Installation Instructions

advertisement

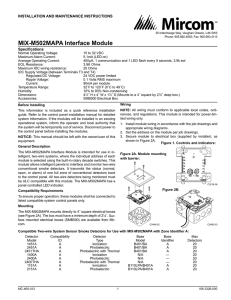

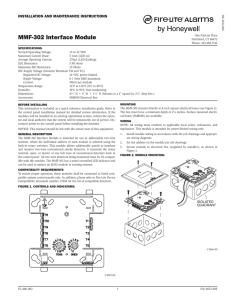

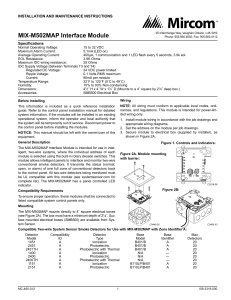

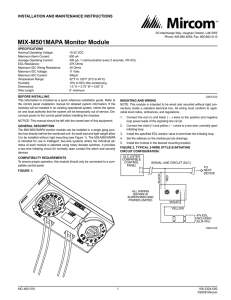

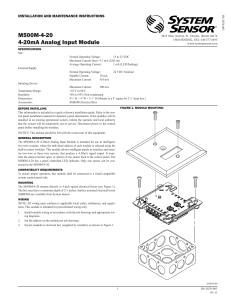

INSTALLATION AND MAINTENANCE INSTRUCTIONS M502MA Two-wire Conventional Detector Interface Module 6581 Kitimat Rd., Unit #6, Mississauga, Ontario, L5N 3T5 1-800-SENSOR2, FAX: 905-812-0771 www.systemsensor.ca Specifications Temperature: 32° to 120° F (0° to 49° C) Humidity: 10% to 93% Noncondensing Weight: .5 lbs (232 g) Dimensions: 41/2" H, 4" W, 11/4" D (Mounts to 4" square by 21/8" deep electrical boxes.) Test Features: Magnetically activated reed switch. Accessories: SMB500 Surface Mount Box for 500 series modules M02-04-00 Test Magnet for testing devices Communication Line – Terminals 1 & 2 Voltage: 15 – 32 VDC Current: 200 µA Max @ 24 VDC, no communication 1.3 mA Max (Style D enabled) 5.1 mA Max 24V (LED latched on) Loop Impedance: 40 Ω Max External Power Supply Requirements – Terminals 3 & 4 Voltage: 17.6 – 28.2 VDC (filtered, regulated, and power-limited) Ripple: 100mV RMS Max Current: 92 mA per module (Power must be interrupted to reset detectors. The interface module must have a minimum of 15 VDC at terminals 3 and 4 to function properly. Ground fault detection must be accomplished by the control panel.) Initiating Device Circuit (IDC) – Terminals 6, 7, 8, & 9 Voltage: 12.5 to 30.3 VDC (Ripple: 100mV RMS Max) Current: 92 mA Max IDC Loop Impedance: 25 Ω Max Standby Current: 10 mA Max @ maximum IDC voltage Detector Current in Standby: Up to 2.4 mA Alarm Current: 20 mA minimum Style: Style B (class B) / Style D (class A) EOL Resistance: 3.9K ohm nominal (Detector loop current is sufficient to ensure operation of one alarmed detector per zone.) Before Installing This information is included as a quick reference installation guide. Refer to the appropriate installation manual for detailed system information. If the modules will be installed in an existing operational system, inform the operator and local authority that the system will be temporarily out of service. Disconnect power to the control panel before installing the modules. NOTICE: This manual should be left with the owner/user of this equipment. General Description The M502MA Interface Module allows intelligent panels to interface and monitor two-wire conventional smoke detectors. All two-wire detectors being monitored must be ULC D500-19-00 REV: 003 compatible with the module. The module is addressed through the communication line of intelligent systems. When the module is interrogated, it transmits the status of one zone of two-wire detectors to an intelligent control panel. Status conditions are reported as normal, open, or alarm. The interface module supervises the zone of detectors and the connection of an external power supply. Two rotary decade switches allow setting module addresses from 00–99. A status LED indicator is provided and is controlled by code command from the control panel. The module provides a magnetically activated test switch for testing the module’s electronics and connections to the control panel (see Figure 1). I56-1051-000 Compatibility Requirements To insure proper operation, this module shall be connected to compatible intelligent ULC listed control panels only. Conventional two-wire smoke detectors must be ULC compatible with the interface module. Figure 1. Module controls and indicators: Package Contents The interface module includes the following items: (1) Two-wire interface module (1) 3.9K ohm end-of-line resistor (A2143-10) (1) Off-white cover plate (1) Screw pack for cover plate Mounting The M502MA Interface Module mounts directly to 4 inch square electrical boxes as shown in Figure 2. The box must have a minimum depth of 2-1/8 inches. Wiring NOTE: All wiring must conform to applicable local codes, ordinances and regulations. When using control modules in nonpower limited applications, the System Sensor CB500 Module Barrier must be used to meet ULC and/or NBC requirements for the separation of power-limited and nonpower-limited terminals and wiring. The barrier must be inserted in a 4"x4"x21 /8" junction box, and the control module must be placed into the barrier and attached to the junction box (Figure 2A). The power-limited wiring must be placed into the isolated quadrant of the module barrier (Figure 2B). STATUS LED 3 2 1 4 5 0 9 6 3 7 2 8 1 4 5 0 9 6 7 8 ROTARY DECADE ADDRESS SWITCHES MAGNET TEST POSITION A78-2318-00 Figure 2A. Mounting module with barrier: 1.Install module wiring in accordance with the job drawings and appropriate wiring diagrams (Figures 3 – 5). 2.Set the address on the module per job drawings. 3.Secure module to electrical box (supplied by installer), as shown in Figure 2A. Testing The M502MA Interface Module can be tested with a test magnet available from System Sensor (M02-04-01- see Figure 1). The magnet test checks the module’s electronics and connections to the control panel. Interfaced two-wire detectors must be tested independently. Test twowire detectors per manufacturer’s installation instructions. A78-2610-00 Figure 2B: ISOLATED� QUADRANT A78-2611-00 D500-19-00 REV: 003 I56-1051-000 M502MA Interface Module Wiring Diagrams Figure 3. Interface two-wire conventional detectors, NFPA Style B: COMMUNICATION LINE 32 VDC MAX. TWISTED PAIR IS RECOMMENDED CONNECT MODULES TO LISTED COMPATIBLE CONTROL PANELS ONLY. FROM PANEL OR PREVIOUS DEVICE (-) (+) (-) (+) TERMINAL WIRING MUST BE POWER LIMITED. TO NEXT DEVICE 2-WIRE CONVENTIONAL DETECTOR INITIATING DEVICE CIRCUIT (IDC) - NFPA STYLE B POWER LIMITED: 92ma MAX; 30.3 VDC MAX IDC INSTALLATION WIRING MUST NOT EXCEED 25 OHMS, 12 - 18 AWG. DO NOT MIX FIRE ALARM INITIATING, SUPERVISORY, OR SECURITY DEVICES ON THE SAME MODULE. MRI-M502M INTERFACE MODULE (-) 9 (-) (+) (-) LISTED BATTERY-BACKUP SWITCHED DC POWER SUPPLY. SEE REQUIREMENTS ON PAGE 3. (+) 1 (-) (+) 8 2 (+) (+) 7 3 (-) (-) 6 4 (+) 5 POWER TO THE INTERFACE MODULE MUST BE EXTERNALLY SWITCHED TO RESET THE DETECTORS. AN MRI-M500CH + + - - 3.9K EOL RESISTOR (INCLUDED) CONTROL MODULE CAN BE USED TO SWITCH POWER FROM A STANDARD POWER SUPPLY - SEE FIGURE 5. DO NOT LOOP WIRE UNDER TERMINALS. BREAK WIRE RUN TO PROVIDE SUPERVISION OF CONNECTIONS. DETECTORS MUST BE UL LISTED COMPATIBLE WITH MODULE. INSTALL DETECTORS PER MANUFACTURER'S INSTALLATION INSTRUCTIONS. OPTIONAL BRANCH CIRCUIT TO NEXT INTERFACE MODULE. MODULE SUPERVISES SUPPLY VOLTAGE AND DETECTOR LOOP. A78-2394-06 Figure 4. Interface two-wire conventional detectors, NFPA Style D: CONNECT MODULES TO LISTED COMPATIBLE CONTROL PANELS ONLY. FROM PANEL OR PREVIOUS DEVICE COMMUNICATION LINE 32 VDC MAX. TWISTED PAIR IS RECOMMENDED (-) (-) (+) (+) TERMINAL WIRING MUST BE POWER LIMITED. TO NEXT DEVICE 2-WIRE CONVENTIONAL DETECTOR INITIATING DEVICE CIRCUIT (IDC) - NFPA STYLE D POWER LIMITED: 92ma MAX; 30.3 VDC MAX IDC INSTALLATION WIRING MUST NOT EXCEED 25 OHMS, 12 - 18 AWG. DO NOT MIX FIRE ALARM INITIATING, SUPERVISORY, OR SECURITY DEVICES ON THE SAME MODULE. MRI-M502M INTERFACE MODULE (-) (+) LISTED BATTERY-BACKUP, SWITCHED DC POWER SUPPLY. SEE REQUIREMENTS ON PAGE 3. (-) (+) (-) 9 1 (-) (-) 8 2 (+) (+) 7 3 (-) (-) 6 4 (+) 5 POWER TO THE INTERFACE MODULE MUST BE EXTERNALLY SWITCHED TO RESET THE DETECTORS. AN MRI-M500CH CONTROL MODULE CAN BE USED TO SWITCH POWER FROM A STANDARD POWER SUPPLY - SEE FIGURE 5. OPTIONAL BRANCH CIRCUIT TO NEXT INTERFACE MODULE. MODULE SUPERVISES SUPPLY VOLTAGE AND DETECTOR LOOP. D500-19-00 REV: 003 3 3.9K EOL RESISTOR REQUIRED AT TERMINALS 8 & 9 (INCLUDED) + + - - DO NOT LOOP WIRE UNDER TERMINALS. BREAK WIRE RUN TO PROVIDE SUPERVISION OF CONNECTIONS. DETECTORS MUST BE UL LISTED COMPATIBLE WITH MODULE. INSTALL DETECTORS PER MANUFACTURER'S INSTALLATION INSTRUCTIONS. A78-2395-07 I56-1051-000 Figure 5. M500C series control module switching a power supply (controls switched 24 VDC external power to M502MA) FROM PANEL OR PREVIOUS DEVICE TERMINAL WIRING MUST BE POWER LIMITED COMMUNICATION LINE 32 VDC MAX. TWISTED PAIR IS RECOMMENDED CONNECT MODULES TO LISTED COMPATIBLE CONTROL PANELS ONLY. (–) (–) (+) (+) TO NEXT DEVICE CONTROL MODULE M500C 9 (–) 1 (–) (+) RELAY CONTACT RATINGS: RESISTIVE: 2 A @ 30 VDC INDUCTIVE: 1 A @ 30 VDC (.6 PF) PILOT DUTY: .6 A @ 30 VDC (.35 PF) .3 A @ 110 VDC (.35 PF) .3 A @ 120 VAC (.35 PF) CONTACTS ARE SHOWN IN STANDBY. CONTACTS MAY HAVE SHIFTED TO ALARM DURING SHIPPING. DO NOT APPLY POWER TO THE CIRCUITS THE MODULE CONTROLS UNTIL THE MODULE IS CONNECTED TO AND ACCEPTED BY THE PANEL. 8 2 (+) 7 3 6 4 5 (+) (–) J1 & J2 BREAK TABS J1 & J2 TO ENABLE FORM 'C' MODE DC POWER SUPPLY, LISTED FOR FIRE PROTECTION WITH BATTERY BACKUP (MONITOR LOSS OF INPUT POWER) SEE REQUIREMENTS ON PAGE 3 SWITCHED RISER CIRCUIT FOR INTERFACE MODULES M500C CONTROL MODULE IS NOT REQUIRED IF SWITCHABLE POWER IS AVAILABLE. (+) (–) A78-2396-06 Three-Year Limited Warranty System Sensor warrants its enclosed module to be free from defects in materials Please include a note describing the malfunction and suspected cause of failure. and workmanship under normal use and service for a period of three years from The Company shall not be obligated to repair or replace units which are found to date of manufacture. System Sensor makes no other express warranty for this be defective because of damage, unreasonable use, modifications, or alterations smoke detector. No agent, representative, dealer, or employee of the Company has occurring after the date of manufacture. In no case shall the Company be liable for the authority to increase or alter the obligations or limitations of this Warranty. The any consequential or incidental damages for breach of this or any other Warranty, Company’s obligation of this Warranty shall be limited to the repair or replacement expressed or implied whatsoever, even if the loss or damage is caused by the Com- of any part of the smoke detector which is found to be defective in materials or work- pany’s negligence or fault. Some legislations do not allow the exclusion or limitation manship under normal use and service during the three year period commencing of incidental or consequential damages, so the above limitation or exclusion may with the date of manufacture. After phoning System Sensor’s toll free number 1- not apply to you. This Warranty gives you specific legal rights, and you may also 800-SENSOR2 (736-7672) for a Return Authorization number, send defective units have other rights under common law. postage prepaid to: System Sensor, Repair Department, RA #__________, 6581 Kitimat Rd., Unit #6, Mississauga, Ontario, L5N 3T5. D500-19-00 REV: 003 4 I56-1051-000 © System Sensor 1997