

Pinto & Cruz

Pipelife Austria

Polysan

Purmo

Rifeng

Rofix

Schlösser EuroPressSystem

Schütz EHT

Seppelfricke SD Sistemi Italia

Seppelfricke GmbH

Sesta

SSt Rolltec

Stelbi

Tiba abit

Tiemme Racorderie Cobrapress

VIESSMANN

Watts MTR

37

Pressing profiles

The usages for which dimensions, profiles and machine types are relevant can be found

in the application and assembly instructions from the system supplier.

KSP 12

HO

Dimension-related for

Pressbacken

;

Interchangeable dies ;

Pressing chains

Machine and system-related for

Oventrop

Cofit-P

KSP 13

Polytherm Polyfix / Polyfix MT

Systerm

WELCOFLEX

ME

Dimension-related for

Pressbacken

;

Interchangeable dies

Pressing chains

Machine and system-related for

Metzerplas

KSP 15

FIL

Dimension-related for

Pressbacken

;

Interchangeable dies

Pressing chains

Machine and system-related for

FG Inox

Filpres

Filtube

Jäger Systemvertrieb

KSP 16

RRB

Dimension-related for

Pressbacken

;

Interchangeable dies

Pressing chains

Machine and system-related for

Rehau

KSP 17(A)

I

Raubasic

Dimension-related for

PPressbacken

;

Interchangeable dies ;

Pressing chains

Machine and system-related for

GALVINS PLUMBING PLUS KSP17A

Iplex

KSP 18

MP

Ken's Plumbing

Dimension-related for

Pressbacken

;

Interchangeable dies

Pressing chains

Machine and system-related for

Poliedra

KSP 19

VAL

Dimension-related for

Pressbacken

;

Interchangeable dies ;

Pressing chains

;

Machine and system-related for

38

BENTONS PLUMBTEC

Valsir

Pexal

Pressing profiles

The usages for which dimensions, profiles and machine types are relevant can be found

in the application and assembly instructions from the system supplier.

KSP 20

RF

Dimension-related for

Pressbacken

;

Interchangeable dies ;

Pressing chains

Machine and system-related for

Blansol / Barbi

Derma Protect + Innovation GmbH

Global Piping System AC-FIX

Ingenieria Plastica del Sur

Intermalia

Saneper

CHE

KSP 24

RRM

KSP 25

PEX

KSP 28 (ABC)

Dimension-related for

Pressbacken

;

Interchangeable dies

Pressing chains

Machine and system-related for

Chemidro

Dimension-related for

Pressbacken

;

Interchangeable dies

Pressing chains

Machine and system-related for

Rehau

Raumulti

Dimension-related for

Pressbacken

;

Interchangeable dies

Pressing chains

Machine and system-related for

Auspex KSP28

DITRON BUTELINE KSP28C

Mr. Pex KSP28B

Nibco KSP28B

PHILMAC KSP28C

Transmatic KSP28A

KSP 33

MA

Dimension-related for

Pressbacken

;

Interchangeable dies

Pressing chains

;

Machine and system-related for

Benkan

Hebei Guangde Stainless/JSL

Samyong

EQJOINT

THA

KSP 35

DB

KSP 36

Dimension-related for

Pressbacken

;

Interchangeable dies

Pressing chains

;

Machine and system-related for

ELSON AUSTRALASIA

Dimension-related for

Pressbacken

;

Interchangeable dies

Pressing chains

;

Machine and system-related for

DASUNG TECH

SEOWON TECHNOLOGY

39

Pressing tools

Pressing jaws, universal jaws, interchangeable dies

Pressing jaws

Klauke pressing jaws with approval from over 150 system suppliers for the applications concerned

Profile coding to verify the

used system pressing jaw

on request

Easy assignment of pressing

jaws and profiles thanks to

coding with nominal size,

profile and production data

Minimum wear thanks

to additional inductionhardening of the wear

points at infeed chamfers

and profile geometry

The additional jaw size

coded on the small face allows the user to pick the jaw

quickly from a full box.

Optimised safety based on the

use of high-resilience tool steel

40

Better corrosion protection

thanks to special surface finish

Compatible with all pressing tools

approved by the system supplier

Pressing profiles

Pressing jaws, universal jaws, interchangeable dies

Pressing jaw Mini

SBMgrp

`

Minimum wear thanks to additional induction-hardening of the wear points

at infeed chamfers and profile geometry

Scope of supply

Characteristics

▪ Easy assignment of pressing jaws and profiles thanks to coding with nominal size,

profile and production data

▪ Compatible with MAP1 und MAP2L

▪ Easy to differentiate between the system-related profiles due to different surface

colours

▪ Better corrosion protection thanks to special surface finish

Suitable for

▪ Stainless steel/steel: max. NS22* (NS28 on request)

▪ Copper/alloys max. NS28*

▪ Multi-layer composite pipe/PEX pipe: max NS32*

▪ * These values are system-related. Please contact your system supplier for binding

information.

Order info

Item

Pressing jaw Mini

Part No.

SBM

Accessories

MAP2L

Description

MAP2L Battery-powered pressing tool 18 V/1.5 Ah to 32 mm

Page

16

HPU32

Manual hydraulic pressing tool for system-related nominal sizes to

32 mm

34

PKMAP2

Pressing head PKMAP2

30

Universal jaw Mini for interchangeable dies, Size 2

UWM32Ngrp

`

Minimum wear thanks to additional induction-hardening of the wear points

at infeed chamfers

Scope of supply

Characteristics

▪ Compatible with MAP1 and MAP2L

▪ Better corrosion protection thanks to special surface finish

Suitable for

▪ Stainless steel/steel(NS28 upon request) max. NS22

▪ Copper/alloys max. NS28

▪ Multi-layer composite pipe/PEX pipe: max. NS32

▪ * These values are system-related. Please contact your system supplier for binding

information.

Order info

Item

Universal jaw Mini for interchangeable dies, Size 2

Part No.

UWM32N

Accessories

MAP2L

Description

MAP2L Battery-powered pressing tool 18 V/1.5 Ah to 32 mm

Page

16

HPU32

Manual hydraulic pressing tool for system-related nominal sizes to

32 mm

34

PKMAP2

Pressing head PKMAP2

30

41

Pressing tools

Pressing jaws, universal jaws, interchangeable dies

SBMXgrp

Pressing

jaw Mini SBMX

Scope of supply

`

Minimum wear thanks to additional induction-hardening of the wear points

at infeed chamfers and profile geometry

`

Enlarged range of application by means of more profile sizes

Characteristics

▪ Easy assignment of pressing jaws and profiles thanks to coding with nominal size,

profile and production data

▪ Compatible with all pressing tools approved by the system supplier

▪ Easy to differentiate between the system-related profiles due to different surface

colours

▪ Better corrosion protection thanks to special surface finish

▪ Optimised safety based on the use of high-resilience tool steel

Suitable for

▪ Stainless steel/steel: max. NS35*

▪ Copper/alloys max. NS35*

▪ Multi-layer composite pipe/PEX pipe: max NS40*

▪ * These values are system-related. Please contact your system supplier for binding

information.

Order info

Item

Pressing jaw Mini

Accessories

MAP2L

SB

1grp

Pressing

Part No.

SBMX

Description

MAP2L Battery-powered pressing tool 18 V/1.5 Ah to 32 mm

Page

18

jaw, Size 1

Scope of supply

`

Minimum wear thanks to additional induction-hardening of the wear points

at infeed chamfers and profile geometry

Characteristics

▪ Easy assignment of pressing jaws and profiles thanks to coding with nominal size,

profile and production data

▪ Compatible with all pressing tools approved by the system supplier

▪ Easy to differentiate between the system-related profiles due to different surface

colours

▪ Better corrosion protection thanks to special surface finish

▪ Optimised safety based on the use of high-resilience tool steel

Suitable for

▪ Stainless steel/steel: max. NS18

▪ Copper/alloys max. NS18

▪ Multi-layer composite pipe/PEX pipe: max NS20

▪ * These values are system-related. Please contact your system supplier for binding

information.

Order info

Item

Pressing jaw, Size 1

42

Part No.

SB 1

Accessories

UAP3L

Description

UAP3L Battery-powered pressing tool 18 V/3.0 Ah to 110 mm

Page

20

UNP2

UNP2 Mains operated pressing tool 230 V to 110 mm

22

HPU2

HPU2 Manual hydraulic pressing tool, to 110 mm

32

PKUAP3

Pressing head PKUAP3

30

UAP4L

UAP4L Battery-powered pressing tool 18 V 3.0 Ah to 110 mm

24

PKUAP4

Pressing head PKUAP4

31

Pressing profiles

Pressing jaws, universal jaws, interchangeable dies

Pressing jaw, Size 2

SB 2grp

`

Minimum wear thanks to additional induction-hardening of the wear points

at infeed chamfers and profile geometry

Scope of supply

Characteristics

▪ Easy assignment of pressing jaws and profiles thanks to coding with nominal size,

profile and production data

▪ Compatible with all pressing tools approved by the system supplier

▪ Easy to differentiate between the system-related profiles due to different surface

colours

▪ Better corrosion protection thanks to special surface finish

▪ Optimised safety based on the use of high-resilience tool steel

Suitable for

▪ Stainless steel/steel: max. NS35

▪ Copper/alloys max. NS35

▪ Multi-layer composite pipe/PEX pipe: max NS40

▪ * These values are system-related. Please contact your system supplier for binding

information.

Order info

Item

Pressing jaw, Size 2

Accessories

UAP3L

UNP2

HPU2

PKUAP3

UAP4L

PKUAP4

Description

UAP3L Battery-powered pressing tool 18 V/3.0 Ah to 110 mm

UNP2 Mains operated pressing tool 230 V to 110 mm

HPU2 Manual hydraulic pressing tool, to 110 mm

Pressing head PKUAP3

UAP4L Battery-powered pressing tool 18 V 3.0 Ah to 110 mm

Pressing head PKUAP4

Part No.

SB 2

Page

20

22

32

30

24

31

SB 3grp

Pressing jaw, Size 3

`

Minimum wear thanks to additional induction-hardening of the wear points

at infeed chamfers and profile geometry

Scope of supply

Characteristics

▪ Easy assignment of pressing jaws and profiles thanks to coding with nominal size,

profile and production data

▪ Compatible with all pressing tools approved by the system supplier

▪ Easy to differentiate between the system-related profiles due to different surface

colours

▪ Better corrosion protection thanks to special surface finish

▪ Optimised safety based on the use of high-resilience tool steel

Suitable for

▪ Stainless steel/steel: max. NS54

▪ Copper/alloys max. NS54

▪ * These values are system-related. Please contact your system supplier for binding

information.

Order info

Item

Pressing jaw, Size 3

Accessories

UAP3L

UNP2

HPU2

PKUAP3

UAP4L

PKUAP4

Description

UAP3L Battery-powered pressing tool 18 V/3.0 Ah to 110 mm

UNP2 Mains operated pressing tool 230 V to 110 mm

HPU2 Manual hydraulic pressing tool, to 110 mm

Pressing head PKUAP3

UAP4L Battery-powered pressing tool 18 V 3.0 Ah to 110 mm

Pressing head PKUAP4

Part No.

SB 3

Page

20

22

32

30

24

31

43

Pressing tools

Pressing jaws, universal jaws, interchangeable dies

UW32Ngrp

Universal

jaw Standard for interchangeable dies, Size 2

Scope of supply

`

Minimum wear thanks to additional induction-hardening of the wear points

at infeed chamfers

Characteristics

▪ Compatible with all pressing tools approved by the system supplier

▪ Better corrosion protection thanks to special surface finish

▪ Optimised safety based on the use of high-resilience tool steel

Interchangeable dies, Size 2

Suitable for

▪ Stainless steel/steel: max. NS22

▪ Copper/alloys: max. NS28

▪ Multi-layer composite pipe/PEX pipe: max. NW32*

▪ * These values are system-related. Please contact your system supplier for binding

information.

Order info

Item

Universal jaw Standard for interchangeable dies, Size 2

WE

1grp

Interchangeable

Scope of supply

Part No.

UW32N

Interchangeable dies, Size 1

WE2

Accessories

UAP3L

Description

UAP3L Battery-powered pressing tool 18 V/3.0 Ah to 110 mm

Page

20

UNP2

UNP2 Mains operated pressing tool 230 V to 110 mm

22

HPU2

HPU2 Manual hydraulic pressing tool, to 110 mm

32

PKUAP3

Pressing head PKUAP3

30

UAP4L

UAP4L Battery-powered pressing tool 18 V 3.0 Ah to 110 mm

24

PKUAP4

Pressing head PKUAP4

31

dies, Size 1

Characteristics

▪ Easy assignment of pressing jaws and profiles thanks to coding with nominal size,

profile and production data

▪ Compatible with MP20

▪ Easy to differentiate between the system-related profiles due to different surface

colours

▪ Better corrosion protection thanks to special surface finish

▪ Optimised safety based on the use of high-resilience tool steel

Suitable for

▪ Multi-layer composite pipe/PEX pipe: max NS20*

▪ * These values are system-related. Please contact your system supplier for binding

information.

Order info

Item

Interchangeable dies, Size 1

Accessories

MP20

44

Description

Manual pressing tool to 20 mm

Part No.

WE 1

Page

57

Pressing profiles

Pressing jaws, universal jaws, interchangeable dies

Interchangeable dies, Size 3

WE 3grp

Characteristics

▪ Easy assignment of pressing jaws and profiles thanks to coding with nominal size,

profile and production data

▪ Compatible with all pressing tools approved by the system supplier

▪ Optimised safety based on the use of high-resilience tool steel

Scope of supply

Suitable for

▪ Stainless steel/steel: max. NS54-2“

▪ Copper/alloys: max. NS54-2“

▪ Multi-layer composite pipe/PEX pipe: max NS63*

▪ * These values are system-related. Please contact your system supplier for binding

information.

Order info

Item

Interchangeable dies, Size 3

Accessories

UW63NK

Description

Pressing element for interchangeable dies

Part No.

WE 3

Page

51

Axial jaw

SBSgrp

`

Minimum wear thanks to additional induction-hardening of the wear points

at infeed chamfers

Scope of supply

Characteristics

▪ Compatible with all pressing tools approved by the system supplier

▪ Better corrosion protection thanks to special surface finish

▪ Optimised safety based on the use of high-resilience tool steel

Suitable for

▪ Multi-layer composite pipe/PEX pipe: max. NS32*

▪ * These values are system-related. Please contact your system supplier for binding

information.

Order info

Item

Axial jaw

Accessories

UAP3L

Part No.

SBS

Description

UAP3L Battery-powered pressing tool 18 V/3.0 Ah to 110 mm

Page

20

UNP2

UNP2 Mains operated pressing tool 230 V to 110 mm

22

HPU2

HPU2 Manual hydraulic pressing tool, to 110 mm

32

PKUAP3

Pressing head PKUAP3

30

UAP4L

UAP4L Battery-powered pressing tool 18 V 3.0 Ah to 110 mm

24

PKUAP4

Pressing head PKUAP4

31

45

Pressing tools

Pressing chains

Pressing chains

Reliable form fit thanks to

forced segment guidance

Solid chain lock allows

strong forces to be

absorbed and prevents

the slipping off the fitting

The pressing chains can be

changed by one person

46

Firm positioning

of the adapter jaw

thanks to optimised design

Simultaneous constriction of the fitting and

deformation of the sealing element thanks

to four-segment technology

I nternational approvals, including for special

system tests with large dimensions

(PN12, 48 bar; PN16, 64 bar)

Pressing tools

Pressing chains

Pressing chain HP (to 64 bar)

BPgrp

Scope of supply

`

Synchronised pressing thanks to four-segment technology

`

Reliable form fit thanks to forced segment guidance

Characteristics

▪ Solid chain lock allows strong forces to be absorbed and prevents the slipping off the

fitting

▪ Firm positioning of the adapter jaw thanks to optimised design

▪ Simple chain changeover even when “working overhead” by separating the chain

from the machine

▪ The pressing chains can be changed by one person

▪ Simultaneous constriction of the fitting and deformation of the sealing element

thanks to foursegment technology

▪ Easy chain removal after the pressing operation due to polished profile surfaces

▪ International approvals, including for special system tests with large dimensions

(PN12, 48 bar; PN16, 64 bar)

Suitable for

▪ Stainless steel/steel: max. NS108 - 4“

▪ Copper/copper alloys: max. NS108 - 4“

▪ Multi-layer composite pipe/PEX pipe: max. NS110

▪ * These values are system-related. Please contact your system supplier for binding

information.

Order info

Item

Pressing chain HP (to 64 bar)

Accessories

UAP100L

Description

UAP100L Battery-powered pressing tool 18 V/3.0 Ah from 76.1 mm

to 108 mm, PN16 approved

PK100

Pressing head PKUAP100

Part No.

BP

Page

26

31

47

Pressing tools

Pressing chains

PressketteLPgrp

Pressing chain

Scope of supply

LP (to 48 bar)

`

Synchronised pressing thanks to four-segment technology

`

Reliable form fit thanks to forced segment guidance

Characteristics

▪ Solid chain lock allows strong forces to be absorbed and prevents the slipping off the

fitting

▪ Firm positioning of the adapter jaw thanks to optimised design

▪ Simple chain changeover even when “working overhead” by separating the chain

from the machine

▪ The pressing chains can be changed by one person

▪ Simultaneous constriction of the fitting and deformation of the sealing element

thanks to foursegment technology

▪ Easy chain removal after the pressing operation due to polished profile surfaces

▪ Optimised safety based on the use of high-resilience tool steel

Accessories

Suitable for

▪ Stainless steel/steel: max. NS108 - 4“

▪ Copper/copper alloys: max. NS108 - 4“

▪ Multi-layer composite pipe/PEX pipe: max. NS110

▪ SBKUAP4 - just compatible with this adapter jaw (to be ordered separately)

▪ * These values are system-related. Please contact your system supplier for binding

information.

Order info

Item

Pressing chain LP (to 48 bar)

48

Part No.

BPLP

Accessories

UAP4L

Description

UAP4L Battery-powered pressing tool 18 V 3.0 Ah to 110 mm

Page

24

PKUAP4

Pressing head PKUAP4

31

SBKUAP4

Adapter jaw for pressing chain LP

48

Pressing tools

Pressing chains

Pressing chain SSK

SSKgrp

Scope of supply

`

Synchronised pressing thanks to 4-segment technology

`

Reliable form fit thanks to forced segment guidance

Characteristics

▪ Solid chain lock allows strong forces to be absorbed and prevents the slipping off the

fitting

▪ Firm positioning of the adapter jaw thanks to optimised design

▪ Simple chain changeover even when “working overhead” by separating the chain

from the machine

▪ The pressing chains can be changed by one person

▪ Simultaneous constriction of the fitting and deformation of the sealing element

thanks to foursegment technology

▪ Easy chain removal after the pressing operation due to polished profile surfaces

▪ Optimised safety based on the use of high-resilience tool steel

▪ Optimum force transmission thanks to the toggle action principle

▪ Profile coding to verify the used system pressing chain on request

Suitable for

▪ Stainless steel/steel: max. NS54 – 2“

▪ Copper/copper alloys: max. NS54 – 2“

▪ Multi-layer composite pipe/PEX pipe: max. NS75

▪ * These values are system-related. Please contact your system supplier for binding

information.

▪ SSK42-54 - just compatible with adapter jaw SBK4254 (to be ordered separately)

Item

Pressing chain SSK

Accessories

UAP3L

Accessories

Part No.

SSK

Description

UAP3L Battery-powered pressing tool 18 V/3.0 Ah to 110 mm

Page

20

UNP2

UNP2 Mains operated pressing tool 230 V to 110 mm

22

HPU2

HPU2 Manual hydraulic pressing tool, to 110 mm

32

PKUAP3

Pressing head PKUAP3

30

UAP4L

UAP4L Battery-powered pressing tool 18 V 3.0 Ah to 110 mm

24

PKUAP4

Pressing head PKUAP4

31

SBK4254

Adapter jaw for pressing chain SSK and QC

49

49

Pressing tools

Pressing chains

QCgrp

Quick-Click-Chain

Scope of supply

QC

`

Easy handling thanks to small weight

`

Optimised safety based on the use of high-resilience tool steel

Characteristics

▪ Firm positioning of the adapter jaw thanks to optimised design

▪ Simple chain changeover even when “working overhead” by separating the chain

from the machine

▪ Easy chain removal after the pressing operation due to polished profile surfaces