Link - Fori Automation

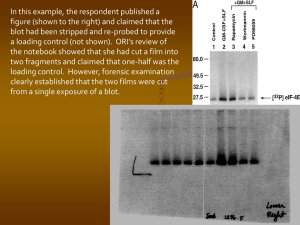

advertisement

www.foriauto.com When Innovation & Performance Count ISO 9001:2000 ISO 14001:2008 Certified Page 1 Volume 5, Number 1 ORI INC. Fori Automation Global Locations Who We Are: Global Design & Builder of Assembly, Welding & Testing Equipment N E WS Our Capabilities: Sales, Engineering (Mechanical / Controls / Software), Manufacturing, Assembly, Full System Integrator & Installation & Service on 5 Continents Global Company Locations in The USA, Mexico, Brazil, Germany, India, China & Korea Fori Automation Newsletter Chassis Marriage with Integrated Module Assembly Fori USA is completing the installation of an engine decking system with integrated front and rear suspension build assembly lines, linked by Fori's twin strand conveyor. A wheel corner build sub assembly line was also installed at the Michigan Assembly Plant in Wayne Michigan. The pallets travel to build stations along the conveyor loop. The pallets are held at each build station by cushioned anti-backup stops until build for that station is complete, and then they are released back on the continuously moving conveyor to travel to the next station. The front module assembly line also incorporates accumulating stops, pallet diverters, and lift and rotate stations to allow both sides of the pallet to be worked on. These conveyor systems streamline the assembly process while feeding the engine decking system. The completed front suspension with the engine pallet is loaded onto the chassis marriage carts by an elevator that transfers the completed pallet to the cart using extending conveyors. Once on the chassis marriage decking cart (further assembly) is completed prior to decking. The 21 carts travel around the marriage loop at variable speeds and through several build stations. When the cart reaches the decking area Fori's patented electric lifts lift the completed chassis to the vehicle body were it is then fastened. The empty engine pallets are offloaded by an elevator where they re-enter the front suspension build conveyor. Aerospace News Update! Fori Automation just secured orders to build AGVs for the Lockheed Martin F35 joint strike fighter assembly line and Bombardier for the CSeries assembly line. All (25) AGVs will be used to move parts of the planes through the assembly process. Look for additional information on our new fleet of high capacity AGVs in future newsletters. ISO 9001:2000 ISO 14001:2008 Certified ITAR Certified Cage Code M20746 Top: Front suspension assembly conveyor. Left: Elevator placing build pallet onto chassis decking cart In This Issue Chassis Marriage / Module Assembly Module Aligners Fuel Tank Strap Weld System Aerospace AGV VW Chassis Marriage System Sun Roof Motor Assembly Lane Departure System 7 Assembly Systems for VW Front & Rear Suspension Systems Ammunition System Upgrades Sun Roof Motor Test Bench Instrument Panel Work Stations Chassis Marriage Upgrade in China End of Line Systems for Geely End of Line Systems for Beijing Hyundai Assembly Plant Rework End of Line Testing 3-D Wheel Aligner with Fender Height Rear Axle Sub Assembly End of Line System for Nissan India Front Corner Assembly System Tire & Wheel Installation Fluid Fill System for Fiat Company Information - 1 2 2 3 4 4 4 5 6 6 7 7 8 8 9 9 9 10 10 10 11 11 11 12 50955 Wing Drive, Shelby Township, Michigan 48315 Phone: 586-247-2336 Option 4 Fax: 586-566-6773 www.foriauto.com When Innovation & Performance Count www.foriauto.com Chrysler Venezuela ISO 9001:2000 ISO 14001:2008 Certified ORI INC. Fori Automation is in the process of the design and build of one (1) front suspension and one (1) rear suspension module aligners for the Chrysler Venezuela assembly plant to produce the new 2011 Jeep Grand Cherokee. The front suspension aligner automatically sets camber and caster, while manually setting toe on the new Jeep Grand Cherokee that will be produced for the South American market. The rear suspension aligner automatically sets toe and camber. The module aligners are similar to the systems provided to Mobis for the 2011 Jeep Grand Cherokee that will be produced at the Jefferson North assembly plant in Detroit, MI. The challenge was to simplify Module Aligner design of the aligners from the Mobis design due to the low production volume rate of 20,000 vehicles annually and reduced model variants. The result is a cost effective aligner that matches the volume and product requirements. Martinrea Fuel Tank Strap Weld Crates Fuel Tank Straps Being Welded Fori Automation USA has designed, built and installed a spot weld system for Martinrea International of Hopkinsville, Kentucky. The system welds nearly every type of fuel tank straps for all of the Ford pickups and SUV's. The two system process is capable of producing endless variants for a total of nearly thirteen million spot welds per year. Some of the unique features are; crate style fixtures which contain four (4) straps at a time, simple effective tool changer, distinguishing part presence laser with vision system and a post end of arm tooling plastic apply station. The laser vision system will improve the overall equipment effectiveness by 5% based on eliminating fixed part present switches on the welding fixtures. This allows the fixture to be simplified with no automated movement. New straps can be added by building new fixtures and programming the laser system to detect part presence as well as manual clamps closed. This allows quick change over for new product production. The state of the art plastic apply station applies all plastic protectors on the painted straps with a unique cam motion. The system also allows for new straps with no additional programming. ORI Page 2 INC. ORI AUTOMATION do BRASIL LTDA ORI INDIA ORI CHINA ORI GERMANY ORI SOUTH AFRICA ORI KOREA LTD ORI AUTOMATION de MÉXICO When Innovation & Performance Count www.foriauto.com ISO 9001:2000 ISO 14001:2008 Certified ORI Spirit Aerosystems INC. Fori Automation has partnered with Brown Aerospace of Port Huron, MI to provide a state of the art automated drill machine for the new Spirit Aerosystem's plant located in Kingston North Carolina. Fori Automation is supplying (2) heavy capacity AGVs which will provide automatic navigation, docking, and leveling for the Brown Aerospace drill machine. These AGVs will be shipped to Brown Aerospace where they will install and integrate their drill machine before shipping to Spirit Aerosystems. Due to the tight drilling tolerances of the aerospace market, each 23,000 lb AGV had to be designed around a strict .03” frame deflection requirement to ensure the drill machine frame did not flex or twist while moving from station to station on the uneven concrete. Additional specifications required that the AGV be capable of leveling to .004 degrees, have no more than .005” deflection after leveling, and that the x/y positioning tolerance of the AGV when docked to the floor bushing at each station be .005”. Utilizing the Fori Automation AGV to transport the drill machine vs. the previous manual method significantly improved efficiency, reduced manpower requirements, and improved cycle time. Fori Automation anticipates just over a 2 minute cycle time from completion of drilling one panel to start of drilling a new panel 8' 6” down the assembly line. Previous manual methods took nearly one day. The Brown Aerospace drill machine is a first of its kind design for the aerospace industry. This 23' tall 18,000 lbs precision drill machine utilizes a curved rail system which mirrors the shape of the fuselage skin. This curved rail system along with a precision linear cross rail system provides precision placement of the drill head. Once in position the machine drills the holes, spot faces, provides sealant, then installs and secures the fasteners into the skin of the fuselage panel. Patented Drive Steer Magnetic Pick-Up Floor Bushing - .005” x-y Accuracy Heavy Duty Suspended Casters with Sweep Brushes Automatically Guided, Auto Decking / Leveling AGV ORI Page 3 INC. ORI AUTOMATION do BRASIL LTDA Servo Leveling Jack with Expanding Arbor High Voltage 312 V control system ORI INDIA ORI CHINA ORI GERMANY ORI SOUTH AFRICA ORI KOREA LTD ORI AUTOMATION de MÉXICO When Innovation & Performance Count www.foriauto.com Volkswagen Bratislava ISO 9001:2000 ISO 14001:2008 Certified ORI GERMANY GmbH Robotic Marriage Fastening Compression Fastening Fori Germany has completed a system upgrade and addition to the chassis marriage line at the Volkswagen Bratislava plant for the Touareg VW726 & Hybrid versions of the Touareg models. The following features were added to the current system; robotic suspension fastening, new hoists, new lift bars, new engine pallets and 48 new nutrunners. Volkswagen The lane departure warning system uses a forward looking camera mounted behind the windshield which is linked to the car controller. Utilizing image recognition software the lane departure system continuously tracks the visible lane markings. The future vehicle position can be estimated using the lines painted on the roadway and some calculations. If the vehicle begins to leave the lane, the system alerts the driver by an audible, visual or tactile signal. This system has been installed in the Volkswagen AG plant in Emden Germany. The rear view camera is mounted on the car boot cover. The driver can see on the screen a live view of the rear part of the vehicle. The system indicates in the display the approximation to an obstacle and warns acoustically by small distances between the car and the obstacle. The Fori Unit provides a reference sample (installed behind the vehicle on the hall floor). The rear view camera takes a picture of the sample, and the calibration is independently Fori Germany calculated in the car controller. has designed Volkswagen Chattanooga and built manipulators f o r t h e Vo l k s w a g e n Chattanooga Tennessee plant for the VW 411 model. The manipulators aid in installing the sun roof. Sun Roof Manipulator ORI Page 4 INC. ORI AUTOMATION do BRASIL LTDA Flip Down Calibration Unit ORI INDIA ORI CHINA ORI GERMANY ORI SOUTH AFRICA ORI KOREA LTD ORI AUTOMATION de MÉXICO When Innovation & Performance Count www.foriauto.com Volkswagen Chattanooga Systems ISO 9001:2000 ISO 14001:2008 Certified ORI GERMANY GmbH Chassis Marriage System demarket. The model is l SliUS Vertitocathe The Volkswagen Group of America is in the process of introducing a new sedan ependent Indmid-size based on the VW411 platform and will be built in a brand new, state of the art assembly facility in Chattanooga, Tennessee. As part of this endeavor, Fori Automation GmbH had successfully earned a contract of substantial size from the Volkswagen Group in Wolfsburg, Germany to build a variety of equipment, tooling and automated systems for this VW assembly plant, which is divided into 7 assembly line segments. Fori Automation is tasked to design, build and integrate state of the art turn-key systems to the very specific VW standards utilizing Siemens Controls System, considering DIN, EN and ISO norms, while meeting OSHA requirements and local electric codes. Although Fori Automation is very familiar with the VW standards, the entire installation system has to be turned over to VW within a very stringent time frame while managing dozens of sub-suppliers located on several continents. This task demands a top level world wide organization like Fori Automation who can leverage experience, innovation, global team work and low cost manufacturing abilities led by the Fori-International Project Management Team. The assembly systems supplied are; Doors off – Doors on, Automatic installation of Roof Dampening Reinforcements or DVD, Tilt/slide Sunroof installation or SAD. VIN stamping and Laser Marking, Gluing, Assembly and Installation, Window Gluing Application, Battery Installation, Front End Assembly and Installation, Wheel Installation, Front- and Rear Seat Installation, TransmissionAGV system and a ChassisAssembly System. ORI Page 5 INC. ORI AUTOMATION do BRASIL LTDA ORI INDIA ORI CHINA ORI GERMANY ORI SOUTH AFRICA ORI KOREA LTD ORI AUTOMATION de MÉXICO When Innovation & Performance Count www.foriauto.com Mobis ISO 9001:2000 ISO 14001:2008 Certified ORI INC. Fori has completed the design, build and installation of a turn key system for Mobis, which supplies the Chrysler Jeep Grand Cherokee. The system comprises of; front suspension assembly, rear suspension assembly, front and rear brake assembly, front coil over shock assembly, rear shock assembly and rear spring systems. All of the sub assembly stations (coil over shock etc.) feed the main lines to streamline the assembly process. The entire system is capable of running 62 jph. The front and rear suspension assembly systems utilized Fori's press style modular aligners. As stated in other Fori news letters, these alignment systems were designed to accommodate many different module sizes and loading means. All the slides were Robotically Loaded (with Manual backup) Module Aligners designed to accommodate all vehicle widths, jounce and rebound parameters. The press style system allows change of the upper and lower platen to accommodate future module types. This system can be orientated to be loaded by operator, robot, pick & place, and conveyor. The aligners are loaded robotically and both the front and rear suspension system utilizes a friction roller low profile conveyor system to convey the production build pallets through the assembly process. This gives the operator freedom to move around the pallet. On the rear line all press operations are integrated into this conveyor system. This makes for less part handling. Fori has also integrated a Wheel Speed Sensor Test station into both the front and rear brake assembly conveyors which perform a pole Front Module Assembly System pitch error test. Systems Alberici / ATK Lake City Fori USA is in the process of building and integrating the mechanical refurbishment of the SCAMP Loading Lines one through four in building 1 on the Lake City Army Ammunition Plant. Line four (4) will be first to be modernized, followed by line three (3), then two (2), then one (1). As a subcontractor, Fori Automation is leading the part supplier coordination, the quality assurance aspect, as well as overseeing the controls and software integration and trouble shooting of the line. These original machines were built decades ago and require refurbishment utilizing very precise machined components along with a state of the art controls system to accommodate for current and future production of NATO round bullets. Refurbishment of 5.56mm NATO bullet assembly machines, assembling 1,200-1,600 bullets per minute each Dual Roll & Brake System line. ORI Page 6 INC. ORI AUTOMATION do BRASIL LTDA ORI INDIA ORI CHINA ORI GERMANY ORI SOUTH AFRICA ORI KOREA LTD ORI AUTOMATION de MÉXICO When Innovation & Performance Count www.foriauto.com ISO 9001:2000 ISO 14001:2008 Certified ORI AUTOMATION de MÉXICO Webasto Fori Mexico designed and installed a sun roof motor assembly test bench for Webasto Mexico for the Volkswagen model 361. The system snaps together the two halves of the motor and inserts a plug into the electrical connector. Each sun roof motor contains a small processor that performs many functions. The processor detects when the sun roof is fully open, partially open and closing force/object detection to avoid injuries. The system will also detect if the sun roof if it is left open when the doors are locked and the engine is not running. This software designed by Fori tests for the correct release level of the sunroof. If the motor passes a bar code label at is automatically printed out and fixed on the motor. If the release level is incorrect the Fori system automatically erases the current motor program and installs the correct program and the test is repeated. Sun Roof Motor Assembly Station Faurecia Fori Mexico completed a system for Faurecia in Puebla Mexico consisting of 13 independent assembly workstations to build the instrument panel for the B299 Ford Focus.Aprinted work order with a bar code is received by each work station. This work order details the model #, color and quantity of parts. Vision cameras are used to verify the correct models, colors and styles are being assembled with the correct parts. After assembly a bar code printer produces a barcode that will be attached to the completed unit. The system supports two color options and four upgrade options at 60 jph and a yearly capacity of 134,500. Assembly Station ORI Page 7 Assembly Station INC. ORI AUTOMATION do BRASIL LTDA ORI INDIA ORI CHINA ORI GERMANY ORI SOUTH AFRICA ORI KOREA LTD ORI AUTOMATION de MÉXICO When Innovation & Performance Count www.foriauto.com ORI CHINA Volkswagen Shanghai Fori China has completed a chassis marriage system u p g r a d e f o r Volkswagen Shanghai CP1 Plant. System improvements included: increase cart speed from 25 jph to 32 jph, new Intermec radio frequency identification system (RFID) and a new front and rear tooling for the Polo and Fabia models. The system was completely installed and running with the 3 week shutdown period, saving Volkswagen S h a n g h a i considerable money. ISO 9001:2000 ISO 14001:2008 Certified Chassis Marriage System Upgrade Geely Huapu Fori China has recently completed the installation of end of line test system at Huapu plant in Shanghai, China. The systems consist of a digital w h e e l a l i g n e r, headlamp aimer, a single axle roll test system, a double axle brake test system and a data link information system. All the systems are capable of running 30 jobs per hour. Wheel Aligner / Headlamp Aimer / Roll Test ORI Page 8 INC. ORI AUTOMATION do BRASIL LTDA ORI INDIA ORI CHINA ORI GERMANY ORI SOUTH AFRICA ORI KOREA LTD ORI AUTOMATION de MÉXICO When Innovation & Performance Count www.foriauto.com ISO 9001:2000 ISO 14001:2008 Certified ORI KOREA Beijing Hyundai Motors LTD Fori Korea has recently completed the installation of end of line test system at Beijing Hyundai Motor Company, China. The systems consist of a wheel aligner, headlamp aimer & a roll and brake testing system capable of running 300,000 units a year. The systems which normally take four (4) months to deliver were delivered in just two (2) months. Fori Korea met this very aggressive delivery by leveraging their existing design knowledge from the two (2) previously installed systems at the same plant. Wheel Aligner / Headlamp Aimer / Roll & Brake Testing System Shanghai Volkswagen Fori Korea recently completed the rework of the assembly shop at Shanghai Volkswagen Nanjing plant 4, China. Fori Korea was initially contracted by SVW to provide an engineering study which included the development of the standard “RFQ” for this project. Included in the RFQ were detailed equipment descriptions and technical specification that met VW strict requirements. This plant will produce a new model VW411CS, Santana B2, and existing model Santana Vista after rework with the line capability of 60 JPH. Furthermore Fori China received the PO for the manufacturing of the entire assembly line. This project will be done another successful story as a cross continent project between Fori Korea and Fori China Mahindra Mahindra Fori Korea is in the process of developing a new green field assembly plant for Mahindra Mahindra in Chakan India to build their newly developed SUV models W201 & U202. Their future plans include introducing one of these new vehicles into the US market. Fori Korea is proud of its ongoing partnership with Mahindra Mahindra in developing complete end of line testing systems that can handle all data management and plant communication. Roll & Brake test System ORI Page 9 INC. ORI AUTOMATION do BRASIL LTDA ORI INDIA ORI CHINA ORI GERMANY ORI SOUTH AFRICA ORI KOREA LTD ORI AUTOMATION de MÉXICO When Innovation & Performance Count www.foriauto.com ISO 9001:2000 ISO 14001:2008 Certified ORI INDIA Ford Chennai Fori Automation India Pvt. Has completed an upgrade for a wheel alignment and headlamp aiming system for Ford India. This updated / reworked system was part of the expansion of the Chennai plant to accommodate the following vehicle models Endeavour, Ikon, Fiesta, Figo & the Fusion with an overall capacity of 150,000 a year. Fori India moved the systems from their original factory in Pune to their new home in Chennai. Several upgrades were installed by Fori India including; new wheelbase adjustment, measuring head risers, fender height measurement using Fori's new 3-D laser modules and automatic X and Y semi-automatic screwdrivers for the headlamp aiming system. Fori Automation Technical News 3-D Wheel Alignment System with Fender Measurement Volkswagen India Fori India supplied an offline rear axle sub assembly system to Volkswagen India with a capacity of 6 jobs per hour for the Polo 250 & 251 vehicle models. This system in Pune India consists of overhead KBK system for loading & unloading, nut runner reaction arms, trolleys with the ability to swivel, aluminum rear axle sub assembly pallets, line side presentation tables and transfer trolleys. Rear Axle Sub Assembly Nissan India Fori India has completed the installation of end of line systems for Nissan Motors of India. The 20 jobs per hour system for the Micra model includes; wheel alignment system, headlamp aiming system, free roll test system, single axle static brake test, audit head lamp aiming test and a smoke meter testing system. All of these systems included special ventilation per Nissan specifications. End of Line System ORI Page 10 INC. ORI AUTOMATION do BRASIL LTDA ORI INDIA ORI CHINA ORI GERMANY ORI SOUTH AFRICA ORI KOREA LTD ORI AUTOMATION de MÉXICO When Innovation & Performance Count www.foriauto.com ISO 9001:2000 ISO 14001:2008 Certified ORI AUTOMATION do BRASIL LTDA GM Rosario Fori Brazil installed a front corner assembly system with a 40 jph rate in the General Motors Rosario plant in Argentina. Utilizing the race track style Fori's twin strand conveyor significantly reduced the required floor space while at the same time reducing man power to run and control the production cells. A poke yoke system ensures the components are placed error free on the pallets which increases performance and product reliability. Fori Automation Featured Product Front Corner Assembly System on a Fori Twin Strand Conveyor GM São Caetano do Sul Fori Brazil completed the installation of a tire & wheel assembly & inflation system for General Motors Brazil in the São Caetano do Sul plant. The system is capable of running a 12 second cycle time which equates to 275 units an hour (55 vehicles with a spare tire) Tires ranged in size from 13” to 17”. The tire & wheel identification is completed automatically using a beam array and vision recognition system. Several combinations of rim diameter, wheel width, tire diameters (outer and inner diameter), tire width and wheel aspect can be set for flexible programming and setup covering up to 30 different combinations. Tire & Wheel / Inflation System Fiat Fori Brazil has completed the design, build and installation of a gear box filling system for Fiat Automoveis at Betim (Brazilian plant). This system includes equipment for 3 different assembly lines that run mineral, synthetic and semi-synthetic oil with new adapters with the ability of faster connection. This system is capable of running 60 jobs per hour. Fluid Flow Adapters ORI Page 11 INC. ORI AUTOMATION do BRASIL LTDA Fluid Fill Controls ORI INDIA ORI CHINA ORI GERMANY ORI SOUTH AFRICA ORI KOREA LTD ORI AUTOMATION de MÉXICO When Innovation & Performance Count www.foriauto.com ISO 9001:2000 ISO 14001:2008 Certified ITAR Certified Mission Statement Cage Code M20746 To provide our customers with sound, imaginative and competitive solutions to their production needs, applying innovative technology in practical ways. To provide rewarding employment with personal growth and educational opportunities for our people, challenging their resourcefulness to find better ways and encouraging them to take ownership; to be enthusiastic team players and to take pride in their accomplishments. To have a performance reputation that allows us to become “The Customer's Choice”. ORI Worldwide Locations ORI CHINA INC. Worldwide Family of Companies ORI GERMANY ORI AUTOMATION do BRASIL LTDA GmbH Fori Company Fori Representative ORI AUTOMATION INDIA ORI KOREA PVT. LTD. ORI AUTOMATION de MÉXICO LTD ORI SOUTH AFRICA Fori Automation inc, Shelby Twp., MI, USA Tel: 586-247-2336 Fax: 586-566-6773 email: sales@foriauto.com Fori Korea Ltd. Sihung-Si, Korea Tel: 82-31-496-3400 Fax: 82-31-431-5280 email: sales@foriauto.com Fori Automation do Brasil São Paulo, Brazil Tel: 55-11-4124-7624 Fax: 55-11-4337-3172 email: sales@foriauto.com Fori Automation GbmH Merzig, Germany Tel: + 49 (0) 6861-70090 Fax: + 49 (0) 6861-7009-310 email: sales@foriauto.com Fori Automation China Beijing, BDA, 100176 China Tel: 86-10-6780-2940 Fax: 86-10-6780-2945 email: sales@foriauto.com Fori Automation India Pune, India Tel: +91-20-6613 5817 / 18 Fax: +91-20-6613 5819 email: sales@foriauto.com Fori Automation de México Saltillo, Coahuila, Mexico Tel: 52-844-416-8918 email: sales@foriauto.com Fori South Africa Primrose, South Africa Tel: +586-247-2336 Fax: + 586-247-6773 email: sales@foriauto.com ORI INC. 50955 Wing Drive, Shelby Township, Michigan 48315 Phone: 586-247-2336 Option 4 Fax: 586-566-6773 www.foriauto.com