central plaza parking garage

advertisement

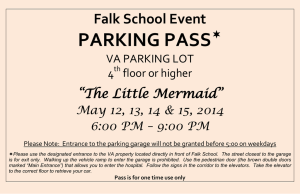

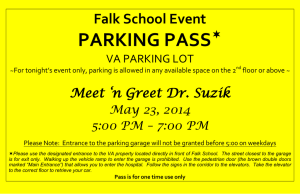

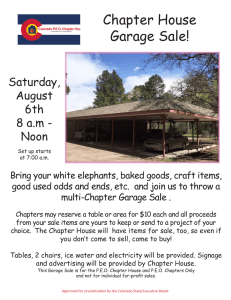

Table Of Contents Category Description Pages CENTRAL PLAZA PARKING GARAGE NE 41ST ST. SEATTLE, WA 98105 FINAL PROPOSAL MAY 10, 2013 CLIENT Month Day Year Table Of Contents Category Description Pages 1 Project Summary Executive Summary Summary of Project and Client Mission Statement Resumes Energy Use Analysis/Retrofit 7 Energy Assessment HVAC Existing Conditions Proposed HVAC Retrofit Lighting Existing Conditions Proposed Lighting Retrofit 10 Lighting Retrofit New System Design Assessment of Space Light Output Fluorescent Lamp Disposal Impacts Table Of Contents Category Description Electrical Vehicle Charging Station Pages 17 Charging Station Analysis Implementation Design Charging Station Savings Summary Alternative Energy Retrofit 21 Ventilation Overview Proposed Ventilation System Renewable Energy Overview Proposed Photovoltaic System Client Image Schematic Estimate and Schedule 26 Schematic Estimate Estimate Breakdown Estimate Schedule Summary Schedule Zoning Plan Project Management Plan Site Layout Safety Plan 31 Table Of Contents Category Description Pages 33 Financing Plan Grants, Rebates and Incentives Lighting Incentives Photovoltaic Incentives EV Charging Station Incentives Financing Strategies Payback Analysis 37 References Outreach Appendix Community Energy Awareness Energy Awareness Plan Feedback & Poster Example Article in University Newsletter Feedback Letter from the Client Local NECA Chapter Interation University of Washington Interaction Appendix A – Alernatives Considered B – Lighting C – EV Charging Station D – PV Energy 120 Architecture Hall | University of Washington | Seattle, WA 98105 Project Summary Executive Summary May 10, 2013 Brian Ho, Parking Facilities and Special Events Manager University of Washington 3745 15th Avenue NE Seattle, WA 98195-5360 Dear Mr. Brian Ho, Husky Electric appreciates the opportunity to present our formal proposal for an energy efficient upgrade of the Central Parking Garage. Our team intends to deliver the project and complete the scope of work in 42 calendar days beginning June 14, 2013, and achieve project completion by August 12, 2013. The initial cost of the project is $423,180. We have identified $227,115 in incentives and rebates that will reduce the cost to the University of Washington to $196,065. Projected annual savings indicate this project will earn a return on investment in 1.7 years. Husky Electric’s scope of work includes: A complete retrofit of the lighting system Installation of electrical vehicle charging stations A ventilation system upgrade Implementation of a photovoltaic energy system Any work within the proposal that is not self-performed will be subcontracted and managed by Husky Electric. Additionally, Husky Electric aims to work with the UW to increase campus energy awareness by involving and improving upon current sustainability efforts. Husky Electric understands UW’s dedication to environmental sustainability without sacrificing the historical integrity of the campus. We are proud to be given the opportunity to assist the UW in this commitment. Our team is confident that our proposal will not only meet your requirements, but also surpass expectations. Husky Electric would like to apply a technical analysis score adjustments as follows: Lighting retrofit proposal x 1.4 Energy Audit/Retrofit Proposal x 1.0 PV and Wind Proposal x 0.6 We look forward to providing the electrical work and solution management for this project. Sincerely, Brandon Burr Project Manager Husky Electric Inc. May 10, 2013 1 120 Architecture Hall | University of Washington | Seattle, WA 98105 Summary of Project and Client The University of Washington has provided Husky Electric with many resources and an excellent opportunity by supporting the NECA Student chapter evaluation of the Central Parking Garage for “The Green Energy Challenge.” Although the Central Parking Garage and the above Red Square are seen as iconic structures on campus, it has potential to meet the rising sustainable standards of the university. Originally constructed in 1972, the Central Parking Garage is a 416,390 sq. ft. underground parking garage located in the center of the campus under other iconic buildings including Meany Hall, Kane Hall, Odegaard Library, and Suzzallo Library. The parking garage features three separate vehicle entrances and a total of 984 parking stalls on three floors. There are four stairs that access Odegaard Library, Kane Hall, Meany Hall, and outside to the west side of the structure. The Central Parking Garage’s outdated electrical systems provide the University of Washington and Husky Electric the opportunity to work together to save money and reduce the university’s energy consumption. Husky Electric has two main points of contact for the retrofit of the Central Parking Garage: Brian Ho, the Parking Facilities and Special Events Manager, and John Shaheen, Assistant Director of UW Transportation Services. Also we have worked with the Capital Projects Office, which is responsible for developing and overseeing most projects on the University of Washington campus. These points of contact emphasized the importance of financial acuity and safety on campus during the development of this proposal. Striving to be a leader in sustainability, the University of Washington is committed to environmental responsibility. Many of the new construction projects and renovations are required to meet or exceed a LEED Gold rating. The University of Washington actively works to become a green campus through a multi-faceted approach. Recycling, composting, and sustainable dining programs have all been recently implemented around campus. Additionally, the University of Washington has taken serious efforts to raise awareness of these efforts to encourage others to follow. The Central Parking Garage has long been recognized as a building in need of renovation. Upgrading the Central Parking Garage presents a unique opportunity to further the University of Washington’s green aspirations while preserving its historical roots. This renovation will further exemplify the university’s commitment to the environment. May 10, 2013 2 120 Architecture Hall | University of Washington | Seattle, WA 98105 Mission Statement “Promoting Green Energy by providing our clients with services that are both energy efficient and economically effective.” Husky Electric aims to provide exceptional electrical construction services and energy solutions consulting to aid in the effort to make the world a more sustainable environment. Our excellent reputation exemplifies the effectiveness of our involvement and dedication to the green energy industry. The quality of our services and value added to our clients demonstrate our experience and expertise in this field. Project Team Brandon Burr, Project Manager: Brandon will coordinate all team activities and serve as the primary source of communication between the project team and client. Brandon managed the development of this proposal and holds authority over his team’s decision making process. JB Gibson, Estimator/Scheduler: JB is responsible for handling the team’s budget and developing and maintaining the project schedule. He will work in conjunction with the superintendent to determine how the project will be built. Kali Leachman, Superintendent: Kali will use areas surrounding and inside the Central Parking Garage to create and adapt the site logistics plan. Also, Kali will be coordinating all work for the scope of this project. David Moore, Design Manager: David performs all calculations to determine the annual savings this project will generate. He also oversees the other design engineers. Tara Harrington, Lighting Design Engineer: Tara is responsible for the lighting retrofit design and will work throughout the project to ensure the design requirements are met. Matthew Watson, Alternative Energy Engineer: Matt is responsible for designing the alternative energy production system and will work throughout the project to guarantee proper installation and operation of the new system. He will also oversee the ventilation system upgrade. Brandon Burr Project Manager David Moore JB Gibson Estimator/Scheduler Design Manager Tara Harrington Lighting Design Engineer May 10, 2013 Matthew Watson Alternative Energy Engineer Kali Leachman Superintendent 3 120 Architecture Hall | University of Washington | Seattle, WA 98105 Resumes Brandon Burr (425) 233-7198 | beeyoudoubler@me.com | 4131 Wallingford Ave N, Seattle, WA 98103 Work Experience Kiewit Construction, Honolulu, HI (2012): Project Engineer Intern Economy Fence Company, Everett, WA (2009,2011): Lead Laborer Intern Alpha Sigma Phi, Seattle, WA (2010): Lead Recruitment Director Education University of Washington (2009-Present) Bachelor of Science Degree in Construction Management GPA: 3.25 Graduation: Spring 2014 Activities Associated Students in Construction (ASIC) Member NECA Student Chapter Awards/Recognition Guinness Book of World Record Holder Sigma Lambda Chi Honor Society Matthew Watson 206) 290-2760 | m9watson@u.washington.edu | 23425 39th Pl Brier, WA 98036 Work Experience Skanska USA Building, Seattle, WA (2012): Project Engineer Intern Granite Construction, Bellingham, WA (2011): Project Engineer Intern All Phase Concrete, Mountlake Terrace, WA (08-12): Concrete Apprentice Education University of Washington (2009-Present) Bachelor of Science Degree in Construction Management GPA: 3.34 Graduation: Spring 2014 Activities Associated Students in Construction (ASIC) Member Fraternity Service Project Chairman Tree House for Kids PUSH International Volunteer NECA Student Chapter Awards/Recognition May 10, 2013 ASC Reno LEED Competition – 3rd place 4 120 Architecture Hall | University of Washington | Seattle, WA 98105 David Moore (360) 632-2094 | dmoore12@u.washington.edu | 5520 17th Ave NE, Seattle, WA 98105 Work Experience College Pro Painters, Seattle, WA (2012): Franchise Manager College Pro Painters, Seattle, WA (2011): Job Site Manager College Pro Painters, Oak Harbor, WA (08-12): Painter/Technician Education University of Washington (2009-Present) Bachelor of Science Degree in Construction Management Graduation: Spring 2014 Activities Associated Students in Construction (ASIC) Member Theta Delta Chi Delegate NECA Student Chapter Awards/Recognition Participant in sustainability study in Fortune 500 companies and worked on development of scoring system JB Gibson (206) 235-8185 | jbgibson6044@gmail.com | 6044 164th Ave SE, Bellevue, WA 98006 Work Experience Sellen Construction, Seattle, WA (2012): Project Engineer Intern Beta Theta Pi, Seattle, WA (2012): House Manager Clise Properties, Seattle, WA (2010,2011): Laborer Education University of Washington (2010-Present) Bachelor of Science Degree in Construction Management Bachelor of Arts Degree in Business Administration (Entrepreneurship) GPA: 3.7 Graduation: Spring 2014 Seattle University – Matteo Ricci College (2009-2010) GPA: 3.9 Activities Associated Students in Construction (ASIC) AGC FLF Correspondent ASC 2013 Region 7 Commercial Construction Student Competition NECA Student Chapter Awards/Recognition May 10, 2013 University of Washington Deans List for 7 Quarters Sigma Lambda Chi Honor Society 2013 AGC Foundation Scholarship Recipient 5 120 Architecture Hall | University of Washington | Seattle, WA 98105 Tara Harrington (425) 319-1305 | tarah4@uw.edu | 12807 72nd St SE, Snohomish, WA 98290 Work Experience UW Capital Projects Office, Seattle, WA (2012-13): Student Intern University of Washington, Seattle, WA (2012): Business School Grader Dionne and Rorick, Seattle, WA (2012): Receptionist & File Clerk Education University of Washington (2010-Present) Bachelor of Science Degree in Construction Management GPA: 3.51 Graduation: Spring 2014 Activities Associated Students in Construction (ASIC) Treasurer Delta Zeta Sorority Technology Chair/House Manager/Risk Manager ASUW Senator UW Leaders Dream Project Mentor NECA Student Chapter Awards/Recognition University of Washington Deans List for 4 quarters Sigma Lambda Chi Honor Society Howard S. Wright, Lee S. Evans, AGC Foundation Scholarship Recipient ASC 2013 Region 7 Mixed-Use Competition 1st Place Winner Kali Leachman (206) 913-9992 | leachmank@yahoo.com | 1904 NE 52nd St Seattle, WA 98290 Work Experience Guy F. Atkinson Construction, Renton, WA (2012): Estimating Intern Windermere Services, Seattle, WA (2011-12): Receptionist Kiewit Construction, Silverdale, WA (2008): Quality Control Office Clerk Education University of Washington (2009-Present) Bachelor of Science Degree in Construction Management GPA: 3.30 Graduation: Spring 2014 Activities Associated Students in Construction (ASIC) Member Member of Kappa Kappa Gamma Sorority NECA Student Chapter Awards/Recognition May 10, 2013 University of Washington Deans List for 5 quarters 6 120 Architecture Hall | University of Washington | Seattle, WA 98105 Energy Use Analysis/Retrofit Energy Assessment Energy usage data for the Central Parking Garage was provided by the University of Washington Facilities Maintenance department with the help of the Energy Database McKinstry created for the entire campus. Energy use is measured on an hourly basis. Central Plaza Parking Garage Energy Usage Energy Usage (kWh) 86,000 84,000 82,000 80,000 78,000 76,000 74,000 72,000 70,000 68,000 Above is the monthly energy usage for the Central Plaza Parking Garage. Total annual energy usage is 953,467 kWh. The following figure shows the breakdown of this total between the major systems of the Central Plaza Parking Garage. Energy Usage Breakdown HVAC System: 34.1% Lighting System: 50.5% Miscellaneous Systems: 15.4% Note: Miscellaneous systems include all systems that fall beyond Husky Electric’s scope of work and are incorporated with surrounding buildings. May 10, 2013 7 120 Architecture Hall | University of Washington | Seattle, WA 98105 HVAC Existing Conditions The Central Plaza Parking Garage is open all hours of the day and therefore requires continuous operation at varying levels throughout the day. The exhaust system for Central Plaza Parking Garage works mainly through the use of a plenum for each mechanical room. These plenums are large open areas that act as a vacuum to allow the air to be removed from the garage. Through suction, the air is pulled through the plenum and up the exhaust vent, which also pulls in air through the intakes. This large vacuum works to provide air to all parts of the garage. This system uses eight fans located in two separate mechanical rooms to exhaust the garage. East Fan Room: (4) 40 HP fans that discharge vertically out of three brick stacks in Red Square West Fan Room: (4) 30 HP fans that discharge up sloping shaft toward 15th Ave NE VFD’s are currently installed on all exhaust fans allowing “soft” starts and stops reducing power surge losses Currently the garage requires no cooling because of two factors. First, the garage being located underground helps maintain a consistent temperature. Second, the buildings located around the garage are exhausted into the garage further regulating the temperature of the garage. Number of Fans 8 Day(s) Mon. – Sun. May 10, 2013 Annual Energy Consumption of Exhaust Fans Run Time (hrs) Total Energy Consumption (kWh) Per Exhaust Fan motor 325,486 speed hours schedule Exhaust Fan Motor Speed Scheduled Hours Off 100% 50% 0000-0700 0700-0900 0900-1600 1600-2000 2000-2200 Off 2200-0000 8 120 Architecture Hall | University of Washington | Seattle, WA 98105 Proposed HVAC Retrofit Husky Electric proposes to adjust the exhaust fan schedule on weekends, summer break, holidays, and breaks when the utilization of the garage is down. With a very low initial investment, the schedule can be adjusted and the energy usage will decrease a substantial amount. For full details and cost analysis see the Ventilation System section. Lighting Existing Conditions The Central Plaza Parking Garage currently uses 1,717 4-foot T-8 32 watt fluorescent lamps with electronic ballasts. Near the 3 garage entrances, cold weather ballasts are used. These fixtures were installed in 1996. The lighting is designated to 4 main control panels; A-1, A-2, A-3 and an emergency panel. Some light fixtures remain deactivated from a prior lighting renovation, but all other fixtures are turned on all hours of the day. The garage is currently unpainted concrete other than a few columns for safety. Annual Energy Consumption of Light Fixtures Number of Fixtures Run Time (Hrs) 1,717 8,760 Total Energy Consumption (kWh) 481,309 Proposed Lighting Retrofit Husky Electric will replace the current T-8 fluorescent fixtures with much more efficient LED fixtures. This replacement also allows us to install much fewer fixtures and still meet the same lighting requirements for the garage. This option will have a short payback period due to the cost savings due to the lower energy use from the lower amount of fixtures in the garage. For detailed cost analysis see the Lighting Retrofit section. May 10, 2013 9 120 Architecture Hall | University of Washington | Seattle, WA 98105 Lighting Retrofit New System Design To provide a design that meets the requests of our owner, safety requirements, local codes and provides a significant energy reduction and short payback period we focus on six characteristics. Our main criterion of analysis included: Safety Energy consumption Future costs Life Expectancy Maintenance Controls In this design we analyzed the installation of new fixture types, the use of occupancy sensors and the addition of white – reflective paint to the garage. Results from this analysis provide us with a retrofit design consisting of fixture replacement and occupancy sensor utilization. Assessment of Space Existing Proposed Fixtures per Floor Breakdown Lower Level: 612 Middle Level: 528 Upper Level: 577 Lower Level: 75 Middle Level: 66 Upper Level: 84 Total: 1,717 Total: 225 We have developed a new lighting plan which is located on the following two pages. Please see Figure 1, 2 and 3 for existing reflected ceiling plans and Figure 4, 5 and 6 for proposed reflected ceiling plans. Fixture Replacement The QLP 32G2 LED lamp with the PX10 Proximo Programmable Occupancy Detector is our proposed fixture for the garage. With the use of this lamp, we can reduce the fixture count by 1,492 fixtures and the energy consumption by 70.4%. Our power consumption from lighting will decrease from 481,309 kWh per year to 142,700.4 kWh per year with the installation of the QLP LED fixtures. The current lighting system is 50.5% of the total energy consumption for the garage and with a retrofit will decrease to only 26%. Initial Investment $238,084.20 Proposed Lighting Cost Analysis Tax Incentives Cost Less Incentives Annual Savings $192,638.72 $45,445.48 $84,652.15 Payback Period 0.54 yrs. An analysis of our alternative fixture options can be found in Appendix A. May 10, 2013 10 120 Architecture Hall | University of Washington | Seattle, WA 98105 QLP 32G2 LED Fixture This particular fixture includes a programmable occupancy detector that dims the light when motion is undetected. This dimming feature reduces the light output by an additional 20% resulting in extended energy savings. This device is mounted with the lamp and provides 360˚ range of detection for a radius of 25 feet when mounted 9 feet high. This device also detects ambient light and ensures that excessive light is not distributed when daylight is detected. For commissioning and control a wireless remote is provided to program and update the device. This is a major factor in the decision to use this fixture. Currently facilities management is struggling to keep up on maintenance in the garage – thus having a wireless device and simple programming strategy will be crucial in the new design of the garage. This fixture comes with a mounting kit and will be mounted on the underside of the beams at a height of 9 feet. The current fixtures are mounted between the beams – casting shadows through the space. The new mounting location will pair with the symmetrical light distribution pattern of the device and better distribute light throughout the garage. This mounting location also provides the occupancy detectors optimal range and minimal interruption to the sensor. May 10, 2013 11 120 Architecture Hall | University of Washington | Seattle, WA 98105 Figure 2. Existing Reflected Ceiling Plan – Middle Level Figure 1. Existing Reflected Ceiling Plan – Upper Level 1 Single Lamp T8 Fixture 2 Fixtures 3 Fixtures 4 Fixtures 5 Fixtures 6 Fixtures Figure 3. Existing Reflected Ceiling Plan – Lower Level May 10, 2013 12 120 Architecture Hall | University of Washington | Seattle, WA 98105 Figure 5. Proposed Reflected Ceiling Plan – Middle Level Figure 4. Proposed Reflected Ceiling Plan – Upper Level - QLP G2 LED Fixture May 10, 2013 Figure 6. Propoesd Reflected Ceiling Plan –Lower Level13 120 Architecture Hall | University of Washington | Seattle, WA 98105 Light Output Foot-Candle Measurements Using the Extech Easy View 30 Light Meter, we measured the current foot-candles throughout the garage. Per the Seattle Energy code, 4.5 foot-candles are required in parking garage spaces. Since the garage is under the policies of the University of Washington, we have been advised that exceeding the minimum requirements is recommended and encouraged for safety. This garage is open and operating 24 hours a day, year round and completely underground – allowing for very minimal natural light near the entrances and a heightened emphasis on safety precautions. With the QLP 32G2 LED fixture from Quality Lighting, we have met the requirement of 4.5 footcandles, exceeding it in the vast majority of the garage. This fixture provides a better distribution of light, higher levels of lighting and increased safety in the garage. Please see Figure 7 below and Figure 8 on the following page to compare the differences in foot-candles in regions of the garage. Figure 7. Existing Foot-Candle Measurements In our analysis of existing foot-candles, we measured 27 locations on the lower level and found that the garage had sufficient lighting to meet code requirements. The minimum foot-candles measured were 6 fc at the Southwest Corner Ramp, and the maximum measured were 16 fc near the Southwest corner entrance during the afternoon. Figure 8. Proposed Foot-Candle Measurements Based on our foot-candle measurements and the safety codes of the University of Washington and Seattle, we have selected a lighting plan that meets the minimum foot-candles required in a parking garage and provides comparable levels of lighting in the garage. Average fc 8.6 May 10, 2013 Max fc 12.7 Proposed Foot-Candle Measurements Min fc Max/Min 4.5 2.8:1 Avg/Min 1.9:1 14 120 Architecture Hall | University of Washington | Seattle, WA 98105 Fluorescent Lamp Disposal Since January 1st, 2013 the City of Seattle prohibits the disposal of fluorescent bulbs/tubes from any commercial customer in the municipal solid waste or at the Seattle transfer stations. (Seattle Municipal Code 21.36.025 – Unlawful Disposal) As a way of continuing our efforts to go green, we have prepared a plan to recycle all 1,717 fluorescent bulbs removed from the garage through Eco Lights – a fluorescent lamp recycling company conveniently located 15 minutes away from the campus. Our magnitude of disposal will require 12 4-ft. Straight Fluorescent Lamp Large Recycling Kits from Eco Lights, priced at $89 each. Each kit will accommodate 144 4-foot T8 lamps and includes a container, heavy duty liner, zip tie, instructions and prepaid return services. According to the Office of Solid Waste and U.S. Environmental Protection Agency, a T8 Lamp manufactured in 1996 or prior to 1996 contains 30 milligrams of Mercury. This means that our total lamp disposal contains 151.51 grams of Mercury. Ensuring that this mercury does not go to landfills is important to the University and is crucial to keeping our efforts eco-friendly. May 10, 2013 15 120 Architecture Hall | University of Washington | Seattle, WA 98105 Impacts Keeping the six key requests of the owner in mind, we have developed a lighting retrofit that suits the needs of students, faculty and visitors using the garage; provides the owner with a reduction in costs and maintenance; and utilizes the new LED technology to conserve energy. Safety – We have ensured that the minimum foot-candle requirements are met and exceeded and that fixtures will be on during all hours of the day. Energy Consumption – We have reduced our energy consumption by 70.4% saving the University $152,374.15 per year. Future Costs and Life Expectancy – LED fixtures have a remarkable life expectancy and minimal future costs. Seattle has an average ambient temperature around 50˚F.The table below indicates that a lamp in this area will last for 24 years when run 24 hours a day, year round. Future costs of an LED fixture include replacing bulbs every few decades or replacing malfunctioning occupancy detectors or fixtures as you would with any other fixture. Life Expectancy of Fixture Average Outdoor Ambient Temperature (°F) -22 4 14 32 50 77 95 Predicted LED Life Expectancy L70 (Hrs) 292,000 268,000 244,000 220,000 208,000 160,000 136,000 Predicted LED Life Expectancy @ 10 Hrs/Day (Yrs) 80 73 67 60 57 44 37 Predicted LED Life Expectancy @ 24 Hrs/Day (Yrs) 33 31 28 25 24 18 16 Maintenance and Controls – Considering the longevity of the fixtures and wireless controls for occupancy detectors, the maintenance required for this lighting system is very minimal and manageable by the current University facilities staff. The lighting retrofit is an excellent savings and energy conservation opportunity for the University of Washington. May 10, 2013 16 120 Architecture Hall | University of Washington | Seattle, WA 98105 Electric Vehicle Charging Stations Charging Station Analysis Husky Electric has worked with the University of Washington (UW) conducting comprehensive traffic studies. We have also conducted surveys with the Central Plaza Garage (CPG) users to assess the demand of electric vehicle (EV) charging stations. The University of Washington currently has three (3) charging stations on campus that has attracted a small community of EV users. With experts predicting an increase of EV's to 300,000 that will be driving on the Washington State roads over the next decade, this community on campus will continue to grow. Implementation After analyzing the data and the surveys that were conducted and in combination with the predicted increase in the number of EV's, Husky Electric believes that there is an opportunity to begin to increase the number of stations that UW houses on campus. Our team believes that the CPG is the ideal location to begin this increase in the number of stations. Our team at Husky Electric has developed a design that fits the image of the owner and will provide an opportunity to increase the EV user community on campus. We are proposing that UW has our team furnish and install 4 new charging stations at each of the three (3) entrances to the parking garage. Disadvantages UW Transportation Services have addressed some concerns with our design team that are the key reasons for why they have not already begun this EV movement including: Not a strong market currently for EV's Limited number of trips allowed by City of Seattle Financial burden Because the market for EV's is so small currently, the university does not believe that there is a need to increase the total number of stations on campus. The university is also concerned because they are limited to 25,000 vehicle trips to campus each day by the City of Seattle. By installing these stations, it would not help reduce the total number of trips. With the market still not at a desirable level, UW feels that it would be more of a financial burden on them than a benefit to the community. However, our team believes that it has developed a strategy to mitigate the concerns that the university has addressed. May 10, 2013 17 120 Architecture Hall | University of Washington | Seattle, WA 98105 Advantages By installing only 12 stations initially, our team believes that this helps alleviate two of the main concerns that the university addressed above. Our team believes that allocating 12 stations in the 984 stall CPG will not create an issue by reducing the number of stalls for motor vehicles. Our team has also developed a strategy for UW to create an additional source of revenue by charging to use the stations and implementing a free voucher program for users that utilize carpooling. University Savings* Initial Cost - Instant Incentives = $60,015.00 - $18,005 = Total Project Cost $42,011 / Revenue / $2,971.51 ROI (Years) 14.14 The detailed summary includes assumptions based on historical data collected from the Mountlake Terrace Park & Ride garage and current electrical rates. Our team is also making the assumption that each station would receive four (4) hours of use each 24-hour period. Obviously, as the market for the EV's increases, the return on investment will approach the break-even point at a faster pace. In order for UW to ensure that these stations are being utilized, they must market the stations to the EV user community. They must also promote the voucher program that our team is developing for those who decide to carpool. This will not only help the university and Seattle increase its rating of being the 8th Greenest City in the United States (according to Popular Science), but it will be beneficial for the user to create additional savings as well. Consumer Savings* Average Motor Vehicle Fuel Cost $1,668.62 Average Electric = Vehicle Charge Cost $639.44 = - Annual Savings $1,029.18 *See page 20 19 for detailed savings summary May 10, 2013 18 120 Architecture Hall | University of Washington | Seattle, WA 98105 Design Overview Husky Electric received two (2) quotes for stations based on two different models. The CT2103 (Level 1 charger) and the CT2023 (Level 2 charger). In order to fit the desires of the owner, Husky Electric proposes that the CT2023 charging stations be chosen. There is an increased cost with selecting the CT2023, however, these stations are better suited for the newer EV's that are being developed. Model - (3) Charge Point CT2023 Gateway Dual Head 240 Volt Wall Mount Holster (3) Charge Point CT2023 Dual Head 240 Volt Wall Mount Holster (5) Year Network Operation & Driver Support Manager Power System Integration May 10, 2013 Three-Line Drawing 19 120 Architecture Hall | University of Washington | Seattle, WA 98105 Charging Station Savings Summary May 10, 2013 20 120 Architecture Hall | University of Washington | Seattle, WA 98105 Alternative Energy Retrofit Ventilation Overview In analyzing the existing system, we identified a potential inefficiency. The baseline schedule for the existing system assumes the same amount of traffic in the structure 365 days per year. This leads us to believe that the baseline schedule for these fans should be off completely unless activated by a CO sensor. However this leads to potential safety hazards with the limited amount of CO sensors in the building. If air in an area of the building were stagnant, there would a greater possibility of CO sensors failing to detect higher levels of CO in the building. Proposed Ventilation System Proposed Solution: Reprograming the ventilation timing system to reduce peak hour ventilation power from 100% to 50% during weekends, holidays, breaks, and summer quarter. Eliminates unnecessary run time of fans Minimizes initial cost Maximizes controllability of existing system Utilizes existing CO sensors to ensure safety Initial Investment $500 System Reprogram Cost Analysis Energy Savings Per Year Total Yearly Savings 80,539.48 kWh $20,134.87 The current building management system is perfectly capable of having more control over the baseline exhaust schedule, which eliminates the need for new systems controls. We determined that we would be able to reduce the baseline schedule for exhaust fans while still maintaining safe levels of circulation and CO during weekends, spring break, winter break, and holidays recognized by the University of Washington schedule based on information obtained from parking services. We determined that the reduction of daily parking permits sold warranted following reductions. Breaks (74 Days) 58% % Drop In Daily Parking Permit Purchases Summer Quarter (61 Days) Weekends/Holidays (72Days) 41% 51% In maximizing the controllability of this system without installing any new equipment, we minimize the cost of this aspect of work. The only investment would be the reprogramming of the ventilation system to a 50% fan schedule on those days. May 10, 2013 21 120 Architecture Hall | University of Washington | Seattle, WA 98105 In the case that an event were to take place during a reduced schedule time period, the existing carbon monoxide sensors would detect the predetermined level set by the university and turn the system on to 100% capacity to maintain a safe and healthy environment Ventilation Alternative: Installing (2) Cook TCN-B fans and associated ductwork Improves cross sectional flow Eliminates risk of air stagnation Allows baseline schedule for main fans to be “off” Additional upfront cost Additional electricity to run fans In looking for alternatives we determined that installing circulation fans would be a feasible option. Below is a cost estimate of installing a fan on each floor will improve cross sectional flow which would ensure the effectiveness of the existing CO sensors. This would ensure there would be no stagnant pockets of air that could potentially not be occupied by a CO sensor. A detailed payback analysis is as follows. Circulation Fan Cost Analysis Initial Investment $98,000 Energy Reduction 24,741.57 kWh Cost Savings $6,185.39 Payback Period 15.84 Cost analysis shows proposed solution would be a better option. Renewable Energy Overview When looking into forms of renewable energy, photovoltaic panels as well as wind turbine energy were analyzed. Through a cost analysis, wind energy in the Seattle region has proved to not be as economical as photovoltaic. However in the appendix we have proposed on the most feasible wind energy system and have provided a payback analysis. Photovoltaic: With the Central Plaza Garage being an underground structure, it proved difficult to find sufficient suitable area for a PV array. Multiple locations were investigated however the best location we identified was the roof of Odegaard Undergraduate Library. The Odegaard roof would prove a very effective and economical location for the PV array. 3,158SF due-south Roof Area 36.88 degree (9/12) Slope Optimal orientation for harvesting potential The most feasible system installation includes PV panels, Inverters, and conduit traveling through the elevator shaft of Odegaard Library, which arrives very close to the electrical room of the Central Plaza Garage. May 10, 2013 22 120 Architecture Hall | University of Washington | Seattle, WA 98105 Proposed Photovoltaic System Proposed Solution: 17.28kW Photovoltaic Panel System mounted to the roof of Odegaard Undergraduate Library consisting of the following. (64) 270-watt SolarWorld Sunmodule Panel with Unirac Racking System (1) - Fronius IG Plus 11.4-1 Inverter (1) - Fronius IG Plus 6.0-1 Inverter (1) - Web based Monitoring System The system will consist of 3 rows of panels feeding 2 inverters. A new electrical panel will be installed in the electrical room of the garage in order to handle the additional feed to the building. Conduit will be run from the roof to the electrical room via the shared elevator shaft. Utilizing the 3,158 square feet of due south sloping roof area will maximize the harvesting potential of this system. Using a Solar Pathfinder, we have determined that the best angle for these panels for 100% sun exposure is a 34-degree tilt. The slope of these roof surfaces will only result in a .388% drop from optimal harvesting potential. May 10, 2013 23 120 Architecture Hall | University of Washington | Seattle, WA 98105 We have decided to utilize Sunmodule solar panels from SolarWorld. In addition, the Fronius IG+ Inverters provide optimal efficiency and are extremely reliable inverters. SolarWorld PV Panels: 25 yr. performance warranty 10 yr. product warranty 16.1% conversion efficiency Initial Investment $54,908 Fronius IG Plus Inverters: 10 yr. product warranty 95% efficiency Proposed PV System Cost Analysis Tax Rebates Cost Less Rebates Annual Production $16,472 $38,436 $7,260 Payback Period 5.29 yrs. Photovoltaic Array Sizing Calculations Project: Central Plaza Garage Energy Use Retrofit Contractor: Husky Electric Maximum Series Module Calculations Vadj = Voc + [(Record Low Temp °C - STC Cell Temp °C) * Voltage (Voc)] = 38.3 + [(-17.8 + 25 °C) * -.3V/°C)] = 36.14 V Maximum Modules in Series = UL / Vadj = 16.6 (Round Down) Maximum Modules in Series = 16 Minimum Series Module Calculations Voltage = Vmpp * Power = 32.8 * -.45 Voltage = -0.15 Vadj = Vmpp + [(Avg. High Temp + 30C - STC Cell Temp)* Voltage] = 32.8V + (59c - 25c) * -.14V/C Vadj = 27.8 V Minimum Modules in Series = Min Operating Power / Vadj = 244V/27.8V = 8.77 (round up) Minimum Modules in Series = 9 Recommendation due to string size calculations as well space confinements: 3 rows - totaling 64 panels Bottom row: 24 Middle row: 33 Top row: 18 Inverters: 3 strings of 14 and 2 strings of 11 Racking System: Solarmount flush mount May 10, 2013 Sunmodule SW 270 mono Open Circuit (Voc) 38.3 Rated (Vmpp) 32.1 Temp Coefficient for Voltage (Voc) -0.30% Temp Coefficient for Power (P) -0.45% Max System Voltage (UL) 600V Fronius IG Inverters Operating Range (MPPT) 244V - 305V Solar Radiation Data (Seattle, WA 47.5N,122.3W) Record Low Temp -17.8 Average High Temp 29 (add 30 for rack mount) 24 120 Architecture Hall | University of Washington | Seattle, WA 98105 Client Image Seattle along with the University of Washington is known in the area as well as the entire nation for being on the cutting edge of innovation and sustainability. The Central Plaza Parking Garage is one of the first places many visitors as well as every day users experience upon arriving on campus. Husky Electric wants every visitor to the University of Washington campus to be well aware of its commitment to sustainability. This impressive solar harvesting technology can not only save money and electricity, but serve as an educational tool and resource with our proposed web based monitoring system. May 10, 2013 25 120 Architecture Hall | University of Washington | Seattle, WA 98105 Schematic Estimate and Schedule Schematic Estimate Husky Electric performed an in depth energy analysis and considered all possible energy efficient retrofit options to reduce energy costs to the University of Washington Central Parking Garage. The schematic estimate for this project includes an alternative energy retrofit, energy use retrofit, lighting retrofit, and electrical vehicle charging station installation. This schematic estimate contains all materials, labor and small tools. This is intended to provide a clear and concise breakdown of all the major costs associated with Husky Electric’s scope of work. Husky Electric obtained labor units from the 2011-2012 NECA Manual of Labor Units. Material Prices were compiled through a combination of local supplier quotes adjusted accordingly by local NECA sponsors. Estimate Breakdown Alternative Energy Retrofit Roof Mounted Photovoltaic System Energy Use Retrofit HVAC Reprogramming Lighting Retrofit Fixture Upgrade $54,908 $500 $238,084 Electric Car Charging Station Charging stations $60,015 General Conditions $25,587 Margin, B&O Tax, Contingency $44,086 Total (Less Grants, Rebates, Incentives) Total Installed Cost May 10, 2013 $423,180 ($227,115) $196,064 26 120 Architecture Hall | University of Washington | Seattle, WA 98105 Estimate Quantity Unit PV Panels PV Panels Electrical Panel Racks Inverters Conduit/Wire Mobile Crane Web based monitoring system 64 1 3 2 100 Labor Rate E E Row E LF Labor Hours Wage Rate 0.6 4 88 3.7 0.16 1E 38.4 4 264 7.4 16 1 $ $ $ $ $ 1 $ Labor Cost $/Unit 60.00 60.00 60.00 60.00 60.00 $ 2,304.00 $ 300.00 $ 19,200.00 $ 240.00 $ 260.00 $ 260.00 $ 15,840.00 $ 1,000.00 $ 3,000.00 $ 444.00 $ 3,450.00 $ 6,900.00 $ 960.00 $ 1.50 $ 150.00 Subcontracted 60.00 $ 60.00 $ 750.00 $ 750.00 Total Ventilation Reprogramming Existing Units Lighting Demo Existing Fixtures LED Fixtures Branch Power Lighting Recycle Boxes 1717 225 9879 12 E E LF E 0.25 1.5 0.03 0 Charging Station Charge Pro EV Charging Station Wall Mounted Conduit/Wire 12 E 1450 LF 16 0.03 429.25 337.5 296.37 0 $ $ $ $ 192 $ 43.5 $ General Conditions 60.00 60.00 60.00 - $ 25,755.00 $ $ 20,250.00 $ $ 17,782.20 $ $ $ May 10, 2013 Fencing/Temp Walls Service Van: Foreman Storage Container Telephone Electrical Permit: City of Seattle Recycling General Expenses Subtotal General Conditions Total Weeks Hours/Week Cost Rate ($) Cost Extension ($) 7 15 $ 80 $ 8,400 4 5 $ 100 $ 2,000 1 20 $ 60 $ 1,200 4 5 $ 55 $ 1,100 2 10 $ 45 $ 900 7 3 $ 40 $ 840 5 2 $ 125 $ 1,250 7 2 $ 55 $ 770 $ 16,460 Weeks Quantity 7 7 6 7 7 726.00 1.00 89.00 $ $ $ $ $ $ $ $ 21,504.00 500.00 18,840.00 7,344.00 1,110.00 4,800.00 810.00 54,908.00 Subcontracted $ 500.00 $ $ 163,350.00 $ 9,879.00 $ 1,068.00 Total $ 25,755.00 $ 183,600.00 $ 27,661.20 $ 1,068.00 $ 238,084.20 60.00 $ 11,520.00 $ 3,642.50 $ 43,710.00 $ 60.00 $ 2,610.00 $ 1.50 $ 2,175.00 $ Total $ Central Parking Garage Indirect Labor Project Manager Alternative Energy Specialist Estimator Lighting Designer Financial Coordinator Administration - Accounting Backup Electrical Engineer Safety Officer Indirect Labor Subtotal General Expenses Material Cost Total Cost Cost Rate $ 300 $ 250 $ 50 $ 33 1 $ 4,480 $ 38 Cost Extension ($) $ 2,100 $ 1,750 $ 300 $ 231 $ 4,480 $ 266 $ 9,127 $ 25,587 55,230.00 4,785.00 60,015.00 Subtotal $ 353,507.20 General Conditions Margin (10%) B&O Tax (.471%) Contingency (2%) $ $ $ $ Project Total (Less: Rebates & Incentives) $ 423,180.08 $ 227,115.22 Proposed Project Total $ 196,064.86 $ Annual Electric Savings/profits $ Break Even (Years) 25,587.00 35,350.72 1,665.02 7,070.14 115,018 1.70 27 44,085.88 120 Architecture Hall | University of Washington | Seattle, WA 98105 Schedule Summary The schedule for this project is separated into three main scopes of work: Renewable Energy System Lighting Retrofit Electrical Vehicle Charging Station. Husky Electric scheduled 9 weeks beginning the week following the last week of spring quarter, so campus activity will be minimal. Major milestones include Notice to Proceed on June 14, 2013, Substantial Completion on August 09, 2013, and project completion on August 12, 2013. Overview This project will follow a zoning sequence to allow for parts of the garage to remain operable during construction. Our simple, yet efficient schedule breaks the work into five stages: 1. Mobilization 4. Zoning Plan 2. Ventilation Programming 5. Demobilization 3. PV Panels Stage 1: Mobilization Crew mobilization and site preparation facilitate project management for the project. Stage 2: Ventilation Programming This work will be subcontracted to a controls contractor. Stage 3: Photovoltaic Panels This stage is not a part of the zoning plan. The PV Panel installation consists of 4 major steps: 1. Rack Installation 3. Conduit/Wiring 2. Panel Components Installation 4. Finish/Start-up Stage 4: Zoning Plan When one zone is under construction, the two other zones will be operational. Temporary walls and signage will be restaged when moving zones. Zoning applies to lighting and charging stations. The interior lighting upgrade consists of 2 major steps: 1. Old Fixture Demolition/Recycle Parking Available During Zone 2. New Fixture Installation Build-Out The EV Charging Station installation consists of 3 major steps: Zone Available Duration 1. Attach Wall Mount Brackets Parking (Days) 2. Install Circuit Breaker/Run Electrical Conduit 1 859 7 3. Mount Head Unit and Connect Electrical Supply 2 674 12 3 447 18 Stage 5: Demobilization Activities include: Commissioning and Start-Up. All equipment and tools will be accounted for and returned. Site office space and lunchroom will be taken down and removed. A punch list will then be created in order to ensure the owner is completely satisfied with all aspects of the electrical retrofit and every concern and/or problem is resolved. Warranty / Continuing Operations Insurance and warranty coverage for defective workmanship within the first year following completion will be covered in its entirety. Optional continued services may be provided for a negotiated fee following the warranty period. May 10, 2013 28 120 Architecture Hall | University of Washington | Seattle, WA 98105 Schedule Activity Based Crew Forecast for Stages 2-5 Activity Based Crew Forecast Task # 17-Jun 24-Jun 1-Jul # Days Start Finish 15-Jul 22-Jul Budget Hours Week Week Week Week Week Week Activity 4 Stage 2 - PV System 1 20 Tue 6/25/13 Mon 7/22/13 331 9 Stage 3 - Zone 1 5 Tue 6/18/13 Mon 6/24/13 245 13 Stage 4 - Zone 2 10 Tue 6/25/13 Mon 7/8/13 439 17 Stage 5 - Zone 3 15 Tue 7/9/13 Mon 7/29/13 615 Available work days 30 May 10, 2013 Total Hrs 2 8-Jul 3 4 5 4 2 2 6 6 6 6 8 8 6 6 6 6 1629 Total Crew Size 6 6 10 29 29 May 10, 2013 30 120 Architecture Hall | University of Washington | Seattle, WA 98105 Project Management Plan Site Layout LEGEND Zone 1 Truck Route Zone 2 Truck Route Zone 3 Truck Route Crew Office Existing Roads Crane Staging Area Connex Container Equipment Staging Area Crew Parking Area High-Visibility Fencing Underground Garage Footprint Site Logistics Crew office, parking area, connex, and equipment area located on Level 1 of garage. George Washington Lane NE runs North/South above the Central Plaza Parking Garage. High-visibility fence located along zone lines during corresponding zone build out. Reference Zoning Plan for exact locations. Truck route corresponds to designated entrance per the Zoning Plan. Mobile crane staging area accessible by Memorial Way and is surrounded by highvisibility fence at all times. May 10, 2013 31 120 Architecture Hall | University of Washington | Seattle, WA 98105 Safety Plan Overview It is the policy of Husky Electric to provide a safe and healthful workplace for its employees that complies will all the requirements of applicable safety rules and orders on the Central Plaza Parking Garage Project. Our Experience Modification Rate is an industry low of 0.53 due to our outstanding lead by example and zero tolerance policies. The Superintendent is responsible for implementation of the project’s safety program and the assurance that it is strictly followed. Lead by example. Correct any unsafe behaviors or unsafe conditions immediately; looking for opportunities to train employees. Perform a daily walk-through of his/her activities, primarily focusing on the identification and correction of unsafe behaviors. Develop hazard analyses with the foreman and crew. Follow up to assure the hazard analysis is effectively being used in the operation. Set expectations of the crews and assure compliance. Conduct a monthly Crew Based Safety Observation (CBSO) on an operation other than their own. Required Personal Protective Equipment Hard Hat Safety Glass Reflective Vests Work Boots with Safety Toe Work Gloves Ear Plugs Fall Protection Durable Work Attire Community Safety The Central Plaza Parking Garage retrofit takes place on the University of Washington campus creating necessary additional safety measures. The garage will remain operational throughout the duration of construction with available parking dictated by the Zoning Plan outlined in the schedule. To compensate for additional safety requirements, we plan to surround all construction zones with high-visibility fencing and strategically place project signage at the garage entrances and construction zones to direct pedestrians safely around construction. Trucks delivering material to and from the job site will be required to travel at speeds no higher than 15 miles per hour. May 10, 2013 32 120 Architecture Hall | University of Washington | Seattle, WA 98105 Financing Plan Grants, Rebates and Incentives Overview We have researched all grants, tax incentives, and rebates applicable to the retrofit of the Central Plaza Parking Garage and have included in our financing plan the specific cost savings from each incentive. Our financial analysis shows a payback period of 2.67 years and our retrofit qualifies for a total of $235,718 from federal and state incentives that are returned to the client. Lighting Incentives Seattle City Light – Commercial Energy Efficiency Rebate Program Seattle City Light offers rebates to commercial customers through the Energy Smart Services Program. Rebates are calculated using the annual kWh savings of a given project offering $0.20/kWh saved for lighting. These incentives have the potential to cover up to 70% of the installation cost for the project. Energy-Efficient Commercial Buildings Tax Deduction The federal Energy Policy Act of 2005 provides a tax deduction for energy-efficient commercial buildings. A deduction of $0.30 per square foot of the project is available to owners who’s interior lighting replacement attributes to at least 50% of the reduction of energy and power cost. Our lighting retrofit accounts for 51% of the total energy and power reduction which qualifies our project for this tax deduction. Description City Light Rebate Federal Tax Deduction Lighting Incentives Savings Breakdown Incentive Rate Unit $0.20 338,608.60 kWh/yr $0.30 416,390 SF Savings ($) $67,721.72 $124,917 Photovoltaic Incentives Business Energy Investment Credit (ITC) The federal business energy investment tax credit is available to commercial sectors with eligible renewable technologies. The implementation of the photovoltaic system in our project qualifies us for this corporate tax credit. The credit is equal to 30% of expenditures on solar equipment used to generate electricity with no maximum credit. May 10, 2013 33 120 Architecture Hall | University of Washington | Seattle, WA 98105 Renewable Energy Cost Recovery Incentive Payment Program Washington State offers a performance-based incentive for photovoltaic systems up to 75kW. The incentives equal $0.15 per kWh saved through 6/30/2020 with a maximum incentive per year of $5,000. We plan to install a 17.28 kW photovoltaic system manufactured in the state of Oregon which qualifies us for the $0.15 per kWh rate. Photovoltaic Incentives Savings Breakdown Description Incentive Rate Unit Business Energy ITC 30% 54,908 Total Cost Energy Cost Incentive Payment $0.15 18,150 kWh/year Savings $16,472 $2,722/year EV Charging Station Incentives Alternative Fuel Infrastructure Tax Credit The U.S. Department of Energy’s alternative fuel infrastructure tax credit is available for 30% of the purchase and installation of EV Chargers up to $30,000 per site. Since we are installing two EV Chargers at three different sites, each site qualifies for this credit. EV Charger Incentives Savings Breakdown Description Incentive Rate Unit Alternative Fuel Tax Credit 30% $60,015 Total Cost May 10, 2013 Savings $18,005 34 120 Architecture Hall | University of Washington | Seattle, WA 98105 Payback Analysis Payback Analysis Central Plaza Parking Garage Return on Investment & Cumulative Savings (Incentives and Energy Reduction) Upgrade Lighting Upgrade Mechanical System Upgrade Photovoltaic System EV Charging Stations Central Plaza Parking Garage (inc. GC's) Initial Cost - Instant Incentives = $238,084.20 $500.00 $54,908.00 $60,015.00 - $192,638.72 $$16,472.00 $18,004.50 = = = = Total Cost $45,445.48 $500.00 $38,436.00 $42,010.50 / Annual Energy Reduction Return on Investments (Years) / / / / $84,652.15 $20,134.87 $7,259.50* $2,971.51 0.537 0.025 5.294 14.138 $423,180.08 $227,115.22 = $196,064.86 / *includes Annual Reduction and Incentive Payment $115,018.03 1.705 Energy Savings Central Plaza Parking Garage Annual Energy Reduction Upgrade Lighting Upgrade HVAC Upgrade Photovoltaic System EV Charging Stations Central Plaza Parking Garage May 10, 2013 Annual Reduction (kWh/Yr) Annual Reduction ($) 338,608.60 $84,652.15 80,539.48 $20,134.87 18,150.00 $7,259.50 (147,198.00) $2,971.51* 290,100.08 *Profit from sale of energy $115,018.03 35 120 Architecture Hall | University of Washington | Seattle, WA 98105 Financing Strategies Husky Electric has designed a very productive PV system and we have decided that it would not be beneficial for the Central Parking Garage to engage in a solar power purchasing agreement. Recently Solar Power-Purchasing agreements have grown more popular. In the state of Washington, they are still relatively new, and there is not much precedent set. Seattle City Light has a system to buy back excess power generated by PV systems. However, our estimates show that the Central Parking Garage will not generate more power than is required for the building. Additionally, the following challenges have confirmed that we will not be negotiating a powerpurchase agreement: More complex negotiations and potential higher transaction costs than buying PV system outright Administrative cost of paying two separate electricity bills if system does not meet 100% of site’s electric load Potential increase in property taxes if property value is reassessed Fairly limited federal sector experience 3rd-Party Solar PV Power Purchase Agreements May 10, 2013 36 120 Architecture Hall | University of Washington | Seattle, WA 98105 References http://www.afdc.energy.gov/laws/law/US/10513 http://www.bls.gov/ro9/cpiseat_energy.pdf http://cars.uk.msn.com/news/in-pictures-updated-2013-nissan-leaf-to-be-built-in-britain?page=4 http://www.chargenw.com/ http://www.coulombtech.com/library.php http://dashboard.mckinstry.com/uw/ http://www.dsireusa.org/incentives/incentive.cfm?Incentive_Code=US02F&re=1&ee=1 http://www.dsireusa.org/incentives/incentive.cfm?Incentive_Code=US40F&re=1&ee=1 http://www.dsireusa.org/incentives/incentive.cfm?Incentive_Code=WA89F&re=1&ee=1 http://www.dsireusa.org/incentives/incentive.cfm?Incentive_Code=WA27F&re=1&ee=1 http://www.ecolights.com/ http://www.fronius.com/ http://www.gemi.org/waterplanner/calc-horsepower.asp http://www.indusprayusa.com/ http://www.popsci.com/environment/article/2008-02/americas-50-greenest-cities?page=1 http://ep-us.mersen.com/resources/media/articles/TT-PVPN5-Sizing-Fuses-of-Photovoltaic-Systemsper-NEC-Tech-Topic.pd http://www.nws.noaa.gov/climate/ http://www.seattle.gov/dpd/Codes/Energy_Code/Overview/2009_ecupdate.asp http://www.semaconnect.com/newsroom-pressrelease_pressrel12.php http://www.sitelighting.com/products.cfm?Style=ELG&Brand=em&ProLine=elg http://www.solarworld-usa.com/installer-program/products/sunmodule-solarpanels.aspx?gclid=CK6wsZb5gbcCFcU5QgodWXgAIg#tab-tab0 http://voices.yahoo.com/how-much-does-cost-charge-electric-car-7408182.html https://www.washington.edu/facilities/records/services.php http://www.widelite.com/products/qlp-gen-2# http://en.wikipedia.org/wiki/Charging_station http://en.wikipedia.org/wiki/Plug-in_electric_vehicles_in_the_United_States http://www.westcoastgreenhighway.com/electrichighways.htm May 10, 2013 37 120 Architecture Hall | University of Washington | Seattle, WA 98105 Outreach Appendix Community Energy Awareness OVERVIEW Husky Electric’s main objective is to create energy conservation awareness amongst University of Washington students. Awareness leads to proper consumption. The retrofit of the Central Plaza Parking Garage is our first step to a green campus. EXISTING PROGRAMS U.S. Department of Energy & UW team up on $178-million Smart Grid Project. System provides means to track student’s electricity usages. Smart meter displays/controls electricity use accurately by the day. Has potential to save UW $350,000 on annual energy bills alone. SEED’s Students Expressing Environmental Dedication run by UW students. Promote sustainability in UW community. Current programs are composting, proper disposal, and campus cleanup. Host successful outreach programs for students including last year’s “Think Outside the Bottle” campaign to limit consumption of bottled-water PROGRAM DESIGN & INTEGRATION Smart Grid installed 235 smart meters in 178 buildings on UW campus. Use social media to educate students on Smart Grid program and its capabilities. Advertise app developed by UW students for smart phones capable of controlling the smart meters away from home. Students could turn off their dorm room lights with their smart phones Partner with SEED to host a Light Swap event on UW campus on May 18th, 2013. Encourage students to swap out their old bulbs for new, energy efficient LED bulbs. LED bulbs last 40 times longer than the commonly used incandescent light bulb. Advertise Light Swap with distribution of our event poster and post details using social media to reach ALL students. FEEDBACK Light Swap event is scheduled for May 18th, 2013 at UW. Reference poster example for details. After little under 2 months of promoting the Smart Grid system, students living in the dormitories have exhibited a slight decrease in electricity consumption. Decrease in consumption from a high of 4,000 Kwh to a low of 2,300 Kwh per day. Husky Electric will continue to promote the usage of the Smart Grid program in the hopes of creating a permanent change in students’ energy consumption behaviors. OUTREACH APPENDIX May 10, 2013 120 Architecture Hall | University of Washington | Seattle, WA 98105 Energy Awareness Plan Feedback & Poster Example March 20, 2013 To: Brandon Burr RE: Light Swap Event and Energy Awareness Proposal Mr. Burr, The Students Expressing Environmental Dedication (SEED) have carefully reviewed Husky Electric’s proposal for energy awareness through your involvement with the Smart Grid project as well as the plan for the Light Swap event. First, we commend you on your involvement with the Smart Grid project. We agree that this particular program has the potential to create a lasting change in the consumption behaviors of students. While social media is a powerful tool to spread information to the University of Washington’s student body, we believe more interaction in person would be beneficial to your cause. This would give you the chance to explain all that you aim to accomplish in your endeavors. Secondly, we would like to officially accept your proposal to co-host the Light Swap event in Red Square. We think this is a smart way to inspire students to make a lasting change to a more energy efficient form of electricity usage. Perhaps in the future we could hold similar events for other types of materials and we encourage any ideas you may have on the subject. I will contact you again within the next few days to figure out the details of the Light Swap. We are excited to see your interest in our cause to create energy awareness on the UW’s campus and we look forward to your further involvement. Thank you, SEED OUTREACH APPENDIX May 10, 2013 120 Architecture Hall | University of Washington | Seattle, WA 98105 Article in University Newsletter April 15, 2013 UW Students Propose Central Plaza Parking Garage Renovation A hardworking team of six Construction Management students are competing in the 5 th annual Green Energy Challenge national competition sponsored by the National Electrical Contractors Association (NECA). The competition consists of the selection of a nearby parking garage and performing an energy audit and design of the power and lighting systems. The students have chosen to conduct their research on the Central Plaza Parking Garage, built in 1972 and in need of an electrical retrofit. Team members Brandon Burr, Matthew Watson, Kali Leachman, Tara Harrington, David Moore and JB Gibson have conducted thorough research and developed a smart and comprehensive plan to transform the Central Plaza Parking Garage, familiarly known as the Odegaard Parking Garage, into an innovative and energy efficient structure. These renovations include but are not limited to upgrading to LED light fixtures, replacing carbon dioxide sensors, adding solar panels to the top of Odegaard, painting the walls with reflective paint, and Central Plaza Parking Garage built 1972 installing car charging stations. This team of students, calling themselves Husky Electric, has teamed up with the UW’s very own SEED organization and the School of Public Affairs’ pilot Smart Grid project to spread energy consumption awareness. Make sure to come exchange your old household bulbs for a new, energy efficient LED bulb at Husky Electric’s Light Swap event in Red Square on May 18th at noon to support their mission to go green! OUTREACH APPENDIX May 10, 2013 120 Architecture Hall | University of Washington | Seattle, WA 98105 Feedback Letter from the Client OUTREACH APPENDIX May 10, 2013 120 Architecture Hall | University of Washington | Seattle, WA 98105 Local NECA Chapter Interaction Person Company Means Mark Anderson Whidbey Sun & Wind Email/Phone Conversation Jim Blaisdell Charge Northwest LLC Email/Phone Conversation Joe Berger Cochran Inc. Email/Phone Conversation Nick Lopez Cochran Inc. Email/Phone Conversation Ken Dyckman Hermanson Mechanical Face to Face Visit/Email Tommy Key NECA NECA Board Meeting Meagan Hillier NECA Face to Face Visit Joe Borrelli Triarc Electrical Email/Phone Conversation Brian Jones Valley Electric Face to Face Visit/Email Interaction Assisted with designing the photovoltaic system Assisted with selecting EV charging stations and provided team with price quote Assisted with overall completition and success of the proposal Assisted with overal completition and success of the proposal Assisted with analysis of existing and proposed mechanical system Acted as initial contact in discovering assistance from local contractors Day to day local contact assisting with project completion Assisted in designing the lighting retrofit Intial contact regarding lighting retrofit University of Washington Interaction Person John Leaden Norm Menter Brian Ho John Shaheen Dan Jerome Steve Tatge Company Means Interaction Initial contact for existing UW Facility Services Face to Face Visit conditions and initial retrofit improvements Assited with receiving UW Facility Services Face to Face Visit current energy usage quantities Assisted with information regarding existing UW Transportation Services Face to Face Visit conditions and proposed retrofit Main contact regarding UW Transportation Services Face to Face Visit Central Plaza Parking Garage Met with to tour and WA Community Transit Face to Face Visit discuss a newly built parking structure Assited with Vehicle Car Capital Projects Office Email/Phone Conversation Charging Stations OUTREACH APPENDIX May 10, 2013 120 Architecture Hall | University of Washington | Seattle, WA 98105 Appendix A - Alternatives Considered HVAC Option 2: Husky Electric also considered the option of installing two Cook TCN-B 20,000 CFM transfer fans to improve the airflow in the garage and allow the CO sensors to be more accurate. The problem with the current system is that the air will stagnate and there will be pockets of air that have a much higher concentration of CO. The installation of these fans would provide a 20% reduction of the required operating time of the exhaust fans. This system however, would not be as effective as the reprograming of the schedule and with the almost 16 year payback period, it would not be a viable option. Initial Cost $98,000.00 HVAC Option 2 Analysis Energy Savings (kWh) Cost savings Payback Period (yrs) 24,741.57 $6,185.39 15.84 *Cost estimate provided by ACI Mechanical Lighting Option 2: Painting the ceilings was a viable option to consider. Given that white – reflective paint can increase the light output by up to 517% and reduce the energy consumption around 20%, we considered using this as a tool to reduce our fixture count. Following a payback period analysis we determined that using paint in garage would come at a significant cost in comparison to the amount of energy savings. In the case that we would have used a newer fluorescent fixture in the garage – the paint would have played a key role in energy savings. With the efficiency and performance of LED lighting, it would be a minimal effect due to the high number of light fixtures we are already reducing, causing a larger issue with safety and full lighting coverage of the garage. Lighting Option 2 Analysis Annual Savings Net Customer Cost Payback Period(yrs) $24,065.45 $166,691.20 6.93 *Quote Provided by Induspray ($0.40/SF) Lighting Option 3: Replacing the existing T8 fixtures with new fluorescent fixtures would require a 1:1 replacement ratio, resulting in a poor opportunity for energy savings and no real reduction in future costs. Therefore this option was not practical for our facility. Another LED fixture considered was the ELG-MR LED fixture from EMCO. This device would result in the same reduction in fixture count, but did not meet code requirements in all locations of the garage. The average foot-candle measurement was 6.7 fc, maximum was 12.7 fc and minimum was 2.5 fc. The EMCO ELG-MR fixtures result in a larger annual savings but due to code requirements and safety restrictions for the University of Washington the EMCO ELG-MR fixture does not meet the needs of our owner. The QLP G2 fixture meets all needs of the owner and will be our fixture of choice. Alternative Fixture: EMCO ELG-EMR Annual Savings Net Customer Cost Payback Period $122,502.75 $168,975 1.38 years May 10, 2013 APPENDIX 120 Architecture Hall | University of Washington | Seattle, WA 98105 Wind Power Overview: The problem with finding a suitable wind energy harvesting system is that most wind turbines have a required cut-in speed of 7-10 mph. With an average wind speed in Seattle of 7.53 mph over the past 3 years, concluded that this system would not be viable in Seattle. If wind energy were to be introduced on the roof of Odegaard Library, a wind turbine system with an extremely low cut-in speed must be used. Since 7.53 is only the average wind speed in Seattle, a lower cut in speed is required. Along with lower cut-in speeds, lower energy production and a longer payback period would be expected. Most Feasible Wind Turbine System: Install a Bergey Excel 10kW turbine on the roof of Odegaard Library. Wind Power Cost Analysis Yearly Production $1,500 Installed Cost $32,200 Payback Period 21.46 years Photovoltaic Alternative: As an alternative to the Sunmodule Photovoltaic panels, we investigated using locally manufactured panels and inverters in order to utilize more Washington State renewable energy incentives. Renewable energy incentives for Washington State: 15 cents / kWh for renewable energy 36 cents / kWh if manufactured in WA In order to utilize the 36-cent incentive, we investigated locally manufactured panels and inverters. It became apparent that the technology of these panels was lacking in comparison to the Sunmodule panels. Locally manufactured panels were also more expensive. This information combined with the fact that these increased energy incentives expire in 2020, we have determined that Sunmodule panels would be a better investment. (64) - Iteck Energy PV Panels (4) - Theia 4.4 Inverters Initial Investment $86,198 WA Manufactured PV Panel Cost analysis Tax Rebates Cost Less Rebates Annual Production $25,859 $60,338.6 $9,821 Payback Period 6.14 yrs. Due to the increased payback period in addition to the fact that production incentives will expire in 2020, our recommendation is to use Sunmodule panels with Fronius inverters. May 10, 2013 APPENDIX 120 Architecture Hall | University of Washington | Seattle, WA 98105 Appendix B- Lighting May 10, 2013 APPENDIX 120 Architecture Hall | University of Washington | Seattle, WA 98105 Appendix C – EV Charging Station May 10, 2013 APPENDIX 120 Architecture Hall | University of Washington | Seattle, WA 98105 Appendix D – PV Energy 9 May 2012 May 10, 2013 May 10, 2013 May 9, 2013 APPENDIX