READ MORE - Frank`s International

advertisement

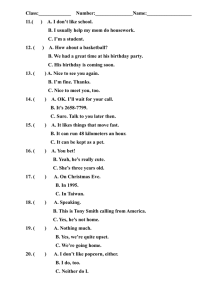

Frank's International Direct April 2014 • Volume 8, Issue 2 • Oil & Gas Industry Frank's CRT Tools Introduced to the Latin American Marketplace PG 10 Letter from the CEO From land to sea, Frank’s International has hit the ground run- ning as we embark on new projects all over the world in 2014. From deepwater contracts in the Middle East to mudline recovery in Malaysia, Frank’s International has continued to build an honest relationship with new and existing customers just like my grandfather, Frank Mosing, in 1938. Research and development is continually evolving in our engineering department as new requests stream in from clients all over the world to meet their ever-changing demands. All of this takes place in Frank’s hometown, Lafayette, Louisiana. Louisiana became known for petroleum and natural gas in the 1940s and is now America’s thirdlargest producer of petroleum and the third-leading state in petroleum refining. As we continue to grow as a company, Frank’s International now employs more than 4,000 individuals. Many employees work a majority of their working careers and even end up retiring with Frank’s. That is a true testament to the kind of family atmosphere that continues today. N ot all companies engage in community involvement, but it has always been our second nature to give back to the community. I am proud to say that Frank’s International has continued to be involved in community service and organizations all over the world. K eeping up with the Frank’s tradition of being “Best in Class” can only be attributed to all our employees, customers and investors who continue to support the company through the hard work and effort of keeping the Frank’s name true to our heritage and all of our industry standards. Safety, as always, is our number-one priority for every job we run, and we celebrate these milestones by taking each step forward. Frank’s International is doing so by utilizing third-party safety organizations in conjunction with other compliance initiatives to continuously improve safety practices. As we begin our 76th year in business, I am eager to continue building upon the Frank’s International legacy. Sincerely, Keith Mosing Chairman & CEO Frank’s International 11 9 15 18 Frank's International Direct Contents 9 Frank’s Integrated Tong Cassette Systems 10 Frank’s CRT Tools Introduced to the Latin American Marketplace 11 New Operations Building 12 Frank’s Brazil Base Improvements 12 Safety and the Community at Frank’s Brazil 13 Frank’s Mumbai 13 Compliance: Step Toward the Future 14 First Below-Mudline Whipstock in Malaysia by Selaut (Frank’s) 16 New Technology Skills Training 16 Global Advantages of the Jet String Elevator 17 Victor C. Szabo Named Chief Accounting Officer 18 LAGCOE 18 Chili Cook-Off 19 Fin, Feather, Fur Food Festival 19 Franksgiving 20 Understanding At-Risk Behaviors 22 Frank’s Employee Anniversaries 2014 15 Frank’s Malaysia Frank's International Direct is published by Innovative Publishing. 10629 Henning Way, Suite 8 Louisville, KY 40241 Phone 502.423.7272 • Fax 888.780.2241 Innovative Publishing specializes in creating custom magazines for associations and businesses. Please direct inquiries to Aran Jackson at aran@innovativepublishing.com. 800-373-0896 • 281-565-9700 • www.flywesternairways.com Western Airways, Inc. • Sugar Land Regional Airport • 100 Jim Davidson Drive • Sugar Land, TX 77498 6 1375-17.indd 1 7/3/13 4:23 PM ® Advertisers Index Volume 8, Issue 2 FI Direct Coordinator: Christina Raynor Christina.Raynor@franksintl.com U.S. Corporate Headquarters: Frank’s International, LLC 10260 Westheimer, Suite 700 Houston, TX 77042 Phone: (281) 966-7300 Fax: (281) 558-0568 Visit us on the Web: www.franksinternational.com Frank’s International Direct features the capabilities and services of Frank’s International’s companies while emphasizing its uncompromising commitment to safety and excellence. Directed to domestic and international drilling contractors, integrated service companies, and oil-company drilling departments, this magazine seeks to distinguish Frank’s International throughout the worldwide energy service industry. Frank’s International, LLC finds its roots in the entrepreneurial spirit and dedication of Mr. Frank Mosing. On the cover: Keith Mosing, Chairman and CEO of Frank’s International, with Donald Mosing at Frank's International's 75th anniversary celebration. We at Frank’s International would like to thank all of our valued partners who have made this issue of Frank's International Direct possible. We appreciate the valuable relationships we have formed with these companies in our locations all over the world, as well as the contributions they make to our successful operations. We look forward to many successful collaborations in the future. Ace Specialties.............................................................................................................30 Amegy Bank......................................................................................................................6 Analytic Stress Relieving, Inc................................................................................26 Blohm + Voss Oil Tools................................................................................................2 Connector Specialists Incorporated.................................................................30 Dwight Andrus Insurance.........................................................................................4 Franklin Electrofluid Co., Inc..................................................................................30 GearTec.............................................................................................................................27 GHX Industrial, LLC.....................................................................................................26 Global Elastomeric Products, Inc........................................................................26 This contains forward-looking statements within the meaning of Section 27A of the Securities Act of 1933 and Section 21E of the Securities Exchange Act of 1934. All statements, other than statements of historical facts, included herein that address activities, events or developments that the Company expects, believes or anticipates will or may occur in the future are forwardlooking statements. Without limiting the generality of the foregoing, forward-looking statements contained herein may include statements, estimates and projections regarding the Company’s future financial position, operations, performance, returns, divestitures, capital expenditure budget, and other guidance. These statements are based on certain assumptions made by the Company based on management’s experience, expectations and perception of historical trends, current conditions, anticipated future developments and other factors believed to be appropriate. Forward-looking statements are not guarantees of performance. Although the Company believes the expectations reflected in its forward-looking statements are reasonable and are based on reasonable assumptions, no assurance can be given that these assumptions are accurate or that any of these expectations will be achieved (in full or at all) or will prove to have been correct. Moreover, such statements are subject to a number of assumptions, risks and uncertainties, many of which are beyond the control of the Company, which may cause actual results to differ materially from those implied or expressed by the forward-looking statements. These include the factors discussed or referenced in the “Risk Factors” section of the Company’s Annual Report on Form 10-K filed with the U.S. Securities and Exchange Commission (the “SEC”) on March. Gulf South Machine, Inc..........................................................................................27 Holloway Drilling Equipment, Inc......................................................................31 Hydradyne LLC.............................................................................................................21 Industrial & Marine Equipment Company, Inc............................................31 Industrial Screw & Supply......................................................................................31 IntegriCert, LLC............................................................................................................31 MC Tubular Products, Inc........................................................................................27 Osha Liang......................................................................................................................27 Phoenix Machine Shop...........................................................................................27 Ralph’s Industrial Electronics Supplies............................................................27 The Newport Group.....................................................................................................8 Western Airways.............................................................................................................6 Womack Machine Supply Company...................................................................8 Any forward-looking statement speaks only as of the date on which such statement is made, and the Company undertakes no obligation to correct or update any forward-looking statement, whether as a result of new information, future events or otherwise, except as required by applicable law. 7 8 Frank’s Integrated Tong Cassette Systems by Brian Begnaud and Mike Webre RTS-H Cassette in MPT-200 Modular Roughneck RTS-ST Cassette in ST-160 Modular Roughneck F rank’s International has developed a range of Integrated RTS Tong Cassettes to interface with specific Iron Roughnecks offered by NOV: the MPT-200, ARN-200, AR-5000 and ST-160 modular roughnecks. The Frank’s tong cassettes are capable of making up and breaking out a large range of pipe sizes employing three tong cassettes. The 7 5/8-inch casing/tubing tong cassette handles 4-inch to 7 5/8-inch diameter pipe, 14 3/8-inch casing/riser tong cassette handles 7-inch to 14 3/8-inch, and XT-22-inch casing tong cassette handles 14-inch to 22-inch. The 7 5/8-inch cassette can be fitted with optional 8 3/4inch fluid grip system to eliminate gripping marks when torquing chromium and other high-grade completion tubing, as can the 14 3/8-inch tong when equipped with 7 5/8-inch jaw reducer kit. The 14 3/8-inch cassette provides for variable separation distance between the tong and backup to accommodate casing and drillpipe landing string connections. Computerized data trek torque turn systems are available for all Frank’s tongs. for our cassette comes from the rig supply. The roughneck frame can position the tong to and from the well center via the driller’s remote-control station. The tong cassette is controlled by Frank’s personnel via a Frank’s pneumatic control console to operate all tong and backup functions. Some roughneck systems can readily accommodate the larger XT-22-inch cassette, while others must employ a Frank’s adapter darriage to handle the extra mass and provide vertical tong positioning, with the adapter installed between the roughneck transport frame and the tong cassette, including all its cassettes. The modular NOV roughnecks rely on either rail or linkage transport systems to manipulate the rig’s pipe wrench module, used to make up and break out drill pipe. These wrench modules can then be uncoupled, and Frank’s casing tong modules (or cassettes) can be installed in their place while the roughneck is in the parked position. Once installed, the hydraulic power The ability of Frank’s to provide something that can achieve quick rig-up, which maintains the safety benefit of the rig’s ZMS (zone management systems) and ESD (emergency shut-down systems), does not require separate hydraulic power units, is simple to operate and troubleshoot, and has been well received on many of the latest deepwater new-build rigs. 9 Frank’s CRT Tools Introduced to the Latin American In September 2013, the regional vice president, all seven country managers and regional supporting functions (marketing, finance, CRT product line, sales and business development) gathered together in Panama City, Panama, to review the new organization and understand the new vision for the region. G oing through the process of reviewing the potential opportunities of each country and comparing them to the Frank’s portfolio of offerings, it was evident that a key component was missing. Casing running tool (CRT) technology was not deployed to almost any country in Latin America; therefore, a strategy was needed to be constructed in order to consider each aspect of deploying the tools into the region. The first key point for the deployment of CRT technology was to analyze the market conditions to determine what tools needed to be brought into each country. Another fundamental step in this process was having the right technical personnel to operate the equipment. The process entailed the selection of existing Frank’s personnel or pulling competent personnel from the region and training and developing their competencies to operate, maintain and troubleshoot the equipment. A multitiered process plan was developed in order to effectively introduce the CRT products into each country. The approach consisted of face-to-face customer visits/ presentations and performing an assessment of the operational facilities to survey their capabilities to support CRT jobs and 10 Operation of CRT in Each Country (Inputs) Identify Potential Clients (determine type of CRT application) Revenue Calculation (utilization + job pricing) Operation Cost (maintenance + spare parts + degradation + labor + insurance, etc.) CRT QTY CRT Operating in Each Country Training and Competence of Employees (identify support personnel for first five jobs) (CAPEX + import tax + mobilization) Identify Equipment to Perform Maintenance (facility and tools) Marketplace New Operations Building service the equipment. A logistical plan was then developed to address shipments of CRT tool packages to the region, and an official training program for Spanish-speaking Frank’s operators was developed. Colombia was strategically targeted as the first country within the region to introduce Frank’s CRT products. First and second steps were completed during the month of November, and a draft copy of the tool list was prepared. For the training and competence part of the process plan, two Colombian operators were scheduled to arrive in Lafayette, Louisiana, for FA-1-14” and FX-350 training in early December 2013. The training program consisted of a basic technical portion delivered by the Lafayette training department and supported by two experienced CRT technicians (Kilgore, Texas, base) who were fluent in Spanish to translate during the training period. Formal training consisted of hands-on training in the shop and on the training rig and a follow-up by field on-the-job training coordinated through our Kilgore, Texas, base that lasted approximately four weeks. The formal classroom training was complemented with training-rig time running and pulling four 200-foot strings of pipe (two strings with FA-1 and two strings with FX-350), on-thejob training in the field running casing and shop maintenance for the CRT products. The Colombian operators were mobilized to the Kilgore operations base and served as observers during two FX-350 jobs in the local area. The trainees returned with certifications of completion of their training and documented on-the-job training within Frank’s Job Data Debriefing System. n September 25, Frank’s held a groundbreaking ceremony for its new Operations Facility on Beau Pre Road in Lafayette, Louisiana. The 175,000-square-foot facility will consist of a combination of shop, warehouse and office space to house the company’s operational departments and approximately 200 employees. To date, CRT equipment has arrived incountry, and CRT jobs are expected to commence by early Q2 in Colombia. Mexico, Ecuador and Peru are slated to be the next countries to receive CRT equipment in an attempt to maximize our presence with regard to CRT in the Latin American region. The facility is the first of several new construction projects planned for Frank’s International’s Lafayette campus. It is designed to safely optimize operational workflow and bring together key components in a centralized location. These changes O will increase procedural continuity and communication among departments and encourage employee crosstraining for greater flexibility. Speaking at the event, Chairman and CEO Keith Mosing discussed the company’s history of innovation and plans for future development. “We want to continue growing our company, investing in research and development, and delivering new products for the energy sector,” he said. “We recognize the importance of Lafayette as the gateway to the oil and gas industry, and we’re proud to continue investing in this community.” 11 Frank’s Brazil Base Improvements by Drew Gardenier, David Anderson and the Operations Team renovation has been undertaken. The area has become wide open with a great space for work and storage. Other large-scale improvements were the addition of a state-ofthe-art accessory bucking system, new high-pressure cleaning systems and a wheel abrader system to aid rapid preparation for regular scheduled inspections per the Frank’s International QA/ QC system. All of this equipment and storage is under a comprehensive shopwide overhead crane system, which again greatly enhances the safety and work flow of all processes involved. T he Frank’s International base in Macae, Brazil, has undergone a round of improvements. After the departure of a long-term tenant that shared the Brazil base, the space opened up to improve the safety and general workflow for ongoing and expanding Frank’s operations. Under the guidance of recently appointed management Dennis Walker, general manager, and David Anderson, operations manager, a large-scale Frank’s Brazil has also gained the second-floor office space, thus making room for the staff to improve and expand its office space. Further improvement to the yard, outside storage and training areas are ongoing, as is a total revamp of the pressure-testing facility in the yard. Even the city of Macae is on board in longterm efforts to renovate the access roads and reroute traffic for efficiency and further safety near completion. All of the above add to Frank’s ability to provide our clients with seamless service in a pleasant, professional environment and achieve the Frank’s advantage! Safety and the Community at Frank’s Brazil by Drew Gardenier, Dilsa Santos and the Human Resources Team Frank’s Brazil recently achieved a milestone of 300 days with no lost time or recordable incidents. The location took this opportunity to celebrate this achievement with a barbecue at the recently renovated Frank’s Macae facility for all employees. The celebration was well attended, and a good time was had by all, as this was a solid example of Frank’s commitment to its employees’ safety around the world. Frank’s also had a training day under the local SIPAT guidelines in Brazil for all employees, which further demonstrated the commitment to safety and excellence of service by the Frank’s Brazil team. Frank’s Brazil employees also demonstrated their commitment to the community by taking part in several charitable activities. Two recent events were a visit/donation to a local retirement center 12 and a visit/donation to a local orphanage. These are ongoing charitable activities by our management and employees and demonstrate the involvement and commitment to the local community that, indeed, supports all of us! We look forward to more safety milestones and community involvement for the team in the future! Frank’s Mumbai Frank’s International Mumbai office serves as a global support hub comprised of the Intellectual Property (IP); Strategic, Economic, Analytics Department (SEAD); Finance; Information Technology (IT); and Commercial Department (CD) teams. The IP team, led by Nivedita Singh, provides integral legal support in prosecuting, maintaining and enhancing worldwide Frank’s patent and trademark portfolio. The SEAD team, led by Madhuri Kohtari, centers its focus and efforts on the company’s comparative advantages. In turn, the SEAD team works with regional and district managers in developing a proactive strategy with the intended objective of enhancing financial performance from a revenue and profitability perspective. The Finance team, lead by Kashyap Acharya, is responsible for accurate US GAAP accounting and auditing, and timely financial reporting. The IT team is involved in the design, development and support of global business-critical applications and computing services for Frank’s International. The CD team, set up more than seven years ago, now comprises 23 members led by Chetan Vakharia, whose primary mission is the preparation, execution and administration of tenders, awards and contracts. Compliance: Step Toward the Future by Nuno Mana The oil and gas industry is now, more than ever, demanding compliance of its products and services. Due to recent safety-related incidents, as well as constant advancements in technology, it is becoming increasingly difficult for organizations to manage compliance, no matter the regions or markets they serve. Frank’s International has an internal compliance group committed to ensuring that the company is able to meet these requirements. Frank’s International, being aware of these significant challenges, has already made this step toward the future, acting proactively in our conceptual engineering work to ensure that our products are designed according to required applicable regulatory legislations and the most current normative references, while implementing state-of-the-art practices and using renowned third-party certification organizations. Regulatory compliance is mandatory and describes the way in which corporations ensure that their products comply with relevant laws and regulations. For example, in the European Union, all the directives under the umbrella of CE marking, such as the Machinery Directive and Explosive Atmospheres (ATEX), are legally required. Failing to meet regulatory compliance represents violations that can have catastrophic consequences or significant penalties. This compliance can be achieved internally or through a third-party certification body. Frank’s International currently has CE marking technical files on 29 different products, ranging from horseshoe elevators to casing running tools. In the Compliance Group, we are very proud of the achievements made so far, thankful for all the support and very excited with the challenges ahead. The Compliance Group is also responsible for interacting with Det Norske Veritas (DNV) for type approvals and case-by-case approvals. DNV offers certifications for containers, baskets and other equipment that is lifted offshore, as well as hoisting equipment (such as elevators, etc.). 13 First Below-Mudline Whipstock in Malaysia by Selaut (Frank’s) by Douglas Reid In September 2013, Selaut Oil Tools Services successfully completed its first belowmudline whipstock project for a major IOC offshore of Malaysia. It consisted of cutting and removing part of a 24-inch conductor string 86 feet below the mudline, replacing it with a new 22-inch string. Planning began months before in December 2012, headed up by Frank’s Far East Regional Hammer Manager Gary Young. Upon analysis, Gary and his team recommended the use of the S-90 Hydraulic Hammer. The target depth calculated took into consideration the bending and driving stresses applied to the new conductor string, giving a target penetration rate. In order to achieve the optimum penetration, Frank’s International designed a custom whipstock for the work, which was built in Singapore to reduce delivery time and cost to the client. Derrick Jones, a whipstock specialist from Frank’s Lafayette base, was selected to head up the job offshore. He worked as a team with Alex Voon, Gajen Kumaresan and Stanley Umpi, all from Selaut Malaysia. Prior to the team arriving on the rig, the well had been abandoned, and an internal cut had been made by another service company. Subsequently, the freed conductor was pulled to the surface and cut into lengths using a Selaut-provided guillotine saw. A dual drill was also used to cut holes for lift pin installation, allowing the remainder of the string to be lifted to the surface. Following the retrieval of the conductor, the hole was enlarged by the rig to ensure a smooth drive off from the whipstock, which was oriented to the planned azimuth. The shoe sheared from the whipstock problem-free. The team ran the replacement conductor, and the S-90 Hydraulic Hammer was used to efficiently drive it to the target depth. Once 14 reached, the team utilized a cold cutting unit to create a clean cut of the conductor at the wellhead deck. The success of this job has highlighted to all operators in the region the capability of Selaut/Frank’s to execute slot recovery work both above and below the mudline. In total, four slot recovery jobs have been completed by Selaut in the region, with more already planned for the future. A special thanks goes out to the engineering groups in Lafayette and Singapore for their calculations and technical drawings. Frank’s Malaysia by Paul Grayson and Ratna Kumar PETRONAS is a Malaysian oil and gas company that was founded in 1974. PETRONAS has more than 100 subsidiaries and many joint venture companies in which PETRONAS has a stake. One of its key subsidiaries, PETRONAS Carigali Sdn Bhd (PCSB), is the main hydrocarbon exploration arm in Malaysia. T o ensure competitive pricing; maximized utilization of resources; and optimization of its project deliveries in terms of safety, costs and schedule, PETRONAS engaged in setting up Pan Malaysia, which contracts in cooperation with its production sharing contractors (PSCs). The provision of tubular handling equipment and services (THES) was one of the contracts that were initiated in 2000. The invitation to tender in cooperation with PCSB was extended to Sarawak Shell Berhad, Exxon Mobile Exploration, and Production (M) Inc. Each PSC technical requirement and commercial evaluation was standardized and transparent among the companies. In 2006, the second Pan Malaysia THES contract was extended to include Nippon Oil & Gas Exploration (Malaysia). For the third Pan Malaysia THES contract, seven PSCs were involved: Sarawak Shell Berhad/Sabah Shell Petroleum Company Ltd., ExxonMobil Exploration and Production (M) Inc., MDC Oil & Gas (SK 320) Ltd., Murphy Sarawak Oil Co. Ltd./Sabah Oil Co. Ltd./Peninsular Malaysia Oil Co., JX Nippon Oil & Gas Exploration (Malaysia) Limited, Petrofac (Malaysia – PM 304) Ltd. and Petronas Carigali Sdn Bhd. A market survey was released in July 2012, followed by an invitation to bid (ITB) through the Shell Marketroot website in January 2013. Selaut Oil Tool Services Sdn Bhd, an associate company of Frank’s International, qualified and was invited to participate in the tender process, and its bid submission was made on March 4, 2013. A total of eight technical clarifications (inclusive of terms and conditions and 21 exceptions), one face-to-face meeting in April 2013, two techno-commercial clarification meetings in September 2013 and a site visit to Selaut Labuan base in September were required between the Pan Malaysia principals and Selaut through the bid evaluation phase. On October 29, Selaut was invited for a kickoff meeting with PCSB and Murphy and was given a letter of award for the “Shallow Water” (East Malaysia Operations). PCSB’s award is considered a huge success since this marks its return to work after more than 12 years since the last serviced PCSB in the Dulang field. This also gives other PSCs options to farm into PCSB’s THES contract, giving Selaut the opportunity to secure additional contracts without bidding exercises through the validity of this contract, which ends in October 2018. Selaut anticipates managing eight rig packages for PCSB and one rig package for Murphy under this contract. Selaut has the option to secure additional rig packages, subject to availability of resources, and also gives opportunities to introduce Frank’s new technology and mechanical tools. The award of this contract cements Selaut Oil Tool Services Sdn Bhd a position in Malaysia and offers a great platform on which to build a long-term future. This success is a product of the hard work and dedication of the Selaut KL team, as well as the Operations and Commercial teams of Frank’s International Singapore, Dubai, India and Lafayette. 15 New Technology Skills Training by Jacke West Skills training and the preparation of new equipment deployment are earning positive returns on investment and recognition from our business partners. These results are only possible through dedicated support across all divisions of Frank’s International. There are many examples that could be shared, all of which are deserving of recognition. I would like to share one of those examples. Angola Services was awarded work using a jet string elevator for one of our business partners in Angola. could achieve operational excellence. Local management acknowledged personnel’s confidence. Engineering, Management and Services worked on a plan to identify Angola personnel and equipment for training to take place in the United States. Training was executed through safety, quality and training systems. Angola Services achieved operational excellence and high marks noted on its job debriefing form. To include the business partner’s quote, “Excellent Performance. First Class operations with Jet String Elevator which added benefit to our operation. Thorough preparation by Frank’s Supervisor.” Personnel returned from the United States highly motivated and confident they The same business partner in the Gulf of Mexico monitors the job performance in Angola. Today, the business partner is requesting additional jet string elevators in Angola and the Gulf of Mexico, due to achieving operational excellence in Angola. Frank’s International truly understands the concept of teamwork to keep Frank’s International … first-class — worldwide in achieving operational excellence. Global Advantages of the Jet String Elevator by Cody Roy T he traditional method of handling jetted pipe can prove problematic because it requires pad eyes or other lifting profiles, which can impair well condition, efficiency and safety. In response, Frank’s International has created the jet string elevator (JSE). Designed to lift flush OD 36-inch casing from the horizontal to vertical position, this new tool eliminates the need for pad eyes or other lifting profiles. Plus, the JSE can support an entire string weighing up to 200 tons. the pad eyes, these predicaments can occur due to the boss design disturbing soil more than flush pipe would. Surface interruptions reduce the skin friction required to support structural casing. The removal of pad eyes — a practice required of other tools — can be troublesome. Casing’s high-grade materials are not designed to withstand heating outside of a controlled environment, so the torches and grinders used to remove these implements can inflict gouges that could potentially reduce pipe strength. Like pad eyes, other lifting profiles have drawbacks too. For example, collars, similar to bosses, cause mudline surface interruptions. The installation and removal of lift subs and clamps prove cumbersome and time-consuming. Furthermore, the height at which these implements must be manipulated necessitates the precarious use of ladders. Bolted-on pad eyes (utilizing bosses) sometimes have complications as well, namely broaching, subsidence, trapped casing or even total wellbore failure. After unbolting By eliminating the need for pad eyes or other lifting profiles, the JSE negates all of the potential problems associated with these implements, which serves 16 the industry well. In fact, using the JSE, one customer reduced average job run time by five hours or more, while saving in excess of $175,000 (as reported in SPE 165897: a case study of large-scale batch sets for Hess’ Tubular Bells Campaign). And BP-Angola, which had also previously used traditional pad eyes, indicated similar benefits for a four-well batch set. The JSE afforded the Angola Region – Ensco DS6 – Top Hole Batch Campaign a 31 percent time improvement (4.3 hours of rig time per well, totaling 17.2 hours for four top holes) and $470,000 in savings. Victor C. Szabo Named Chief Accounting Officer In February 2014, Franks International’s chairman and CEO, Keith Mosing, named Victor C. Szabo as the company’s chief accounting officer. Victor and his accounting team were instrumental in transitioning Frank’s International from a private company to a public entity in August 2013. Victor has spent the last eight years of his nearly 20-year career working for Frank’s International. He began as an assistant controller and was quickly promoted to controller in 2006. Victor progressively expanded his job duties and responsibilities to become the group controller in 2010. Before joining Frank’s International, Victor obtained a diverse background with upstream and midstream energy companies. In these roles, he had various levels of accounting and financial planning and analysis responsibilities with both privately held and publicly traded companies. to go the extra mile for the sake of the company. The dedication and work ethic that Victor and the entire accounting organization demonstrated during the company’s public filing last year was reflected in the ability to meet all of the filing deadlines as set forth by the initial public offering team. Victor’s philosophy of teamwork and cooperation has fostered an accounting team dedicated to excellence and has cultivated individuals who are willing This continued cooperation and dedication is necessary for the future success of the organization. Victor’s focus on continued business process improvement and change management will lead us to improved efficiencies while providing additional information that our management team requires. Despite the change required when the company successfully became public, we are confident Victor and his team will continue this momentum by adding to and maintaining the needed systems and structure to sustain the company’s growth and ensure compliance amid the stringent public-company regulations. 17 LAGCOE F rank’s International’s booth at the biennial LAGCOE exhibition in Lafayette was based on our proud history in the oil and gas industry. Frank’s representatives were on hand to share some of our industry-leading innovations, including high-definition animations of some of our patented tools, and, as always, Mr. Vic was on hand to serve up his famous roasted peanuts. In addition to banners with images from Frank’s history going back to 1938, the booth featured another memorable guest: a Cessna 180 Amphibian airplane. The plane served to highlight the important role aviation has played in the history of Frank’s, beginning with Frank Mosing’s second son, Billy, and continuing to Keith and Mike Mosing. Chili Cook-Off On a chilly Thursday in November, Frank’s International hosted its second annual Chili Cook-Off to benefit the United Way of Acadiana in Lafayette, Louisiana. The cool temperatures were a perfect match for the spicy competition, with 75 teams producing unique chili dishes from ingredients both traditional and exotic. An appreciative crowd of hundreds attended the event 18 outside the Acadiana Mall, raising $43,280 for the United Way of Acadiana and collecting 629 pounds of nonperishable food items for FoodNet of Acadiana. Prizes were awarded for best chili in each category, as well as for spirit and costumes. The event was made possible by the generous support of many sponsors, volunteers and cooking teams. Frank’s presented the check to the United Way of Acadiana on December 12, 2013. The money raised by the event will go to support United Way of Acadiana’s efforts to help create an educated, prosperous and safe community where all individuals and families achieve their potential. Fin, Feather, Fur Food Festival On November 14, Frank’s International competed in the 10th Annual Fin, Feather, Fur Food Festival put on by the American Association of Drilling Engineers in Houston, Texas. Led by Frank’s very own master chefs, Ferdie Dupuis and Toby Pitre, the Frank’s team cooked up the first-place finish in the “Fur” category with its wild boar pizza. What a way for Frank’s International to wrap up its 75-year anniversary! M All proceeds went toward AADE activities and educational opportunities, such as the Offshore Energy Center in Galveston. This center showcases aspects of the oil and gas industry with teaching resources, interactive lessons and hands-on activities. Franksgiving ore than 220 families in Lafayette, Louisiana, received all the ingredients for a delicious holiday meal courtesy of Frank’s employees and vendors. The annual event took place on November 26, with dozens of Frank’s employees helping with boxing and unloading. Meals were picked up by individual families, local churches and FoodNet. Each box included the fixings for a festive Thanksgiving meal, including a 12- to 14-pound turkey, dirty rice, green beans, yams, corn, bread, macaroni and cheese, and two liters of soda. It was another great year for our signature “Franksgiving” event. 19 Understanding At-Risk Be by Cliff Roberts, CSP At-risk behaviors normally surface as a major contributing cause during incident investigations. Risk is defined as the possibility that something bad or unpleasant (such as an injury or a loss) will happen. Behavior is defined as the way in which one acts or conducts oneself. The table on page 21 is a simple way of understandDecision ing at-risk behaviors. When at-risk behaviors are controlled, only then will incident prevention will improve in a large way. At-Risk Behaviors/ Conditions Errors 20 Knowledge/ Information Technique Examples of at-risk behaviors include but are not limited to: • Not following a written or well-established procedure • Placing hands on or in an identified pinch-point zone • Speeding beyond the established speed-limit posting • Handling hazardous chemicals without proper PPE • Not using a safety/seat belt Deviations Perceptual Routine Exceptional Attention/ Memory Prevention of at-risk behaviors include but is not limited to: • Never bypass or not use a safety device (safety belt, fall-arrest harness, interlocks, etc.) • Always follow established and well-known procedures • Receive formal training (HSE, skilled, awareness, customer, etc.) • Follow the safety rules 100 percent of the time • Pay attention to your surroundings, and when in doubt, ask good questions haviors Behavioral Behavioral Factors Factors The events and conditions that are closely tied to the occurrence and can be described as active failures of actions committed by the employee that resulted in the human error or at-risk situation. Errors Errors are factors in a mishap when mental or physical activities of the employee fail to achieve their intended outcome as a result of skill-based, judgment-based and/or perception-based errors. These types of errors are unintended. Decision • Was the behavior or action of the individual intended yet the chosen plan inadequate to achieve the desired outcome? o Rules-based decision (if X, then do Y; highly procedural tasks) o Choice decision (knowledge-based, inadequate knowledge of systems/procedures) o Structured (procedures not 100 percent complete) Technique (Execution) • Was the execution of the technique being applied somehow flawed (lack of ability or skill)? Attention/ Memory • Was there an attention/memory error during the employee’s execution of a routine task whereby his or her lack of attention to detail while performing a specific task resulted in the omission of a required step or inadvertent activation of equipment? Knowledge/ Information • Did the error involve incorrect or insufficient information applied to a routine task? This can happen due to lack of training, confusing or multiple sources of information, or incorrect work direction being provided. Perceptual • Was there a loss of attention, auditory cues, balance, focus or visual cues leading to the human error? o Misjudged clearance o Loss of situational awareness o Visual illusions Deviations Deviations are factors in an occurrence when an employee’s actions represent willful disregard for or noncompliance to company policy, standard operating processes and procedures. Routine and exceptional deviations are not differentiated by the nature of the act but whether or not the act had become the norm within the organization, whatever its level. Routine Deviations • Did the behavior involve a willful disregard for company policy, standard operating processes and procedures whereby the deviation has become the norm in the workplace and noncompliance has been accepted or condoned by at least one level of supervision? Exceptional Deviation • Did the behavior involve a willful disregard for or noncompliance to company policy, standard operating processes and procedures whereby compliance is normally enforced at all levels of supervision? o When fundamental processes are performed and steps of the process are omitted, an exceptional deviation may have occurred 337-839-8612 SYSTEMS COMPONENTS - DESIGN - FABRICATION - SERVICE REPAIR www.franksinternational.com Anchor Flange Braden/Gearmatic Brevini Parker Filtration Braden Authorized Service Center Chelsea PTO Parker Denison D.P. Mfg. Parker Cylinders Parker Commercial Poclain Custom HPUs Parker Olaer Parker IQAN MICO Brake NOSHOK Parker Pneumatic Fax 337-839-8619 2937 US Hwy. 90 Broussard, LA. 70518 Parker Hose Prod. Parker Snap-tite Stauff Zinga Industries You are invited to explore Job Opportunities with Hydradyne Today www.hydradynellc.com 21 Frank’s Employee Anniversaries 2014 Donald Mosing, 64 years Thomas Thibodeaux, 49 years Elie Prejean, 47 years Dennis Castille, 46 years Keith Mosing, 42 years Donald Cain, 41 years Voorhies Short, 41 years Pamela Doucet, 40 years Brad Mosing, 40 years Brent Mosing, 40 years Jerel West, 40 years Dale LeBlanc, 39 years Wilmer Comeaux, 38 years Huey Romero Jr., 38 years Johnnie Stinson, 38 years Francis Charleville, 37 years Robert Gilbert, 37 years Aubrey Castille, 35 years Leonard Castille, 35 years Wayne Champagne, 35 years Jack Foman, 35 years Randy Patin, 35 years Terri Vasquez, 35 years Mike Webre, 35 years Joseph Antoine, 34 years Jerry Cameron, 34 years Russell Carr, 34 years Todd Lavergne, 34 years Michael Mosing, 34 years Murphy Narcisse, 34 years Terry Bartuska, 33 years David Bearb, 33 years Rahmat Hamzah, 33 years Mike Mather, 33 years Nicholas Mirza, 33 years Michael Primeaux, 33 years Dick Rader, 33 years Mark Sibille, 33 years Dale Smith 33 years Francis Suire, 33 years Jon Veverica, 33 years John Bearb, 32 years James Hay, 32 years Gary LeBlanc, 32 years Kendall Mosing, 32 years Jack Crooks, 31 years Jim Delaney, 31 years Paulo Acevedo, 30 years Lawrence Angelle, 30 years Dwayne Dugas, 30 years Les Ellis, 30 years Thomasine Hollier, 30 years Guy Hustinx, 30 years Jamil Madin, 30 years Randy Reed, 30 years Gerald Rice, 30 years Lester Roberts, 30 years David Scott, 30 years Claude Jackson, 29 years Alain Miramon, 29 years 23 Frank’s Employee Anniversaries 2014 Mo Tusheng, 29 years Jimmy Guangfei Xu, 29 years James Castille, 28 years Donald Fontenot, 28 years David Hays, 28 years Jerry Hemmingway, 28 years James LeBlanc, 28 years Dance Mailangkay, 28 years Kirkland Mosing, 28 years Vernon Bouligny, 27 years Ricky Breaux, 27 years James Denton, 27 years David Garrett, 27 years Bridget Ho, 27 years Nick Jain, 27 years Frank Lester, 27 years John Lethbridge, 27 years Randy Menard, 27 years Dale Patin, 27 years Jose Quinonez, 27 years Hector Ramos, 27 years Angel Salas, 27 years Edward Savoie, 27 years McLemore Savoy, 27 years Eugene Stelly, 27 years Perry Taylor, 27 years John Walker, 27 years Donald Walsh, 27 years Brady Bellot, 26 years Margaret Champagne, 26 years Gery Farnsworth, 26 years Rocky Guidry, 26 years Henry Lantz, 26 years Rhonda Melancon, 26 years Christopher Richard, 26 years Paul Shillings, 26 years Pat Sibille, 26 years Shauna Turner, 26 years Jacke West, 26 years Terry Cochran, 25 years Reginald Eagins, 25 years Drew Gardeier, 25 years Eddie Hutto, 25 years Kenneth Joubert, 25 years Kern LeBlanc, 25 years Kumar Mallenahalli, 25 years Eddie Sinclair, 25 years James Smith, 25 years Darryl Swierc, 25 years Colin Thatcher, 25 years Erie Tiwon, 25 years Not Pictured: Eddie Meche, 35 years Joseph Fontenot, 30 years Roger Stelly, 30 years Charles Adams, 29 years Ross Broussard, 26 years Rodney Turman, 26 years Antonio Valdez, 26 years Dale Castille, 25 years Ali Bin Junos, 25 years Richard Leggett, 25 years Dean Mallet, 25 years Chandrasekar Nadarasan, 25 years 25 Analytic Stress Analytic Stress Relieving, Inc. Equipment Sales, Onshore and Offshore Preheating and Stress Relieving and the largest furnace facilities on the Gulf Coast. Offices in Houston, Beaumont and Corpus Christi, Texas; Lafayette, Baton Rouge, Lake Charles and New Orleans, Louisiana; Richmond, Virginia; Trenton, New Jersey; and Pascagoula, Mississippi. • Industrial Hose • Hydraulic Hose • Metal Hose • Teflon Hose • Gasket Products • Fasteners 337-837-4673 (337) 237-8790 GHX Industrial, LLC 5425 US Highway 90 East Broussard, LA 70518-5906 117 Board Road • Lafayette, LA 70508 (337) 237-1257 Fax • www.analyticstress.com Inquiries: pat@analyticstress.com WAITING FOR THE ECONOMY TO CHANGE? Made in USA Proudly Serving Frank’s International While you’re waiting, your competitors are changing their economy. They’re targeting Frank's International clients who make purchasing decisions in this multimillion-dollar industry. And these members actively read this publication like you’re doing right now. WANT TO INFLUENCE THEIR BUYING DECISIONS? Contact Bob Sales at 502.423.7272 or bob@innovativepublishing.com to see how you can advertise in future issues of Frank's International Direct! Custom Molded Rubber Products – For the Oilfield Specializing in packer cups ● 3” – 26” Standard and custom applications www.globaleee.com GLOBAL ELASTOMERIC PRODUCTS, INC. 5551 District Blvd. Bakersfield CA 93313 ●Phone (661) 831-5380 ●Fax (661) 661-6562 26 www.innovativepublishing.com Precision Machined Products MC TUBULAR PRODUCTS, INC. Machining bar stock, castings and forging from brass, carbon steel, stainless steel, alloy steel and many others. Together, GSM and Drilex use versatile equipment and operations efficient enough to complete with your inhouse production, or stay within your outsource budgets. We are a trading company specializing in the import and export of steel pipes and tubes to the U.S. market and to various overseas countries. • • • • • CNCProductionMachining 2,4&7AxisCNCTurning 3&4AxisCNCMilling PrecisionCNCMachining Welding,Grinding,Honing,Broaching, Casting&Forging • MiI-I-45208A • ISO9002,ANSI/ASZ1.4&ANSI/VCSL Z540.1Compliant Ponchatoula, LA Houston, TX 985-386-9401 • 985-510-9551 rener@gulfsouthmachine.com www.gulfsouthmachine.com www.drilex.com Houston • Calgary 757 N. Eldridge Pkwy., Suite 650 Houston, Texas 77079 sales@mctp.com • 281-870-1212 Ralph’s IndustRIal ElEctRonIcs supplIEs In eight locations with over 80,000 square feet of sales and warehouse area, we offer more inventory from more sources than any distributor serving our region. Ralph’s Industrial Electronics Supplies is a diversified full-line electronic distributor offering products of some 300 manufacturers. Alexandria, LA 318-443-4517 Lafayette,LA 337-234-4507 Baton Rouge, LA 225-344-3761 Lake Charles, LA 337-439-2493 Beaumont, TX 409-833-9443 Morgan City, LA 985-384-9831 Houston, TX 713-645-2211 New Iberia, LA 337-369-9816 www.ralphselectronics.com “We Specialize in Precision Machining and Offer Both CNC and Conventional Manufacturing” 105 E. Angus Drive Youngsville, LA 70592 337.856.8228 27 Frank's International Directory United States Corporate Headquarters: Frank’s International, LLC Houston, TX Phone: 281-966-7300 Frank’s International, LLC Lafayette, LA Phone: 337-233-0303 Algeria Frank’s International Ltd. Hassi Messaoud Phone: 21-3-297-33073 Angola Frank’s International West Africa (BVI) Ltd. Luanda and Soyo Phone: see Nigeria-Lagos Australia Frank’s Oilfield Services (AUST) PTY Ltd. Perth, WA Phone: 61-8-6937-5090 Azerbaijan Frank’s International Middle East (BVI) Ltd. Baku Phone: 994-12-497-7858 Brazil Frank’s International Brasil, Ltd. Macae Phone: 55-22-27-63-4250 Rio de Janeiro Phone: 55-21-2533-8182 Brunei Frank's International Sdn Bhd Negara Brunei Darussalam Phone: 673-3-333835 Cameroon Frank’s International West Africa (BVI) Ltd. Douala Phone: see Nigeria-Lagos Canada FI Oilfield Services Canada, ULC Edmonton, Alberta Phone: 780-463-3333 Calgary, Alberta Phone: 403-261-1995 Dartmouth, Nova Scotia Phone: 902-481-8880 Edson, Alberta Phone: 480-723-2880 Fort Nelson, British Columbia Phone: 250-233-8867 Grande Prairie, Alberta Phone: 780-539-9313 Mount Pearl, Newfoundland Phone: 709-745-3330 China Frank’s Oilfield Services Ltd. Shenzhen, Guangdong Phone: 86-755-2685-1271 Colombia Frank’s International Sucursal Colombia Bogota Phone: 057-1-321-4275 or 057-1-211-8705 or 057-1-211-4112 Yopai Congo Frank’s International West Africa (BVI) Ltd. Pointe Noire Phone: see Nigeria-Lagos Ecuador Frank’s International Equador C.A. Coca Phone: 593-6-286-0673 Quito Phone: 593-2-333-0100 England Frank’s International Ltd. Great Yarmouth Phone: 44-1-493-443044 Lowestoft Phone: 44-(0) 1502-588422 Egypt Frank’s International Middle East (BVI) Ltd. Alex Cairo Phone: 2022-758-1497 28 France Frank’s France S.A. Lescar Phone: 33-559-323810 Pau Gabon Frank’s International West Africa (BVI) Ltd. Port Gentil Phone/Fax: 241-56-5871 Germany Frank’s International GmbH Muhlen Phone: 49-549-296400 Ghana Frank's International West Africa (BVI) Ltd. Takoradi Phone: 233-31-21-97-390 Holland Frank’s International B.V. Den Helder Phone: 31-223-670000 Indonesia P.T. Selaut Insani Jakarta and Kalimantan Timur Phone: 62-21-7224437 India Frank’s International Middle East (BVI) Ltd. Mumbai Phone: 91-22-6702-8900 Israel Frank’s International Middle East (BVI) Ltd Haifa Phone: 972-(0) 52-8888265 Italy Frank’s International SRL Ravenna Phone: 39-0544-501-592 Ivory Coast Frank’s International West Africa (BVI) Ltd. Abidjan Phone: 234-(0)8055151424 Japan Integrated Services (Intl) Ltd. Tokyo Phone: see Singapore Kazakhstan Frank’s International Ltd. Atyrau Phone: 7-7122-58-6158 and 7-7122-58-6886 Kenya Frank’s International Middle East (BVI) Ltd. Phone: 971-5-06458720 Kingdom of Saudi Arabia Frank’s Rawabi S.A. Ltd. Al-Khobar Phone: 966-3-859-1494 Korea Frank’s Logistic Singapore Pte.Ltd. Phone: 65-6542-8948 Libya Frank’s International West Africa (BVI) Ltd. Tripoli Phone: 218-914628268 Malaysia Selaut Oil Tool Services Sdn Bhd. Kuala Lumpur and Labuan Phone: 60-3-7842-8010 Mauritania Frank’s International West Africa (BVI) Ltd. Phone: 234-(0)8055151424 Mexico FI Mexico de R.L. de C.V. Villahermosa Phone: 52-993-339-0287 Mozambique Frank’s International Middle East (BVI) Ltd. Phone: 255-759449510 Myanmar Frank’s Logistic Singapore Pte.Ltd. Phone: 65-6542-8948 Frank's International Domestic Locations Nigeria Frank’s International Oilfield Services (Nigeria) Ltd. Port Harcourt Phone: 234-84-231-482 Frank’s International West Africa (BVI) Ltd. Lagos Phone: 234-01-461-9416 Norway Frank’s International A.S. Sandnes Phone: 47-51-81-95-50 Stavanger Phone: 47-51-819550 Peru Frank’s International Peru S.R.L. Lima Phone: 511-421-5434 Talara Phone: 51-73-381-306 Phillippines Frank’s Oilfield Services Ltd. Makati City Phone: see Singapore Manila Russia Sakhalin Phone: 7-4242-450-545 Sakhalin Island Frank’s International Ltd. Yuzhno-Sakhalinsk Phone: 7-4242-450-545 Saudi Arabia Frank’s International Middle East (BVI) Ltd. Al- Khobar Phone: 9663-859-1494 Scotland Frank’s International Ltd. Aberdeen Phone: 44-1-224-248200 Singapore Frank’s Logistic Singapore Pte. Ltd. Tuas Basin Link Phone: 65-6542-8948 South Africa Frank’s International Ltd. Mossel Bay Phone: 44-1-224-248200 Tanzania Frank’s International Middle East (BVI) Ltd. Phone: 255-759449510 Thailand Frank’s Logistic Singapore Pte. Ltd. Phone: 65-6542-8948 Togo Frank’s International West Africa (BVI) Ltd. Phone: 234-(0)8055151424 Trinidad W.I. Frank’s International Trinidad, Ltd. San Fernando Phone/Fax: 868-652-8411 United Arab Emirates Frank’s International Middle East LLC Al Quoz Dubai Phone: 971-4-3472253 United Kingdom Pilot Drilling Control Ltd. Lowestoft Phone: 44 (0) 1493-588422 Paramode Limited Great Yarmouth Phone: 44 (0) 1493-412940 Venezuela Frank’s International Venezuela, C.A. Anaco, Anzoategui Phone: 58-282-4251395 Ojeda Phone: 58-265-632-0106 Vietnam Frank’s Logistic Singapore Pte.Ltd. Phone: 65-6542-8948 Colorado Grand Junction, CO....................................................................................970-245-5365 Louisiana Bossier City, LA...............................................................................................318-747-6119 Houma, LA........................................................................................................985-876-2392 Lafayette, LA....................................................................................................337-233-0303 Mandeville, LA................................................................................................504-525-3421 New Iberia, LA................................................................................................337-560-5552 New Orleans, LA...........................................................................................504-525-3421 Mississippi Laurel, MS (Ellisville)....................................................................................601-649-9555 New Mexico Hobbs, NM........................................................................................................575-392-7636 North Dakota Williston, ND....................................................................................................701-572-9626 Ohio Massillon, OH..................................................................................................330-236-4264 Oklahoma Elk City, OK.........................................................................................................580-225-0027 McAlester, OK..................................................................................................918-423-0688 Oklahoma City, OK......................................................................................405-672-8064 Pennsylvania Greensboro, PA..............................................................................................724-943-3243 Montgomery, PA..........................................................................................570-547-0525 Texas Alvin, TX...............................................................................................................281-331-1501 Bryan, TX.............................................................................................................979-778-8700 Burleson, TX.....................................................................................................817-447-6000 Corpus Christi, TX.........................................................................................361-289-1955 Houston, TX......................................................................................................281-966-7300 Kilgore, TX..........................................................................................................903-984-0261 Laredo, TX..........................................................................................................956-717-8500 Odessa, TX.........................................................................................................432-332-5908 Perryton, TX......................................................................................................806-436-2335 Utah Vemal, UT...........................................................................................................435-789-1698 Wyoming Casper, WY........................................................................................................307-234-1796 Cheyenne, WY................................................................................................307-634-2090 Evanston, WY..................................................................................................307-789-1801 Rock Springs, WY..........................................................................................307-382-0930 29 www.frankelectro.com • HYDRAULICS • PNEUMATICS • VACUUM • ELECTRONICS • AUTOMATION Tim Ernest Cell: 504-452-4651 E-mail: timernest@frankelectro.com Southern Louisiana MS Gulf Coastal Area Tel: 504-486-6653 800-535-2010 Fax: 504-486-6444 STRENGTH IN NUMBERS Frank's International Direct April 2014 • Volume 8, Issue 2 • Oil & Gas Industry Frank's CRT Tools Introduced to the Latin American Marketplace PG 10 To be successful in any organization, you need the right kind of help. Let us help you create a magazine that your business can be proud of. To find out how your business can have its own magazine, contact Aran Jackson at 502.423.7272 or aran@innovativepublishing.com. www.innovativepublishing.com 30 anchor • atlantic int’l coupling • Bandit • dixon emerson power transmission flex-weld (metal hose) • general ruBBer hanna • hBd thermoid • kuriyama linn • lovejoy • omega flex parker industrial hose • ross snap-tite • ssp • texcel unaflex • wika 525 Elmwood Park Blvd. New Orleans, LA 70123 Phone: (504) 733-5030 Wats: (800) 535-3003 Fax: (504) 736-0243 Email: sales@industrial-marine-eq.com Serving the Gulf South Since 1968 All Types of Fasteners 24-Hour Service (225) 356-0158 FAX (225) 356-0200 Industrial Screw & Supply 4535 Choctaw Dr. Baton Rouge, LA 70805 www.indscrew.com 31 Frank’s International 10260 Westheimer, Suite 700 Houston, TX 77042 PRSRT STD US POSTAGE PAID CHAMPAIGN, IL PERMIT NO. 100 Years of Service Mr. Frank Mosing Mr. Donald Mosing Mr. Keith Mosing Founder and President of Frank's Casing Crew & Rental Tools, Inc. 1938-1988 President of Frank's Casing Crew & Rental Tools, Inc. 1989-2011 Chairman, President and CEO of Frank's International N.V. Founder and CEO of Frank's International, LLC 1981-Present CEO of Frank's Casing Crew & Rental Tools, LLC 2011-2013 Merger with Frank’s International, LLC 1st Generation 2nd Generation 3rd Generation 1938 – 2014 ®