Report

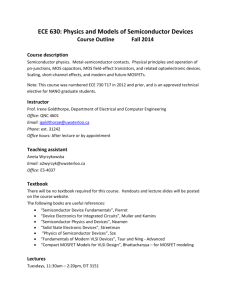

advertisement