Category 5, Shielded, Offset, Press Fit,

Modular Jacks with Integrated

Light Emitting Diodes (LED)

NOTE

i

Application Specification

114-- 13179

26 APR 10 Rev D

All numerical values are in metric units [with U.S. customary units in brackets]. Dimensions are in millimeters. Unless

otherwise specified, dimensions have a tolerance of +0.13 and angles have a tolerance of +2_. Figures and

illustrations are for identification only and are not drawn to scale.

1. INTRODUCTION

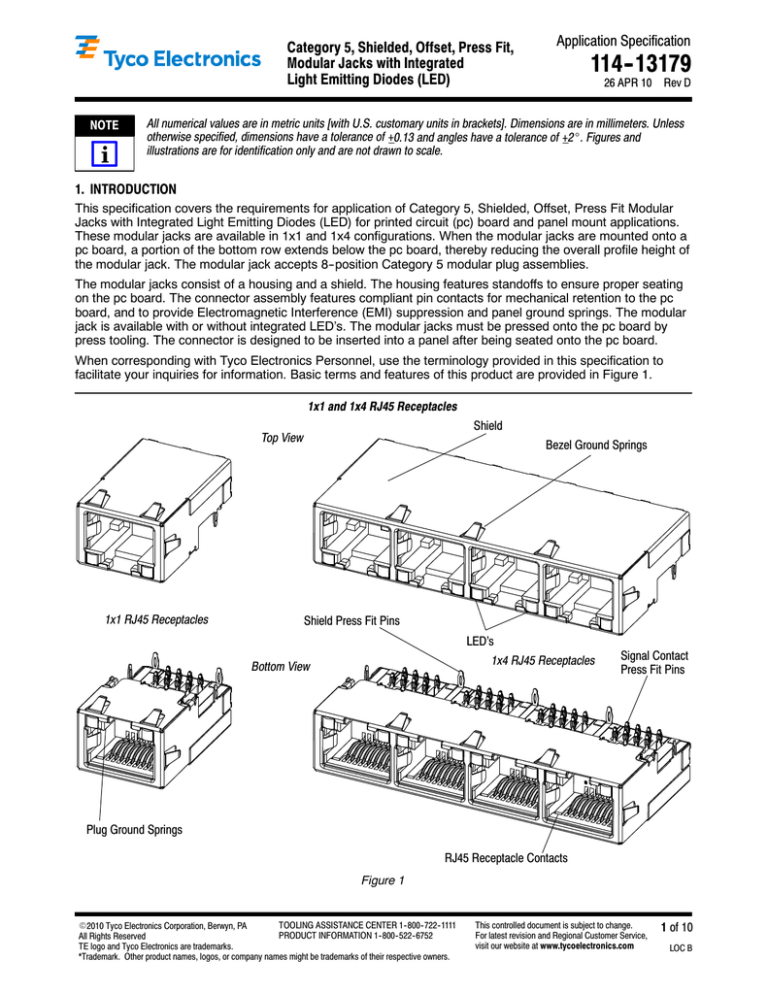

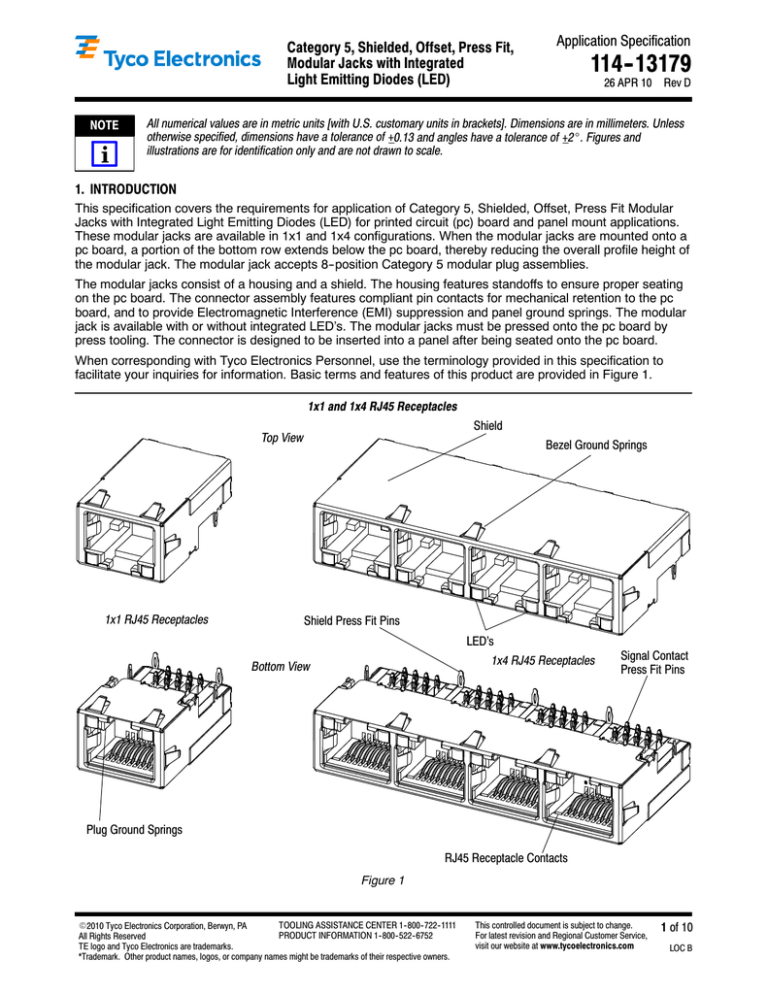

This specification covers the requirements for application of Category 5, Shielded, Offset, Press Fit Modular

Jacks with Integrated Light Emitting Diodes (LED) for printed circuit (pc) board and panel mount applications.

These modular jacks are available in 1x1 and 1x4 configurations. When the modular jacks are mounted onto a

pc board, a portion of the bottom row extends below the pc board, thereby reducing the overall profile height of

the modular jack. The modular jack accepts 8--position Category 5 modular plug assemblies.

The modular jacks consist of a housing and a shield. The housing features standoffs to ensure proper seating

on the pc board. The connector assembly features compliant pin contacts for mechanical retention to the pc

board, and to provide Electromagnetic Interference (EMI) suppression and panel ground springs. The modular

jack is available with or without integrated LED’s. The modular jacks must be pressed onto the pc board by

press tooling. The connector is designed to be inserted into a panel after being seated onto the pc board.

When corresponding with Tyco Electronics Personnel, use the terminology provided in this specification to

facilitate your inquiries for information. Basic terms and features of this product are provided in Figure 1.

1x1 and 1x4 RJ45 Receptacles

Shield

Top View

1x1 RJ45 Receptacles

Bezel Ground Springs

Shield Press Fit Pins

LED’s

1x4 RJ45 Receptacles

Bottom View

Signal Contact

Press Fit Pins

Plug Ground Springs

RJ45 Receptacle Contacts

Figure 1

TOOLING ASSISTANCE CENTER 1-- 800-- 722-- 1111

E2010 Tyco Electronics Corporation, Berwyn, PA

PRODUCT INFORMATION 1-- 800-- 522-- 6752

All Rights Reserved

TE logo and Tyco Electronics are trademarks.

*Trademark. Other product names, logos, or company names might be trademarks of their respective owners.

This controlled document is subject to change.

For latest revision and Regional Customer Service,

visit our website at www.tycoelectronics.com

1 of 10

LOC B

Category 5 Modular Jacks with Integrated LED

114- 13179

2. REFERENCE MATERIAL

2.1. Revision Summary

S Updated document to corporate requirements and new format

S Changed “Design Objective” to “Product Specification” in Paragraph 2.4

S Added new information to table in Figure 3 and corrected leader arrows in Figure 4

2.2. Customer Assistance

Reference Product Base Part Numbers 1888250, 1888251, and Product Code 2239 are representative

numbers of the Category 5, Shielded, Offset, Press Fit, Modular Jacks with Integrated Light Emitting Diodes

(LED). Use of these numbers will identify the product line and expedite your inquiries through a service network

established to help you obtain product and tooling information. Such information can be obtained through a

local Tyco Electronics Representative or, after purchase, by calling the Tooling Assistance Center or the

Product Information numbers at the bottom of page 1.

2.3. Drawings

Customer Drawings for specific products are available from the responsible Tyco Electronics Engineering

Department via the service network. The information contained in the Customer Drawings takes priority if there

is a conflict with this specification or with any other technical documentation supplied by Tyco Electronics.

2.4. Specifications

Product Specification 108--2274 provides product performance and test information.

3. REQUIREMENTS

3.1. Safety

Do not stack component packages so high that the shipping containers can buckle or deform.

3.2. Limitations

The connectors are designed to operate in a temperature range of --40 to 85C [--40 to 185F].

NOTE

i

The panel requirements given in this document are specifically configured for products used in the communications

industry. It is strongly recommended that this panel configuration NOT be used for peripheral component interconnect

(PCI) applications.

3.3. Materials

The front housing is molded from thermoplastic, UL 94--V--0. All jack interface and compliant pin contacts are

made from Phosphor Bronze under plated with nickel, plated with gold or tin at the plug/pc board interface

area. The shells are made from brass plated with nickel.

3.4. Storage

A. Ultraviolet Light

Prolonged exposure to ultraviolet light may deteriorate the chemical composition used in the connector

material.

B. Shelf Life

The connectors should remain in the shipping container until ready for use to prevent deformation to the

compliant pin contacts and mounting posts. The connector should be used on a first in, first out basis to

avoid storage contamination that could adversely affect signal transmission and performance.

C. Chemical Exposure

Do not store connectors or cage assemblies near any chemicals listed below as they may cause stress

corrosion cracking in the compliant pin contacts or mounting posts.

Alkalies

Amines

2 of 10

Ammonia

Carbonates

Citrates

Nitrites

Phosphates Citrates

Sulfides Nitrites

Tyco Electronics Corporation

Sulfur Compounds

Tartrates

Rev D

Category 5 Modular Jacks with Integrated LED

114- 13179

3.5. LED Operation

The LED operation requirements for these modular jacks are provided in Figures 2 and 3.

DESCRIPTION

(Test Condition)

Luminance Intensity, Iv @ 20mA

Viewing Angle

LIGHT PIPE MODULAR JACK

ABSOLUTE MAXIMUM RATING

GREEN

YELLOW

BI-- COLOR

8 Typ (2.6 min)

7 Typ (1.8 min)

5 Typ (1.8 min)

4 Typ (1.6 min)

100

100

100

Lens

With Resistor (250 Ohm)

Forward Voltage, Vf = 20mA

Reverse Voltage

Peak Forward Current

DC Forward Current

Reverse Current, VR = 5V

Operating/Storage Temperature

UNIT

[Iv(mcd)]

Green

No

2.5

Yellow

No

2.5

White Diffused

No

2.5

--V

5

140

25

10

--40 TO 85C

[--40 to 185F]

5

140

25

10

--40 TO 85C

[--40 to 185F]

5

140

25

10

--40 TO 85C

[--40 to 185F]

V

mA

mA

3.6. PC Board

A. Material and Thickness

mA

C

[F]

Figure 2

The pc board material shall be glass epoxy (FR--4 or G--10). The minimum pc board thickness shall be

1.60 +0.16 mm.

NOTE

Contact PRODUCT INFORMATION at the number at the bottom of page 1 for suitability of other pc board materials.

i

B. Tolerance

Maximum allowable bow of the pc board shall be 0.08 mm over the length of the connector.

C. Hole Dimensions

The holes for the connector must be drilled and plated through to dimensions specified in Figure 3. The pc

board holes can withstand modular jack removal up to three times without damage to the plated through

hole.

D. Layout

The holes for the connector must be precisely located to ensure proper placement and optimum

performance of the connector. Recommended hole pattern, dimensions, and tolerances are provided in

Figure 4.

SURFACE FINISH

THICKNESS

PLATING

0.004--0.010

Hot Air Solder Leveling (HASL) Tin--Lead (Sn--Pb)

0.0005--0.004

Immersion Tin (Sn)

0.0002--0.0005

Organic Solderability Preservative (OSP)

0.0001--0.0005 Au; 0.00127--0.0076 Ni

Immersion Gold (Au) Over Nickel (Ni) (ENIG)

0.0001--0.0005

Immersion Silver (Ag)

Figure 3 (cont’d)

Rev D

Tyco Electronics Corporation

3 of 10

Category 5 Modular Jacks with Integrated LED

114- 13179

Recommended Hole Dimensions: LED Contact

1.00 Ref Pad Diameter

Tin-- Lead Plating

0.004-- 0.010

Finished Hole Dia

After Plating 0.55-- 0.65

Copper Thickness 0.025-- 0.050

(Maximum Hardness of Copper

to be 150 Knoop)

0.675-- 0.725

Drilled Hole Dia

Recommended Hole Dimensions: Shield Pins

Tin-- Lead Plating

0.004-- 0.010

1.00-- 1.10 Finished

Hole Dia After Plating

Copper Thickness 0.025-- 0.050

(Maximum Hardness of Copper

to be 150 Knoop)

Drilled Hole Dia

1.125-- 1.175

Recommended Hole Dimensions: Signal Contacts

Tin-- Lead Plating

0.004-- 0.010

0.75-- 0.85 Finished

Hole Dia After Plating

Copper Thickness 0.025-- 0.050

(Maximum Hardness of Copper

to be 150 Knoop)

Drilled Hole Dia

0.875-- 0.925

Figure 3 (end)

4 of 10

Tyco Electronics Corporation

Rev D

Category 5 Modular Jacks with Integrated LED

114- 13179

Recommended PC Board Layout. See Drawing for “Side A” Reference

(AMC PC Board Width Shown)

PC BOARD CUTOUT

Standard Face Plate

AMC Module Face Plate

“D”

11.34

11.50

58

1.05

THRU--HOLE REFERENCE

DESIGNATORS FOR LAYOUT

PURPOSES ONLY

0.05

0.1

A B

FINISHED PTH DIAMETER

5 PLC

13.97

2 PLC

SEE DETAIL H

11.85

--A-6.25

2 PLC

R 0.50

TYP

1.55 REF

ANNULAR RING

TYP

OF DATUM B

D

13.97

3 PLC

20.955

29

60.00

0.10

--B--

73.50

0.1

8

0.10

A B

1.05

0.05

A B

0.1

FINISHED PTH DIAMETER

4 PLC

16.09

6.00

2 PLC

SEE DETAIL H

THRU--HOLE REFERENCE

DESIGNATORS FOR LAYOUT

PURPOSES ONLY

1.55 REF

ANNULAR RING

TYP

11.85

6.25

--A-R 0.50

TYP

D

8.045

2 PLC

18.09

OF DATUM B

0.10

--B--

73.50

0.1

0.10

A B

8

Figure 4 (cont’d)

Rev D

Tyco Electronics Corporation

5 of 10

Category 5 Modular Jacks with Integrated LED

114- 13179

3.556

DETAIL H

2.032

TYP

OF DATUM B

1.016

TYP

0.80

0.05

1.3 REF

ANNULAR RING

TYP

0.1

A B

FINISHED PTH DIA

32 PLC

9.64

7.1

3.8

1.5

0.60

5.58

2 PLC

0.05

4.14

2 PLC

1.1 REF

ANNULAR RING

TYP

0.1

A B

FINISHED PTH DIA 16 PLC

Figure 4 (end)

3.7. Insertion Force

To properly seat the modular jack and avoid damage to any components during seating, the appropriate

insertion force must be used. The minimum force necessary to seat modular jacks with LED’s onto a pc board

with nominal size holes is provided in Figure 5. Insertion force for all other variations must be determined by

using the data stated.

NOTE

i

For example, modular jacks without LED’s would require slightly less insertion force, and modular jacks seated onto pc

boards with minimum size holes would require significantly more insertion force that stated in Figure 5.

MODULAR JACK

MINIMUM INSERTION FORCE (N [lbs-- Force])

(Modular Jacks with LED’s onto PC Board with Nominal Size Holes)

1X1

234 [48]

1X4

707 [159]

Figure 5

3.8. Checking Installed Connector

All contacts, pc board ground pins, and pc board side ground pins (if applicable) must be fully inserted into the

pc board holes. All standoffs must be seated on the pc board not exceeding the dimensions shown in Figure 6.

See customer drawing for additional details.

0.10 Max Standoff

to PC Board

Standoff (Ref)

6 of 10

7.38 Max

Figure 6

Tyco Electronics Corporation

Rev D

Category 5 Modular Jacks with Integrated LED

114- 13179

3.9. Panel Mounting

The panel must be cut using the dimensions provided on the customer drawing for the specific modular jack.

The panel thickness shall be approximately 0.60 mm. A reference sample of a recommended panel cutout for

the modular jack is shown in Figures 7 and 8.

The panel must provide a cutout that allows proper mounting of the connector. The connector panel ground

springs must be compressed by the panel in order to provide an electrical ground between the connector and

the panel for EMI suppression. Care must be used to avoid interference between adjacent connectors and

other components. Dimensions for panel cutout and minimum allowable distance between cutouts are shown in

Figure 8. See the customer drawings for additional details.

--A-11.59

0.25

REF

2.56

REF

0.25

--M--

VIEW SHOWN ASSEMBLED

TO PCB AND RECOMMENDED

STANDARD FACE PLATE

--A-8

2.40

REF

11.75

0.50

0.25

8

0.25

SIDE A

1.60

0.16

8

--M-SIDE B

8

0.50

VIEW SHOWN ASSEMBLED

TO PCB AND RECOMMENDED

AMC MODULE FACE PLATE

Figure 7

Rev D

Tyco Electronics Corporation

7 of 10

Category 5 Modular Jacks with Integrated LED

114- 13179

3.10. PC Board and Panel Position

The panel and pc board must be positioned in relation to each other in order to avoid interference with the

function of the connector panel ground springs. This relationship must conform to the dimensions shown in

Figure 8.

8

--M-7.88

Recommended Panel Cutout

AMC Module Face Plate

13 MIN

2 PLC

16.84

0.10

1.3

2 PLC

12.58

Z

0.10

0.10

8

SECTION Z--Z

R0.65

2 PLC

11.75

Z

73.8 REF

--A--

AMC SINGLE WIDTH, HALF HEIGHT MODULE FACE PLATE

Side view applies to both 1x1 and 1x4

1x1 RJ45 Assembly

Recommended Panel Cutout

Standard Flat Panel

11.59

--M--

0.10

X

12.34

--A--

7.76

16.94

0.65

SECTION X--X

X

STANDARD FACE PLATE

Side view applies to both 1x1 and 1x4

1x1 RJ45 Assembly

Recommended Panel Cutout

1x4 Front View

58.75

58.85

0.10

Z

0.10

X

Z

X

73.8 REF

AMC SINGLE WIDTH, HALF HEIGHT MODULE FACE PLATE

STANDARD FACE PLATE

AMC Module Face Plate

Standard Flat Panel

Figure 8

3.11. Placement

The following requirements also apply to connectors used for rework purposes.

CAUTION

!

Connectors should be handled only by the shield and to avoid deformation, contamination, or damage to the compliant

pin contacts.

A. Registration

The compliant pin contacts must be aligned with matching holes in the pc board, then inserted into the pc

board simultaneously to prevent twisting or bending of the compliant pin contacts. The shield pins will

need to be located first, followed by the signal contacts and then the LED contacts.

8 of 10

Tyco Electronics Corporation

Rev D

Category 5 Modular Jacks with Integrated LED

114- 13179

B. Seating

Using proper seating force and seating height is essential to interconnection performance. The force used

to seat the connector must be applied evenly to prevent deformation or damage to the compliant pin

contacts. The force required to seat the connector onto the pc board can be calculate by:

Number of compliant pins X 22.25 N [5 lbs] (Force per Compliant Pin) = Seating Force

CAUTION

Over--driving of the connector will deform parts critical to the quality of the connection to the pc board. Maximum force

occurs prior to the connector assembly bottoming on the pc board.

!

The shut height of the application tool must be specifically set for proper seating of the connector. The

shut height can be calculated by:

Seating Height (Connector Seated) + Height of Tool + PC Board Thickness + PC Board Support Base

= Shut Height of Ram

The seating height, measured from the top of the connector assembly (not including panel ground springs

or fold over tabs) to the top of the pc board, is given in Figure 6.

The connector assembly must be seated on the pc board not to exceed the dimensions shown in Figure 6.

NOTE

The shut height may be adjusted to obtain the 0.10 mm maximum gap between the standoffs of the connector

assembly and the pc board.

i

3.12. Checking Assembly

After assembly, the panel must compress the connector panel ground springs. A slight bow in the shield is

permitted. The panel and pc board must be positioned according to the dimensions shown in Figure 8.

3.13. Repair/Replacement

These modular jacks are not repairable. Damaged or defective modular jacks MUST NOT be used. Damaged

or defective modular jacks must be removed and replaced. Modular jacks may be removed by standard

desoldering methods. The modular jacks MUST NOT be re--used after being removed from the pc board.

4. QUALIFICATIONS

No qualification documentation is available at the time of publication of this document.

5. TOOLING

5.1. PC Board Support

A pc board support must be used with the seating tool. The support fixture provides proper support for the pc

board and protects the pc board and the connector assembly from damage. The support fixture must be

customer designed. It is recommended that the support fixture be at least 25.4 mm longer and wider than the

pc board and have flat surfaces with holes or channels long enough and deep enough to receive any

protruding components of the connector assembly or customer pc board. See Figure 9.

5.2. Arbor Frame Assembly

Manual arbor frame assemblies are used to exert a downward force used to apply connectors to a pc board

using seating tools. These frame assemblies are commercially available or you may contact Tyco Electronics

Tooling Center at the bottom of page 1. See Figure 9.

PC Board Support

(Customer Supplied)

Arbor Frame Assembly

(Commercially Available or

Contact Tyco Electronics)

Holes

(Ref)

Channel

(Ref)

Rev D

Figure 9

Tyco Electronics Corporation

9 of 10

Category 5 Modular Jacks with Integrated LED

114- 13179

6. VISUAL AID

Figure 10 shows a typical application of a Category 5, Shielded, Offset, Press Fit, Modular Jack with Integrated

Light Emitting Diodes (LED). This illustration should be used by production personnel to ensure a correctly

applied product. Applications which DO NOT appear correct should be inspected using the information in the

preceding pages of this specification and in the instructional material shipped with the product or tooling.

NOTE: 1X4 AMC MODULE FACE PLATE AND CARD SHOWN, 1X1 WOULD HAVE THE SAME REQUIREMENTS

(ASSEMBLY SHOWN IN TAB UP ORIENTATION)

ALL CONTACTS, PC BOARD GROUND

PINS, AND (IF APPLICABLE) LED

CONTACTS MUST BE FULLY INSERTED INTO THE PC BOARD HOLES

PANEL GROUND(S)

MUST TOUCH PANEL

SIDE “A”

SEE FIGURE 4

ALL STANDOFFS MUST BE

VISUALLY SEATED ON THE

PC BOARD (REVERSE SIDE)

THERE MUST BE NO

DAMAGE TO ANY PART

OF THE MODULAR JACK

FIGURE 10.

10 of 10

VISUAL AID

Tyco Electronics Corporation

Rev D